Are you tired of frantically searching for a solution to fix that torn hem or unraveling fabric? Well, get ready to discover the ultimate secret weapon of savvy DIYers – fabric glue.

In this blog post, we’re diving deep into the world of adhesive magic to uncover the truth about whether fabric glue truly lives up to its promises. From delicate laces to heavy-duty denims, we’ll explore just how effective and versatile this wonder adhesive really is.

Let’s get started on this journey together.

Factors That Affect the Effectiveness of Fabric Glue

Contents

Fabric glue is a versatile adhesive that allows crafters, designers, and hobbyists to effortlessly join fabric pieces together without the need for sewing. However, not all fabric glues are created equal. The effectiveness of fabric glue can vary based on various factors. In this article, we will delve into the crucial elements that influence the performance of fabric glue, providing insights on how to achieve a strong and durable bond.

Type of Fabric:

Different fabrics possess distinct properties that impact their compatibility with fabric glue. Delicate fabrics, like silk or chiffon, necessitate a gentle adhesive that won’t harm or stain the material. Conversely, heavier fabrics such as denim or canvas require a stronger glue to withstand their weight and durability.

Surface Preparation:

Properly preparing the fabric surface is essential for ensuring a successful bond. Thoroughly cleaning the fabric to remove dirt, dust, and oils is imperative. Some fabric glues may even require pre-treatment with a bonding agent or primer to enhance adhesion.

Application Technique:

The technique used to apply fabric glue significantly affects its effectiveness. Adhering to the manufacturer’s instructions and applying an even layer of glue is vital. Using too little glue may result in a weak bond, while excessive application can lead to messy results. Employing the right tools, such as brushes or nozzle applicators, enables better control and precision during application.

Drying Time:

Patience is key when it comes to allowing fabric glue to dry properly. Each product has its recommended drying time, which should be followed diligently. Rushing the process by applying pressure or moving the glued fabric prematurely can compromise the strength of the bond.

Environmental Conditions:

The environment in which fabric glue is used can significantly impact its performance. Extreme temperatures or high humidity levels may interfere with the drying process and weaken the bond. Additionally, exposure to sunlight or water can cause the glue to deteriorate over time, reducing its effectiveness.

Quality of the Fabric Glue:

Choosing a high-quality fabric glue is vital for achieving optimal results. Reputable brands often offer superior adhesive properties and formulate their glues to work well with a variety of fabrics. Reading reviews and seeking recommendations can help ensure the selection of the right glue for your project.

Types of Fabric Glues

When it comes to crafting and sewing projects, fabric glue can be a real lifesaver. But did you know that there are different types of fabric glues? Each type has its own unique characteristics and uses. Let’s take a closer look at some of the most common types of fabric glues and their purposes.

Permanent Fabric Glue

This type of fabric glue is perfect for projects that require a strong and long-lasting bond. Whether you’re hemming clothes, attaching patches, or bonding fabrics together, permanent fabric glue will get the job done. It’s even waterproof, so you don’t have to worry about your creations falling apart in the rain or washing machine.

Temporary Fabric Glue

Sometimes you need a temporary bond that can be easily removed or washed off. That’s where temporary fabric glue comes in handy. It’s great for sewing projects where you need to position fabric pieces before stitching them together. You can easily reposition your fabrics without leaving any sticky residue behind.

Spray Fabric Adhesive

When you’re working on larger projects or need to bond fabrics quickly, spray fabric adhesive is your best friend. Just grab a spray can and evenly distribute the adhesive over the fabric. Spray fabric adhesive is commonly used in upholstery projects or when attaching fabric to other surfaces like foam or wood.

