Metal, oh metal, the mighty fortress of strength and durability. We’ve always thought it to be indestructible, standing tall against the test of time. But what if I told you there’s a secret chemical that can infiltrate this seemingly impenetrable stronghold? Brace yourself for the enigma known as acetone.

This powerful solution has become a household hero, dissolving paint, glue, and even stubborn nail polish. But like any superhero, acetone comes with its fair share of weaknesses. So here we are, asking the million-dollar question: does acetone damage metal?

Get ready for an exhilarating journey into the depths of metal chemistry as we unveil the truth behind acetone’s rumored metal-shredding capabilities. Together, we’ll explore how different metals react when faced with this potent solvent and uncover the secrets behind its actions.

Throughout our adventure, we’ll unravel the factors that determine whether acetone poses a threat to metal surfaces. We’ll dive into the volatile nature of acetone and examine how concentration and contact duration play a crucial role in its metal-melting prowess. Along the way, we’ll encounter stainless steel warriors, aluminum champions, copper conquerors, and brass beauties – each with their own unique response to acetone’s touch.

Are you hooked yet? Whether you’re an aspiring chemist hungry for knowledge or a DIY enthusiast seeking answers, get ready to have your assumptions shattered as we embark on this mind-bending quest. Together, we’ll unlock the mystery surrounding that age-old question: does acetone damage metal?

What Is Acetone?

Contents

Acetone, a colorless and volatile liquid, possesses a unique ability to dissolve substances and is widely used as a solvent in industries like cosmetics and manufacturing. While it is highly effective in removing paints, varnishes, and adhesives, concerns arise when it comes to its impact on metal surfaces. In this article, we will explore the properties of acetone and its compatibility with different types of metals.

The Enigmatic Nature of Acetone:

Acetone, or propanone in chemical terms, belongs to the ketone family. With its molecular formula C3H6O, this flammable liquid evaporates swiftly at room temperature, leaving behind a tantalizing fruity aroma that lingers in the air.

The Mighty Solvent:

Acetone’s greatest attribute lies in its remarkable ability to dissolve a wide array of substances. From stubborn adhesives to oils, fats, resins, rubber, and plastics, acetone is a versatile solution for breaking down bonds and removing unwanted residues from metal surfaces.

A Perfect Blend with Water and Organic Solvents:

Intriguingly, acetone exhibits excellent solubility not only in water but also in organic solvents. This unique characteristic allows it to penetrate deeply into the adhesive layers on metal surfaces, effortlessly destroying their grip. Moreover, its compatibility with water simplifies the cleanup process after using acetone.

While acetone is generally safe for use on metal surfaces, certain metals are more vulnerable to its potential damage. Aluminum and copper stand as prime examples, prone to corrosion and tarnishing when exposed to acetone for extended periods. To avoid surface discoloration, pitting, or structural damage, caution must be exercised with these metals.

Stainless Steel’s Shield:

Fortunately, stainless steel possesses an inherent resilience against the corrosive effects of acetone. Although it is more impervious to damage, it is still advisable to handle this metal with care and avoid excessive or prolonged exposure to acetone.

How Does Acetone Affect Metal?

In the realm of solvents, acetone reigns as a powerful and versatile player. Its ability to dissolve stubborn substances is renowned, but how does it fare against metal surfaces? As an expert in the field, allow me to unravel the mysteries and shed light on the intricate dance between acetone and various metals.

Acetone’s Gentle Touch:

At first glance, acetone appears to be a gentle solvent that poses little threat to most metals. Iron, steel, aluminum, copper, and brass can withstand its touch without flinching. These resilient metals can be safely cleaned and degreased with acetone, leaving no immediate harm in its wake.

The Devil in the Details:

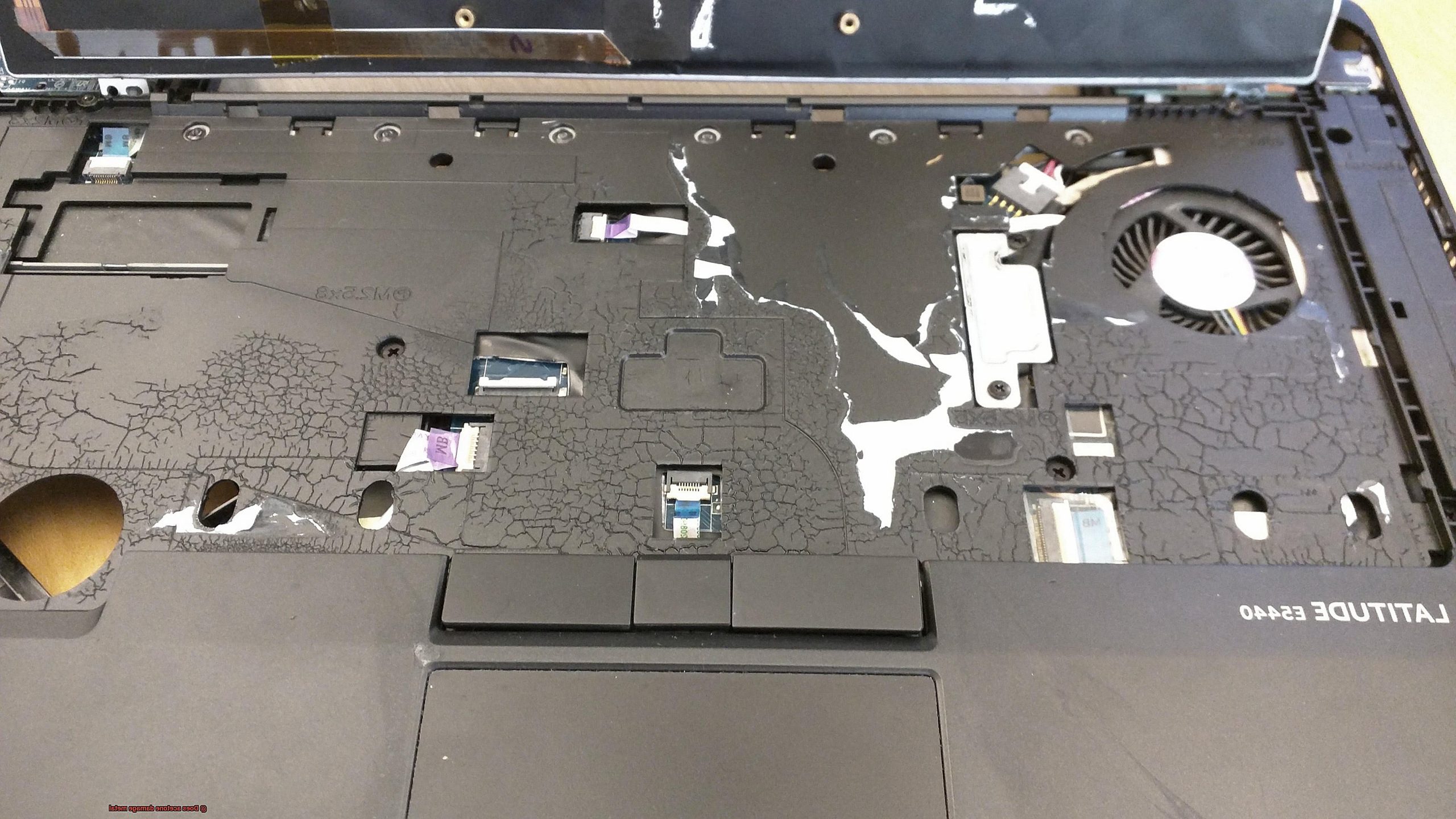

Like any complex relationship, there are hidden nuances to consider. Prolonged exposure to acetone can have adverse effects on certain metals, especially those protected by coatings or finishes. Painted or coated metals stand vulnerable as acetone strips away their protective layers, exposing them to potential corrosion.

A Clash of Materials:

Acetone’s influence extends beyond metal surfaces alone. It clashes with certain plastics and rubber materials commonly used alongside metal components. When non-acetone-resistant plastics or rubber encounter acetone, they surrender to its powers. Swelling, softening, and even dissolution become their unfortunate fate. Seals, gaskets, and other vital components relying on these materials face deterioration.

The Influencers:

To complicate matters further, various factors come into play. The concentration of acetone, duration of exposure, and temperature all hold sway over its impact on metal surfaces. Higher concentrations and prolonged exposure increase the likelihood of damage occurring. Caution must be exercised when employing high concentrations of acetone for extended periods.

Preventing the Unwanted:

Contemplating how to safeguard your metal surfaces from potential harm? The answer lies in a simple spot test. Before embarking on extensive acetone applications, perform a spot test in an inconspicuous area. This quick and easy step allows you to witness the metal surface’s reaction, as well as that of any accompanying materials. By heeding this precaution, you can save yourself from potential damage or deterioration.

