Ever wondered if these two materials can form a solid bond or if they simply repel each other?

Well, get ready to dive headfirst into the world of adhesion as we explore whether acrylic holds on tight to plastic. We’ll uncover their compatibility, discover where they commonly intersect in various applications, and reveal the secret ingredients that influence their bond.

So, whether you’re a curious hobbyist or a pro seeking some insights, let’s embark on this casual yet informative journey together.

Cleanliness of Plastic Surfaces and Bonding Strength

Contents

- 1 Cleanliness of Plastic Surfaces and Bonding Strength

- 2 Types of Plastics Compatible with Acrylic Adhesives

- 3 Application Methods for Acrylic Adhesives

- 4 Factors Affecting Bond Strength between Acrylic and Plastic

- 5 Benefits of Using Acrylic Adhesive on Plastic Surfaces

- 6 How to Achieve a Strong and Durable Bond between Acrylic and Plastic

- 7 Tips for Selecting the Right Type of Acrylic Adhesive

- 8 Common Mistakes When Applying Acrylic Adhesive to Plastic

- 9 Conclusion

Cleanliness is not just a virtue but a necessity when it comes to bonding acrylic and plastic surfaces. Whether you’re embarking on a DIY project or working in an industrial setting, ensuring the cleanliness of plastic surfaces is crucial for achieving strong bonding with acrylic adhesive. In this article, we will explore the fascinating relationship between cleanliness and bonding strength, delving into various factors that can impact the strength of the bond.

Why Cleanliness Matters:

Contaminants or residues on the plastic surface can undermine the adhesive’s ability to form a robust bond. Thoroughly cleaning the plastic surface before attempting to bond it with acrylic is therefore essential. To achieve this, solvents or cleaners specifically formulated for plastic surfaces can be used. However, it is crucial to select a cleaner or solvent that is compatible with both the plastic material and the adhesive being used, ensuring a harmonious combination.

Surface Roughening:

In some cases, cleaning alone may not suffice. Surface roughening techniques, such as sanding or etching, may be necessary to enhance bonding strength. By roughening the surface, more surface area becomes available for adhesion, creating micro-interlocking between the plastic and acrylic. It’s important to exercise caution during this process to avoid damaging or weakening the plastic surface.

The Drying Process:

After cleaning and roughening, complete drying of the surface is paramount before applying the adhesive. Moisture or humidity can significantly compromise the adhesive’s performance and bonding strength. A dry surface provides optimal conditions for adhesion and minimizes the risk of adhesive failure.

Choosing the Right Acrylic Adhesive:

Not all acrylic adhesives are created equal. Selecting an adhesive that is suitable for bonding plastics is crucial. Acrylic adhesives work well with various plastics like polycarbonate, acrylic, PVC, and ABS. However, some plastics with low surface energy may require special treatments or primers to enhance bond strength.

Types of Plastics Compatible with Acrylic Adhesives

Acrylic adhesives are the superheroes of the adhesive world, capable of bonding a wide range of materials, including different types of plastics. However, not all plastics are created equal when it comes to compatibility with acrylic adhesives. In this article, we will explore the types of plastics that are a match made in adhesive heaven with acrylic adhesives.

Polycarbonate – The Tough Guy:

Polycarbonate is a strong and durable plastic commonly used in car parts and electronics. It has a high surface energy, which means it loves to stick to acrylic adhesives. When you need a bond that can withstand tough conditions and provide excellent impact resistance, polycarbonate and acrylic adhesives make the perfect team.

Acrylic – Two Peas in a Pod:

Acrylic plastic, also known as PMMA (polymethyl methacrylate), is like a sibling to acrylic adhesives. They share similar chemical structures, making them the dream team of bonding. Whether you’re working on signage or architectural installations, acrylic-to-acrylic bonds are reliable and strong.

ABS – The Blend with Benefits:

ABS is a special plastic made up of three different monomers: acrylonitrile, butadiene, and styrene. The acrylonitrile component gives ABS its compatibility with acrylic adhesives. From toys to car parts, ABS and acrylic adhesives create bonds that can weather any storm.

