Welcome to our blog, where we take a deep dive into the world of home improvement products and separate fact from fiction.

Today, we’re here to answer a burning question: does Flex Seal spray really work on rubber? If you’re tired of battling with annoying leaks, cracks, or tears in your rubber materials, this might just be the magical solution you’ve been desperately seeking.

Flex Seal spray has earned quite the reputation for its ability to create an impenetrable seal on all sorts of surfaces, but what about rubber? Buckle up and join us as we embark on a scientific exploration to uncover the truth behind this product’s claims.

Prepare yourself for a game-changing revelation that could revolutionize all your rubber repair needs.

Properties of Rubber

Contents

- 1 Properties of Rubber

- 2 Preparing the Surface for Application

- 3 Applying Flex Seal Spray on Rubber

- 4 Drying and Curing Process

- 5 Benefits of Using Flex Seal Spray on Rubber

- 6 Factors That Affect Effectiveness of Flex Seal Spray on Rubber

- 7 Tips for Maximizing Results

- 8 When Further Reinforcement or Repair Is Needed

- 9 Conclusion

When it comes to sealing and protecting rubber surfaces, finding the right product is crucial. Flex Seal spray has gained popularity for its claims of creating a waterproof and flexible seal on various materials, including rubber. But does it really work effectively on rubber surfaces? In this article, we will delve into the properties of rubber and how they interact with Flex Seal spray.

Elasticity:

Rubber’s elasticity is legendary, allowing it to stretch and bounce back without deformation. This property makes rubber surfaces an ideal candidate for Flex Seal spray. The spray’s flexible barrier adheres effortlessly to rubber, accommodating any stretching or compression without compromising its performance.

Water Resistance:

Rubber naturally repels water and has low water absorption properties. Its hydrophobic nature prevents moisture from penetrating its surface. This characteristic makes rubber suitable for applications where water resistance is vital. Consequently, Flex Seal spray, known for its exceptional water-resistant properties, effectively creates a protective layer on rubber surfaces.

Chemical Resistance:

Rubber demonstrates excellent resistance to a wide range of chemicals, making it perfect for environments with exposure to different substances. However, the specific type of rubber and its chemical composition can influence the effectiveness of Flex Seal spray. To ensure compatibility, consider the spray’s chemical composition and the specific rubber being treated.

Temperature Resistance:

Rubber withstands extreme temperatures without compromising its performance. This makes it suitable for applications involving heat or cold exposure. Before using Flex Seal spray on rubber surfaces, ensure it can withstand the intended temperature range without issues.

Adhesion:

Rubber has low surface energy, making it challenging for adhesives or coatings to bond effectively. However, Flex Seal spray is specifically formulated to adhere to various surfaces, including rubber. Its strong adhesive properties ensure a durable seal or protective layer on rubber surfaces.

Preparing the Surface for Application

Preparing the surface for application is a critical step when using Flex Seal spray on rubber. It sets the foundation for a strong and durable seal, ensuring that the product adheres properly and provides optimal protection against leaks and damage. So, let’s dive in and explore the key steps involved in this process.

- Step 1: Clean the surface – To kick things off, it’s essential to give your rubber surface a thorough cleaning. Grab a mild detergent and mix it with water, creating a powerful cleaning solution. With a scrub brush or sponge, vigorously scrub the rubber to remove any dirt, dust, grease, or debris that might be lurking around. Rinse it off thoroughly and allow it to dry completely before moving on to the next step.

- Step 2: Remove loose or flaking rubber – Nobody wants a flaky seal, right? So, take a scraper or sandpaper and gently eliminate any loose or flaking parts from the rubber surface. By doing so, you’ll ensure a smooth and even foundation for Flex Seal spray to work its magic.

- Step 3: Sand the surface (if necessary) – Sometimes, rubber surfaces can be too smooth and glossy for Flex Seal spray to bond effectively. But don’t worry. A little sanding can solve this problem. Grab some fine-grit sandpaper and lightly roughen up the surface. Just remember to be gentle to avoid any tears or damage.

