Foam, that versatile and wallet-friendly material, has taken the crafting world by storm. But here’s the burning question: can a trusty hot glue gun really stick foam together?

In this blog post, we’re diving deep into this adhesive adventure to see if hot glue guns are up to the task. We’ll explore the best types of foam and glue guns for the job and even share some real-life examples to show you what works (and what doesn’t).

So, if you’ve ever wondered if hot glue and foam are a match made in crafting heaven, get ready for some enlightening answers that will help you make smart choices for your projects.

Different Types of Foam and Their Properties

Contents

- 1 Different Types of Foam and Their Properties

- 2 Adhesion Considerations for Hot Glue on Foam

- 3 Polystyrene Foam and Hot Glue Compatibility

- 4 Polyethylene Foam and Hot Glue Compatibility

- 5 Polyurethane Foam and Hot Glue Compatibility

- 6 Techniques to Improve the Bond of Hot Glue on Foam

- 7 Testing the Adhesion of Hot Glue on a Small Area Before Use

- 8 Applying the Hot Glue to the Foam Surface Properly

- 9 Conclusion

If you’ve ever wondered whether your trusty hot glue gun will work its magic on foam, you’re in luck. Foam comes in various types, each with its own unique properties that can affect hot glue adhesion.

In this article, we’ll take a deep dive into the world of foam and explore how different types interact with hot glue. So, let’s embark on this adhesive adventure and discover which foams are perfect for sticking with confidence.

Polystyrene Foam – The Tricky One:

Polystyrene foam, popularly known as Styrofoam, is a lightweight wonder often found in insulation and packaging. However, when it comes to hot glue adhesion, things can get a little tricky.

The high heat generated by the glue gun can cause polystyrene foam to melt or deform, creating challenges for a strong bond. Proceed with caution when using hot glue on this foam type to avoid disappointment.

Polyurethane Foam – The Reliable Companion:

Polyurethane foam is a versatile material commonly used in upholstery, mattresses, and cushions. Good news. Hot glue tends to adhere well to polyurethane foam surfaces. Thanks to its density and resilience, a strong and durable bond can be achieved. Don’t forget to test a small area first to ensure compatibility and prevent any unwanted damage.

EVA Foam – The Crafty Delight:

Whether you’re into crafting or sports equipment, chances are you’ve encountered EVA foam. This lightweight and flexible foam boasts excellent shock-absorbing properties. Luckily, hot glue and EVA foam go hand in hand. The porous nature of EVA foam allows the hot glue to penetrate and bond effectively, making it a crafty delight for all your projects.

Neoprene Foam – The Water Wizard:

Neoprene foam is a specialty foam renowned for its resistance to water, oils, and chemicals. It finds its niche in gaskets and sealing applications. While hot glue can stick to neoprene foam, it’s crucial to select the right adhesive for maximum effectiveness. Explore specialized adhesives designed specifically for neoprene foam to ensure a bond worthy of a water wizard.

Silicone Foam – The Heat-Resistant Hero:

When it comes to high-temperature applications and electronics, silicone foam takes center stage. This foam is highly heat resistant and boasts excellent cushioning properties. While hot glue can adhere to silicone foam, it’s wise to opt for adhesives specifically formulated for silicone materials to achieve optimal results.

Conclusion:

Foam, with its diverse properties, can greatly impact hot glue adhesion. Understanding the different types of foam and their compatibility with hot glue is vital for successful crafting endeavors. Remember to test a small area before committing to larger projects and follow proper surface preparation techniques for optimal bonding.

Adhesion Considerations for Hot Glue on Foam

Before you dive into your next project, let’s delve into the important adhesion considerations for hot glue on foam.

First and foremost, let’s talk about the type of foam you’re working with. There are various types, such as polystyrene foam (also known as Styrofoam), polyurethane foam, and EVA foam. Each type has its own unique properties and compatibility with hot glue.

Polystyrene foam, favored for crafts and insulation, generally forms a strong bond with hot glue. However, caution is advised when using a low-temperature hot glue gun to prevent any potential melting or warping of the foam.

Polyurethane foam, commonly found in upholstery and cushioning, can also be bonded with hot glue. But here’s the catch – it’s crucial to test the hot glue on a small, inconspicuous area beforehand to ensure it won’t cause any damage or discoloration.

Now let’s talk about EVA foam, the darling of cosplay and craft projects. This foam type boasts a smooth surface that allows for excellent hot glue adhesion. Just remember to apply the hot glue evenly and avoid excessive amounts, as too much glue can make the foam stiff or deformed.

