Imagine a world without adhesives. No more smartphones held together, no towering skyscrapers, and no DIY projects. Adhesives have revolutionized the way we live and build. But when it comes to craft and construction, there’s one burning question on everyone’s minds: can acrylic stick to PVC?

Picture this: you’re knee-deep in a DIY project or stuck in a sticky situation (pun intended), needing to join two versatile materials – acrylic and PVC. Both known for their durability, flexibility, and affordability. But do they have what it takes to form a mutual adhesive bond?

Get ready to dive into the captivating world of acrylic and PVC bonding as we unravel the mysterious secrets behind their compatibility. Whether you’re a DIY hobbyist, an aspiring builder, or just curious about material science, this exploration will grab your attention and give you valuable insights.

In this blog post, we’ll explore the main points surrounding this topic, demystifying the enigmatic relationship between acrylic and PVC. We’ll uncover the factors that influence their bond, discover the best types of adhesives that work like magic, and learn essential preparation steps for a successful union. Brace yourself for an enlightening journey into the realm of adhesive miracles.

So if you find yourself in a home improvement conundrum or simply want to expand your knowledge of materials, join us as we uncover whether acrylic truly sticks to PVC. Get ready for an educational quest that will leave you armed with newfound adhesive expertise

Adhesive Considerations for Bonding Acrylic and PVC

Contents

- 1 Adhesive Considerations for Bonding Acrylic and PVC

- 2 Types of Adhesives Suitable for Bonding Acrylic and PVC

- 3 Preparing Surfaces Prior to Applying Adhesive

- 4 Applying the Adhesive Properly

- 5 Factors That Can Affect the Strength of the Bond

- 6 Mechanical Fasteners for Enhancing the Bond Between Acrylic and PVC

- 7 Benefits of Using an Adhesive to Bond Acrylic and PVC Together

- 8 Conclusion

Acrylic and PVC are versatile materials used in construction, signage, and manufacturing. To create a reliable bond between these materials, adhesive selection is crucial. In this article, we will explore the key considerations for choosing the right adhesive, preparing the surfaces, and achieving a strong and durable connection between acrylic and PVC.

Chemical Compatibility and Adhesive Selection:

The chemical composition of acrylic (PMMA) and PVC poses a challenge for traditional adhesives. However, specific adhesives formulated for bonding acrylic and PVC exist. These solvent-based adhesives contain chemicals that effectively bond the two materials without causing damage or discoloration. Choosing an adhesive designed for this purpose is essential to ensure a reliable and long-lasting bond.

Surface Preparation:

Proper surface preparation is vital to achieve a successful bond. Before applying the adhesive, both surfaces must be clean, dry, and free from contaminants like dust or grease. Enhancing adhesion can be achieved by lightly roughening the surfaces using sandpaper or a fine-grit abrasive pad. This creates a roughened surface that provides better contact between the adhesive and the materials.

Application Techniques:

Following proper application techniques is crucial for optimal bonding results. The adhesive is typically applied as a thin layer to both surfaces, which are then pressed firmly together. Depending on the adhesive’s curing time, clamps or other means of securing the materials may be necessary while the bond sets. Following the manufacturer’s instructions ensures a reliable connection.

Curing Time and Environmental Factors:

Consideration should be given to the adhesive’s curing time. Some adhesives require longer curing times to achieve maximum bond strength, while others offer quick-curing options for faster project completion. It is essential to follow the manufacturer’s instructions regarding curing time and consider environmental factors such as temperature and humidity. These factors can affect the adhesive’s curing process and ultimately impact the bond strength.

Mechanical Support:

In certain cases, using mechanical fasteners in conjunction with adhesives can provide additional structural support. Screws or rivets, when combined with adhesive, enhance the overall strength and durability of the bond. This combination ensures a secure connection between acrylic and PVC.

Types of Adhesives Suitable for Bonding Acrylic and PVC

When it comes to bonding acrylic and PVC, the quest for the perfect adhesive begins. These two materials possess distinct chemical compositions, making it a challenge to achieve a strong and durable bond. However, fret not. There are specific adhesives available that are designed to conquer this bonding dilemma. In this blog post, we will delve into the world of adhesives suitable for bonding acrylic and PVC, ensuring a flawless union every time.

