Wondering if Aleene’s glue is the real deal for your leather projects? Look no further.

Aleene’s glue is a crafting favorite, but does it stick like glue to leather? In this blog post, we’ll dig into the nitty-gritty of Aleene’s glue on leather and weigh its pros and cons.

So, let’s saddle up and uncover whether Aleene’s glue and leather are a match made in crafting heaven.

Overview of Leather: Types and Properties

Contents

- 1 Overview of Leather: Types and Properties

- 2 Adhesive Requirements for Leather

- 3 Does Aleene’s Glue Work on Leather?

- 4 Factors to Consider When Using Aleene’s Glue on Leather

- 5 Techniques to Improve Bonding Strength Between Aleene’s Glue and Leather

- 6 Alternatives to Aleene’s Glue for Bonding Leather

- 7 Pros and Cons of Using Aleene’s Glue on Leather

- 8 Conclusion

Leather is a fascinating and versatile material that has been cherished for centuries for its durability and natural beauty. It is made from the hides or skins of animals, primarily cattle, but also sheep, goats, and pigs. There are different types of leather, each with its own unique characteristics.

Let’s explore some of the most common types and their properties.

Full-Grain Leather: The King of Leather

Full-grain leather is considered the highest quality and most durable type of leather. It retains the natural grain and imperfections of the hide, giving it a rich and luxurious appearance. This type of leather develops a beautiful patina over time, making it even more special.

With its strong fibers and inherent strength, full-grain leather is like the king of the leather kingdom.

Top-Grain Leather: Smooth and Strong

Top-grain leather is also high-quality but has been sanded or buffed to remove any imperfections. It still maintains its strength and durability, making it a popular choice for luxury goods. It’s slightly more affordable than full-grain leather but still packs a punch in terms of quality. Smooth to the touch and resilient in nature, top-grain leather stands as a testament to both style and strength.

Corrected-Grain Leather: Uniformity at Its Best

Corrected-grain leather is made by buffing away the natural grain and applying an artificial one. This type of leather is often used for furniture or upholstery as it has a more uniform appearance. It’s a great option if you’re looking for consistency in your leather products. With its refined texture and consistent look, corrected-grain leather brings a touch of elegance to any setting.

Bonded Leather: Affordable but Less Durable

Bonded leather is made by shredding leftover scraps of leather and bonding them together with adhesive. It’s a more affordable option but lacks the durability and natural characteristics of full-grain or top-grain leather. It’s suitable for less demanding applications.

While not as strong as its counterparts, bonded leather still offers an affordable and accessible option for those seeking the look and feel of genuine leather.

Leather has several properties that make it desirable for various applications. It is naturally breathable, allowing air to pass through and preventing moisture buildup. This makes it comfortable to wear or sit on for extended periods. Leather is also resistant to fire, tearing, and punctures, making it a popular choice for protective gear such as jackets or gloves. Its innate ability to withstand the elements makes leather a reliable and trustworthy ally.

Leather can be dyed in a variety of colors, allowing for customization and creativity in design. It also develops a patina over time, enhancing its aesthetic appeal and giving it a unique character. However, leather can be expensive compared to other materials, and proper care and maintenance are necessary to keep it in good condition.

Adhesive Requirements for Leather

Leather is a magnificent material that requires careful consideration when it comes to bonding. Whether you’re a DIY enthusiast or a professional craftsman, understanding the adhesive requirements for leather is crucial to ensure a successful bonding process. In this blog post, we will explore the key factors to consider when choosing the perfect glue for your leather projects.

Flexibility:

Leather is known for its flexibility and ability to withstand constant movement and stretching. Therefore, it is vital to select an adhesive that can match this unique property of leather. Look for adhesives that offer flexibility, allowing the leather to move without cracking or breaking the bond.

Strength:

Durability and longevity are essential in any leather project, be it a pair of shoes or a handbag. To ensure your creation lasts for years to come, opt for adhesives that provide strong bonding capabilities. This will help the bond withstand stress and strain, maintaining its integrity even in high-stress applications.

Environmental Resistance:

Leather items are often exposed to various environmental conditions, including moisture, heat, and cold. It’s imperative to choose an adhesive that can withstand these elements without compromising the bond’s strength. Look for adhesives with good resistance to moisture and temperature fluctuations.

Compatibility with Leather Finishes:

Leather finishes, such as dyes or coatings, add beauty and protection to the material. However, some adhesives may react negatively with certain finishes, leading to discoloration or damage. To avoid such mishaps, always choose adhesives that are specifically formulated for use with leather or have been tested and proven compatible with various finishes.

