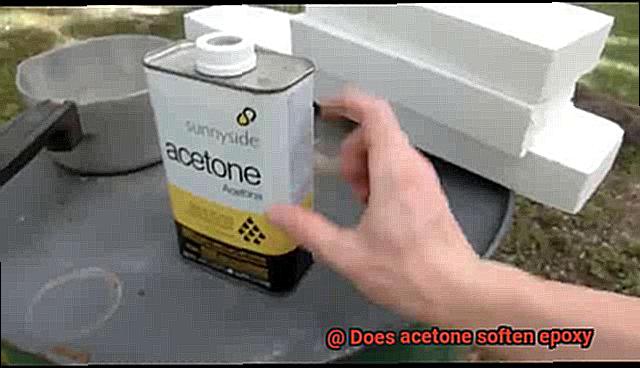

Have you ever found yourself in a sticky situation with cured epoxy? Perhaps you made a mistake during application, or maybe you need to remove the adhesive for some reason. Regardless of the reason, you may have heard that acetone can soften or dissolve adhesives like epoxy. But does it really work?

The answer is not black and white. Epoxy is renowned for its toughness and resistance to chemicals, so removing it can be a challenge. Acetone is a popular solvent that can dissolve many types of adhesives, but its effectiveness on epoxy is limited. That’s because epoxy is a thermosetting polymer, which means that once it cures, it cannot be melted or softened using heat.

So what’s the role of acetone when it comes to epoxy? Well, for starters, it can help clean up any uncured epoxy or residue after application. But there are also instances where acetone can weaken the bond of cured epoxy by breaking down the surface layer and making it easier to remove with mechanical tools.

However, before you start soaking your cured epoxy in acetone, there are some limitations and safety concerns to consider. For instance, prolonged exposure to acetone can be harmful to your health and damage certain surfaces. Additionally, other chemicals like vinegar or rubbing alcohol may react with the adhesive and soften the surface layer.

In this blog post, we’ll dive deep into the science behind curing processes and explore how different solvents interact with adhesives like epoxy. We’ll also provide alternative methods for removing or softening cured epoxy that may be safer and more effective than relying solely on acetone.

Whether you’re an experienced craftsman or just starting out with DIY projects, this post will offer valuable insights into working with adhesives and solvents. So let’s get started on our journey to discover Does Acetone Soften Epoxy.

What is Epoxy?

Contents

A true jack-of-all-trades, epoxy has become one of the most widely used adhesives in various industries and applications. A thermosetting polymer, epoxy is formed by combining a resin and a hardener to create a material that is resistant to heat, water, and chemicals.

Epoxy’s incredible bonding properties make it an ideal choice for construction, automotive, aerospace, marine, and electronics industries. It can bond to a wide range of materials such as metals, plastics, ceramics, and wood. Additionally, epoxy can be used as a coating or a sealant to protect surfaces from corrosion, moisture, and wear.

One of the most remarkable properties of epoxy is its ability to cure without the need for air or heat. This means that it can be used under almost any conditions and on surfaces that other adhesives may not be able to bond with. Once mixed, the epoxy starts to harden and become solid. The curing time can vary depending on the type of epoxy used and environmental conditions.

Moreover, epoxy’s chemical structure makes it tough as nails. Its strength and durability make it perfect for harsh environments where other adhesives would deteriorate over time. It can also withstand temperature changes without losing its bonding properties.

When it comes to removing or softening cured epoxy, acetone is often used as a solvent. However, its effectiveness may vary from one type of epoxy to another. Therefore, proper safety precautions should always be taken when handling it.

What is Acetone?

Acetone, or propanone, is a colorless and flammable liquid that boasts a sweet aroma. This multi-purpose solvent is commonly used in a variety of industries such as pharmaceuticals, cosmetics, and manufacturing due to its ability to dissolve many substances including plastics, paints, and resins.

Impressively, acetone can be produced through the dehydrogenation of isopropyl alcohol or the oxidation of cumene. It’s an incredibly versatile compound that can be used as a cleaning agent, solvent, and even as an intermediate in the production of other chemicals.

Thanks to its highly volatile nature, acetone evaporates quickly when exposed to air making it an ideal solvent for cleaning purposes. Additionally, it’s miscible with water and other organic solvents, which makes it an effective solvent for dissolving many substances.