PET – Bottled Up Bonding Power:

PET (polyethylene terephthalate), commonly found in beverage bottles and food containers, can be bonded with acrylic adhesives too. However, proper surface preparation is key to ensure a strong bond. With the right techniques, PET and acrylic adhesives can join forces to keep our favorite drinks and snacks safe.

PVC – The Versatile Team Player:

PVC (polyvinyl chloride) is a versatile plastic used in pipes, fittings, and signage. While it has moderate compatibility with acrylic adhesives, a little surface preparation can go a long way in improving the bond. With the right treatment, PVC and acrylic adhesives become an unstoppable duo.

The Challengers – Polypropylene and PTFE:

Not all plastics are easy to bond with acrylic adhesives. Polypropylene (PP) and polyethylene (PE) have low surface energy, making them a challenge. However, with special primers or treatments like corona or flame treatment, acrylic adhesives can conquer PP and PE.

Bonus Tip: Fluoropolymers like PTFE (polytetrafluoroethylene) are chemical resistant and have low surface energy, making them difficult to bond with most adhesives. But don’t worry. Specialized surface treatments or primers can help acrylic adhesives conquer these slippery foes.

Application Methods for Acrylic Adhesives

This article explores the various application methods that can help you achieve a strong and durable bond. Get ready to unleash the magic of these incredible adhesives.

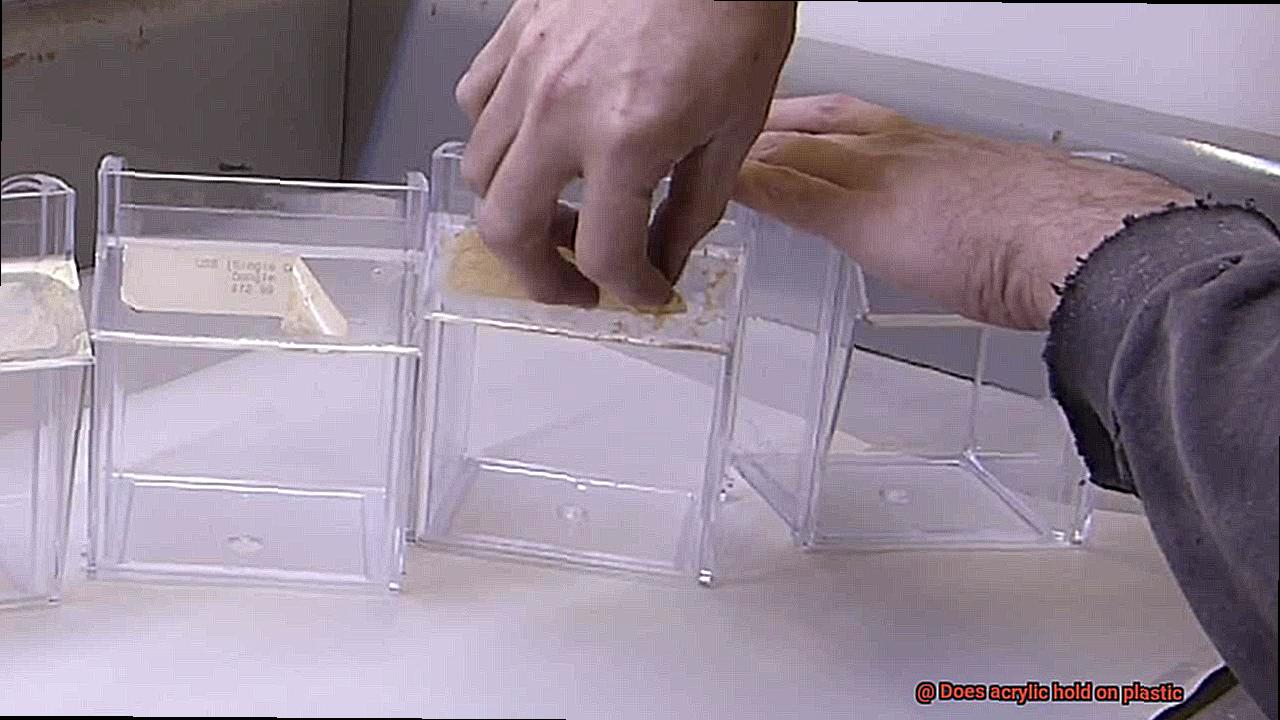

Surface Preparation:

