In the world of arts and crafts, finding that perfect adhesive to stick things together is like discovering a hidden treasure. Whether you’re into woodworking, DIY projects, or acrylic paintings, knowing how different materials interact is key. And one burning question that keeps popping up is whether acetone, that trusty solvent we all know, can bond acrylic.

Today, we’re diving deep into this enigma to explore the fascinating world of chemical connections.

Acetone – the superstar solvent found in nail polish removers and industrial cleaning products. Acrylic – that versatile material loved by creatives for its durability, transparency, and vibrant colors. When these two cross paths, something extraordinary happens.

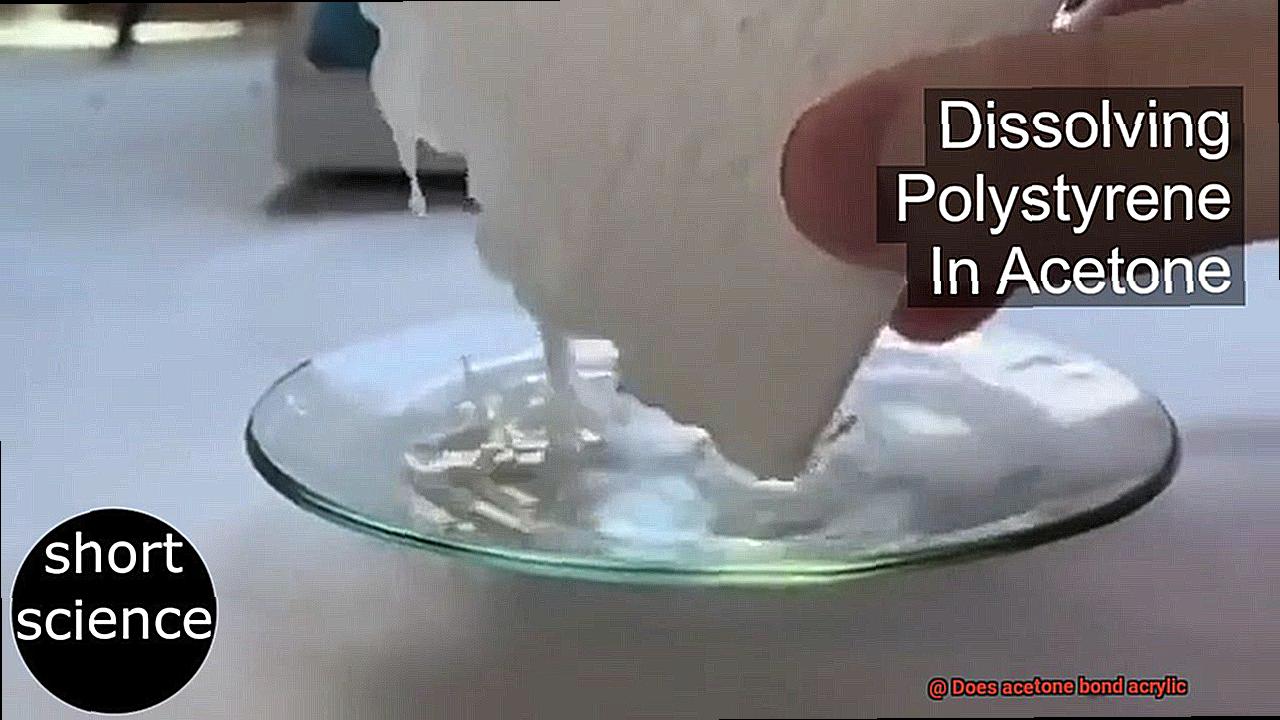

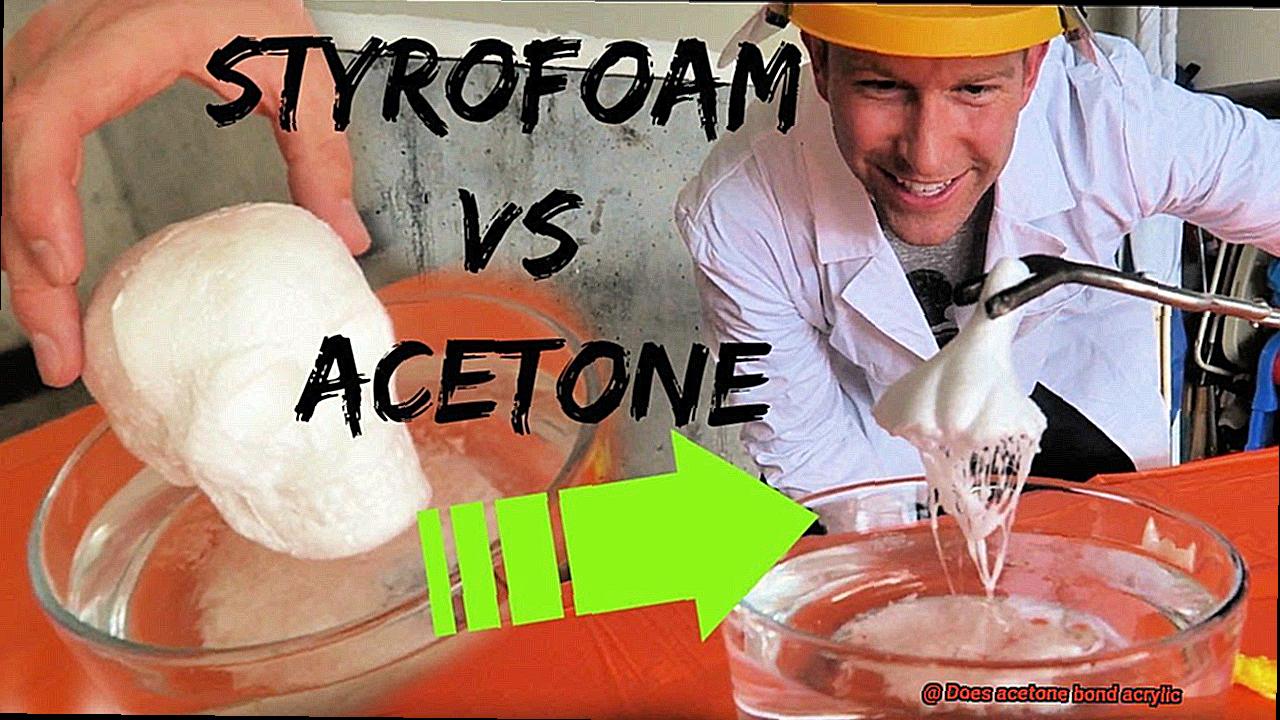

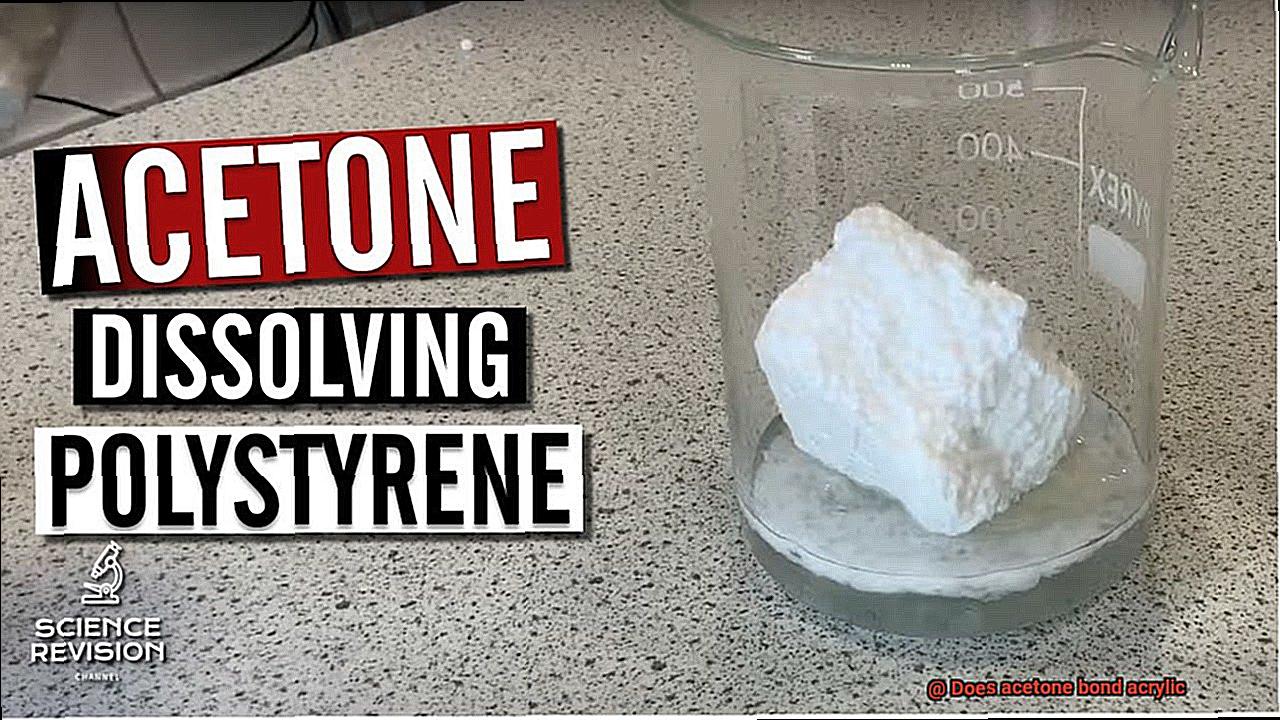

Acetone has this cool power to soften and partially dissolve acrylic when they meet. It’s like watching a superhero melt away obstacles with a single touch. But hold on tight – this doesn’t mean acetone forms an unbreakable bond with acrylic.

