Craft projects and DIY repairs often call for the superpowers of adhesive, allowing us to seamlessly bond materials together. But what about foam? Does adhesive stick to this lightweight, spongy material? You might be surprised.

Foam’s smooth, closed-cell surface doesn’t offer much for traditional adhesives to grab onto. You’d think it would be a difficult match. However, with finesse and the right type of adhesive, foam and adhesive can create a strong and reliable bond. So let’s dive into the fascinating world of adhesive-foam relationships and uncover the secrets that allow these seemingly incompatible materials to join forces.

Together, we’ll explore the science behind foam and adhesives, examine different types of foam and their compatibility with adhesives, and discover handy tips for successful adhesion. Whether you’re upholstering cushions, sculpting intricate foam designs, or just curious about the science of sticking things together, fasten your seatbelts as we unravel the sticky riddle – can adhesive really stick to foam?

What is Adhesive?

Contents

- 1 What is Adhesive?

- 2 Types of Adhesives

- 3 Can All Adhesives Stick to Foam?

- 4 Benefits of Using Foam Adhesive

- 5 Factors to Consider When Using Foam Adhesive

- 6 Preparing the Surface for Bonding

- 6.1 Step 1: Immaculate cleansing of the foam surface

- 6.2 Step 2: Thoroughly desiccate the foam surface

- 6.3 Step 3: Embrace surface roughness

- 6.4 Step 4: Harness the magic of primers or adhesion promoters

- 6.5 Step 5: Verify compatibility between adhesive and foam

- 6.6 Step 6: Factor in environmental conditions

- 7 Open Time and Drying Time of Foam Adhesives

- 8 Other Types of Adhesives for Bonding Foam Materials

- 9 Conclusion

Adhesive, also known as glue, is a remarkable substance that serves as a critical tool across a wide range of industries and applications. From arts and crafts to construction and manufacturing, adhesive plays an indispensable role in creating strong and durable bonds between different materials.

In this article, we will embark on an exciting journey into the world of adhesives, unraveling their diverse types, unique properties, and the captivating science behind their bonding abilities.

Types of Adhesives:

- Cyanoacrylate adhesives: These super glue-like adhesives possess exceptional bonding capabilities, swiftly and firmly adhering to a variety of materials such as metal, plastic, and rubber.

- Epoxy adhesives: Renowned for their unparalleled strength and durability, epoxy adhesives are ideal for bonding metals, ceramics, and composites with utmost reliability.

- Polyurethane adhesives: Versatile in nature, these adhesives exhibit remarkable bonding prowess with an extensive array of materials, including wood, metal, plastics, and even foam.

- Hot melt adhesives: Transforming from solid sticks to molten wonders using a hot glue gun, these adhesives provide swift bonding for lightweight materials like paper and fabric.

How Adhesives Work:

Adhesives forge bonds through either physical or chemical means:

- Physical bonds: Non-reactive adhesives employ physical mechanisms such as drying or evaporation to bond surfaces together. They form a thin layer that gradually solidifies over time, effectively securing the materials in place.

- Chemical bonds: Reactive adhesives necessitate a chemical reaction to occur, generating robust molecular bonds between the adhesive and the surface it is applied to. This reaction can involve heat, moisture, or the blending of two components.

Bonding Foam Materials:

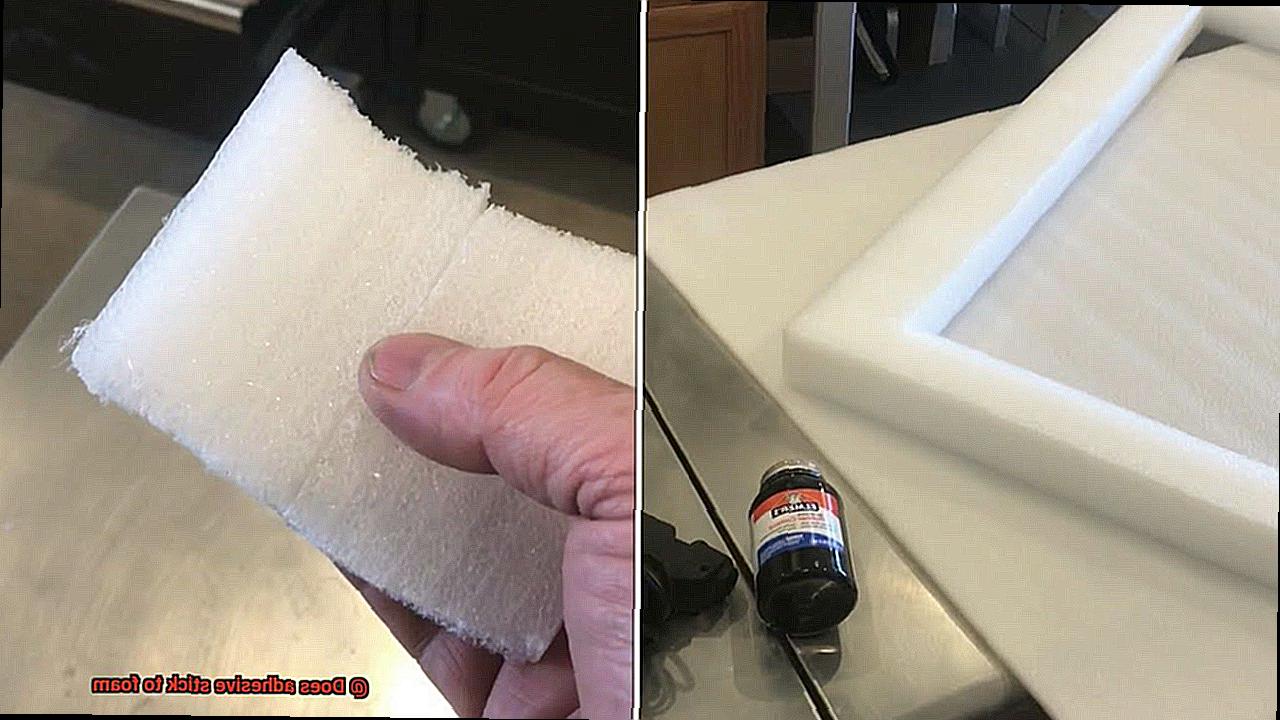

When it comes to bonding foam materials, selecting the right adhesive is of paramount importance. Foam adhesives are specifically formulated to possess exceptional bonding properties with foam while retaining flexibility to accommodate movement and compression. Ensuring thorough cleaning and removal of any contaminants on the foam surface is vital to enhance the adhesive’s effectiveness.

Types of Adhesives

Whether you’re a crafty DIY-er or simply curious, understanding the different types of adhesives available can make your foam projects a breeze. So, let’s dive right in.

Liquid Adhesives: Versatile and Easy to Apply

Liquid adhesives, like glue or epoxy, are commonly used for bonding various materials. However, not all liquid adhesives are suitable for foam surfaces. Some may struggle to adhere properly or even cause damage. That’s why it’s crucial to select a liquid adhesive specifically designed for foam bonding. These adhesives are easy to apply and provide a strong bond without harming your precious foam creations.

Spray Adhesives: Convenient and Even Application

Spray adhesives, available in handy aerosol cans, are perfect for lightweight foam materials. They offer a convenient and even application, ensuring a smooth bond between the adhesive and the foam surface. Remember to choose a spray adhesive specifically designed for foam to achieve optimal results. General-purpose sprays might not work as effectively.

Hot Glue: Quick Bonding Superhero

Ah, hot glue – the superhero of quick bonding. Also known as hot melt adhesive, hot glue is a popular choice for bonding foam. This adhesive is applied in its molten state and solidifies rapidly upon cooling, creating a strong bond. With hot glue guns readily available, you can tackle your foam projects with precision and ease. Just be cautious with the temperature setting to avoid accidental melting or damage to the foam.

Foam-Specific Adhesives: A Match Made in Foam Heaven

For the ultimate foam bonding experience, some manufacturers have crafted adhesives specifically formulated for foam materials. These adhesives provide a strong and durable bond without causing damage or discoloration. You can find them in the form of contact adhesives or adhesive sprays at specialty craft stores or online. They’re like a match made in foam heaven.

Tape: Quick and Mess-Free Bonding

Tape might not be the first thing that comes to mind when thinking of adhesives, but it’s a handy option for bonding foam materials. Double-sided adhesive tapes, specifically designed for foam applications, provide a quick and mess-free way to secure foam pieces together. Just peel, stick, and voila – your foam creations are ready to shine.

Conclusion:

Now armed with knowledge about different types of adhesives suitable for bonding foam materials, you’re ready to tackle any foam project that comes your way. Whether you opt for liquid adhesives, spray adhesives, hot glue, foam-specific adhesives, or tape, always choose the one that suits your specific foam type and project requirements.