Temperature is another vital consideration when using hot glue on foam. Using a high-temperature hot glue gun can spell disaster – think melted or damaged foam. Opt for a low-temperature hot glue gun or adjust the temperature setting accordingly.

Before applying hot glue to your foam masterpiece, don’t forget about surface preparation. Clean the surface with rubbing alcohol or acetone to remove any dirt, oils, or residues that might hinder adhesion. A slight roughening of the surface with sandpaper can also enhance the bond between the hot glue and the foam.

When it’s time to apply the hot glue, remember that less is more. Thin, even lines or dots work better than large blobs of glue. And here’s a pro tip – press the foam firmly together while the glue is still hot to ensure a strong bond.

It’s important to note that not all foams are compatible with hot glue. Some foams have smooth, non-porous surfaces that don’t provide enough area for the glue to adhere properly. In these cases, consider using foam-safe adhesives or specialty glues designed specifically for foam.

Always test the adhesion of hot glue on a small, inconspicuous area of the foam before committing to your project. This allows you to identify any potential issues or incompatibilities before going all-in with the adhesive.

Polystyrene Foam and Hot Glue Compatibility

If you’ve ever pondered whether polystyrene foam and hot glue can join forces harmoniously, you’re not alone. In this captivating blog post, we shall delve into the compatibility between these two materials and unravel the factors that can influence their bond. So grab hold of your trusty glue gun and prepare to plunge into the depths of this intriguing topic.

Factors Affecting Compatibility:

- Temperature: Polystyrene foam, a thermoplastic material, has a low melting point. Hot glue guns wield their power within a broad temperature range, necessitating the selection of an appropriate glue stick. Opting for low-temperature glue sticks that melt at lower temperatures is generally advisable when working with polystyrene foam to avoid unwanted meltdowns or deformations.

- Foam Thickness: Delightfully, thicker foam possesses superior heat dissipation properties compared to its thinner counterparts. This means it can withstand the heat from hot glue more effectively without succumbing to melting or warping. For those embarking on ventures involving delicate or thin sheets of polystyrene foam, it is prudent to perform a small-scale test before fully committing to the project.

- Glue Type: Not all hot glues are created equal, dear reader. Different types of glue sticks boast varying melting points and adhesive properties. To minimize the risk of harm to the material, low-temperature hot glue sticks prove to be a safer choice when working with polystyrene foam. Always consult the specifications of your chosen glue sticks prior to usage.

- Application Method: Ah, here lies an intriguing facet of our tale. The manner in which you apply hot glue to polystyrene foam can indeed impact compatibility. Crafters have discovered success by employing low-temperature hot glue guns and adorning the foam with small dots or lines of glue instead of spreading a thick layer. This technique facilitates superior heat dissipation and reduces the likelihood of melting or deforming the foam.

Safety Precautions:

Venture forth, but remember, dear reader, that safety must reign supreme when toying with hot glue and polystyrene foam. Ensure proper ventilation in your workspace to prevent inhaling any fumes released by the glue gun. Additionally, don protective gloves and wield a heat-resistant surface upon which to work. Recall, prevention outshines cure.

Polyethylene Foam and Hot Glue Compatibility

Polyethylene foam is a versatile and durable material that is widely used in packaging, insulation, and padding applications. When it comes to bonding polyethylene foam, hot glue is often considered as an adhesive option. However, the compatibility between polyethylene foam and hot glue depends on several crucial factors.

The temperature at which hot glue is applied plays a significant role in the compatibility with polyethylene foam. Polyethylene foam has a low melting point, typically around 200 to 220 degrees Fahrenheit. If hot glue is applied at a temperature higher than this, it can cause the foam to melt or deform, resulting in a weak bond or even damage to the foam itself.

Another factor to consider is the surface texture and composition of the polyethylene foam. Smooth and dense polyethylene foams tend to have better adhesion with hot glue compared to rough or porous foams. The smooth surface allows for more contact area between the adhesive and the foam, ensuring a stronger bond.

To enhance the compatibility between polyethylene foam and hot glue, there are several techniques you can try. Firstly, use a low-temperature hot glue gun or adjust the temperature setting to prevent excessive heat that could damage the foam. Additionally, clean the surface of the foam before applying the hot glue to remove any dust, oils, or contaminants that could hinder proper adhesion. Wiping the foam with a mild detergent solution and allowing it to dry thoroughly can significantly improve bonding.

Using an adhesive primer or promoter specifically designed for bonding polyethylene foam is another technique worth considering. These primers create a chemical bond between the foam and the hot glue, further enhancing adhesion. However, it’s important to choose a primer that is compatible with the specific type of polyethylene foam being used.