Ease of Application:

Time is precious when it comes to crafting with leather, so opt for adhesives that are easy to apply and work with. This will save you effort and ensure a smoother bonding process. Additionally, consider adhesives that dry clear or match the color of the leather for a more aesthetically pleasing result.

Does Aleene’s Glue Work on Leather?

In the world of crafting and DIY projects, finding the perfect adhesive can be like discovering a hidden treasure chest. When it comes to bonding leather, it’s essential to choose an adhesive that can withstand the unique properties of this material.

While some individuals have reported success using Aleene’s glue on leather, it is generally recommended to opt for adhesive products specifically designed for use with leather. In this article, we’ll explore why it’s important to use specialized leather adhesives and provide some tips for achieving strong and durable bonds.

Understanding Leather’s Unique Properties:

Leather, with its non-porous and smooth surface, is a material unlike others in the crafting realm. Conventional adhesives, such as Aleene’s glue, may struggle to penetrate and adhere to the leather’s surface, resulting in weak bonds that crumble over time. To ensure a lasting bond, it’s crucial to use adhesives specifically formulated for use with leather.

The Importance of Compatibility:

Aleene’s glue, tailored for porous materials, may not play well with leather. This mismatch of compatibility can lead to damage or unsightly discoloration. Opting for adhesives specifically made for leather ensures that they have undergone rigorous testing to guarantee safe and effective performance on this material.

Superior Adhesion and Flexibility:

Specialized leather glues are crafted with ingredients that expertly infiltrate the pores of the leather, forging a bond that endures natural movements and flexing. These adhesives offer unrivaled adhesion and flexibility, ensuring your leather creations remain intact even under stress.

Tips for Success:

Should you decide to venture into using Aleene’s glue on leather for certain projects, a small test on an inconspicuous area is vital to assess its performance. For application, spreading a thin and even layer on both surfaces being bonded is key. Press the surfaces firmly together and hold them in place for a few minutes, allowing the glue to set. To secure a tight bond, consider employing clamps or weights to prevent any shifting during the drying process.

Factors to Consider When Using Aleene’s Glue on Leather

When it comes to using Aleene’s glue on leather, there are several key factors to consider to ensure a successful and long-lasting bond. Let’s dive deeper into these factors:

First, consider the type of leather you are working with. Different types of leather have varying levels of porosity and texture. Smooth or lightly-textured leathers, like pigskin or lambskin, tend to work best with Aleene’s glue. However, heavily textured or suede-like leathers may not provide optimal results.

Properly preparing the leather surface is crucial for achieving a strong bond. Clean the leather thoroughly with a mild soap and warm water solution, removing any dirt, oils, or finishes that may hinder adhesion. Allow the leather to dry completely before applying the glue.

Conducting a small test patch is always recommended before applying Aleene’s glue to a larger area of leather. This allows you to assess adhesion and check for any discoloration or damage. Apply a small amount of glue to an inconspicuous area and let it dry according to the manufacturer’s instructions.

When applying the glue, use a thin, even layer on both surfaces that need to be bonded together. Avoid applying too much glue as it can create excess bulk and uneven adhesion. Make sure to spread the glue evenly without leaving any gaps or air bubbles.

Allow the glued leather pieces to dry undisturbed for at least 24 hours or as recommended by the manufacturer. Rushing the drying process may result in a weaker bond or even glue failure. Keep the leather flat and away from moisture or excessive heat during this time.

Consider the flexibility and durability of the adhesive when choosing Aleene’s glue for leather. Leather undergoes natural movements and stress, so the glue should be able to withstand these without weakening or breaking the bond. Look for a flexible and strong adhesive formula designed specifically for leather.

Ensure that the glue you use has good resistance to moisture, temperature changes, and other environmental factors. This is particularly important for leather items that will be subjected to regular use or wear. Aleene’s glue should provide a durable and long-lasting bond on leather.

Techniques to Improve Bonding Strength Between Aleene’s Glue and Leather

With the right techniques, you can improve the bonding strength between Aleene’s glue and leather, ensuring that your projects stand the test of time.

Prepare the Leather Surface:

To achieve a strong bond, it is crucial to properly prepare the leather surface. Start by cleaning the leather with a mild detergent and water solution to remove any dirt, dust, or oils that could hinder adhesion. Allow the surface to dry completely before moving on to the next step.

Roughen the Surface:

Take your bond to new heights by gently roughening the leather surface. Use fine-grit sandpaper or a sanding block to create a better texture for the glue to grip onto. Be careful not to overdo it and damage the leather in the process.

Apply Aleene’s Glue Properly:

The key to a strong bond lies in applying Aleene’s glue evenly and in the right amount. Applying too much glue can lead to seepage, while applying too little may result in weak adhesion. Follow the manufacturer’s instructions for application and consider using a small brush or applicator for precise control.