While acetone won’t chemically bond with acrylic, it can still play matchmaker under certain circumstances. Let’s say you want to join two pieces of acrylic together – applying acetone to both surfaces before pressing them firmly creates a temporary bond. It’s like a fling that holds things in place until you’re ready for the real deal – a more permanent adhesive like acrylic cement or epoxy.

The dance between acetone and acrylic reminds us how vital it is to understand the properties of our materials. Knowing which substances work together in harmony or clash like bitter enemies allows us to unleash their full potential for creating jaw-dropping art or nailing those project goals.

So even though acetone won’t magically bond with acrylic, it opens doors to endless creative possibilities when paired with the right adhesive sidekick. In our upcoming blog posts, we’ll dive deeper into other bonding options for acrylic and reveal techniques to amp up your artistry and craftsmanship. Stay tuned.

Remember, my fellow creative souls, experimenting and understanding the properties of different materials are the keys to unlocking a world of artistic wonders. Let’s embark on this thrilling journey together.

What is Acetone?

Contents

- 1 What is Acetone?

- 2 What is Acrylic?

- 3 How Does Acetone Bond Acrylic?

- 4 Advantages of Using Acetone for Bonding Acrylic

- 5 Disadvantages of Using Acetone for Bonding Acrylic

- 6 Different Types of Acrylic and Their Response to Acetone Bonding

- 7 Potential Damage Caused by Prolonged Exposure to Acetone

- 8 Alternatives to Using Acetone for Bonding Acrylic

- 9 Conclusion

Step into the world of acetone, a colorless and volatile liquid that tantalizes the senses with its sweet aroma. Beyond its role as a cleaner, acetone is a multi-talented solvent that has revolutionized industries ranging from manufacturing to cosmetics. Get ready to explore the fascinating properties, diverse uses, and essential precautions associated with this remarkable compound.

Properties:

Prepare to be amazed by acetone’s extraordinary characteristics:

- Highly Flammable: Handle with care. Acetone is like a fire-breathing dragon and should be kept far away from any source of heat or open flames.

- Master Solvent: Acetone boasts miscibility in both water and organic solvents, making it a prized choice for dissolving stubborn substances.