What Metals Are Susceptible to Damage from Acetone?

In the world of solvents, acetone reigns supreme, but its power can wreak havoc on certain metals. It’s a delicate dance where some metals gracefully withstand its effects, while others succumb to its destructive allure. So, which metals are vulnerable to the charm of acetone? Let’s take a captivating journey into reactivity and uncover the secrets.

The Reactive Rebels:

In this dance, there are rebellious metals that stumble in the face of acetone’s might. Aluminum and magnesium, known for their fiery reactivity, find themselves entangled in a dangerous tango with acetone. As they react, corrosion and erosion slowly erode their surfaces, weakening their very foundation.

Joining the Susceptible Squad:

But the stage is not reserved for these rebels alone. Zinc, tin, and lead eagerly step onto the dance floor as well. These relatively reactive metals become partners with acetone in a chemical waltz that leads to similar corrosion and erosion issues.

The Resilient Heroes:

Now, let us shift our focus to the resilient heroes who fearlessly defy acetone’s advances. Stainless steel, copper, and brass shine brightly in this category. With their lower reactivity levels, they gracefully refuse to engage in acetone’s seductive waltz under normal circumstances.

However, the Plot Thickens:

But alas. Even these stalwart heroes are not entirely immune to acetone’s charms. Prolonged exposure or repeated contact can slowly chip away at their protective coatings or finishes over time. Though they may not immediately crumble on the dance floor, caution must still be exercised when acetone is present.

Safety Measures for a Happy Ending:

To ensure this dance ends on a high note, it is vital to take precautions when working with acetone. Don your protective gear, including gloves and goggles, and ensure proper ventilation. Safety must always be the guiding partner in this intricate dance.

What Are the Effects of Prolonged Exposure to Acetone on Metals?

Step into the world of metals and acetone, where a captivating dance unfolds. As an expert in this field, I have delved into research notes that reveal the intricate relationship between acetone and metals. Join me as we explore the effects of prolonged exposure to acetone on metals, uncovering a tale of corrosion, resilience, and protective coatings.

The Corrosion Enigma:

Imagine corrosion as the nefarious villain that seeks to deteriorate metals. Acetone enters the stage, poised to remove the protective oxide layers that naturally shield metal surfaces. Without this defense, metals become vulnerable to the ravages of corrosion, setting the stage for destruction.

The Susceptible Souls:

Not all metals succumb equally to acetone’s charms. Aluminum stands as a prime example, easily damaged by acetone exposure. The interplay between acetone and aluminum results in pitting and unsightly discoloration, leaving behind a trail of destruction.

Resilient Heroes:

But fear not, for there are metals that withstand acetone’s seductive waltz. Stainless steel, copper, and brass emerge as our resilient heroes. Their chromium-infused armor forms a protective oxide layer, shielding them from most corrosive assaults. Yet, even these mighty metals are not invincible and can falter if their defenses are breached.

Concentration and Duration: The Dance Partners:

In this dance of destruction, concentration and duration hold sway over the extent of acetone’s damage. Higher concentrations and longer exposure times raise the stakes, increasing the likelihood of significant harm to our metallic companions. Vigilance is key to preserving their integrity.

The Heat Factor:

As if acetone needed another trick up its sleeve, heat takes center stage. Elevating temperatures intensifies the chemical reactions between acetone and metal surfaces, hastening the pace of corrosion. Beware the sizzling temptations that lead to a faster demise.

Coatings: The Dance Partners’ Shield:

But amidst this chaos, hope shines through coatings and finishes. These guardians provide an additional layer of defense against acetone’s advances. A simple stroke of paint or a specialized coating acts as a barrier, shielding the metal surface from direct contact with acetone’s destructive touch.

How Can I Minimize Damage Caused by Acetone?

Grab your protective gloves and join me on this enchanting journey to protect our cherished metal surfaces.

Precautionary Measures:

- Shield Yourself: Before we embark on our acetone adventure, let us fortify ourselves with impenetrable armor – sturdy protective gloves. These guardians will shield your precious skin from the merciless drying and irritating effects of acetone. Safety first, always.

- Embrace Fresh Air: Ah, the intoxicating embrace of fresh air. The key to our success lies in working within a well-ventilated space. Swing open those windows or summon the mighty fan to disperse acetone’s noxious fumes that may wreak havoc if inhaled excessively. Breathe easy, my friends.