Clamp for Success:

Applying pressure during the drying process is crucial for optimal bonding strength. After applying the glue, use clamps or weights to firmly hold the pieces together. This ensures maximum contact between surfaces, allowing the glue to cure effectively.

Patience is Key:

Allow ample drying time for the glue bond to fully form before subjecting it to any stress or strain. Remember, rushing this step can compromise the final result. Refer to the product instructions for specific drying guidelines based on temperature and humidity.

Test Your Bond:

Once completely dried, it is essential to test the bond for strength. Apply gentle pressure or pull on the bonded area to check for any signs of weakness or separation. A strong and secure bond means you can trust Aleene’s glue for your leather projects.

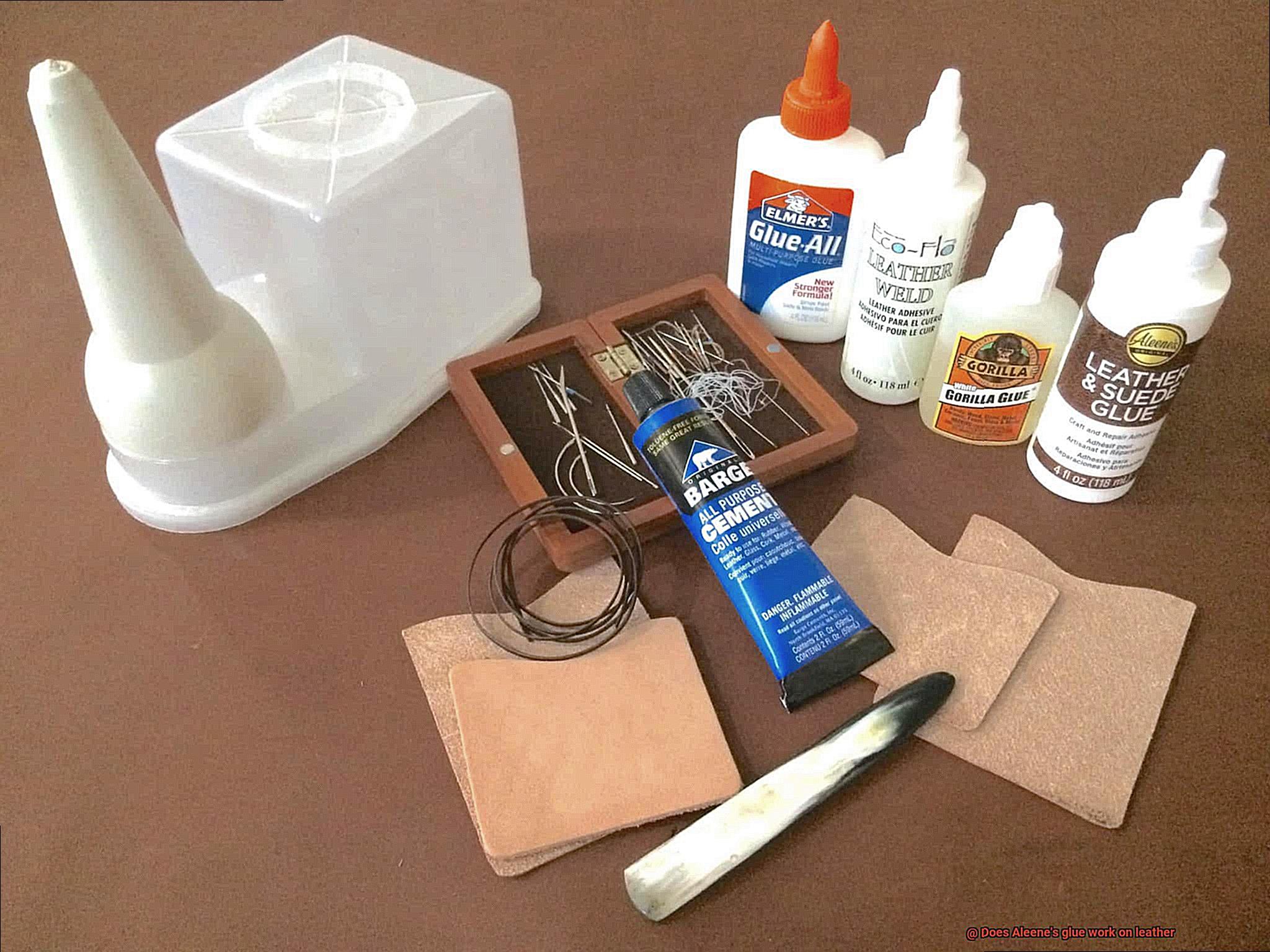

Alternatives to Aleene’s Glue for Bonding Leather

When it comes to bonding leather, Aleene’s glue has been a trusted choice for its strength and versatility. However, there are times when individuals may seek alternative options that better suit their specific needs. Whether you’re a leatherworking enthusiast or a DIY enthusiast, this comprehensive guide will introduce you to the best alternatives to Aleene’s glue for bonding leather.