- Speedy Evaporation: Watch in awe as acetone disappears into thin air at room temperature, making it the ultimate superhero for applications requiring lightning-fast drying.

Uses:

Unlock the myriad of applications where acetone reigns supreme:

- The Cleaning Maestro: Say goodbye to pesky paint, sticky adhesives, and stubborn varnishes. Acetone effortlessly dissolves these foes, leaving surfaces pristine.

- Industrial Alchemy: Enter the realm of pharmaceuticals, plastics, fibers, and countless other industrial products. Acetone plays a pivotal role in their synthesis, transforming raw materials into remarkable creations.

- Nail Polish Vanisher: Ever wondered how your nails become a blank canvas? The secret lies with acetone, which effortlessly erases even the most vibrant polishes.

- Coatings and Resins Magician: Witness the wizardry of acetone in manufacturing processes for coatings and resins. Its ability to dissolve a multitude of compounds creates remarkable finishes.

Precautions:

Tread carefully when venturing into the realm of acetone:

- Flammable Foe: Beware the fiery nature of acetone. Store it far away from heat sources and open flames to prevent disaster.

- Breath of Fresh Air: Let the winds of ventilation whisk away acetone vapors. Proper airflow is crucial to protect against inhalation hazards.

- Shield Thyself: Keep your skin and eyes shielded from direct contact with acetone. Don the armor of gloves and goggles to guard against potential harm.

What is Acrylic?

Prepare to be dazzled by the captivating world of acrylic, a versatile wonder material that has revolutionized industries ranging from art and design to construction and manufacturing. Derived from acrylic acid or its derivatives, acrylic is a type of plastic that has taken center stage with its remarkable properties.

At its core, acrylic is polymethyl methacrylate (PMMA), a thermoplastic polymer that boasts an impressive array of characteristics. First and foremost, acrylic is known for its transparency. With exceptional optical clarity, it allows light to pass through without distortion, making it an ideal choice for applications where transparency is crucial. Picture yourself gazing through crystal-clear windows or sporting eyeglasses with lenses made from this remarkable material.

But acrylic’s allure doesn’t stop at transparency. It is also incredibly lightweight, making it a popular choice for applications where weight is a concern. From aircraft windows to lightweight signage, its lightness simplifies handling and transport, benefiting manufacturers and consumers alike.

While it may be lightweight, acrylic is no pushover when it comes to durability. Its impressive impact resistance means it can withstand accidental knocks and bumps without shattering like glass. This durability makes it suitable for a wide range of applications, from protective barriers to aquariums.

Not only is acrylic durable, but it is also weather-resistant. It can brave exposure to sunlight, heat, and moisture without significant degradation. Automotive parts, architectural glazing, and outdoor furniture all benefit from the long-lasting beauty of acrylic.

One of the most exciting features of acrylic is its ability to be colored. With ease, it can be dyed or pigmented to achieve a vast array of colors. Artists and designers rejoice as this characteristic opens up a world of possibilities for vibrant creations. Acrylic paints have become a favorite medium in the art world due to their brilliant hues and fast-drying properties.

However, while acrylic possesses numerous remarkable qualities, it does have a vulnerability. Acetone, a common solvent found in cleaning agents and nail polish removers, can soften and potentially bond with acrylic. This can be advantageous for joining acrylic pieces together using acetone as a solvent-based adhesive. However, it is important to exercise caution when working with acetone, as excessive exposure can cause damage to the acrylic.

How Does Acetone Bond Acrylic?

In this blog post, we will explore the captivating process of how acetone works its magic in bonding acrylic. Join us as we delve into the secrets behind this chemical reaction.

The Power of Acetone:

Acetone, a commonly used solvent, plays a pivotal role in bonding acrylic. Here’s how it works:

Softening the Surface:

Acetone has a low viscosity, effortlessly penetrating the surface of acrylic. When acetone comes into contact with acrylic, it softens the material, making it pliable and ready for bonding.

Molecular Rearrangement:

As acetone softens the acrylic, the molecules within the material rearrange themselves. This molecular dance enables them to form intermolecular bonds, creating a strong connection between the two pieces of acrylic.