Polyurethane Foam and Hot Glue Compatibility

The compatibility between polyurethane foam and hot glue is a match made in crafting heaven. Polyurethane foam, with its lightweight and spongy texture, is the perfect canvas for your creative endeavors. And when it comes to adhesives, hot glue guns are the superheroes of sticking things together – quick-drying and strong-bonding. But can they form a bond that’s as unbreakable as Batman and Robin?

Let’s delve into the factors that affect the compatibility between polyurethane foam and hot glue. First up, temperature. Polyurethane foam can be sensitive to high temperatures, so it’s crucial to use a low-temperature hot glue gun or adjust the settings accordingly. We don’t want any foam-melting disasters.

Next, the type of hot glue matters. For polyurethane foam, it’s best to choose a low-temperature hot glue specifically designed for lightweight materials. These glues have a lower melting point, ensuring a secure bond without damaging the foam.

Surface preparation is key. Just like a painter preps their canvas, clean the foam surface thoroughly to remove any dust, debris, or oils that could hinder the adhesive process. Some crafters even suggest roughening the surface slightly with sandpaper for an extra-strong bond.

Now let’s talk technique. Apply hot glue in small dots or lines rather than spreading it over a large area. This gives you better control and minimizes the chance of excessive glue seeping through the foam. And remember to apply pressure to the glued areas while the hot glue is still liquid – this ensures a bond that’s as tight as a bear hug.

With these guidelines in mind, you can achieve a bond between polyurethane foam and hot glue that’s stronger than Batman and Robin fighting crime together. So go forth and create with confidence, knowing that the world of polyurethane foam and hot glue is yours to conquer.

Techniques to Improve the Bond of Hot Glue on Foam

If you’ve ever struggled with hot glue not sticking well to foam, fear not. I’m here to share some techniques that can help you improve the bond of hot glue on foam. Whether you’re a crafter or a DIY enthusiast, these tips will come in handy for your foam projects.

First and foremost, surface preparation is key. Roughening the surface of the foam before applying hot glue can significantly enhance the bond. You can achieve this by gently sanding the foam with fine-grit sandpaper or using a foam sanding block. This creates more texture for the glue to adhere to, resulting in a stronger bond.

Another technique is using a primer or adhesive promoter. These products act as a barrier between the foam and the glue, allowing for better adhesion. Look for adhesive promoters specifically designed for hot glue and foam bonding, which can be found at craft stores or online.

Adjusting the temperature setting on your hot glue gun can also make a difference. Using a higher temperature can help melt the foam slightly and create a stronger bond. However, be cautious not to use excessive heat that may damage or deform the foam.

Applying pressure while the glue is still hot is another great technique. After applying the hot glue, use a clamp or your hands to firmly press the glued surfaces together. This ensures that the glue fully adheres to the foam and creates a strong bond. Just remember to be careful not to burn yourself when handling hot glue.

Using a specialized hot glue formulated for bonding foam can also greatly improve the bond. These glues are specifically designed to adhere to foam surfaces and often have stronger bonding properties compared to regular hot glue sticks. Investing in these glues is worth it if you frequently work with foam and hot glue.

Lastly, it’s important to note that not all foams are compatible with hot glue. Some foams, such as polystyrene or expanded polystyrene (EPS), can melt or deform when in contact with hot glue. In such cases, it’s best to use alternative adhesive options like foam-safe adhesives or double-sided tape specifically designed for foam bonding.

Testing the Adhesion of Hot Glue on a Small Area Before Use

This expert guide will walk you through the process of testing the adhesion of hot glue on a small area before use. Let’s dive in.

Step 1: Select your foam

To begin, choose a small piece of foam that closely resembles the one you plan to use for your project. Opt for an inconspicuous area to conduct the test.

Step 2: Clean the surface

Give your foam a gentle cleaning using mild soap and water. This ensures there’s no dirt or debris that could interfere with the glue’s adhesion. Make sure the foam is completely dry before moving forward.

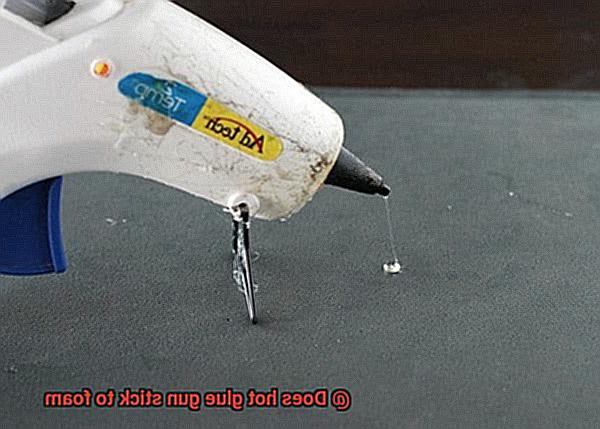

Step 3: Heat up that glue gun.