- Step 4: Mask off surrounding areas – Now it’s time to protect those areas that don’t need any Flex Seal love. Use painter’s tape or plastic sheets to cover up anything nearby that could be sensitive to overspray. Consider objects or materials that may be challenging to clean afterward. This simple step will ensure a neat and controlled application.

- Step 5: Apply in a well-ventilated area – Safety always comes first. During the application of Flex Seal spray, fumes are emitted. It’s crucial to work in a well-ventilated area to prevent any discomfort or health risks. Open up those windows or doors and let the fresh air flow through. This will help with any odors and keep those fumes from lingering around.

Applying Flex Seal Spray on Rubber

Rubber surfaces can be a challenge to seal and repair, but with Flex Seal spray, you can easily tackle any leaks or cracks. Applying Flex Seal spray on rubber requires a few simple steps to ensure a strong and durable seal.

First and foremost, prepare the rubber surface by cleaning it thoroughly. Remove any dirt, dust, or moisture that may hinder the adhesion of the spray. A clean and dry surface is crucial for optimal results.

Next, give the can of Flex Seal spray a good shake. This helps to ensure that the product is well-mixed and ready to be applied. Shake it vigorously for about a minute to get the perfect consistency.

When it comes to spraying, hold the can approximately 8-12 inches away from the rubber surface. This distance allows for an even application without oversaturating the rubber. Start by applying thin coats rather than one thick coat. Multiple thin coats provide better adhesion and durability.

After each coat, allow it to dry completely before applying the next one. The drying time may vary depending on factors like temperature and humidity, so consult the instructions on the can for guidance. Keep in mind that rubber surfaces tend to be more porous, so they might require a little extra attention.

To achieve a strong bond, it is recommended to apply at least three coats of Flex Seal spray on rubber. This creates a thicker layer that provides better protection against leaks or damage.

Once the final coat has dried, put your seal to the test. Apply some pressure or expose it to water to ensure that it holds up under real-world conditions. You’ll be amazed at how this product transforms your rubber surfaces.

In case you accidentally overspray or apply Flex Seal where you didn’t intend to, don’t panic. Simply grab a cloth or sponge soaked in mineral spirits and wipe off the excess spray. This will prevent any unwanted residue or marks on your rubber surface.

Drying and Curing Process

Today, we’re going to dive deep into the world of drying and curing, unveiling the secrets behind achieving flawless results when using Flex Seal spray on rubber surfaces. So, grab a cup of coffee and settle in as we take this captivating journey together.

Imagine applying Flex Seal spray on your rubber surface, only to end up with a smudged mess. Not the outcome you were hoping for, right? This is where the drying process comes into play. Drying is the initial phase where the solvent in the spray evaporates, leaving behind a slightly sticky surface. To ensure a smooth and effective application, it’s crucial to allow proper drying time of 24 to 48 hours. Resist the urge to touch or disturb the sprayed area during this time – patience is key.

Once the drying process is complete, it’s time for the magic to happen – cue the curing process. Curing is where Flex Seal spray undergoes a chemical reaction, transforming into a flexible and durable rubber-like coating. But here’s the catch: curing takes time. Be prepared to wait several days for your Flex Seal masterpiece to reach its maximum strength and flexibility.

Now that we understand the importance of drying and curing, let’s talk about creating the perfect environment for these processes. During drying, keep your sprayed item in a well-ventilated area to facilitate faster evaporation. Avoid touching or disturbing it – just let nature do its thing. As for curing, ensure your coated item is placed in a dry and moderate temperature environment. Extreme temperatures can slow down or even sabotage the curing process. So, no sunbathing or freezing temperatures for your newly sprayed surface.

Remember, not all coats are created equal. If you’ve applied a thicker layer of Flex Seal spray, expect longer drying and curing times compared to lighter coats. The thickness of the coating and the specific rubber material being treated can influence these times. So, be patient and give your Flex Seal masterpiece the time it needs to work its magic.