Can All Adhesives Stick to Foam?

Foam, a versatile material found in various industries, poses a challenge when it comes to bonding. Not all adhesives are created equal in their ability to stick to foam. In this article, we will dive into the world of glue and explore the factors that determine effective bonding with foam. Discover which adhesives are best suited for your foam projects.

The Type of Adhesive Matters:

Different adhesives possess unique properties and applications. When it comes to foam bonding, certain adhesives excel while others fall short. Let’s explore popular adhesive options and their suitability for foam:

Hot Glue:

Versatile and fast-drying, hot glue is a favorite among crafters. It forms a strong bond and adheres well to various foam types like polystyrene, polyurethane, and EVA foam. However, exercise caution and use a low-temperature hot glue gun to prevent foam melting.

Spray Adhesive:

Ideal for large foam surfaces due to its quick and even application, spray adhesives come in varying formulations. Look for formulas specifically designed for foam bonding to ensure proper adhesion.

Epoxy:

A powerful two-part adhesive with exceptional bonding strength, epoxy can bond foam with wood, metal, and plastic. However, handle with care as epoxy may not be suitable for all types of foam.

Contact Cement:

Contact cement is a popular option for bonding foam, offering strength and durability. Apply it precisely as it dries quickly and forms an instant bond upon contact. Ensure even application on both surfaces and allow complete drying before joining the foam pieces.

Surface Characteristics:

The surface of the foam also influences adhesive compatibility. Smooth, textured, or porous surfaces impact how well an adhesive adheres to the foam. Consider these characteristics when selecting an adhesive.

Testing and Precautions:

Before committing to a project, test the adhesive on a small, inconspicuous area of the foam. This step ensures compatibility and bond strength, preventing potential damage or failure.

Benefits of Using Foam Adhesive

Foam adhesive – the unsung hero of bonding foam materials. If you’re a fan of all things glue-related, then you’re in for a treat. Today, we’re going to dive deep into the benefits of using foam adhesive and why it’s the ultimate choice for bonding foam materials.

First and foremost, let’s talk about strength. Foam adhesive is like the Hulk of adhesives – it creates a bond that is strong and durable. Unlike regular adhesives that struggle to adhere to porous surfaces, foam adhesive has a special formulation that allows it to penetrate the surface of foam and create a firm attachment. This means that no matter how much stress or strain your foam materials are under, the bond will remain intact.

Now, let’s move on to versatility. Foam adhesive is a true chameleon – it can bond with different types of foam, whether it’s polyurethane foam, expanded polystyrene (EPS) foam, or polyethylene foam. It doesn’t discriminate between open-cell and closed-cell foams either, making it the go-to choice for all your foam bonding needs. So whether you’re working on upholstery projects, packaging solutions, or insulation installations, foam adhesive has got your back.

But wait, there’s more. Applying foam adhesive is a breeze. It comes in spray or liquid form, making it easy to apply onto the foam surface. The spray form ensures even distribution and coverage, ensuring that every nook and cranny of your foam gets a dose of adhesive goodness. Plus, foam adhesive dries relatively quickly, so you won’t have to wait around for hours before you can move on to the next step of your project.

One of the best things about foam adhesive is that it won’t harm your precious foam materials. Unlike some other adhesives that contain harsh chemicals or solvents that can degrade or weaken your foams over time, foam adhesive is specially formulated to be non-damaging. It’s like a gentle giant – strong enough to create a bond, but gentle enough to keep your foams in pristine condition.

But the benefits of foam adhesive don’t stop there. It’s also heat and moisture resistant, making it perfect for both indoor and outdoor applications. It can withstand fluctuations in temperature without losing its adhesive properties, ensuring that your bond will stay put no matter the weather. And when it comes to moisture, foam adhesive is like a waterproof shield – it won’t absorb water or get weakened by high humidity.

Did we mention that foam adhesive is also an insulation superhero? By creating a seamless connection between foam layers or surfaces, foam adhesive minimizes air gaps and enhances the insulation properties of your foam materials. So whether you’re insulating your HVAC system, soundproofing a room, or creating protective packaging, foam adhesive will help you achieve maximum thermal or acoustic performance.