Contact Cement:

Contact cement, widely used in construction, offers a strong bond and quick drying time. It is ideal for bonding leather to various materials like wood and metal. With its instant and permanent bond, contact cement is perfect for projects requiring immediate strength.

Epoxy Resin:

Known for exceptional strength and durability, epoxy resin is a popular two-part adhesive used in automotive and industrial settings. It can also be effectively used on leather. Proper surface preparation and cleaning are essential when using epoxy resin on leather to ensure optimal adhesion.

Natural Alternatives:

For those seeking natural alternatives, gum tragacanth and hide glue are excellent options. Gum tragacanth, derived from plant sap, offers flexibility and leaves no residue. Hide glue, made from animal collagen, has stood the test of time, providing a strong bond that can be easily reversed if needed.

Fabric Glue and Leather Adhesive:

If flexibility is a priority in your leather projects, consider using fabric glue or specially formulated leather adhesive. These adhesives offer a strong yet flexible bond capable of withstanding everyday use.

Pros and Cons of Using Aleene’s Glue on Leather

When it comes to leather projects, finding the right adhesive is essential for success. One popular option on the market is Aleene’s glue, known for its strong bonding capabilities. However, before you jump into your next project, it’s important to weigh the pros and cons of using Aleene’s glue on leather.

Let’s start with the advantages. First and foremost, Aleene’s glue creates a strong bond that can withstand regular wear and tear. No need to worry about your project falling apart – this adhesive has got you covered. Another advantage is its versatility. Whether you’re working with genuine leather, suede, or synthetic leather, Aleene’s glue can handle it all. This makes it a convenient option for various leather projects, from repairing shoes to creating custom accessories.

Ease of use is another perk of using Aleene’s glue. Its user-friendly packaging and nozzle or brush applicator make application a breeze. No more struggling with messy glue bottles – Aleene’s glue spreads smoothly and evenly on leather surfaces. And let’s not forget about its quick drying time. In just minutes, your project will be ready to go. Perfect for those time-sensitive tasks or when you need to move swiftly through multiple steps.

In terms of appearance, Aleene’s glue dries to a clear and flexible finish. This means that your bonded leather will remain pliable and comfortable, without any visible traces of adhesive. A truly seamless finish for your projects.

But like any product, there are a few downsides to consider. One drawback is the limited water resistance of Aleene’s glue. While it offers good adhesion on leather, it may not hold up as well when exposed to moisture frequently. If you’re working on shoes or outdoor gear that will encounter water often, it may be best to opt for a waterproof adhesive specifically designed for leather.

Another potential con is the possibility of staining or residue on certain types of leather. To avoid any mishaps, it’s always recommended to test the glue on a small area of the leather before applying it to the entire surface.

Furthermore, Aleene’s glue may not provide the same level of bond strength on extremely smooth or heavily treated leather surfaces. If you’re working with these types of leather, it might be worth considering a specialized leather glue that is formulated for those specific materials.

Lastly, if you’re tackling high-stress areas like seams or joints, Aleene’s glue may not be the most durable option. In these cases, exploring stronger adhesives or alternative methods like stitching or riveting might be more suitable.

V4_EaCHcyNY” >

Conclusion

In conclusion, while some people have found success using Aleene’s glue on leather, it is generally recommended to opt for adhesives specifically designed for this unique material. Leather has its own set of requirements when it comes to bonding, and conventional adhesives like Aleene’s may struggle to penetrate and adhere to its smooth and non-porous surface. This can result in weak bonds that may fail over time.

Specialized leather adhesives offer superior compatibility, adhesion, flexibility, and resistance to environmental factors such as moisture and temperature fluctuations. These products have undergone rigorous testing to ensure safe and effective performance on leather.

However, if you choose to use Aleene’s glue on leather for certain projects, there are techniques you can use to improve bonding strength. Properly preparing the leather surface, applying the glue evenly and in the right amount, clamping during drying, allowing ample drying time, and conducting a test patch are all important steps for achieving a strong bond.

Alternatively, there are other adhesive options available for bonding leather that may better suit your needs. Consider contact cement, epoxy resin, natural alternatives like gum tragacanth or hide glue, as well as fabric glue or specially formulated leather adhesive.

Ultimately, selecting the right adhesive for your leather project is crucial for long-lasting results.