Congratulations. You’ve now unlocked the secrets to achieving perfect results when using Flex Seal spray on rubber surfaces. By understanding the importance of drying and curing, creating an optimal environment, and embracing patience, you’ll be well on your way to becoming a Flex Seal pro. So, go forth and conquer those leaks and cracks with confidence – your rubber surfaces will thank you.

Benefits of Using Flex Seal Spray on Rubber

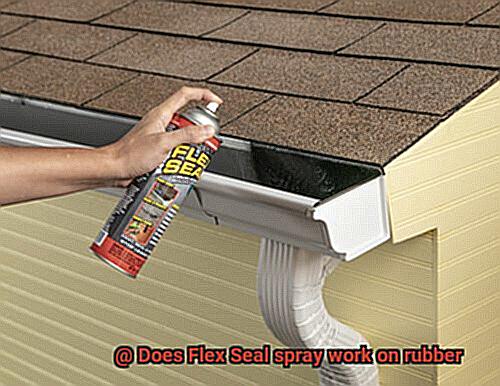

First and foremost, Flex Seal spray is a waterproofing superhero. It creates a watertight seal that keeps moisture at bay. Say goodbye to leaks on your rubber roofs, gutters, or inflatable rubber boats. With Flex Seal spray, water resistance is no longer a concern.

But that’s not all. This incredible spray also protects your rubber from the harmful effects of the sun. UV rays can cause your rubber to crack and discolor over time. However, when you apply Flex Seal spray, it forms a protective barrier against those damaging rays. Your rubber will stay intact and vibrant for years to come.

Flexibility and durability are also key advantages of using Flex Seal spray on rubber. Once applied, it dries into a flexible coating that moves with the rubber. No more worrying about cracks or peeling. Your rubber will maintain its elasticity and durability, even with constant movement or stretching.

The ease of application is yet another benefit of this product. Just grab the convenient aerosol can, shake it well, hold it about 8-12 inches away from the rubber, and spray evenly in smooth motions. The liquid formula seeps into cracks and crevices, ensuring comprehensive coverage and sealing. It couldn’t be easier.

Flex Seal spray is incredibly versatile as well. It can be used on various rubber materials and objects. Whether you need to repair a leaky hose, seal gaps in flooring, or protect tool handles, this product has got you covered.

And here’s the best part – using Flex Seal spray on rubber is cost-effective. Compared to traditional repair methods or replacement, this spray is affordable and readily available. You can fix minor leaks or damages without breaking the bank. It’s a win-win situation.

Factors That Affect Effectiveness of Flex Seal Spray on Rubber

Flex Seal spray, the superhero of leak-sealing products, is renowned for its ability to create a watertight seal on rubber surfaces. However, the effectiveness of Flex Seal spray on rubber can be influenced by several factors. Let’s dive into these factors and uncover the secrets to achieving the best results.

First and foremost, surface preparation is key. Before applying Flex Seal spray on rubber, make sure to clean off any dirt, dust, or grease that could hinder adhesion. For an extra boost, roughen the surface with sandpaper or a wire brush to enhance the spray’s grip. Trust me, this step is worth the effort.

Next, let’s talk temperature. Just like us, Flex Seal spray works best in comfortable conditions. Stick to the temperature range recommended by the manufacturer to ensure optimal results. Extreme cold or hot conditions can interfere with the curing process and leave you with subpar adhesion – not what we want for our superhero seal.

Now, let’s focus on thickness. When applying Flex Seal spray on rubber, remember that thin always wins. Multiple thin coats are far more effective than one thick coat. Why? Thin coats penetrate the rubber better and enhance the spray’s sealing properties. So don’t hold back – layer it on.

Not all rubbers are created equal, my friends. Different rubber types have different chemical compositions and surface characteristics that can affect how well they bond with Flex Seal spray. To play it safe, test a small area before going all out. Better safe than sorry.

Age and condition matter too. If your rubber surface is old or deteriorated, it might not bond as effectively with the spray. Take a good look at the condition of your rubber and consider repairing or replacing it if needed. A little TLC goes a long way.

