Picture this: you’re knee-deep in a crafting frenzy, eagerly awaiting the moment when your glue dries and brings your masterpiece to life. But what if there was a secret trick to make that drying process go faster? Enter the intriguing concept of freezing glue. Before you sprint to your freezer with glue bottle in hand, let’s dig into the science behind it and find out if this hack is fact or fiction.

On the surface, freezing glue might sound like a wild idea. I mean, we all know liquids turn into ice when exposed to freezing temperatures, right? But in the sticky world of adhesive enthusiasts, whispers of freezing glue as a time-saving technique have spread like wildfire.

From a casual perspective, it’s easy to see why some folks believe that freezing glue could speed up its drying time. After all, cold temperatures tend to solidify or preserve other substances, so why not glue?

However, before we jump to conclusions, let’s take a step back and approach this concept with a more critical eye. Adhesive properties are influenced by various factors such as chemical composition, environmental conditions, and evaporation rates. Manipulating these elements through freezing requires us to dive deeper into the fascinating world of glue drying.

So, join me on this adventure as we explore the science behind glue drying and uncover whether freezing it truly holds the key to rapid adhesion or is just another crafty myth floating around.

How Does Freezing Glue Help with the Drying Process?

Contents

- 1 How Does Freezing Glue Help with the Drying Process?

- 2 What Types of Glue Respond Best to Freezing?

- 3 Potential Adverse Effects of Freezing Glue

- 4 Manufacturer Guidelines for Handling and Storing Glue

- 5 Alternative Methods for Speeding up the Drying Process

- 6 Pros and Cons of Using Freezing as a Drying Method

- 7 Safety Considerations When Using Extreme Temperatures on Glue

- 8 Conclusion

Glue is a versatile adhesive used in various applications, from crafting to woodworking. However, waiting for glue to dry can be time-consuming, especially when efficiency is crucial. One technique that has gained attention is freezing glue to speed up the drying process. In this article, we will explore the science behind how freezing glue helps it dry faster and discuss important considerations.

Understanding Glue Drying:

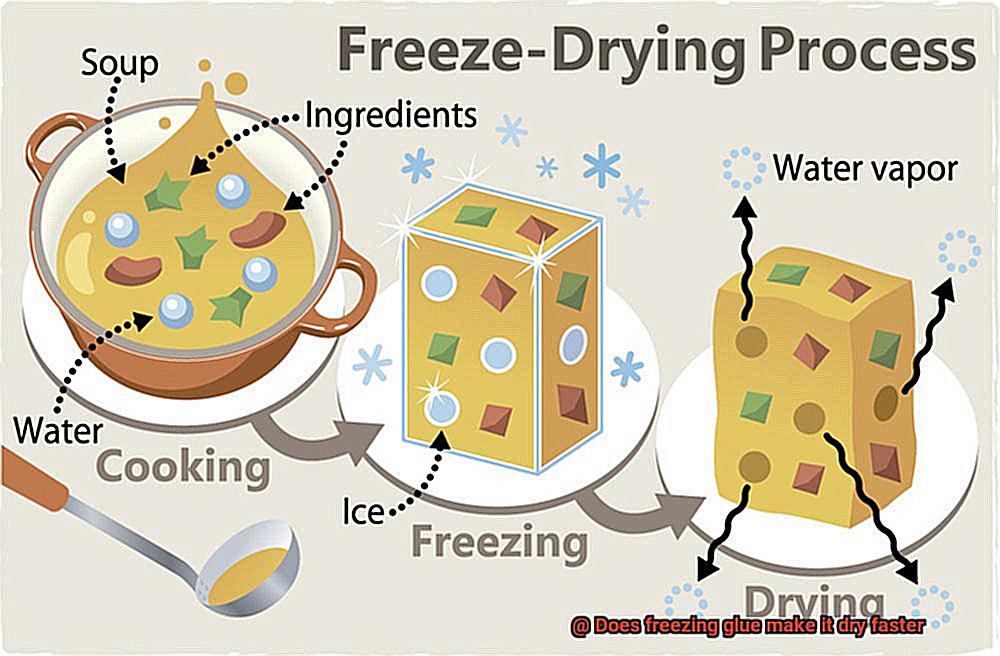

To comprehend how freezing affects glue drying, let’s review the process. Glue is composed of polymers, long chains of molecules that create bonds when exposed to air. As these polymers cross-link, they form a solid bond that solidifies the glue. External factors like humidity and temperature can influence the drying time.