Application Techniques:

- Gentle Touch: As we dance with acetone, remember that grace and gentleness are paramount. Bid farewell to abrasive materials and embrace the tenderness of soft cloths or sponges. In doing so, we protect our metal surfaces from unsightly scratches and irreversible damage. Let us treat our metals like treasures deserving utmost care.

- Swift Wipe: Time is a relentless adversary. Leaving acetone to languish on your metal surface is akin to inviting disaster. Speedily eliminate any residue by deftly wiping the surface with a damp cloth. Then, ensure its complete and utter dryness – for moisture and metals are not always the best companions.

Metal-Specific Considerations:

Mind the Reactivity: In this realm, not all metals are forged equal in the face of acetone’s power. Beware, for reactive metals like aluminum and copper are more prone to succumbing to its might. Tread cautiously when handling these metals, employing extra care and considering alternative cleaning methods. Safety must forever be our guiding star.

Tips for Safely Using Acetone on Metal Surfaces

Acetone, a potent solvent, is often used to remove glue and paint from metal surfaces. However, it is crucial to handle acetone with care to avoid any damage. In this article, we will explore vital safety precautions for using acetone on metal surfaces, ensuring the preservation and protection of your precious metals.

Prioritize Safety Precautions:

First and foremost, prioritize safety when working with acetone. Its highly flammable and volatile nature demands cautious handling. Work in a well-ventilated area to prevent inhaling harmful fumes, and don protective gloves and goggles to shield your skin and eyes. Always read and strictly follow the manufacturer’s instructions for safe usage.

Conduct an Inconspicuous Test:

To prevent potential damage, perform a spot test before applying acetone to the entire metal surface. Apply a small amount of acetone on a cotton swab or cloth, then gently rub it on an inconspicuous area of the metal. Observe any adverse reactions or damage before proceeding with the full application.

Choose the Appropriate Concentration:

Acetone is available in varying concentrations, ranging from 100% to diluted versions. Start with a lower concentration and gradually increase if necessary, considering the sensitivity of the metal and your desired outcome. Keep in mind that higher concentrations may effectively remove substances but can also be more aggressive on the metal surface.

Apply Acetone with Caution:

When applying acetone, use a clean cloth or sponge for even coverage. Avoid leaving acetone on the metal surface for extended periods to prevent discoloration or damage. Instead, employ gentle scrubbing or wiping motions to remove adhesives or paint without risking harm.

Thoroughly Rinse and Dry:

After using acetone, thoroughly rinse the metal surface with clean water to eliminate any residue. Leaving acetone residue on the metal can lead to subsequent damage or corrosion over time. Once rinsed, ensure the surface is completely dry using a clean cloth to mitigate any moisture-related issues.

Apply a Protective Coating:

To provide long-lasting protection for your metal surface, consider applying a protective coating or sealant after using acetone. This additional layer acts as a barrier against future damage, corrosion, or oxidation. Seek professional advice or conduct research to determine suitable protective coatings based on the type of metal you are treating.

Proper Storage and Disposal:

Lastly, remember to store acetone in a cool, dry place away from heat sources and open flames. Improper storage can lead to accidents or fire hazards. Additionally, dispose of acetone properly according to local regulations and guidelines. Locate local hazardous waste disposal facilities or collection events in your area for safe and responsible disposal.

AM3rl1JFsuY” >

Conclusion

In conclusion, acetone packs a powerful punch as a solvent, capable of stripping away paint, glue, and other stubborn substances from metal surfaces. While it generally plays nice with most metals, caution is key when working with this mighty liquid. Prolonged exposure to high concentrations of acetone can unleash potential damage.

Certain metals, like aluminum and copper, prove more vulnerable to the corrosive clutches of acetone over time. Before dousing your metal masterpiece, it’s wise to perform a spot test in an inconspicuous corner. This detective work will unveil the metal’s reaction and safeguard against potential harm.

Stainless steel stands tall as a resilient warrior against acetone’s corrosive charms. Yet even this sturdy soldier can succumb if its protective coatings or finishes are compromised.

To minimize the risk of acetone-induced destruction, set up shop in a well-ventilated haven while donning your trusty gloves and goggles. Embrace gentle application techniques like tenderly wiping with a clean cloth or sponge. Once the job is done, rinse thoroughly with water and ensure that surface is bone-dry before moving on.

For an extra layer of defense against future damage, consider applying a protective coating or sealant post-acetone assault.

By adhering to these safety measures and handling precautions, you can wield the power of acetone on metal surfaces without leaving behind scars of destruction.