It’s a battle of adhesion versus mechanical strength, and we’re here to break it down for you. Whether you’re a seasoned pro or just starting out, choosing the right method for your Medium Density Fiberboard (MDF) project is crucial.

In this blog post, we’ll take you on a wild ride through the world of MDF craftsmanship. We’ll explore the pros and cons of both gluing and screwing techniques so that you can confidently decide which route to take. From strength to aesthetics, and even budget considerations – we’ve got you covered.

So, buckle up and get ready to unleash the power of adhesion or embrace the might of screws. By the end, you’ll be armed with all the knowledge you need to make informed decisions tailored to your unique woodworking needs. Your MDF creations deserve nothing less than perfection, my friend.

Let’s dive in and discover how to secure MDF’s mighty structure while achieving flawless finishes and assembly ease. It’s time to settle this age-old debate once and for all.

Advantages of Gluing MDF

Contents

Medium Density Fiberboard (MDF) is a versatile and popular material in woodworking and construction projects. When it comes to joining MDF panels, the decision between gluing and screwing often arises. While both methods have their merits, gluing MDF offers a range of advantages that make it the perfect choice for your next project. In this blog post, we will explore the benefits of gluing MDF, including its strength, seamless finish, enhanced durability, reduced risk of splitting, design versatility, moisture resistance, and cost-effectiveness.

Advantage 1: Strong and Durable Bond

Gluing MDF creates a robust and long-lasting bond, ensuring your project remains sturdy throughout its lifespan.

This advantage is crucial for large and heavy MDF projects like cabinets or furniture. With a properly glued joint, your MDF panels become a single solid piece that can withstand the test of time.

Advantage 2: Seamless Finish

Gluing MDF allows for a flawless finish without any visible fasteners. Say goodbye to unsightly screws or nails protruding from your workpiece. By using glue instead, you achieve a clean and professional appearance that enhances the visual appeal of your project.

Advantage 3: Enhanced Strength

Glued MDF joints often boast greater strength than those created by screws alone. The adhesive seeps into the porous surface of the MDF panels, reinforcing the joint and providing additional stability and support. This advantage is particularly valuable for applications that require extra strength, such as load-bearing structures.

Advantage 4: Reduced Risk of Splitting

Compared to screwing, gluing MDF significantly reduces the risk of splitting the material. MDF is prone to splitting when screws are driven too close to the edge or when excessive force is applied during installation. Using glue instead of screws minimizes this risk, ensuring the integrity of the material remains intact.

Advantage 5: Design Versatility

Gluing MDF offers greater versatility in terms of design and construction options. Unlike screws that require pre-drilling holes and leave visible marks, glue allows for invisible connections between MDF panels. This opens up opportunities for more intricate and seamless joints, giving you the freedom to explore creative designs without compromising structural integrity.

Advantage 6: Moisture Resistance

When waterproof glue is used, gluing MDF can provide increased moisture resistance compared to screwing. This advantage is especially beneficial in environments where humidity levels fluctuate, such as bathrooms or kitchens. The adhesive acts as a reliable barrier, preventing moisture from penetrating the joints and potentially causing damage to the MDF.

Steps for Glueing MDF

Gluing MDF may seem like a simple task, but there are a few key steps you need to follow to ensure a strong bond that will stand the test of time. In this guide, we’ll take you through the process step by step, so you can confidently tackle any project that requires gluing MDF. Get ready to unlock the power of adhesion and create woodworking masterpieces that will leave everyone in awe.

Step 1: Prepare the Surface

To ensure a solid bond, start by sanding the edges that will be glued together. This creates a rough surface that allows the glue to grip better. Use fine-grit sandpaper and take your time to achieve a smooth finish.

Step 2: Cleanliness is Key

After sanding, wipe away any dust or debris from the MDF using a damp cloth or tack cloth. This step is crucial as it ensures direct contact between the glue and the MDF, maximizing adhesion.