Solvent-Based Adhesives: Unleashing the Power of Chemical Fusion

One exceptional option for bonding acrylic and PVC is the solvent-based adhesive, also known as acrylic cement or solvent cement. These remarkable adhesives work their magic by dissolving the surfaces of both materials, resulting in a chemical bond once they dry. Solvent-based adhesives are incredibly effective, delivering a robust and permanent bond. They find extensive use in plumbing, sign making, and construction projects where reliable bonding is paramount.

Epoxy Resin: Forging Bonds of Unyielding Strength

Another adhesive type ideal for bonding acrylic and PVC is epoxy resin. Renowned for its exceptional strength and superior bonding properties, epoxy resin consists of two components – the resin and the hardener – which must be meticulously mixed before application. Once blended, epoxy resin adhesives yield an unwavering and enduring bond between acrylic and PVC. Their applications span across industries requiring steadfast bonding, such as automotive parts and industrial machinery.

Specialized Adhesives: Tailor-Made for Acrylic and PVC Fusion

For those seeking an adhesive formulated exclusively for bonding acrylic and PVC, specialized adhesives hold the key. Often available in two-part systems, these adhesives demand the application of a primer or activator on the surfaces prior to adhesive use. This meticulous process ensures remarkable bonding strength, rendering them ideal for applications that necessitate an indelible bond.

Not All Adhesives Are Equal: Selecting Wisely

It is essential to remember that not all adhesives possess the desired qualities for bonding acrylic and PVC. For instance, cyanoacrylate (super glue) is ill-suited for this purpose, as it may fail to achieve an enduring bond over time. To ensure optimal results, it is imperative to choose an adhesive specifically designed for bonding acrylic and PVC.

Surface Preparation: The Gateway to Achieving Perfection

Before applying any adhesive, proper surface preparation serves as the gateway to achieving a flawless bond. Thoroughly cleaning and drying both the acrylic and PVC surfaces while eliminating contaminants like dust or grease is crucial. Lightly sanding the surfaces can further enhance adhesion by creating a rough texture, cementing the bond between the adhesive and the materials.

Preparing Surfaces Prior to Applying Adhesive

Are you ready to unlock the secret behind a strong and long-lasting bond between acrylic and PVC? The key lies in properly preparing the surfaces before applying adhesive. In this article, we will reveal the step-by-step process to ensure your materials are clean, dry, and perfectly primed for the ultimate adhesion experience. Get ready to witness the magic.

Step 1: The Cleanliness Chronicles

Before embarking on your adhesive adventure, cleanliness is paramount. Bid farewell to dirt, dust, and greasy contaminants that may hinder your bond. Arm yourself with a gentle detergent or cleaner suitable for both acrylic and PVC. Immerse the surfaces in a thorough scrubbing session, leaving them spick and span – ready to conquer the world of adhesion.

Step 2: Achieving Dryness Mastery

Moisture is the arch-nemesis of adhesion, so drying your surfaces like a pro is essential. Grab a lint-free cloth or paper towel, gently patting away any lingering moisture. Leave no trace behind; we want those surfaces bone dry and prepared for the adhesive magic that awaits.

Step 3: A Touch of Roughness

Now it’s time to add some texture to your surfaces, but fear not – we’re not going full-on sandpaper frenzy here. Equip yourself with fine-grit sandpaper and lightly sand both the acrylic and PVC. The goal is to create a slightly roughened surface, providing an optimal grip for the adhesive. Remember, gentle strokes are key – we don’t want any scratches or damage along the way.

Step 4: Dust Busting Extravaganza

After your sanding adventure, it’s crucial to rid your surfaces of any dust or debris left behind. Grab a soft brush or harness the power of compressed air, gently blowing away those pesky particles. A pristine surface is the ultimate goal before moving on to the next step. Leave no debris unturned.

Step 5: The Perfect Adhesive Match

With your surfaces now clean, dry, lightly sanded, and free from unwanted intruders, it’s time to find the perfect adhesive for your acrylic to PVC bond. Specialized adhesive products tailored for this purpose exist, so be sure to follow the manufacturer’s instructions. They hold the key to creating a bond that will withstand the test of time.