How Freezing Affects Glue Drying:

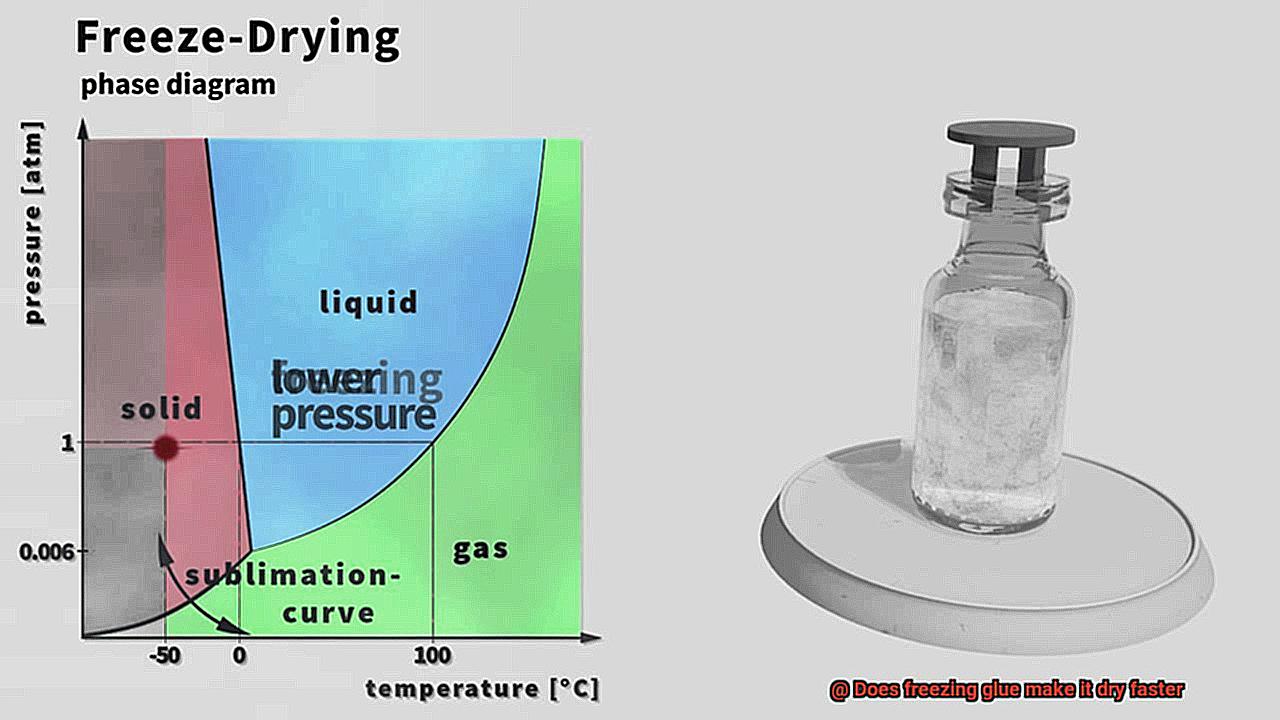

When glue is frozen, the low temperature slows down molecular movement. This reduced motion allows the polymers to cross-link more efficiently, expediting the drying process. Furthermore, freezing can remove excess moisture from the glue, further aiding in drying.

Suitable Glues for Freezing:

While freezing can be beneficial, not all glues respond well to this method. For instance, cyanoacrylate (super glue) may lose effectiveness when frozen. Therefore, it is crucial to consider the specific type of glue being used before attempting to freeze it for accelerated drying.

Consistency and Quality Considerations:

It’s important to note that freezing glue may alter its consistency or bonding strength. Water-based glues or certain adhesives can undergo changes that hinder their ability to dry faster. Additionally, repeated freezing and thawing cycles can degrade the glue and impact its performance.

Alternative Methods for Speeding Up Glue Drying:

If freezing is unsuitable or if you prefer an alternative approach, there are other ways to accelerate the drying process. For example, using heat sources like hair dryers or placing glued items in a warm environment with good air circulation can expedite drying.

What Types of Glue Respond Best to Freezing?

Curiosity often arises about whether freezing glue can speed up its drying process. In this blog post, we will explore the effects of freezing on different types of glue and determine which ones respond best to the cold. Let’s embark on this journey to understand how glue behaves when exposed to freezing temperatures.

Comprehending Glue Composition:

Glues can be broadly categorized into two types: water-based glues and solvent-based glues. Water-based glues, such as white glue or PVA glue, consist of water and polymers, while solvent-based glues, like super glue or epoxy resin, contain solvents that evaporate during drying.