Prepare for battle. Before bonding, ensure that both the acrylic and plastic surfaces are clean, dry, and free from contaminants like oil, grease, dust, or debris. A quick wipe-down with a suitable solvent or cleaner is all it takes to suit up for success.

Direct Application:

Unleash the power of direct application. Apply the adhesive directly onto the surfaces using a brush, roller, or spray. Create an even and consistent layer for a solid foundation.

Double-Sided Tape:

For hassle-free bonding, grab double-sided tape with acrylic adhesive. Apply strips onto both surfaces and press firmly. Watch as the adhesive creates an instant bond – it’s like magic.

Dispensing Systems:

When precision matters, dispensing systems come to the rescue. These tools allow controlled and accurate adhesive application. With dispensing guns or applicators in hand, achieve uniform coverage and minimize waste – your secret weapon in the arsenal.

UV Curing:

Let there be light. Some acrylic adhesives cure under UV light. Apply adhesive to surfaces and expose them to UV light, triggering fast curing. Perfect for transparent or translucent plastics – harness the power of the sun.

Structural Bonding:

Need a bond as strong as Thor’s hammer? Enter structural acrylic adhesives. Mix components and apply onto surfaces for exceptional strength and durability. Create an unbreakable bond that withstands any test.

Factors Affecting Bond Strength between Acrylic and Plastic

Well, buckle up because we’re about to uncover the key factors that can make or break the strength of this bond.

First up, let’s talk about surface preparation. Just like a clean canvas is essential for a masterpiece, the surfaces of acrylic and plastic need to be squeaky clean. Make sure to get rid of any grease, oil, or dust by using a suitable solvent or cleaner. And here’s a pro-tip: roughening the plastic surface can actually improve adhesion by giving the acrylic more surface area to grip onto.

Next, let’s consider the compatibility of materials. You know how some people just don’t get along? Well, the same goes for acrylic adhesives and different types of plastics. Each plastic has its own unique composition and surface energy, which can affect how well it bonds with acrylic. To ensure a strong bond, choose an acrylic adhesive that is specifically formulated for your type of plastic. Don’t be afraid to do some compatibility tests or consult adhesive manufacturers for expert advice.

Now it’s time to pick the right adhesive for the job. There are various formulations of acrylic adhesives out there, from solvent-based to water-based or structural acrylics. Consider factors like cure time, temperature resistance, flexibility, and chemical resistance when making your selection. Remember, the adhesive you choose can make a big difference in the strength of your bond.

Don’t forget about environmental conditions. Temperature and humidity can have a major impact on bond strength. Make sure you follow the recommended ranges for your acrylic adhesive. Extreme temperatures or high humidity levels can mess with the curing process and weaken your bond. So keep an eye on those conditions to achieve maximum strength.

Mechanical stress is another factor to consider. Different plastics have different levels of flexibility and thermal expansion properties. So think about the kind of forces your bonded acrylic and plastic will face, whether it’s tension, compression, shear, or impact. Design your assembly accordingly to ensure your bond can withstand the stress.

Last but not least, let’s talk about aging and chemical resistance. Acrylic adhesives are generally resistant to aging and offer good chemical resistance. But it’s important to consider the specific chemical environment your bonded assembly will be exposed to. Some chemicals or solvents can weaken or degrade the adhesive over time. So do some compatibility tests or consult adhesive manufacturers to make sure your bond can stand the test of time.