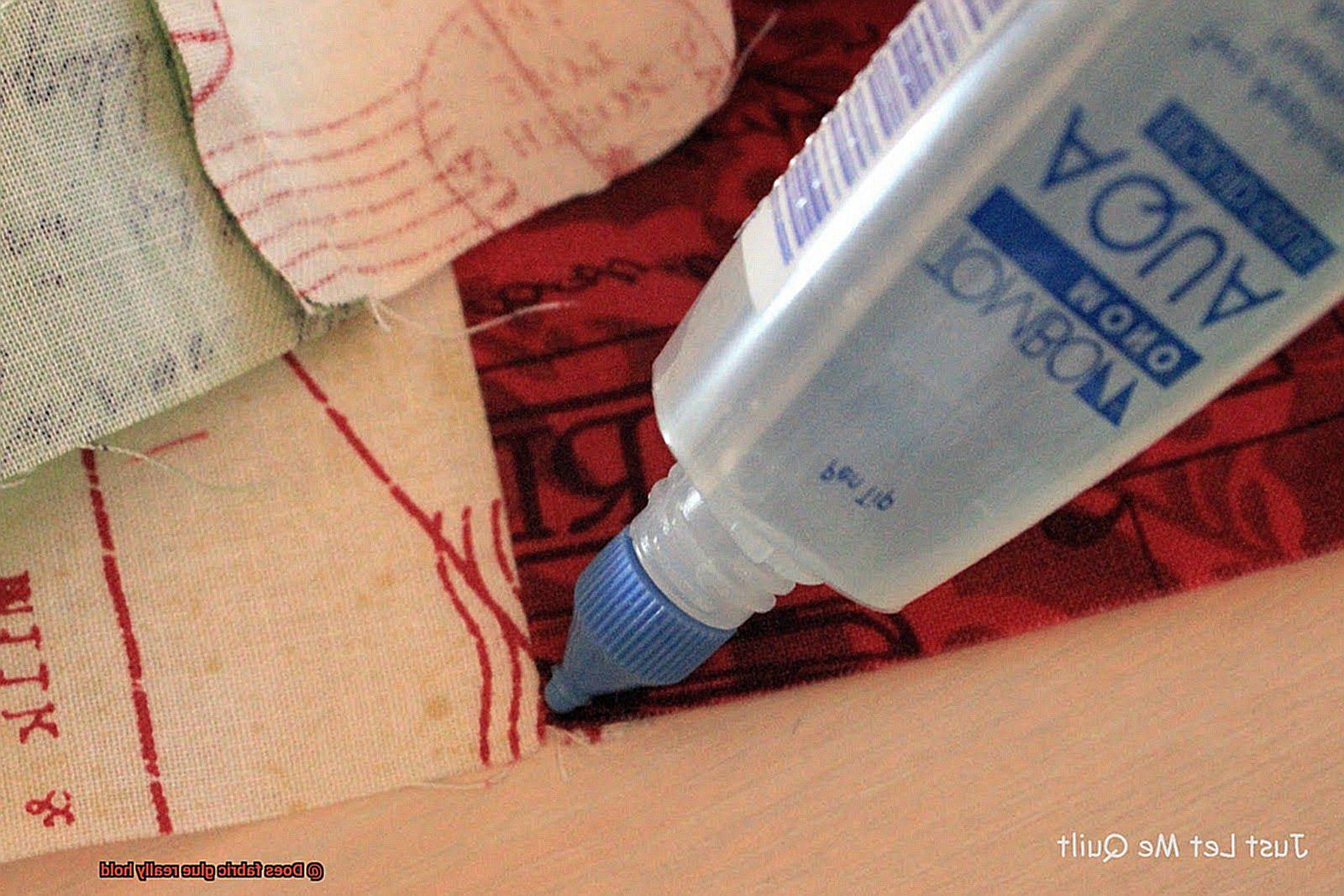

Fusible Web

Fusible web is a thin layer of adhesive that melts when heat is applied. It’s not exactly a glue, but it serves a similar purpose. Fusible web is often used in appliqué work, where fabric shapes are attached to a base fabric using heat from an iron. It creates a strong bond without the need for sewing.

Liquid Stitch

Liquid stitch is a flexible adhesive that dries clear and remains soft on fabrics. It’s perfect for repairs, hemming, or bonding fabrics where sewing may not be possible or desired. You can even use it to add decorative accents to your fabric projects, like rhinestones or sequins.