Water-Based Glues and Freezing:

Freezing temperatures can cause water-based glues to form ice crystals due to the freezing of their water content. This leads to increased brittleness and reduced flexibility in the glue, thereby compromising its adhesive properties. Hence, freezing may not be an effective method for accelerating the drying process of water-based glues.

Solvent-Based Glues and Freezing:

Solvent-based glues generally have a lower freezing point compared to water-based ones. While these glues may not solidify when frozen, extreme cold temperatures can still impact the evaporation rate of their solvents. Consequently, freezing may actually slow down the drying process rather than speeding it up.

The Impact of Glue Formulation:

The formulation of different glue brands plays a crucial role in how they withstand freezing temperatures. Certain glues are specifically designed to maintain their adhesive properties even when exposed to extreme cold. It is advisable to refer to the manufacturer’s instructions for information on how a particular glue might be affected by freezing.

Exploring Alternative Approaches:

If you seek ways to expedite the drying process of glue, alternative methods can be considered. Utilizing heat sources like hair dryers or placing glued items in a warm environment with good air circulation can accelerate drying without subjecting the glue to freezing temperatures.

Potential Adverse Effects of Freezing Glue

Glue is a versatile and indispensable tool in many DIY projects, crafts, and repairs. But have you ever wondered if freezing glue could be a game-changer? In this article, we’ll explore the potential adverse effects of freezing glue and why it might not be the best idea. So, grab your favorite glue gun and let’s dive in.

Brittle Bonds:

Freezing glue can be a recipe for disaster. When glue freezes, water content expands, creating ice crystals that weaken its structure. Imagine spending hours on a delicate craft project, only to find it shattered like a frozen icicle. Don’t let brittle bonds break your heart.

Loss of Adhesive Properties:

The cold truth is that freezing glue can compromise its adhesive power. The chemical composition of glue can be altered by freezing, affecting its ability to provide a strong bond. Don’t get stuck with a weak bond that leaves you frustrated instead of satisfied.

Consistency Conundrum:

Freezing and thawing can turn your glue into a consistency conundrum. Depending on its formulation, frozen glue may become thicker or thinner, making it harder to apply evenly. Say goodbye to smooth application and hello to lumpy messes. Don’t let your projects become sticky situations.

Components Separation:

Some glues require mixing before use, but freezing can cause these components to separate. Good luck achieving a proper mixture when your glue turns into a chemistry experiment gone wrong. Mixing mishaps could result in subpar performance that leaves your projects hanging by a thread.

Warranty Woes:

Freezing glue may void any manufacturer warranties or recommendations. Manufacturers provide specific guidelines for storage conditions and temperature ranges for optimal performance. By freezing the glue, you risk decreased effectiveness or even damaging the product itself. Don’t let your warranty melt away.

Safety Considerations:

Let’s not forget about safety. Freezing glue that contains hazardous chemicals could potentially release harmful fumes or substances. Handle frozen glue with caution and consult the product’s safety data sheet for specific information on potential hazards. Stay safe and keep crafting.

Manufacturer Guidelines for Handling and Storing Glue

Following manufacturer guidelines for handling and storing glue is the secret sauce to ensure your adhesive performs at its best. Let’s dive into the specifics, shall we?

First off, temperature is key. Glue is like Goldilocks – it needs to be stored at just the right temperature. Extreme heat or cold can mess with its adhesive properties. Aim for that sweet spot between 60°F and 75°F (15°C and 24°C). Glue doesn’t like to be hot-headed or too chilly.

And don’t even think about exposing your glue to direct sunlight or UV radiation. It’s like giving it a one-way ticket to adhesive failure city. Store your glue in a dark area or use opaque containers to keep those harmful rays away.

Now, let’s talk sealing the deal – I mean, containers. When you’re not using your glue, seal the container tightly. Air and moisture are villains that can ruin your adhesive dreams. Air exposure can make your glue thick and gloopy, while moisture messes with its composition and bonding abilities. So, seal it up tight.

Safety first, people. Keep glue out of reach of children and pets. Some glues contain chemicals that could be harmful if ingested or come into contact with skin or eyes. We want sticky situations only in a metaphorical sense.

Last but not least, read the fine print. Different glues may have specific storage requirements based on their composition or chemical properties. Store the glue upright, avoid certain chemicals or substances, or use it within a specific timeframe after opening – follow those instructions.

Alternative Methods for Speeding up the Drying Process

Waiting for glue to dry can be a real buzzkill, especially when you’re excited to see the finished result of your project. But fear not. We’ve got some alternative methods up our sleeves that will have your glue drying faster than you can say “instant gratification.” So, let’s dive in and discover these time-saving techniques.