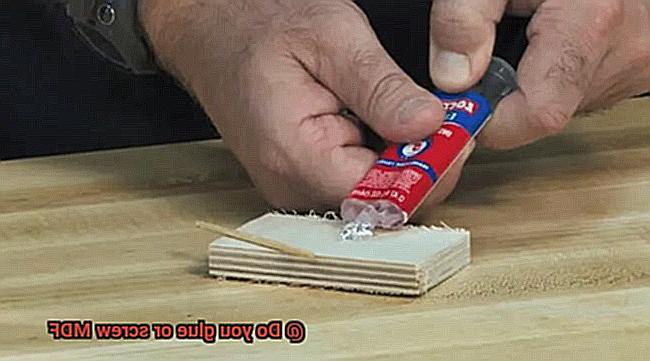

Step 3: Choose Your Weapon – The Right Adhesive

Selecting the right adhesive is vital for a successful glue joint. Opt for an adhesive specifically designed for MDF, such as polyurethane glue, epoxy, or wood glue. Read the instructions carefully to choose the one that suits your project best.

Step 4: Apply with Precision

Apply the adhesive evenly to one of the surfaces you want to join together. Depending on the adhesive type, you can use a brush, roller, or even your finger. Remember not to go overboard with the glue – too much can lead to messy excess squeeze-out.

Step 5: Clamp it Down

Once the adhesive is applied, carefully align and press the two pieces of MDF together. Use clamps or heavy objects to hold them firmly in place while the glue dries. Make sure the pressure is evenly distributed across the joint for a super-strong bond.

Step 6: Tidy Up

While the glue is still wet, remove any excess squeeze-out using a damp cloth or putty knife. This step guarantees a clean and professional-looking finish.

Step 7: Patience is a Virtue

Allow the glue to cure fully according to the manufacturer’s instructions. Generally, it’s recommended to leave the clamped pieces together for at least 24 hours. This patience will be rewarded with a rock-solid bond that can withstand whatever life throws at it.

Disadvantages of Gluing MDF

Gluing MDF may seem like a convenient choice for woodworking projects, but it’s important to be aware of its disadvantages. Here are the drawbacks you should consider:

- Time-consuming process: Achieving a strong bond with MDF requires meticulous surface preparation, including sanding and cleaning. Additionally, clamping is necessary to hold the pieces together until the adhesive fully cures. These extra steps can significantly slow down your project timeline, especially if you have multiple pieces to glue.

- Weaker joints: Compared to methods like screwing, gluing MDF may result in weaker bonds. The dense and heavy nature of MDF makes it difficult for adhesive to effectively penetrate or bond with its surface. As a result, joints may be more prone to failure or separation over time.

- Limited flexibility: Once the adhesive is applied and the pieces are pressed together, repositioning or making adjustments becomes challenging without causing damage. This lack of flexibility can be a disadvantage if you need to make changes or corrections during the assembly process.

- Susceptibility to moisture: Glued MDF can be weakened by exposure to high humidity or water. Over time, the adhesive may break down, compromising the strength of the bond. This makes glued MDF less suitable for areas with high moisture content, such as bathrooms or kitchens.

- Need for additional support: MDF has a relatively low density and tends to swell when exposed to moisture. To ensure structural integrity, additional measures like bracing or using mechanical fasteners may be necessary. These measures add complexity and potentially additional costs to your project.

- Visible glue lines: If the adhesive is not properly applied or excess glue is not cleaned up immediately, visible glue lines can mar the surface of your project. This can be especially problematic when working with veneered or finished surfaces, as it becomes difficult to hide or disguise these unsightly marks.

Advantages of Screwing MDF

In this blog post, we will delve into the world of screwing MDF and explore its undeniable advantages over traditional gluing methods. From unmatched strength and stability to easy disassembly and enhanced load-bearing capacity, screwing MDF takes your woodworking projects to a whole new level. So put on your tool belt and get ready to revolutionize your craft.

Unmatched Strength and Stability:

Say goodbye to weak joints and hello to unyielding durability. Screwing MDF provides a rock-solid connection that can withstand the test of time. Unlike glue, which may weaken over time or fail under stress, screws create an unbreakable bond that keeps your project intact. No more worrying about split or cracked MDF panels – with screws, your creations will stand strong against any challenge.

Effortless Disassembly:

Need to modify or disassemble your project? No sweat. With screws, you have the ultimate flexibility to easily dismantle MDF components without causing any damage. It’s like having a magical undo button for your woodworking endeavors. Simply unscrew and voila – your project is ready for a makeover or a complete transformation.

Enhanced Load-Bearing Capacity:

Whether you’re crafting furniture or cabinetry, load-bearing capacity is essential. Screwed MDF takes it up a notch with its superior weight-bearing capabilities compared to adhesives alone. The threaded design of screws creates a mechanical interlocking effect that distributes weight evenly across the joint. You can confidently trust your projects to handle heavier loads without compromising their structural integrity.