Follow the manufacturer’s instructions to heat up your trusty hot glue gun. Once it’s melted and ready to go, apply a small amount of glue onto the selected area of the foam.

Step 4: Press and cool

Press firmly on the glued area for a few seconds, ensuring good contact between the glue and foam. Allow the glue to cool completely before proceeding.

Step 5: The peeling test

Gently try to peel off the glued area. If it sticks well and doesn’t budge easily, congratulations. You’ve achieved good adhesion. However, if it peels off or doesn’t adhere properly, it’s time to explore other adhesive options.

Remember, different foams have varying levels of compatibility with hot glue, so this test is crucial. Also, consider adjusting your hot glue gun’s temperature settings for better results.

In conclusion, don’t let your crafting dreams crumble due to weak adhesion. By following these steps, you can ensure successful bonding between hot glue and foam. So go forth and create amazing projects without worrying about glue mishaps.

Applying the Hot Glue to the Foam Surface Properly

Are your foam crafts falling apart due to subpar glue adhesion? Fear not. This guide will walk you through the art of applying hot glue to a foam surface. With these expert tips, your creations will withstand the test of time, ensuring a strong and secure bond.

Preparing the Foam Surface:

Cleanliness is key: Before applying hot glue, ensure your foam surface is pristine. Rid it of pesky dust, dirt, or oil that could hinder adhesion. Use a soft cloth or brush to sweep away debris, and if necessary, gently scrub the surface with mild detergent. Allow it to dry completely.

Choosing the Right Glue Gun Temperature:

Mind the temperature: When working with foam, opt for a low-temperature setting on your glue gun. Protect your foam from damage or unsightly melting caused by high temperatures that can warp its delicate structure.

Applying the Glue:

Even and thin layers: Heat up your glue gun and insert an appropriate-sized glue stick. Squeeze the trigger gently to dispense the glue onto the foam surface. Apply it evenly and in thin layers for optimal adhesion. Avoid excessive amounts that create messiness and hinder bonding.

Working Efficiently:

Swift action: Hot glue dries rapidly, so work swiftly once applied to the foam surface. Position your materials accurately before pressing them firmly together. If repositioning is necessary, act promptly before the glue sets completely.

Pressure for Better Bonding:

Crush it with pressure: To achieve a sturdy bond, exert pressure on the glued areas. Use your hands or a clamp to hold materials firmly while the glue dries. This helps the adhesive penetrate into the foam, creating a secure attachment.

Allowing for Drying Time:

Patience pays off: Allow ample time for the hot glue to dry completely before handling or moving your project. The drying time depends on the size of the glued area and the temperature of the glue. Consult the manufacturer’s instructions or wait at least 30 minutes before handling the foam.

Conclusion

The conclusion is clear: hot glue guns do stick to foam. This adhesive tool forms a strong bond with foam materials, making it an excellent choice for various crafting and DIY projects. Whether you’re creating foam decorations, assembling foam props, or designing foam costumes, a hot glue gun can securely hold the pieces together.

With its high melting point and fast-drying properties, hot glue quickly adheres to foam surfaces, ensuring a reliable and durable connection. The heat from the glue gun causes the foam to melt slightly, allowing the adhesive to penetrate the material and create a solid grip. As the glue cools and hardens, it forms a tight seal that withstands pressure and movement.

Not only does hot glue provide a strong bond on foam, but it also offers versatility in application. Its ability to adhere to different types of foam – such as expanded polystyrene (EPS), extruded polystyrene (XPS), and polyethylene (PE) foam – makes it suitable for a wide range of projects. Whether you’re working with floral foam, craft foam sheets, or upholstery foam, hot glue can effectively join these materials together.

Furthermore, using a hot glue gun on foam provides several advantages over other adhesives. Unlike liquid glues that may seep into the porous surface of the foam or leave visible residue marks after drying, hot glue creates clean and seamless connections. Its quick-setting nature allows for faster project completion without compromising quality.

However, it’s important to note that not all types of foams are compatible with hot glue guns. Heat-sensitive foams like styrofoam should not be used with this adhesive method as they can melt or deform under high temperatures. It’s essential to check the compatibility of your specific type of foam before applying hot glue.

In conclusion, when it comes to bonding foam materials together in crafting or DIY projects, a hot glue gun is an effective and reliable choice. Its ability to form a strong and durable bond, versatility in application, and clean finishing make it an ideal adhesive for various foam projects. Just remember to consider the compatibility of your foam type before using hot glue.