Fabric Tape

If you’re looking for a quick and easy way to bond fabrics without sewing or ironing, fabric tape is the answer. It’s a double-sided adhesive tape specifically designed for fabric applications. Use it to hem pants or secure fabric trims in a flash.

Proper Application Techniques for Maximum Bond Strength

When it comes to crafting and sewing, fabric glue is a true game-changer. Say goodbye to needles and thread and embrace the convenience of adhesive bonding. However, to ensure maximum bond strength, proper application techniques are essential. In this article, we will explore the dos and don’ts of fabric glue application, guaranteeing that your creations stand the test of time.

Preparing the Fabric:

Before diving into the gluing process, take a moment to prepare your fabric for its adhesive makeover. Banish dirt, oil, and stains that could sabotage your bond by giving your fabric a thorough cleaning. Then, iron out any wrinkles or creases that might interfere with a smooth application. Think of it as creating a pristine canvas for your adhesive masterpiece.

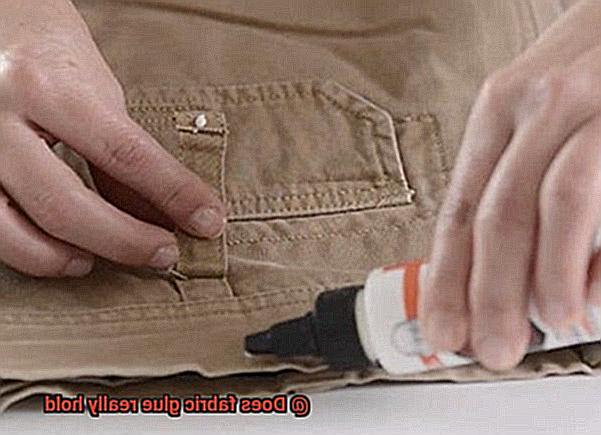

Applying the Glue:

Remember the golden rule: less is more. Resist the urge to drown your fabric in glue; instead, apply a thin, even layer using a small brush or applicator. Embrace precision and finesse as you delicately spread the glue on both surfaces to be joined. Trust us, a little dab will do.

Pressing the Fabrics Together:

Now comes the moment of truth – bringing your fabrics together. Apply gentle pressure to ensure optimal contact between the adhesive and the fabric. Whether you choose to use your nimble fingers or a trusty roller tool, make sure to distribute pressure evenly across the entire glued area. It’s like a secret handshake between your fabrics and the glue.

Allowing Ample Drying Time:

Patience is key when it comes to fabric glue mastery. Allow your adhesive creation to dry and cure fully before handling it with confidence. Remember, drying times may vary depending on the brand or type of glue used, so always consult the manufacturer’s instructions.

Be strong; resist temptation and refrain from disturbing or moving the glued fabrics until they have reached their maximum bond strength.

Enhancing the Bond:

To reinforce your bond and ensure its unwavering strength, consider using clamps or binder clips to hold the fabrics together during the drying process. This extra step is like having a personal bodyguard for your adhesive masterpiece. And for ultimate peace of mind, perform a simple bond strength test by gently tugging on the fabrics once the glue has dried. If they hold firm, you’ve nailed it.

Temporary vs Permanent Bonds

Fabric glue comes in two main types: temporary and permanent bonds. These two options offer distinct characteristics and purposes, making them suitable for different needs.

Temporary fabric glue provides a quick and easy solution for temporary alterations or fixes. Whether you want to hem your pants for a special event without permanently altering their length or attach appliques or decorations to clothing for a short period, temporary fabric glue is your go-to option.

It dries clear and flexible, ensuring that there is no residue left behind when removed. This means no damage to your fabric, as if it was never there in the first place.

On the other hand, permanent fabric glue is all about creating a strong and long-lasting bond that can withstand regular wear and tear.

If you’re working on projects that require a more permanent attachment, such as permanently attaching patches or embellishments to clothing or creating fabric crafts, permanent fabric glue is the way to go. It dries clear and hard, creating a strong bond that can withstand washing and multiple uses.