Rapid Evaporation:

Acetone boasts a high evaporation rate, swiftly dissipating after softening the acrylic surface. This rapid evaporation ensures that the bond between the acrylic pieces remains solid and undisturbed.

The Right Match:

While acetone is effective for bonding most types of acrylic, not all variations are compatible. Some acrylics may be resistant or react poorly to acetone, potentially leading to weak bonds or damage. Thus, always perform a small compatibility test before proceeding with bonding.

Preparation Is Key:

To achieve successful bonding with acetone, proper surface preparation is crucial. Follow these steps:

Cleanliness:

Ensure that the surfaces you wish to bond are clean and free from dirt, dust, or oils that may interfere with the bonding process.

Surface Roughening:

Gently roughen the surfaces using sandpaper or an abrasive material. This creates more surface area for the acetone to penetrate and bond with the acrylic.

Bonding Process:

- To bond acrylic using acetone, follow these simple steps:

- Apply a small amount of acetone to both surfaces.

- Allow the acetone to soften the acrylic for a few seconds.

- Press the two pieces of acrylic together firmly.

- Hold the pieces in place for a short period, allowing the bond to form and strengthen.

Remember that once acrylic is bonded with acetone, it becomes permanent and cannot be easily undone. Separating or removing bonded acrylic may require cutting or alternative methods of physical separation.

Advantages of Using Acetone for Bonding Acrylic

In this blog post, we’ll dive into the advantages of using acetone for bonding acrylic materials. Acetone, a solvent widely used in various industries, has some incredible properties that make it an ideal choice for creating strong and durable bonds between acrylic pieces. So, let’s explore the enchanting chemistry behind acetone and discover why it’s the go-to adhesive for professionals and hobbyists alike.

Advantage 1: Strong and Durable Bond

Acetone possesses a secret superpower – its ability to dissolve the surface of acrylic materials. When you apply acetone to two pieces of acrylic, it softens and rearranges the surface molecules. As it evaporates, the molecules solidify, creating a seamless bond that is resistant to breaking or coming apart. This means your bonded acrylic pieces will stand the test of time.

Advantage 2: Fast Drying Time

In a world where time is precious, acetone saves the day with its lightning-fast drying time. Unlike other adhesives that require hours or days to cure, acetone evaporates quickly, allowing you to handle and use your newly bonded acrylic pieces shortly after the bonding process. Perfect for those urgent projects or when you simply can’t wait to show off your craftsmanship.

Advantage 3: Precision Application

Acetone’s liquid form provides the ultimate precision when bonding acrylic. With easy application and control, you can ensure that every nook and cranny of your acrylic pieces receives a coat of adhesive. This level of precision is especially useful when working with intricate or small acrylic components that require meticulous bonding.

Advantage 4: Transparent Finish

Who wants visible traces or residue ruining the beauty of their acrylic masterpiece? Not us. Fortunately, acetone dries without leaving any noticeable marks. This makes it an excellent choice for working with transparent or translucent acrylic materials, ensuring a seamless and aesthetically pleasing finish that lets your creativity shine.

Advantage 5: Affordability and Availability

Glue doesn’t have to break the bank. Acetone is not only effective but also readily available and cost-effective. You can easily find it at hardware stores or online suppliers at affordable prices. Its widespread availability makes it a convenient option for professionals and hobbyists alike, allowing you to unleash your creativity without worrying about breaking the budget.

Advantage 6: Easy Repairs and Modifications

Mistakes happen, or perhaps you want to make modifications to your bonded acrylic piece. No problem. Acetone comes to the rescue once again. By applying acetone, you can dissolve the existing bond, allowing for easy separation and re-bonding. This flexibility makes acetone a versatile choice for projects that may require adjustments or repairs over time.

Disadvantages of Using Acetone for Bonding Acrylic

Acetone, the adhesive superhero renowned for its ability to dissolve and soften surfaces, is a popular choice for bonding acrylic. However, even superheroes have their weaknesses. In this article, we will delve into the disadvantages of using acetone for bonding acrylic, shedding light on potential challenges and risks.