Increase Air Circulation:

Who knew that good airflow could make such a difference? By using fans or opening windows, you can ensure that fresh air circulates around the glued object. This helps the moisture in the glue evaporate more quickly, resulting in a faster drying time. So, let the breeze do its magic and watch your glue dry in no time.

Apply Heat:

If you’re in a hurry, heat is your best friend. By applying heat to the glued area, you can accelerate the evaporation process and speed up drying. A hairdryer set on low heat is perfect for most glues, but for tougher adhesives like superglue, a heat gun with higher temperatures might be necessary. Just remember to keep a safe distance to avoid any mishaps.

Use a Dehumidifier:

Humidity can really put a damper on your drying time. But fear not. A dehumidifier is here to save the day. By reducing the moisture content in the air, a dehumidifier allows your glue to dry faster. So, if you live in a particularly humid area or it’s just one of those sticky days, bring out the dehumidifier and watch your glue dry at lightning speed.

Utilize Absorbent Materials:

Sometimes, all you need is a little help from some absorbent superheroes. Paper towels, cloth rags, or even cat litter can work wonders in speeding up the drying process. Simply place these materials around or on top of the glued area, and they’ll draw out excess moisture, leaving your glue to dry faster. Talk about a quick fix.

Choose Fast-Drying Glues:

When time is of the essence, fast-drying glues are your saving grace. These specially formulated glues have shorter drying times, allowing you to complete your projects in record time. So, make sure to check the label and grab a bottle of fast-drying glue for those time-sensitive projects that can’t wait.

Pros and Cons of Using Freezing as a Drying Method

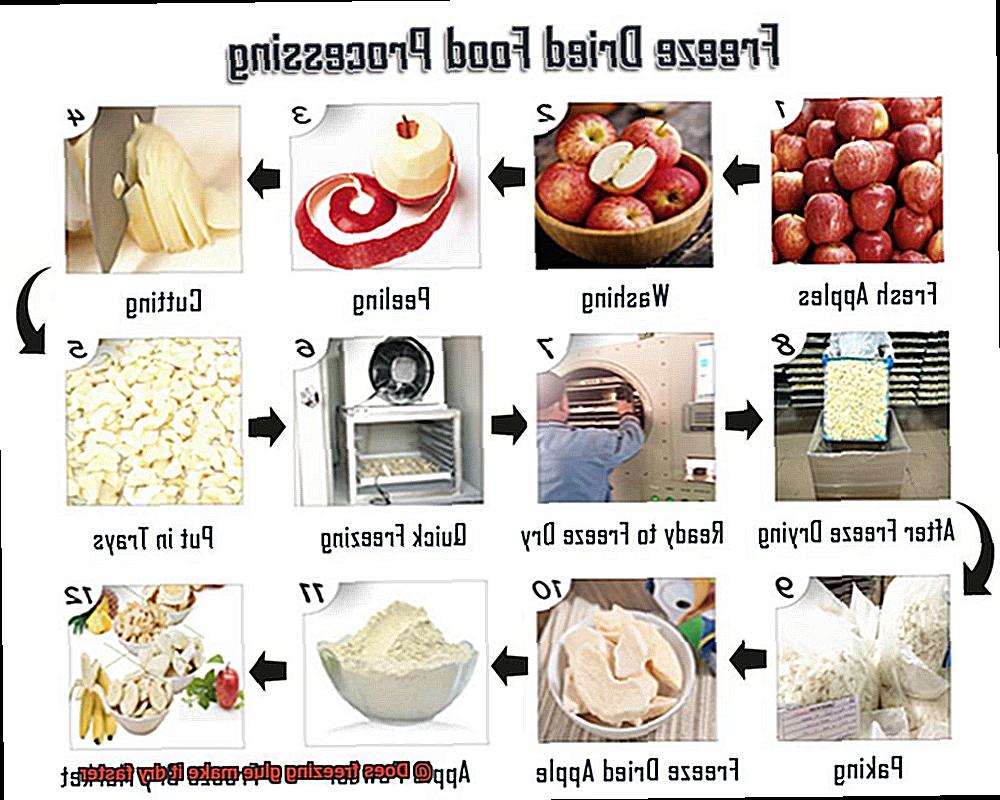

This chilling technique offers a unique alternative that preserves quality, color, and aroma. However, like any frontier, it comes with its own set of advantages and limitations. In this article, we will delve into the frozen frontier and explore the pros and cons of using freezing as a drying method.

Pros of Freezing as a Drying Method:

Preservation of Quality:

- Frozen in time, delicate substances are shielded from damage or alteration during the drying process.

- By converting water content into ice, freezing maintains the original properties of the material, making it ideal for heat-sensitive substances.