Applying the Adhesive Properly

Step 1: The Power of Cleanliness

Prepare for success by eliminating any obstacles that may hinder your bond. With a gentle touch, cleanse both the acrylic and PVC surfaces using a mild detergent and water solution or trusty isopropyl alcohol. A pristine canvas sets the foundation for an unbreakable connection.

Step 2: Texture Matters

Smooth surfaces lack the grip needed for a strong bond. Embrace the power of sandpaper or a reliable sanding block to create a fine texture on both the acrylic and PVC surfaces. It’s all about providing the adhesive with an optimal grip, ensuring a bond that defies expectations.

Step 3: The Right Adhesive, The Perfect Match

Selecting the ideal adhesive is key to unlocking a successful bond. Seek out adhesives specifically engineered for bonding acrylic to PVC. Opt for solvent-based options like cyanoacrylate or methyl methacrylate (MMA) adhesives, tailored to meet your needs. Remember, compatibility is everything.

Step 4: Test Your Boundaries

Before embarking on your bonding journey, take a moment to run a compatibility test in an inconspicuous area. This trial will gauge adhesion strength and guarantee a seamless union between your chosen adhesive and materials. Embrace experimentation to ensure a flawless result.

Step 5: Precision in Application

With preparations complete, it’s time to showcase your skills in adhesive application. Follow the manufacturer’s instructions meticulously, as some adhesives require meticulous component mixing before use. Employ a brush or applicator recommended by the manufacturer, ensuring an even and thin coating on one of the surfaces.

Step 6: The Dance of Fusion

It’s time for the grand finale. As soon as the adhesive is applied, bring the acrylic and PVC surfaces together without delay. Apply firm pressure, ensuring complete contact across the entire bonding area. Elevate your game with clamping pressure or strategically placed weights, maximizing your chances of a flawless bond.

Factors That Can Affect the Strength of the Bond

In this section, let’s embark on a thrilling exploration of the factors that can influence the strength of the bond between acrylic and PVC. From the very foundation of surface preparation to the heroic joint design, these factors hold the key to creating an unbreakable connection that defies all odds. So, let’s dive deep into this magical realm.

Surface Preparation: The Gateway to Strength

Picture surface preparation as the sacred groundwork for a mighty bond. Before bringing acrylic and PVC together, it is absolutely essential to ensure both materials are cleansed of any impurities like dirt, dust, or grease. Through a meticulous cleaning and degreasing process using mild detergent or alcohol-based cleaner, we pave the path towards optimal adhesion.

Compatibility of Adhesive: The Perfect Match

Selecting the right adhesive is akin to discovering the elusive soulmate for your bond. Acrylic adhesives possess an extraordinary affinity for bonding with acrylic surfaces, while PVC adhesives work their magic exclusively on PVC materials. To unlock maximum strength, it becomes imperative to choose an adhesive that harmonizes seamlessly with both acrylic and PVC. Conducting compatibility tests or seeking guidance from adhesive manufacturers will guide you towards this perfect pairing.

Adhesive Application: The Artistry in Motion

The technique by which adhesive is applied can either make or break the strength of your bond. Embrace the artistry of application and ensure uniform coverage and meticulous distribution of the adhesive. Apply it with grace, in a thin, even layer without any gaps or excessive accumulation. This delicate dance establishes maximum contact between the acrylic and PVC surfaces, paving the way for superior adhesion and a bond that knows no bounds.

Curing Time: Patience Rewarded

In this realm, patience reigns supreme when it comes to curing time. Each adhesive possesses its own unique timeline for full setting and the development of maximum strength. It is crucial to honor this sacred period as prescribed by the manufacturer before subjecting the bonded materials to any form of stress or load. Rushing this process would be akin to jeopardizing the very foundation of your bond, resulting in a feeble connection that crumbles under pressure.

Mechanical Fasteners for Enhancing the Bond Between Acrylic and PVC

Unveiling the Hidden Strength

Mechanical Fasteners for Unbreakable Bonds between Acrylic and PVC. While adhesive bonding is the standard method, mechanical fasteners are the secret weapon that takes the connection to new heights. Explore the world of screws, nuts and bolts, clamps, and specialized fasteners that provide unparalleled strength, stability, and peace of mind.