While acetone is considered safe to use in most applications, it should be handled with care due to its flammable nature. It can also cause skin irritation and respiratory problems if not used properly. Therefore, it is important to use acetone in a well-ventilated area and avoid inhaling its vapors.

Does Acetone Soften Epoxy?

As a seasoned expert, I’ve delved into the research and have some enlightening insights to share with you.

Epoxy is a tough customer – a thermosetting polymer that’s renowned for its ability to form robust bonds. It’s a popular choice for a wide range of applications, from construction to aerospace and marine industries. But what happens when you need to remove it? That’s where acetone comes in.

Acetone is a widely used solvent that’s known for its efficacy in dissolving adhesives. It works by breaking down the molecular bonds that hold the adhesive together, gradually weakening its strength and allowing it to be removed. But does it work on epoxy?

The answer is yes – to an extent. The effectiveness of acetone on epoxy depends on several factors, including the type of epoxy used, the curing time, and the concentration and duration of acetone exposure.

Freshly cured epoxy is more susceptible to acetone than fully cured epoxy. This is because newly cured epoxy hasn’t had sufficient time to form strong cross-linking bonds that make it resistant to solvents. As a result, acetone can penetrate the surface of freshly cured epoxy more easily and begin to soften it.

However, fully cured epoxy is much harder to soften with acetone. The cross-linking bonds have already formed, hardening the epoxy into a robust material that’s highly resistant to solvents. While acetone can still dissolve fully cured epoxy over time, it’ll take longer and require higher concentrations of acetone.

So if you’re looking to remove epoxy from a surface or material, it’s crucial to consider these factors before reaching for the acetone. Other methods such as mechanical abrasion or specialized chemical removers may be more appropriate for your specific application.

Different Types of Epoxy

Epoxy is a remarkable adhesive that has found its way into various industries due to its exceptional bonding properties and durability. However, not all epoxy is created equal. Different types of epoxy are available in the market, each with its unique properties and characteristics. Here are the six types of epoxy that you should know about:

Standard Two-Part Epoxy

This type of epoxy is the most commonly used in construction and woodworking. It comprises two components, the resin and the hardener, that are mixed together before application. Once mixed, the epoxy cures and hardens to provide a strong bond. Standard two-part epoxy is also known for its resistance to water and chemicals.

Fast-Curing Epoxy

Fast-curing epoxy does exactly what its name suggests – it cures much faster than standard two-part epoxy. It’s ideal for automotive repairs and other applications where quick curing time is essential. This type of epoxy is also known for its excellent bonding properties and resistance to heat and chemicals.

Marine-Grade Epoxy

Marine-grade epoxy is specifically designed for use in marine environments, where it provides excellent resistance to water and saltwater corrosion. It’s perfect for boats and other watercraft.

High-Temperature Epoxy

If you’re looking for an adhesive that can withstand high temperatures up to 500°F, then high-temperature epoxy is your best bet. It’s ideal for use in high-temperature environments such as engines and machinery.

Solvent-Based Epoxy

Solvent-based epoxies are renowned for their high strength and durability, making them ideal for industrial applications. They can bond different materials such as metals, plastics, and ceramics, among others. However, they contain solvents like acetone, which makes them hazardous to work with and require proper ventilation.

Water-Based Epoxy

Water-based epoxies are a new type of epoxy that offers many advantages over their solvent-based counterparts. They are safer to use, have fewer volatile organic compounds (VOCs), making them better for indoor use. They also dry faster than solvent-based epoxies and have a longer shelf life.

How to Soften Uncured Epoxy with Acetone

Epoxy is a versatile adhesive that is used in a variety of applications due to its strong bonding properties. However, there are times when it needs to be removed or softened, and acetone is a powerful solvent that can do the job. In this blog post, we will provide a detailed guide on how to soften uncured epoxy with acetone.

Materials Needed

To start, you will need acetone, a plastic scraper, and a clean cloth. It’s important to note that acetone should only be used on uncured epoxy. If the epoxy has already hardened, it may be more difficult or even impossible to soften it with acetone. Additionally, acetone can be harmful if not used properly, so it is important to wear protective gloves and work in a well-ventilated area.

Step 1: Apply Acetone

Apply a small amount of acetone to the hardened epoxy using a clean cloth. Avoid rubbing too hard or applying too much pressure. Allow the acetone to sit for several minutes to penetrate the epoxy and begin to break it down.