Retention of Color and Aroma:

- Freeze. Vibrant colors and fragrances are locked in by freezing, preserving the essence of materials like herbs, flowers, and spices.

- Low temperatures put oxidation and degradation on ice, ensuring dried products that retain their original characteristics.

Energy Efficiency:

- Driven by cold efficiency, freezing as a drying method consumes less energy compared to air or oven drying.

- The slow removal of moisture in a low-temperature environment chills out energy consumption, making it cost-effective in the long run.

Cons of Freezing as a Drying Method:

Time-consuming Process:

- Frozen in waiting, materials endure a longer drying process compared to other methods.

- Patience is required as they bide their time in a low-temperature environment until all moisture evaporates.

- This may not suit industries or individuals seeking instant results.

Equipment Requirements:

- Embarking on the frozen frontier demands specialized equipment like freeze dryers or blast freezers.

- Investing in these tools can carry a hefty price tag, especially for small-scale operations or those without access to them.

Limited Applicability:

- The frozen frontier may not be for everyone, as freezing may not suit all types of substances.

- Some fruits or vegetables lose their texture and taste after being frozen and dried, leaving them frostbitten in flavor.

- High water content materials may find little relief from moisture removal, as ice crystal formation hinders their progress.

Safety Considerations When Using Extreme Temperatures on Glue

In this blog post, we will embark on a quest to uncover the safety considerations when using freezing temperatures on glue. So, don your safety goggles and prepare for an engaging exploration of the potential risks and benefits associated with this practice.

Preserving the Bond:

Freezing glue poses potential risks due to extreme cold. The low temperatures can make glue brittle, increasing the risk of cracking or breaking. This compromises its bonding strength and structural integrity, rendering it less effective for its intended purpose. To mitigate this risk, it is crucial to store glue properly in a temperature-controlled environment that prevents freezing.

The Chilling Effect on Chemical Composition:

Extreme temperatures can alter the chemical composition of glue, impacting its adhesive properties. This may result in reduced bonding strength and durability, making the glue less reliable for long-term usage. To prevent this, always follow the manufacturer’s instructions regarding temperature requirements for glue usage. Adhering to these guidelines ensures optimal performance and longevity.

Thawing Techniques:

If you encounter frozen glue, resist the temptation to thaw it rapidly. Rapid temperature changes can introduce condensation, compromising the glue’s performance and potentially causing adhesion issues. Instead, thaw frozen glue slowly at room temperature to avoid moisture-related problems and maintain its effectiveness.

Safety First:

When working with frozen glue (or any type of glue), prioritize personal safety by wearing appropriate personal protective equipment (PPE). Gloves and safety goggles provide essential protection for your skin and eyes, shielding them from potential hazards during handling or accidental splashes.

Fire and Toxic Fumes:

Exposing frozen glue to open flames or high heat sources is strictly discouraged. Extreme temperatures can cause the glue to release toxic fumes or even ignite, posing a significant safety risk. Always exercise caution and ensure that flammable materials are kept away from extreme temperatures to prevent accidents and potential harm.

Childproofing and Pet Safety:

Regardless of whether it has been frozen or not, glue should always be stored out of reach of children and pets. Accidental ingestion or contact with eyes or skin can have severe consequences. By securely storing glue in a designated location, you can ensure the safety of everyone in your household.

1nEgFzKl60g” >

Conclusion

To conclude, the notion of freezing glue to hasten its drying time is not as straightforward as it initially appears. While freezing can potentially expedite the drying process for certain glues, like those with solvents, it can have adverse effects on others, particularly water-based variants. Freezing can result in brittleness, loss of adhesive properties, changes in consistency, and even separation of components in certain glues.

Before attempting to freeze glue for quicker drying, it is crucial to consider the specific type of glue being used. Some glues are specially designed to withstand freezing temperatures without compromising their performance. To determine how a particular glue might be affected by freezing, it is advisable to consult the manufacturer’s instructions.

If you seek alternative methods to speed up the drying process of glue, there are several viable options available. Enhancing air circulation, applying heat, using a dehumidifier, employing absorbent materials, or selecting fast-drying glues are all effective alternatives that can expedite drying without subjecting the glue to freezing temperatures.

Ultimately, when handling and storing glue, adhering to manufacturer guidelines is essential for optimal performance and longevity. Maintaining the proper storage temperature, tightly sealing containers to prevent air and moisture exposure, and considering safety precautions are all critical aspects that ensure your glue performs at its peak.

In summary, while freezing glue may offer some advantages in terms of accelerated drying for specific types of glues, it also carries potential risks and limitations.