When choosing between temporary and permanent bonds, consider the intended use of the fabric glue. Temporary fabric glue is ideal for quick fixes or temporary solutions, while permanent fabric glue is better suited for projects that require a more lasting bond. Some fabric glues even offer both options, giving you the flexibility to choose based on your needs.

How Fabric Properties Impact Bonding Strength

Today, we embark on an exciting journey into the world of fabric glue and its superhero-like ability to create strong bonds. Join me as we explore how fabric properties influence the strength of this adhesive, unlocking the secrets to successful fabric bonding.

Fabric Composition:

Just like superheroes, different fabrics possess unique characteristics that impact bonding strength. Natural fibers, such as cotton, readily absorb glue, allowing it to penetrate deeply and form a strong bond. On the other hand, synthetic fibers like polyester or nylon may present a smoother surface, posing a challenge for adhesive adherence.

Thickness Matters:

Next up is the thickness of the fabric. Picture this: a powerful hero needs a solid foundation to exert their strength. Similarly, thicker fabrics provide a larger surface area for the glue to grip onto, resulting in a stronger bond. Thin fabrics, however, may require additional adhesive to ensure a secure hold.

Weave Patterns and Surface Texture:

Our journey takes a twist as we encounter weave patterns and surface texture. Think of weave patterns as the intricate designs on a hero’s costume – they can greatly impact bonding strength. Fabrics with tight weaves or smooth surface textures provide better contact for the glue, resulting in stronger bonds. Conversely, loose weaves or larger pores may allow the glue to penetrate deeper into the fabric for enhanced adhesion.

Surface Preparation:

Preparing the battlefield is crucial for any superhero showdown. Similarly, proper surface preparation is essential for optimal bonding strength. Before applying fabric glue, ensure your fabric is clean, dry, and free from contaminants. Some synthetic fabrics may even benefit from gentle sanding to enhance adhesion.

Environmental Factors:

Now let’s consider environmental factors – the external challenges that can affect our hero’s performance. Temperature and humidity levels can impact the curing process of fabric glue. To unleash the full potential of our adhesive superhero, follow the manufacturer’s instructions regarding temperature and humidity requirements.

When Is Sewing a Better Option?

When it comes to choosing between sewing and using fabric glue, there are certain situations where sewing is a better option.

While fabric glue can be convenient and easy to use, it may not always provide the same durability and strength as sewing.

Firstly, let’s consider the type of fabric you are working with. Lightweight materials like cotton, silk, or polyester can often be effectively bonded with fabric glue. However, when dealing with heavyweights like denim, canvas, or upholstery fabrics, sewing reigns supreme. These robust materials exert stress on seams, and sewing provides a stronger bond that can withstand the weight and tension.

Secondly, think about the purpose of your creation. If it’s something that will be used frequently or subjected to movement, such as garments or bags, then sewing is your go-to. Sewn seams are flexible and less likely to come undone compared to glued seams. Plus, sewing allows for precise control over construction, ensuring your masterpiece holds up beautifully over time.

Moreover, if you need to make alterations or repairs, sewing offers a more permanent solution. Fabric glue might offer a quick fix, but sewing is like giving your beloved item a new lease on life. With strong stitches and expert needlework, your repairs will stand the test of time.

Sewing gives you unparalleled design flexibility. While fabric glue simply bonds two pieces together, sewing allows you to explore various stitches and embellishments that add both functionality and aesthetic appeal to your project. It’s like adding a touch of personality to your creation.

Lastly, let’s not forget personal preference and skill level. Some of us find joy in the rhythmic motion of sewing and take pride in our stitching skills. If that sounds like you, then sewing is undoubtedly the path to follow.

In conclusion, when it comes to the great sewing versus fabric glue debate, consider the fabric type, intended use, need for alterations or repairs, design possibilities, and personal preference. Armed with this knowledge, you’ll be able to create durable, functional, and visually stunning projects that will leave everyone in awe.