Step 2: Scrape

After a few minutes, use a plastic scraper or putty knife to gently scrape away the softened epoxy. Be careful and work slowly and carefully, as you do not want to damage the surface underneath the epoxy. If there are still areas of hardened epoxy remaining after scraping, repeat the process of applying acetone and allowing it to sit for several minutes before scraping again.

Step 3: Repeat

Depending on the thickness of the epoxy and how long it has been curing, you may need to repeat this process several times before all the uncured epoxy is removed. Remember to use caution and follow proper safety procedures when working with acetone.

Step 4: Clean Up

After all the uncured epoxy has been removed, use a clean cloth and mild soap to clean the surface. Rinse thoroughly with water and allow it to dry completely before applying any new adhesive or coating.

Step 5: Test on Small Area

It’s important to note that acetone can also damage certain surfaces such as plastic or painted surfaces. Before applying acetone more widely, test it on a small, inconspicuous area to ensure it won’t cause any damage.

How to Soften Cured Epoxy with Acetone

Softening cured epoxy with acetone is a common process, but it requires some careful steps to ensure success. Here are five sub-sections that will guide you through the process:

Prepare materials and safety precautions

To begin, gather all the necessary materials, including acetone, a plastic container, and a scraper or putty knife. It’s essential to use acetone with caution in a well-ventilated area and wear personal protective equipment such as gloves and protective eyewear.

Pour acetone into a container

Carefully pour enough acetone into the plastic container to cover the cured epoxy area you want to soften. Ensure that the container is large enough so the epoxy can fully submerge in the acetone.

Submerge cured epoxy in acetone

Next, place the cured epoxy into the acetone and let it soak for several hours. The duration of the soaking time will depend on various factors such as the thickness and curing time of the epoxy layer.

Gently remove softened epoxy

After the epoxy has softened, use a scraper or putty knife to gently remove it from the surface. Be cautious not to damage any underlying surfaces.

Be cautious and seek professional assistance if needed

Although acetone can be an effective solution for softening cured epoxy, it may not always work depending on the strength and thickness of the adhesive. If you are unsure about how to approach removing cured epoxy from a particular surface or project, it’s best to seek professional advice or assistance.

Safety Precautions When Working with Acetone and Epoxy

These materials are incredibly useful, but they also come with some risks. That’s why it’s crucial to take the necessary safety precautions to avoid any accidents or injuries.

Here are some key safety precautions that you should keep in mind when working with acetone and epoxy:

Ventilation is critical. Ensure that you’re working in a well-ventilated area to prevent inhaling harmful fumes that could cause respiratory problems. Open windows or doors and use fans to circulate fresh air throughout the workspace.

Protective gear is non-negotiable when working with acetone and epoxy. It’s essential to wear gloves, eye protection, and respirators for your safety and well-being. These tools will help prevent skin irritation, burns, and respiratory problems.

Storage is also vital. Keep acetone and epoxy away from heat sources and direct sunlight. Storing them in a cool, dry place away from children and pets is a must.

Handling acetone can be tricky as it is highly flammable. Avoid smoking or using any open flames nearby when handling it. Also, do not use metal containers or utensils as acetone can react with some metals. Instead, opt for plastic or glass containers.

Accidents can happen even if you take all the necessary precautions. That’s why it’s essential to clean up spills immediately using absorbent materials such as sand or kitty litter. Dispose of waste properly in accordance with local regulations.

v6LuNGv4IKo” >

Conclusion

In summary, while acetone can be a handy tool for removing or softening uncured epoxy, it’s not the most effective solution for cured epoxy. Epoxy is a formidable thermosetting polymer that forms sturdy cross-linking bonds after curing, which makes it resistant to solvents like acetone. However, acetone can still weaken cured epoxy’s bond by breaking down its surface layer, making it easier to remove using mechanical tools.

It’s worth noting that working with acetone and epoxy requires caution due to safety concerns. Prolonged exposure to acetone can cause health issues and damage certain surfaces. Moreover, other chemicals like vinegar or rubbing alcohol may react with the adhesive and soften the surface layer.

Fortunately, there are alternative methods available that can safely and effectively remove or soften cured epoxy. For instance, you could try mechanical abrasion or specialized chemical removers that are better suited for specific applications.

Ultimately, whether you’re a seasoned craftsman or just starting out with DIY projects, understanding how different solvents interact with adhesives like epoxy is essential for success.