Factors to Consider When Using Foam Adhesive

Foam adhesive is a versatile product that can be used for various applications, such as bonding foam to foam, foam to other materials like wood or metal, or even foam to non-porous surfaces. However, there are several factors that need to be considered when using foam adhesive to ensure a strong and long-lasting bond.

- Surface Preparation: Before applying foam adhesive, it is crucial to prepare the surfaces that need to be bonded. The surfaces should be clean, dry, and free from any dust, dirt, or grease. Any contaminants on the surface can interfere with the adhesive’s ability to bond effectively. It is recommended to use a mild detergent or solvent to clean the surfaces thoroughly and allow them to dry completely before applying the adhesive.

- Compatibility: Not all adhesives are compatible with foam materials. Foam adhesives are specifically designed to bond well with foam substrates. It is important to choose an adhesive that is specifically formulated for foam bonding. Using a general-purpose adhesive may not provide the desired results and could result in a weak bond or even damage to the foam material.

- Adhesive Selection: There are different types of foam adhesives available in the market, including spray adhesives, contact adhesives, and adhesive tapes. The choice of adhesive depends on the specific application and requirements. Spray adhesives are easy to apply and provide a uniform coverage, while contact adhesives offer high strength bonds but require careful application due to their fast bonding nature. Adhesive tapes are convenient for certain applications and offer instant bonding without the need for drying time.

- Open Time: Open time refers to the duration during which the adhesive remains tacky and workable after application. Different foam adhesives have different open times, which can vary from a few minutes to several hours. It is important to consider the open time of the adhesive based on the size of the project and the time needed for proper alignment and positioning of the foam materials. Applying the adhesive too soon or waiting too long can affect the bond strength.

- Temperature and Humidity: The temperature and humidity conditions during the bonding process can significantly impact the performance of foam adhesives. Some adhesives may require specific temperature ranges for optimal bonding. It is important to follow the manufacturer’s recommendations regarding temperature and humidity conditions. Extreme temperatures or high humidity can affect the curing and bonding process, leading to a weak bond.

- Pressure Application: Applying pressure on the bonded surfaces helps to ensure a strong bond. It is recommended to use a roller or apply even pressure using hands or clamps to ensure maximum contact between the adhesive and the foam material. This helps in spreading the adhesive evenly and removing any air bubbles, resulting in a stronger bond.

Preparing the Surface for Bonding

Foam adhesive is a versatile and potent tool that forges formidable bonds between foam materials and other surfaces. However, to harness its full power, meticulous surface preparation is paramount. In this article, we will delve into the step-by-step process of preparing a foam surface for bonding with adhesive, guaranteeing optimal bond strength and durability.

Step 1: Immaculate cleansing of the foam surface

Initiate the process by banishing any dust, dirt, oils, or contaminants that might impede the adhesive’s grip. Employ a mild detergent or soap and water solution to gently cleanse the foam. Refrain from employing harsh chemicals or solvents that may harm the delicate foam material.

Step 2: Thoroughly desiccate the foam surface

Moisture can sabotage adhesive bonds, making it crucial to diligently dry the foam surface. Wield a pristine cloth or allow ample time for the foam to air dry completely before proceeding.

Step 3: Embrace surface roughness

Foam surfaces often boast an unyielding smoothness and non-porosity, posing a challenge to adhesives seeking steadfast bonds. Mitigate this obstacle by delicately sanding or scoring the surface, creating micro-abrasions that enable the adhesive to penetrate and securely grip the foam. Exercise caution to avoid excessive force or deep cuts that could inflict damage.

Step 4: Harness the magic of primers or adhesion promoters

To fortify adhesion further, consider employing primers or adhesion promoters expressly formulated for bonding foam materials. These products facilitate a chemical interaction between adhesive and foam surface, elevating bond strength. Adhere scrupulously to manufacturer instructions when applying primers or adhesion promoters.

Step 5: Verify compatibility between adhesive and foam

Ensuring harmony between adhesive and foam surfaces is imperative. Certain adhesives may not harmonize well with specific foam materials due to chemical composition or surface properties. Consult adhesive manufacturer guidelines to assess compatibility and any pertinent recommendations or precautions.

Step 6: Factor in environmental conditions

Contemplate temperature, humidity, and exposure to chemicals or solvents within the intended application environment. Select an adhesive capable of withstanding these conditions and performing optimally.