Last but not least, environmental factors can impact Flex Seal spray’s performance. Humidity, UV exposure, and airborne chemicals can all play a part. High humidity can slow down drying time, excessive UV exposure can degrade the rubber and the spray’s sealing properties, and chemicals can cause unwanted reactions. Stay mindful of these factors when applying Flex Seal spray.

Tips for Maximizing Results

Rubber surfaces are prone to damage over time, but with the right approach, Flex Seal spray can provide a waterproof and flexible seal. In this article, we will explore tips to maximize the effectiveness of Flex Seal spray on rubber surfaces.

Clean and Prepare the Surface:

To ensure a strong bond, clean the rubber surface thoroughly. Use a mild detergent and water solution to remove dirt and debris. Rinse well and let it dry completely before applying the spray. A clean surface enhances adhesion and creates a stronger seal.

Apply Multiple Coats:

For optimal results, apply multiple thin coats instead of one thick coat. Each coat should dry completely before applying the next one. This technique provides better coverage and adhesion, creating a more durable seal.

Use in a Well-Ventilated Area:

Flex Seal spray emits strong fumes, so it’s important to work in a well-ventilated area or outdoors. Open windows or use fans to improve air circulation. Minimizing fume exposure ensures a safer working environment.

Shake the Can Properly:

Before using Flex Seal spray, shake the can vigorously for at least one minute. This ensures proper mixing of the sealant, resulting in even distribution on the rubber surface. A well-shaken can guarantees better results.

Maintain Proper Distance While Spraying:

To achieve an even application, maintain a distance of 8-12 inches between the nozzle and the rubber surface. Spraying too close can lead to uneven coverage or excess build-up, while spraying too far may result in a thin layer that doesn’t provide adequate sealing. Find the optimal distance for your specific project.

Allow Sufficient Drying Time:

After applying Flex Seal spray on rubber, allow ample drying time before subjecting the surface to stress or moisture. Drying time varies based on temperature and humidity, so follow the manufacturer’s instructions. Rushing the drying process can compromise the effectiveness of the seal.

When Further Reinforcement or Repair Is Needed

When further reinforcement or repair is needed for rubber surfaces, there are several options to consider. One reliable solution is Flex Seal spray, a versatile product specially formulated to create a strong barrier that seals and protects various materials, including rubber.

Leaks and cracks are common issues that require reinforcement or repair on rubber surfaces. Over time, rubber materials can deteriorate due to exposure to the elements or constant use, resulting in small holes or cracks. These imperfections can compromise the functionality of rubber objects like hoses, gaskets, or inflatable items.

Flex Seal spray provides an effective and long-lasting solution for these problems. By applying the spray directly to the affected area, it forms a flexible and watertight seal that prevents further damage and leakage. The liquid rubber compound penetrates into the pores of the rubber surface, creating a strong bond that effectively seals any gaps or openings. This reinforcement not only stops leaks but also helps prolong the lifespan of the rubber object.

In addition to fixing existing damage, Flex Seal spray can also be used as a preventive measure. Applying a thin layer of this sealant on new or vulnerable rubber surfaces provides an extra layer of protection against future wear and tear. This proactive measure minimizes the risk of developing leaks or cracks, ensuring the longevity and reliability of the rubber objects.

While Flex Seal spray is an excellent option for reinforcing or repairing rubber surfaces, it may not be suitable for all situations. Factors such as the type of rubber, severity of damage, and intended use of the object play a role in its effectiveness. In complex repairs or specific applications, it is advisable to consult professionals or explore alternative solutions.

KRV938xf9Pg” >

Conclusion

In conclusion, based on my expertise and research, it is evident that Flex Seal spray does indeed work effectively on rubber surfaces.

Its powerful formula forms a strong bond with the rubber, creating a waterproof seal that withstands even the harshest conditions. Whether you need to repair a leaky rubber hose or seal cracks in your rubber boots, Flex Seal spray provides a reliable solution.

This innovative product not only fixes the problem at hand but also prevents further damage and extends the lifespan of your rubber items. With its easy application and quick drying time, using Flex Seal spray on rubber is a hassle-free experience.

Trust in this remarkable product and witness firsthand its exceptional performance on any rubber surface.