Precision Alignment:

In the world of woodworking, precision is key. Screwed MDF allows for easy adjustment and alignment during assembly, guaranteeing a flawless finish every time. Unlike glue, which sets quickly and leaves no room for corrections, screws give you the freedom to fine-tune your project before securing everything in place. Achieve that professional touch with ease.

Limitless Versatility:

Screwing MDF opens up a world of possibilities for your woodworking projects. From cabinets and shelves to larger structural elements, screws provide a reliable method of joining MDF. But why stop there? Combine screws with other joining techniques like dowels or biscuits to take your creations to new heights of strength and stability. The options are endless, limited only by your imagination.

Steps for Screwing MDF

Well, my friend, it’s time to take matters into your own hands – quite literally. In this comprehensive guide, we’ll walk you through the steps involved in screwing MDF panels together, unlocking a world of strength, stability, and limitless possibilities for your woodworking projects. So grab your power drill and get ready to dive into the art of screwing MDF like a pro.

Step 1: Prepare the MDF

Before diving into the screwing action, take a moment to prepare your MDF panels. Smooth out those rough edges by gently sanding them with some fine-grit sandpaper. This step not only ensures a cleaner finish but also provides a better surface for screws to sink their teeth into.

Step 2: Mark Your Target

Next, it’s time to mark the spots where your screws will find their perfect home. Measure and mark equal distances along the edges, ensuring you leave a gap of at least 1 inch from the edge to prevent any unwanted splitting. Precision is key here, so take your time and double-check those measurements.

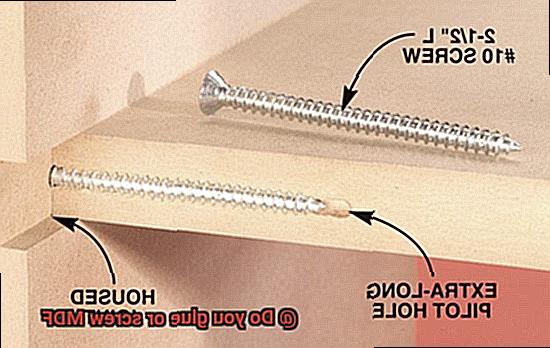

Step 3: The Unsung Heroes – Pilot Holes

To prevent any heartbreaking splits in your beloved MDF panels, it’s time to call in the unsung heroes of screwing – pilot holes. Grab a drill bit that’s slightly smaller than the diameter of your screws and carefully pre-drill pilot holes at the marked spots. These tiny heroes will guide your screws in without causing any damage or heartache.

Step 4: Countersinking – The Secret to a Flawless Finish

For that extra touch of professionalism, countersinking is your secret weapon. Embrace it. Take a countersink bit or use a slightly larger drill bit to create a small recess for the screw heads to sit flush with the surface of the MDF. This not only adds aesthetic value but also ensures a seamless look that will make you the envy of all woodworkers.

Step 5: Screw It, Secure It.

Now comes the moment you’ve been waiting for – screwing those MDF panels together. With your pilot holes and countersinks ready, grab your trusty power drill or screwdriver and drive those screws home. Remember, don’t go overboard with the tightness; just keep it snug and secure without risking damage to your precious MDF.

Disadvantages of Screwing MDF

While screwing MDF may appear to be a straightforward joining method, it has its fair share of disadvantages that can compromise the integrity and aesthetics of your projects. So, let’s dive into the world of screwing MDF and uncover its drawbacks.

Splitting Risk:

MDF, being a composite material, is prone to splitting when screws are driven in too forcefully. The small wood fibers compressed together with adhesive can weaken joints and compromise the overall structural integrity of your project. To avoid this, it’s crucial to exercise caution and use proper techniques when screwing into MDF.

Bulging and Warping:

The dense composition of MDF can cause screws to struggle to sink in smoothly, resulting in surface bulges or warping. This becomes particularly problematic when working with thin or delicate pieces of MDF. To achieve a flat and even surface, extra care must be taken during screwing.

Visible Screw Heads:

Unlike other types of wood that can easily conceal screws, MDF tends to show screw heads more prominently. This can be aesthetically unpleasing, especially if you plan on leaving the surface exposed or if you desire a seamless appearance for furniture or cabinetry projects.