Open Time and Drying Time of Foam Adhesives

Whether you’re embarking on a foam project or simply curious about adhesives, understanding open time and drying time is crucial. These mystical properties can determine the success or failure of your adhesive bond. So, let’s take a deep dive into the enchanting world of foam adhesives and unravel the mysteries of open time and drying time.

Open Time: The Dance of Precision

Imagine having the power to adjust and perfect your foam creation even after applying adhesive. This is where open time comes into play. Unlike other adhesives that set within seconds, foam adhesives grant you a generous window of opportunity. This allows for meticulous positioning, ensuring that your foam aligns flawlessly before the adhesive solidifies.

Factors Influencing Open Time:

Temperature, humidity, and adhesive formulation are the key influencers of open time. Higher temperatures and humid conditions accelerate the drying process, limiting your open time. Conversely, cooler temperatures and drier environments extend this precious window. Paying attention to these factors while working with foam adhesives will maximize your open time and unleash your creativity.

Drying Time: From Liquid to Indestructible Bond

Once your foam masterpiece is perfectly positioned, the magic of curing begins. Drying time refers to how long it takes for the adhesive to fully cure and create an unbreakable bond. Foam adhesives are renowned for their relatively fast drying time compared to other types of adhesives. This rapid transformation allows for quick assembly and efficient project completion.

Determining Drying Time:

Several factors play a role in determining the drying time of foam adhesives including adhesive type, adhesive layer thickness, environmental conditions, and substrate material. To ensure optimal results, consult the manufacturer’s instructions or guidelines. These recommendations are based on extensive testing and provide valuable insights into when your adhesive will reach its optimal bonding strength.

Patience is the Key:

While foam adhesives may achieve initial bond strength within minutes to hours, it’s crucial to exercise patience. To allow for maximum strength and durability, it is recommended to wait at least 24 hours before subjecting the bonded foam to significant stress or load. Remember, good things come to those who wait.

Other Types of Adhesives for Bonding Foam Materials

When it comes to bonding foam materials, choosing the right adhesive is key to achieving a strong and durable bond. In this blog post, we will explore different types of adhesives used for bonding foam materials and their advantages. Whether you’re working on a craft project or upholstery, understanding these adhesives can help you make an informed decision and achieve the desired results.

Spray Adhesive:

Spray adhesives are a popular choice for bonding foam materials due to their ease of use and quick bonding properties. With a thin, even layer applied on both surfaces, spray adhesives create a strong and secure bond when pressed together. They are particularly useful for larger foam pieces or projects where time efficiency is crucial. The aerosol can allows for easy application, ensuring an even coverage on the foam surface. Additionally, spray adhesives offer versatility as they can be used to bond foam to various materials such as fabric, wood, or metal.

Contact Adhesive:

Contact adhesives are known for their ability to bond uneven or irregular surfaces, making them an excellent choice for foam materials with textured or uneven surfaces. Applied to both the foam and the surface it will be attached to, contact adhesives dry before the two surfaces are pressed together, creating a robust bond. This type of adhesive is ideal for upholstery projects or bonding foam to wood or fabric. Contact adhesives provide good initial tack, allowing for repositioning if necessary, before forming a strong bond.

Polyurethane Adhesives:

Polyurethane adhesives are specifically formulated for bonding foam materials. These adhesives provide a strong and flexible bond, perfect for applications where the foam material needs to retain its flexibility or withstand movement or stress. They are commonly used in the upholstery industry due to their durability and ability to withstand frequent use. Polyurethane adhesives also offer good resistance to water, heat, and chemicals, ensuring a long-lasting bond.

Epoxy Adhesives:

For industrial or heavy-duty applications, epoxy adhesives are an excellent choice for bonding foam materials. Known for their exceptional bonding strength and resistance to chemicals and solvents, epoxy adhesives create a durable bond that can withstand harsh environments. They are suitable for bonding foam to metals, plastics, and wood. Epoxy adhesives require mixing two components – a resin and a hardener – before application, ensuring a proper chemical reaction and a strong bond.

mPxS-iCMxSM” >

Conclusion

Adhesive and foam may seem like an unlikely pair, but let me tell you, they can stick together like glue.

Yes, my friends, adhesive does indeed have the power to bond with foam. Whether you’re working on a craft project or tackling a DIY home improvement task, rest assured that adhesive will hold those foam pieces in place.

It’s like magic. No more worrying about your foam creations falling apart.

So go ahead and unleash your creativity with foam knowing that adhesive has got your back.