Benefits of Using Acrylic Adhesive on Plastic Surfaces

Today, we embark on a thrilling exploration of the captivating world of acrylic adhesive and its remarkable ability to bond plastic surfaces. So, fasten your seatbelts and prepare for an exhilarating journey as we uncover the myriad benefits of using acrylic adhesive on plastic surfaces.

First and foremost, let’s marvel at the superhero-like strength possessed by acrylic adhesive. When you require a bond that can withstand the test of time, this adhesive becomes your unwavering sidekick. With its exceptional adhesion properties, acrylic adhesive creates a resolute and enduring bond that holds plastic pieces together with unwavering strength. From constructing robust automotive parts to building sturdy electronics, acrylic adhesive emerges as the reliable guardian of your projects.

But wait, there’s more. Acrylic adhesive also boasts incredible versatility. It harmonizes perfectly with various types of plastics such as polycarbonate, acrylic, PVC, ABS, and more. This means you can freely mix and match different types of plastics without concerns about compatibility issues. Talk about a true team player.

Let us now turn our attention to durability in the face of adversity. Acrylic adhesive fearlessly defies extreme temperatures, moisture, UV radiation, and chemicals. It acts as an impenetrable shield against the elements. Whether you’re working on an indoor project or braving the great outdoors, acrylic adhesive stands steadfast. It maintains its bond strength even in the harshest conditions, making it a reliable companion for any endeavor.

But here’s where it gets truly fascinating – acrylic adhesive is practically invisible. Its transparent or low viscosity properties create an unseen bond line. Bid farewell to unsightly globs of glue tarnishing your immaculate projects. Furthermore, it does not yellow or become discolored over time, ensuring that your bond remains visually appealing for years to come.

Time is a precious commodity, isn’t it? Well, rejoice, for acrylic adhesive boasts a swift curing time. It rapidly reaches its full strength, allowing your production process to soar with efficiency and reducing the agonizing wait time. Need even more flexibility? Some acrylic adhesives offer adjustable cure times, enabling you to tailor your application to suit your specific needs.

And here comes the pièce de résistance – acrylic adhesive is user-friendly and effortlessly applied. It is available in various forms such as liquids, gels, tapes, or films, granting you the freedom to choose the ideal format for your project. Applying it is a breeze with simple techniques like brushing, spraying, or dispensing. No advanced adhesive skills required.

How to Achieve a Strong and Durable Bond between Acrylic and Plastic

If you’re looking to bond acrylic and plastic together, you’ve come to the right place. In this blog post, we’ll explore the world of adhesives and reveal the secrets to creating an unbreakable bond between these two materials. So grab your safety goggles and get ready for a journey into the art of bonding.

The Power of the Right Adhesive:

Choosing the correct adhesive is the first step towards achieving a strong and durable bond. Two-part epoxy adhesives are renowned for their exceptional bonding strength and durability. Consisting of a resin and a hardener, these adhesives create a chemical reaction when mixed, resulting in an unbreakable bond.

Cleanliness is Key:

Before applying any adhesive, it’s crucial to ensure that both the acrylic and plastic surfaces are clean and dry. Use a mild detergent or alcohol solution to eliminate any dirt or grease. A pristine surface allows the adhesive to form a strong connection without any hindrance.