Tips for Ensuring Long-Lasting Bonds

In this comprehensive guide, we will explore essential tips for ensuring long-lasting bonds with fabric glue. By following these expert recommendations, your glued fabric creations will withstand the test of time and maintain their beauty for years to come.

Fabric Selection: The Foundation of a Strong Bond

The first step to achieving a long-lasting bond is selecting the right fabric for your project. Not all fabrics are created equal when it comes to bonding with fabric glue. Opt for fabrics with a tight weave, such as cotton or polyester, as they provide a solid surface for the glue to adhere to.

Avoid fabrics that are excessively stretchy or slippery, as they may not hold the glue as effectively. By choosing a fabric that is compatible with fabric glue, you lay the groundwork for a durable bond that will stand up to wear and tear.

Surface Preparation: The Key to Enhancing Adhesion

Before applying fabric glue, take a moment to properly prepare the surface. A clean and residue-free fabric is essential for optimal adhesion. Remove any dirt, dust, or oils that could hinder the bond by washing the fabric if necessary.

For smooth surfaces that may resist bonding, lightly sanding them can create a textured surface that provides better grip for the glue. By investing time in surface preparation, you set the stage for a strong and lasting bond.

Glue Application: The Art of Precision

Mastering the technique of applying fabric glue is crucial for achieving a secure bond. Begin by applying a thin and even layer of glue on both surfaces that need to be bonded. Remember, a little goes a long way, so avoid using excessive amounts of glue as it can lead to messy results and may not necessarily enhance the bond’s strength.

For precise application, consider using a brush or toothpick to ensure an even and controlled distribution of the glue. By employing a steady hand and meticulous approach, you can achieve a flawless bond that will endure.

Drying Time: Patience for Perfection

Patience is the key to success when it comes to drying time. Different fabric glues have varying drying times, so it is crucial to follow the instructions provided by the manufacturer. Rushing the drying process by handling or stressing the glued fabric before it is fully dry can compromise the bond’s strength and longevity.

Allow adequate drying time according to the manufacturer’s recommendations, and resist the temptation to rush the process. By exercising patience during the drying phase, you lay the foundation for a bond that will withstand the test of time.

CpMhRyabggI” >

Conclusion

In summary, fabric glue proves to be a dependable and efficient solution for seamlessly joining fabric pieces together sans the hassle of sewing. However, its effectiveness hinges on a multitude of factors. The type of fabric utilized, meticulous surface preparation, precise application technique, appropriate drying time, environmental conditions, and the quality of the fabric glue all contribute to determining the strength of the bond.

Various types of fabric glues cater to diverse needs. Permanent fabric glue is tailor-made for projects necessitating a robust and enduring bond. Conversely, temporary fabric glue enables effortless removal or washing off. Spray fabric adhesive is an ideal choice for larger projects or quick bonding while fusible web guarantees a sturdy bond when heat is applied.

Liquid stitch offers flexibility and dries clear on fabrics while fabric tape provides a swift and easy alternative to sewing or ironing.

To maximize the adhesive properties of fabric glue, it is crucial to employ proper application techniques. This entails thoroughly cleaning the fabric and eliminating any dirt or oils, applying an even layer of glue using suitable tools, gently but firmly pressing the fabrics together to ensure optimal contact between the adhesive and the material, adhering to ample drying time as specified by the manufacturer’s instructions, and bolstering the bond with clamps or binder clips during the drying process.

While fabric glue boasts convenience and versatility, there are instances where sewing may prove superior. When dealing with heavyweight fabrics or projects requiring durability and frequent use such as garments or bags, sewing affords a stronger and more permanent bond. Sewing also allows for greater design flexibility and precise control over construction.

In conclusion, when used correctly with consideration given to factors like fabric type, surface preparation, application technique, drying time, environmental conditions, and quality of the glue – fabric glue can undoubtedly hold its own. By adhering to these guidelines and incorporating tips that ensure long-lasting bonds with fabric glue into your creative endeavors – you can confidently fashion exquisite yet resilient fabric projects that withstand the test of time.