Screws: Mighty Warriors of Connection

Harness the power of screws to elevate the bond between acrylic and PVC. By drilling holes in both materials and tightly securing screws, you create an unyielding connection that fortifies strength and stability. Choose screws compatible with both materials to ward off corrosion and damage. Find the perfect match and conquer any challenge.

Nuts and Bolts: A Match Made in Fastening Paradise

Unlock the potential of nuts and bolts for an indomitable joint. Drill holes in both acrylic and PVC, insert a bolt, and secure it with a nut to create a bond that withstands anything. Nuts and bolts provide exceptional strength while allowing for effortless adjustments or removal when necessary. Embrace their power and conquer every fastening endeavor.

Clamps: The Guardians of Unity

Embrace the clamps’ unwavering embrace to hold acrylic and PVC materials tightly together during the adhesive’s curing process. With a plethora of sizes and designs available, clamps offer versatility for any application. They ensure a tight bond during the curing process, guaranteeing maximum stability. Let the clamps be your guardians on the path to unity.

Specialized Fasteners: Swift Solutions for Security

When time is of the essence, specialized fasteners like snap fasteners come to the rescue. These ingenious connectors boast male and female components that interlock upon pressing together, creating an unbreakable connection. Snap fasteners offer a quick and effortless solution to join acrylic and PVC, making your life a breeze. Experience the speed and security they provide.

Considerations for Optimal Results

To achieve the pinnacle of success with mechanical fasteners, consider the thickness of the materials. Thicker materials may require longer screws or bolts to penetrate and provide sufficient strength. Additionally, determine the spacing of the fasteners based on the size and weight of the objects being joined. These considerations ensure a bond that withstands any test.

Benefits of Using an Adhesive to Bond Acrylic and PVC Together

In the world of construction, signage, and manufacturing, acrylic and PVC have become essential materials. But how do we create a bond that can withstand the test of time between these two powerhouses? Enter adhesive bonding, the ultimate connection method. In this article, we will uncover the remarkable benefits that make adhesive bonding the preferred choice for joining acrylic and PVC. Prepare to be amazed as we explore its unmatched bond strength, seamless finish, design flexibility, time and cost savings, and even its vibration-damping superpowers.

Unmatched Bond Strength:

When it comes to forging an unbreakable bond between acrylic and PVC, adhesive bonding reigns supreme. With the use of a high-quality adhesive, you can trust that your connection will remain steadfast even under extreme stress or pressure. This means no more worries about your materials coming apart when faced with challenging circumstances.

Seamless Finish:

Adhesive bonding offers more than just strength; it provides a visually pleasing finish. Unlike traditional fastening methods like screws or nails that leave behind unsightly marks or visible fixtures on the surface, adhesive bonding ensures a clean and professional appearance. Say goodbye to blemishes and hello to a sleek and flawless finish.

Even Stress Distribution:

Stress concentration is a notorious challenge when joining materials together. However, adhesive bonding comes to the rescue by evenly distributing stress across the entire bonded area. This clever mechanism helps prevent cracks or damage from occurring over time, ensuring your connection remains strong and resilient.

Versatility in Bonding:

No matter the size or shape of your acrylic and PVC materials, adhesive bonding has got you covered. Whether you’re working with large sheets or small components, adhesives offer the flexibility to effectively join them together. It’s like having a perfect match for every scenario.

Flexibility in Design:

Adhesive bonding not only offers strength and versatility but also grants you the freedom to explore intricate designs and joint configurations. Unlike other bonding methods, adhesives can be applied in various ways, such as tapes, liquids, or films. This opens up a world of possibilities for creating unique and eye-catching connections. Let your imagination run wild.