Time is of the Essence:

One significant drawback of using acetone is its rapid evaporation rate. This means that the bonding process must be completed swiftly. For inexperienced users or those lacking dexterity, this can be a daunting task. Failing to complete the process quickly enough can result in weak bonds or complete failure.

Fire Hazard:

Acetone possesses a highly flammable nature, making it a fire risk during use. To ensure safety, it should be used in a well-ventilated area away from open flames or heat sources. Wearing protective gloves and eyewear is essential to prevent accidents or injuries.

Compatibility Issues:

Not all acrylics respond favorably to acetone. Some types may become discolored, warped, or weakened when exposed to acetone. Conducting compatibility tests before bonding is crucial to avoid compromising the quality and durability of the bond.

Strong Odor:

The pungent odor emitted by acetone can be unpleasant and irritating to work with. Individuals with sensitivity to strong smells or respiratory issues may find it particularly challenging. Working in a well-ventilated area or using additional respiratory protection is highly recommended.

Proper Handling and Disposal:

Acetone is classified as a hazardous chemical and requires proper handling and disposal procedures. Pouring it down the drain or disposing of it in regular trash bins is strictly prohibited. Storing it in a designated container and taking it to a hazardous waste disposal facility is necessary to ensure safety and environmental responsibility.

Different Types of Acrylic and Their Response to Acetone Bonding

Acrylic is a versatile material renowned for its transparency, durability, and ease of fabrication. However, not all acrylics are created equal when it comes to their response to acetone bonding. In this essay, we will explore the diverse types of acrylic and unravel their unique interactions with acetone.

Extruded Acrylic – The Resilient Rebel:

Extruded acrylic, also known as “continuous cast” acrylic, boasts exceptional strength and a flawlessly smooth surface. It’s the superhero of the acrylic realm. However, when it comes to acetone bonding, extruded acrylic can be somewhat resistant. To ensure successful bonding, it’s advisable to conduct a small test area before embarking on a larger project.

Cell Cast Acrylic – The Radiant Beauty:

Cell cast acrylic, the shining star of the acrylic world, is poured into molds and cured to create a pristine finish. With its superior visual appeal, cell cast acrylic triumphs over extruded acrylic in terms of acetone bonding. The lower internal stress within this type of acrylic makes it more receptive to acetone bonding, resulting in a stronger bond.

Impact-Modified Acrylic – The Indestructible Guardian:

Impact-modified acrylic harnesses the power of specialized additives that render it highly resistant to impact and shattering. This type of acrylic, akin to the mighty Hulk, is commonly employed in safety applications such as riot shields and bulletproof windows. The response of impact-modified acrylic to acetone bonding can vary due to the diverse additives used. Consulting the manufacturer or conducting a preliminary test is wise before attempting acetone bonding.

UV-Resistant Acrylic – The Sun’s Protector:

UV-resistant acrylic acts as a sun shield for your windows, safeguarding them from yellowing caused by prolonged exposure to UV radiation. With its added UV-resistant additives, bonding UV-resistant acrylic with acetone follows a similar process to regular acrylic bonding. However, the special additives may necessitate extra attention during the bonding process, warranting adherence to manufacturer guidelines or a preliminary test.

Colored Acrylic – The Enchanting Kaleidoscope:

Colored acrylic presents a mesmerizing array of vibrant hues, making it perfect for artistic projects and decorative installations. When it comes to acetone bonding, colored acrylic can be a delightful enigma. Different pigments may react distinctively to acetone, necessitating caution and the implementation of small-scale tests before committing to gluing.

Potential Damage Caused by Prolonged Exposure to Acetone

Acetone, often hailed as a superhero in the realm of paint and glue removal, can actually have some not-so-super effects on our bodies and materials like acrylic. So, let’s delve deeper into the potential damage caused by prolonged exposure to this powerful solvent.