Weaker Connections:

Using screws alone in MDF may result in weaker connections compared to alternative joining methods such as glue or nails. The nature of MDF’s composition makes it less conducive for screws to create secure connections. Glue, on the other hand, distributes the load across a larger area, resulting in stronger and more durable bonds.

Enlarged Screw Holes:

Over time, repeated use or movement can cause screw holes in MDF to become enlarged, compromising the stability of your project. This is due to MDF’s relatively less dense and sturdy nature when compared to solid wood. It’s important to consider this factor when deciding on the long-term durability of your MDF creations.

Time and Precision:

Screwing MDF requires careful planning and precision. Pre-drilling pilot holes before driving in screws is essential to prevent splitting and ensure a secure connection. However, this extra step adds time and effort to the assembly process, making it less convenient compared to other joining methods like using glue or nails.

Comparison between Gluing and Screwing MDF

When it comes to joining Medium Density Fiberboard (MDF), there are two common methods: gluing and screwing. Each method has its own advantages and disadvantages, so it’s important to understand the differences before deciding which one is right for your project.

Gluing is a popular choice for joining MDF because it creates a seamless and smooth joint. This is especially important for projects that require a clean and professional finish, like cabinetry or furniture. Gluing also eliminates the need for visible fasteners, which can detract from the overall aesthetic appeal of the project. However, gluing MDF requires meticulous surface preparation. The mating surfaces need to be clean, dry, and free from dust or debris for the glue to adhere properly. Additionally, clamping the glued pieces together until the adhesive cures is essential to ensure a tight bond.

Screwing, on the other hand, offers excellent holding power and durability. Screws can withstand heavy loads or stress, making them suitable for projects that require extra strength. They also provide a level of adjustability, allowing for minor adjustments or modifications during the construction process. However, screwing MDF can be risky. The material is more prone to splitting compared to solid wood, so pre-drilling pilot holes before driving screws into the MDF is crucial. Additionally, visible screw heads may not be desirable in projects that require a clean and seamless finish.

In summary, gluing MDF creates a seamless and smooth joint without visible fasteners, but requires meticulous surface preparation and clamping. Screwing MDF offers excellent holding power and adjustability, but carries the risk of splitting and visible screw heads. Consider these factors when deciding which method is best suited for your project.

When comparing gluing vs. screwing MDF, here are some key points to consider:

Advantages of Gluing MDF:

- Creates a seamless and smooth joint.

- Eliminates the need for visible fasteners.

- Ideal for projects that require a clean and professional finish.

- Can be used on various types of MDF.

Disadvantages of Gluing MDF:

- Requires meticulous surface preparation.

- Clamping is necessary until the adhesive cures.

- May not provide as much holding power as screwing.

- Not suitable for projects that require frequent disassembly or adjustments.

Advantages of Screwing MDF:

- Offers excellent holding power and durability.

- Allows for minor adjustments or modifications during construction.

- Provides a mechanical connection that can withstand heavy loads or stress.

- Suitable for projects that require extra strength or stability.

- Material is more prone to splitting compared to solid wood.

- Pre-drilling pilot holes is necessary to minimize splitting risk.

- Visible screw heads may not be desirable for projects requiring a clean and seamless finish.

- Can be more time-consuming compared to gluing.

Disadvantages of Screwing MDF:

Esvb64fUQ10″ >

Conclusion

When it comes to working with MDF, the question of whether to glue or screw it is a common dilemma. Both methods have their advantages and disadvantages, so it ultimately depends on the specific project and your desired outcome.

Gluing MDF can provide a strong bond that eliminates the need for visible screws or nails. This can result in a cleaner and more seamless finish, especially if you plan on painting or veneering the surface. However, it’s important to choose the right adhesive for MDF, as not all glues are suitable for this material. Additionally, gluing can be time-consuming as you need to allow sufficient drying time for the adhesive to set properly.

On the other hand, screwing MDF offers a quick and secure method of joining pieces together. Screws provide mechanical strength and stability, making them ideal for load-bearing applications or when you anticipate frequent disassembly. They also allow for easier adjustment or removal if needed. However, using screws requires pre-drilling pilot holes to prevent splitting or cracking of the MDF.

Ultimately, the decision between gluing or screwing MDF boils down to your specific needs and preferences. Consider factors such as aesthetics, strength requirements, ease of assembly/disassembly, and long-term durability before making your choice. And remember, regardless of which method you choose, always use proper safety precautions and follow manufacturer guidelines for best results.