VYtahH5ndJ0″ >

Conclusion

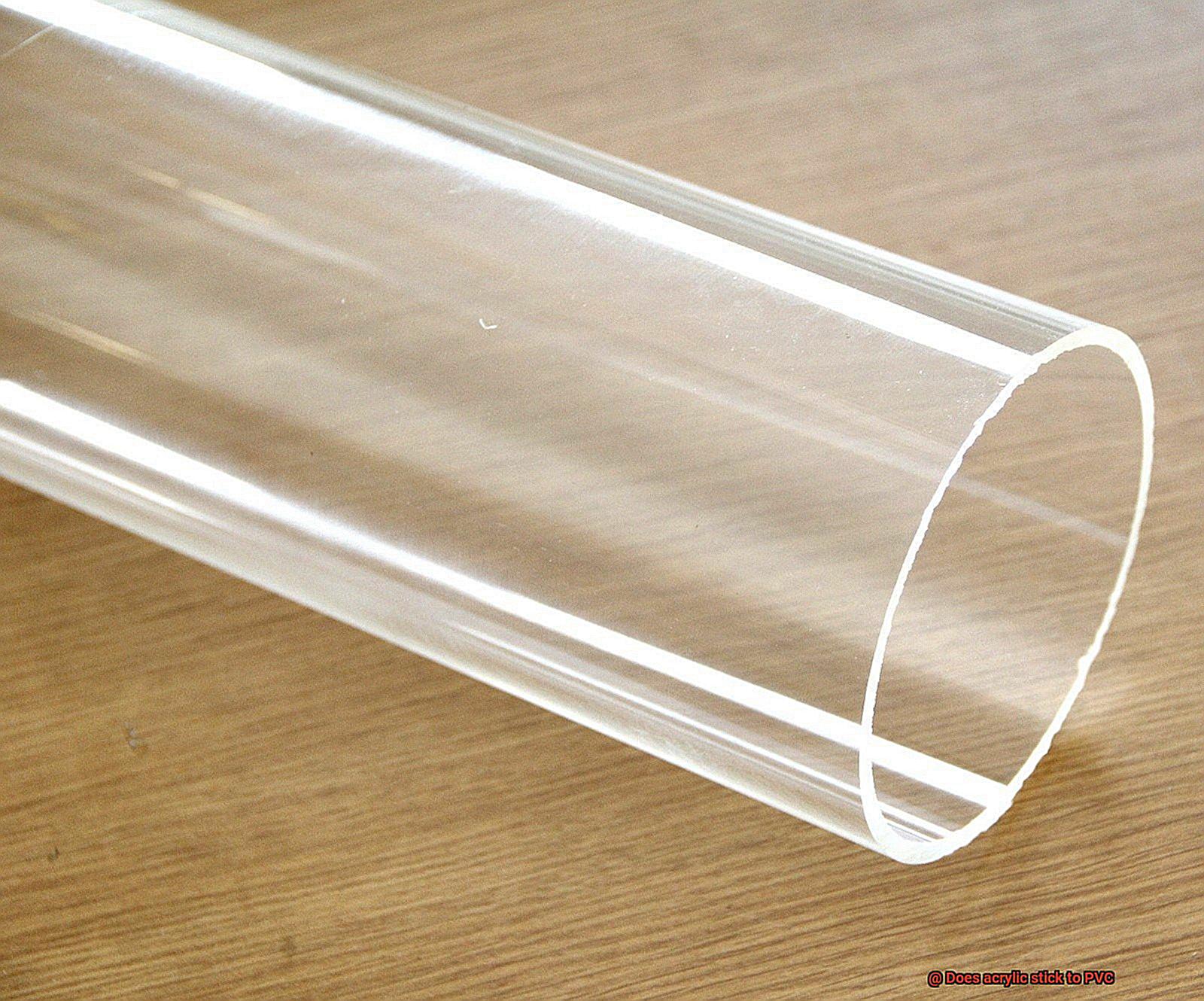

Acrylic and PVC may seem like a match made in heaven, but when it comes to sticking them together, things get a little more complicated.

While acrylic does have some adhesive properties, it doesn’t have the same affinity for PVC as it does for other materials. The smooth surface of PVC makes it difficult for acrylic to form a strong bond.

However, with the right preparation and adhesive, you can still achieve a decent level of adhesion between these two materials. It’s important to thoroughly clean both surfaces and roughen up the PVC to create more surface area for the acrylic to adhere to.

Additionally, using a specialized adhesive designed for bonding PVC and acrylic can greatly improve the chances of success.