First and foremost, let’s talk about our skin. Prolonged exposure to acetone can strip away the natural oils that act as a protective barrier, leaving our skin dry, cracked, and vulnerable. The thought of cracked skin is enough to make anyone wince in discomfort. And it doesn’t stop there – inhaling acetone vapors can also wreak havoc on our respiratory system. These vapors irritate the delicate tissues lining our airways, leading to troublesome symptoms such as coughing, shortness of breath, and chest tightness. Just imagine gasping for air while trying to catch your breath – definitely not a pleasant experience.

But humans aren’t the only ones who should be wary of acetone’s harmful effects. Acrylic, that versatile material we adore for its durability and versatility, is also at risk. Acetone possesses a sneaky ability to dissolve acrylic, making it susceptible to weakening or even disintegration when exposed for extended periods. This means that cherished acrylic pieces could lose their structural integrity and become mere shadows of their former selves. Talk about heartbreak.

So what’s the key takeaway here? Handle acetone with utmost care. Whether you’re using it in a nail salon or an industrial setting, keep a watchful eye on how long you’re exposed to this potent solvent. Proper ventilation is crucial in minimizing the inhalation of harmful vapors, while keeping acetone far away from sources of ignition is essential due to its highly flammable nature.

Now here’s an intriguing twist: while acetone can damage acrylic, it’s also frequently used as a solvent for bonding acrylic. It acts as a softening agent, preparing the surface for improved adhesion. However, it’s vital to remember that this delicate process should only be carried out by professionals who possess the necessary knowledge and expertise.

Alternatives to Using Acetone for Bonding Acrylic

In this captivating exposé, we delve into the realm of possibilities, discovering a wide range of options that can effortlessly bond acrylic surfaces without the need for acetone. Whether you’re an intrepid DIY enthusiast or a seasoned professional in the industry, these alternatives will revolutionize your acrylic bonding endeavors, providing safe and reliable options for every need.

Specialized Acrylic Adhesive:

Step into a world of bespoke bonding with specialized acrylic adhesives or glues. Crafted with precision for acrylic surfaces, these products offer unparalleled strength and durability. Liquid adhesives, tapes, and structural adhesives cater to diverse application methods, ensuring a secure bond that withstands the test of time.

Two-Part Epoxy Resin:

Unleash the power of alchemy with two-part epoxy resins. Renowned for their Herculean bonding properties, these resins form a formidable adhesive when the resin and hardener are mixed. The resulting concoction creates an unyielding bond capable of braving even the harshest environmental conditions.

Cyanoacrylate Adhesive (Super Glue):

Witness the unexpected as cyanoacrylate adhesives, also known as super glue, reveal their hidden talents. Although not designed exclusively for acrylic bonding, select cyanoacrylate adhesives can forge a robust bond on acrylic surfaces. Opt for varieties marked suitable for plastics like acrylic to unlock optimal results.

Thermal Bonding:

Ignite a new era in bonding with thermal fusion. Harnessing heat’s transformative prowess, this method softens acrylic surfaces before pressing them together until they cool and solidify into an unbreakable bond. Be prepared to wield specialized equipment such as hot air guns or infrared heaters to master this technique.

Ultrasonic Welding:

Experience the harmonious union of high-frequency vibrations and acrylic surfaces with ultrasonic welding. Initially reserved for industrial settings, this extraordinary method melds acrylic surfaces together, creating a bond that defies conventional wisdom. Prepare to be captivated as chemicals become obsolete in the face of this awe-inspiring technique.

Mechanical Fasteners:

Fortify your bond with mechanical fasteners as screws, bolts, or rivets join forces with adhesive bonding. These stalwart companions provide additional support while the adhesive cures, cementing a bond that surpasses mere adequacy.

Mx10ZN9Jigo” >

Conclusion

In conclusion, it is clear that acetone does not bond acrylic.

Acetone may soften or dissolve the surface of acrylic, but it does not create a strong bond between the two materials. This is due to the chemical properties of both acetone and acrylic.

However, once the acetone evaporates, the acrylic returns to its original state without any significant bonding occurring.