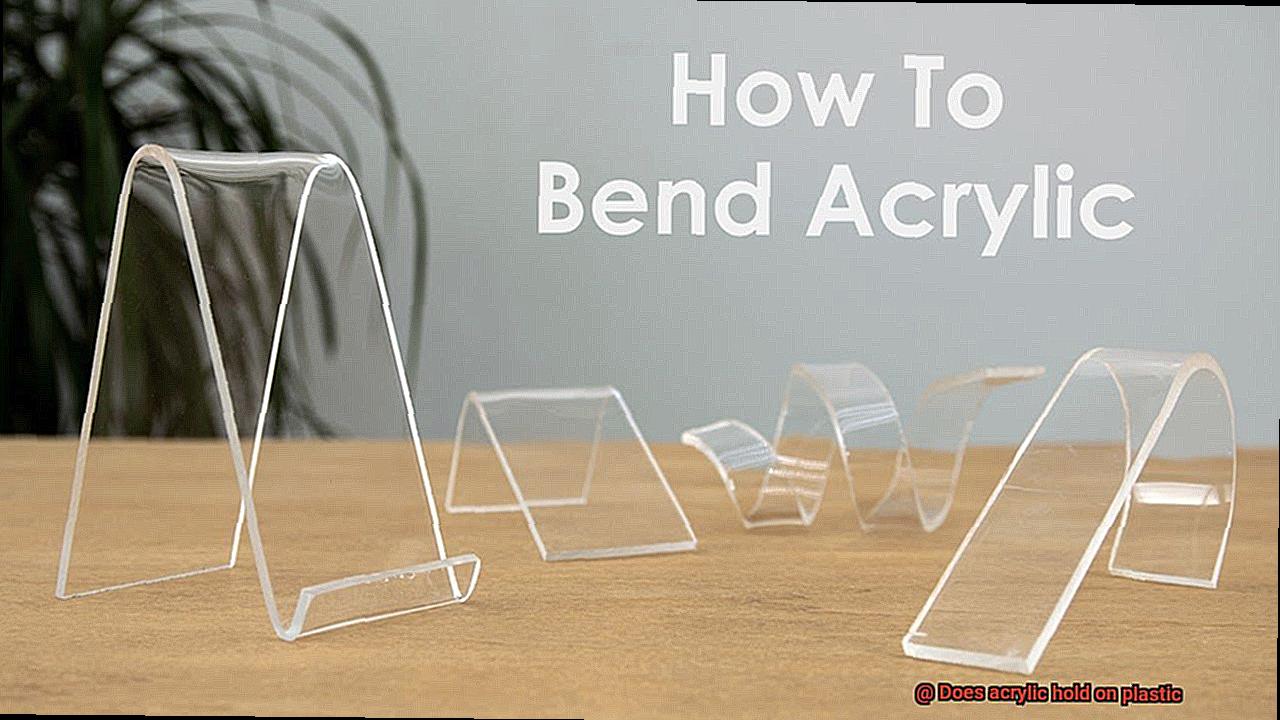

Roughening Up for Success:

To enhance bond strength, consider lightly sanding both the acrylic and plastic surfaces with fine-grit sandpaper. This creates a roughened texture that provides more surface area for the adhesive to grip onto, resulting in a stronger bond. Alternatively, you can use a special adhesive promoter designed for plastics to achieve the same effect.

Adhesive Application Mastery:

Follow the manufacturer’s instructions for applying the adhesive correctly. Whether it’s a two-part epoxy or a solvent-based adhesive like super glue, ensure even application in the correct amount. Applying too much or too little adhesive can compromise bond strength.

Pressure and Patience:

After joining the acrylic and plastic surfaces together, apply even pressure using clamps or heavy objects. This ensures full contact between the surfaces and allows the adhesive to cure properly. Follow the recommended curing time provided by the manufacturer to achieve maximum bond strength.

Tips for Selecting the Right Type of Acrylic Adhesive

Acrylic adhesives are versatile and commonly used for bonding plastic materials. However, choosing the right type of acrylic adhesive is crucial to ensure a strong and durable bond. In this blog post, we will discuss five important factors to consider when selecting an acrylic adhesive for plastic bonding.

Surface Energy of the Plastic Material:

The surface energy of the plastic material plays a significant role in determining the adhesive’s effectiveness. Plastics with low surface energy, such as polyethylene and polypropylene, can be challenging to bond with acrylic adhesives. To overcome this, specialized acrylic adhesives designed for bonding low surface energy plastics should be used. These adhesives have unique formulations that enable strong adhesion to these difficult-to-bond plastics.

Compatibility with Specific Plastic Types:

Different types of plastics have unique chemical compositions and surface characteristics that can affect bonding performance. It is essential to consult the manufacturer’s guidelines or conduct compatibility tests to ensure the chosen adhesive is suitable for bonding with the specific plastic type. This step helps prevent issues such as adhesion failure or weakening of the bond over time.

Temperature Resistance:

Consider the temperature resistance of the adhesive, especially if the bonded assembly will be exposed to high temperatures or thermal cycling. Some plastics may soften or deform at elevated temperatures, and the adhesive needs to be able to maintain its bond strength under these conditions. It is advisable to choose an acrylic adhesive that has a high-temperature resistance and can withstand the anticipated temperature fluctuations.

Application Requirements and Conditions:

Evaluate factors such as load-bearing capacity, flexibility, and durability based on the application requirements. For example, select an adhesive with high impact resistance and flexibility if the bonded assembly will be subjected to vibrations or impacts. Understanding the specific demands of your application will help you choose an adhesive that can provide the necessary performance and longevity.

Curing Time and Process:

Consider the curing time and process of the adhesive. Some adhesives require long curing times or special curing conditions that may not be suitable for certain plastic materials. Opt for an adhesive that offers a fast curing time and can be easily integrated into the production process. This will help increase efficiency and reduce production time, ensuring a timely completion of the bonding project.

Common Mistakes When Applying Acrylic Adhesive to Plastic

Today, let’s explore the world of acrylic adhesives and delve into some common mistakes that can easily be avoided when applying them to plastic. Whether you’re a DIY enthusiast or a seasoned professional, these tips will help you achieve strong and reliable bonds.

So, let’s dive right in.

Improper Surface Preparation:

Imagine this: you apply the adhesive, expecting a bond as strong as steel, only to see it peel off like a bad sunburn. Ouch. This can happen if you don’t properly prepare the plastic surface. Dust, dirt, and grease act as barriers, hindering adhesion and resulting in weak bonds. To avoid this disaster, make sure to thoroughly clean the plastic before applying the adhesive.

Excessive Adhesive Application:

Remember, more is not always better. Using too much adhesive can create messy and uneven bonds. Acrylic adhesives are renowned for their strength, so a thin and even layer will do the trick. It’s all about finding that perfect balance.

Insufficient Drying or Curing Time:

Patience is a virtue when it comes to bonding plastics with acrylic adhesives. Rushing the drying or curing process can compromise the strength of the bond. Take your time and allow ample drying and curing time according to the manufacturer’s instructions. Trust us; it’ll be worth the wait.

Lack of Proper Ventilation:

Safety first. Some acrylic adhesives emit fumes during the curing process that can be harmful if inhaled. To avoid any unwanted side effects, make sure to work in a well-ventilated area or wear appropriate personal protective equipment. Let’s keep those lungs happy.

Incompatible Adhesive Selection:

Not all plastics are created equal, and neither are acrylic adhesives. Using the wrong type of adhesive for a specific plastic can result in poor bonding. Different plastics have different surface properties, so it’s crucial to select an adhesive specifically designed for the type of plastic you’re working with. Match made in adhesive heaven.

Ignoring Manufacturer’s Instructions:

We get it; reading instructions may not be the most exciting part of the process. However, ignoring the manufacturer’s guidelines can lead to a weaker bond or other issues. Take a few minutes to familiarize yourself with the recommended application techniques and curing times. It’s a small investment that pays off in the end.

VYtahH5ndJ0″ >

Conclusion

Acrylic and plastic, two versatile materials often used in various applications.

But does acrylic hold on plastic? The answer is a resounding yes.

Acrylic has a remarkable ability to adhere to plastic surfaces, forming a strong bond that can withstand the test of time. Whether you’re working on a DIY project or engaging in professional craftsmanship, acrylic will provide you with the reliability and durability you need.

Its adhesive properties ensure that once it’s applied to plastic, it forms an unbreakable connection that won’t easily peel or chip away.