Confused about whether to whip out the Teflon tape when connecting PVC to brass?

You’re not alone, my friend. Even seasoned DIYers and plumbing pros can get caught up in this conundrum.

But fret not, because I’m here to untangle this sticky situation for you. In this blog post, we’ll dive headfirst into the world of plumbing connections, specifically focusing on the mind-boggling dance between PVC pipes and brass fittings.

So, grab a cuppa, sit back, and let’s unravel this tape tale together.

Understanding the Properties of PVC and Brass

Contents

- 1 Understanding the Properties of PVC and Brass

- 2 Why Teflon Tape Is Not Necessary for PVC to Brass Connections

- 3 The Advantages of Using PVC Glue Instead of Teflon Tape

- 4 How to Properly Install PVC Fittings

- 5 Cleaning and Drying the Surfaces Before Installation

- 6 Applying the Appropriate Glue According to Manufacturer’s Instructions

- 7 Pressing the Fittings Together Securely

- 8 Allowing Sufficient Time for the Adhesive to Cure

- 9 Conclusion

When it comes to joining PVC and brass pipes, understanding their unique properties and selecting the appropriate connection method is crucial. In this article, we will delve into the properties of PVC and brass, explore the use of Teflon tape, and unveil why glue is the preferred choice for creating secure and leak-free connections.

PVC Properties:

Known for its versatility and durability, polyvinyl chloride (PVC) is a popular plastic used in plumbing systems. Its resistance to corrosion, chemicals, and UV rays makes it suitable for various environments. Lightweight, easy to install, and cost-effective, PVC pipes have become a go-to option in many applications.

Brass Properties:

Made primarily of copper and zinc, brass is renowned for its strength, durability, and corrosion resistance. Plumbing systems often incorporate brass fittings due to their ability to withstand high pressure and temperature conditions. Additionally, their golden color adds an aesthetic appeal to any plumbing system.

Compatibility:

When connecting PVC to brass, ensuring compatibility between the two materials is paramount. Despite both materials being resistant to corrosion, their chemical properties may affect compatibility. It is crucial to select an adhesive or glue that is suitable for both PVC and brass.

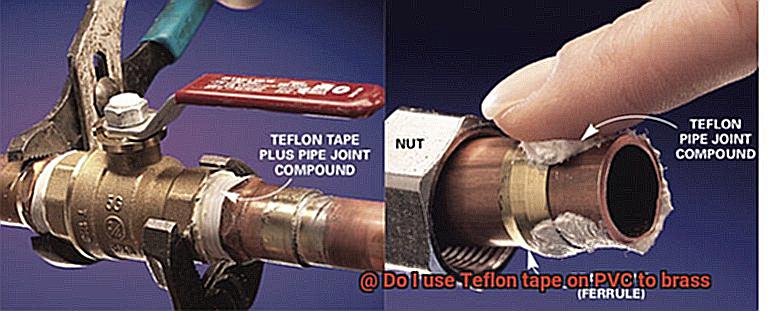

Teflon Tape vs. Glue:

While Teflon tape, also called plumber’s tape or thread seal tape, is commonly used on threaded connections for watertight seals and leak prevention, it is not suitable for PVC to brass connections. Unlike threaded connections, PVC fittings rely on solvent-based cement or adhesive specially formulated for PVC pipes.

The use of Teflon tape on PVC to brass connections can hinder the adhesive properties of PVC glue, compromising the bond between the materials. This interference can introduce gaps or uneven surfaces, jeopardizing the effectiveness of the connection.

Glue as an Alternative:

To ensure secure and leak-free connections between PVC and brass, the preferred method is to use solvent-based cement or glue. This adhesive forms a robust chemical bond between PVC components and brass, guaranteeing a tight and durable connection.

Specifically designed to withstand the high pressures typically found in plumbing systems, PVC and brass glue creates a reliable seal that is resistant to water, chemicals, and temperature variations. Following the manufacturer’s instructions for proper installation is crucial to achieve a successful bond.

Why Teflon Tape Is Not Necessary for PVC to Brass Connections

When it comes to plumbing connections, we often rely on trusty ol’ Teflon tape to create a watertight seal. But did you know that when it comes to connecting PVC and brass pipes, Teflon tape is not necessary? In this blog post, we’ll explore the fascinating world of PVC to brass connections and uncover why Teflon tape takes a backseat in this scenario.

The Perfect Match:

PVC and brass, two rigid materials, don’t require the added sealing properties of Teflon tape. Imagine this: PVC pipes have threaded ends that securely tighten onto brass fittings without additional sealing. It’s like a match made in plumbing heaven. Both PVC and brass have tapered threads, creating a tight seal as they are tightened together. Rest assured, your PVC to brass connection is designed to be leak-free without Teflon tape.

Teflon Tape: The Uninvited Guest:

Teflon tape is a great companion for metal-to-metal connections with gaps or imperfect threading. It fills in gaps and provides an extra layer of sealing. However, with PVC to brass connections, the threads are specifically designed for a tight seal without Teflon tape.

Alternative Options:

If you still have concerns about leaks or sealing, fear not. Pipe dope or thread sealant designed for PVC connections can be used instead of Teflon tape. These alternatives provide the necessary seal while ensuring proper joint tightening.

The Advantages of Using PVC Glue Instead of Teflon Tape

When joining PVC and brass fittings, opting for PVC glue over Teflon tape offers numerous advantages. From providing a stronger seal to easier application, PVC glue ensures a leak-free and durable connection. This blog post explores the benefits of using PVC glue in this specific plumbing scenario.

Stronger and More Reliable Seal:

- PVC glue creates a permanent bond between PVC and brass fittings, reducing the likelihood of leaks.

- A reliable seal is crucial in plumbing systems to prevent damage.

Easy Application:

- Applying PVC glue is simple, requiring less time and effort than wrapping Teflon tape.

- Quick and efficient installation process by applying the glue directly to the fitting surface.

Versatility:

- PVC glue can be used for various plastic pipe connections, not limited to PVC and brass fittings.

- Saves the need for multiple products, making it a valuable tool in your plumbing toolkit.

Clean and Neat Appearance:

- Unlike Teflon tape’s protruding excess material, PVC glue provides a tidy finish.

- Professional-looking plumbing connections without visible residue or mess.

Chemical and Temperature Resistance:

- PVC glue offers better resistance to chemicals and high temperatures compared to Teflon tape.

- Ideal for plumbing systems exposed to harsh chemicals or extreme temperatures, ensuring a long-lasting seal.

Long-Term Solution:

- PVC glue creates a strong and durable bond that stands the test of time.

- Reduces the need for frequent maintenance or repairs, providing a more permanent solution.

How to Properly Install PVC Fittings

Properly installing PVC fittings is crucial for creating secure and leak-free connections in plumbing and irrigation systems. In this comprehensive guide, we will walk you through the step-by-step process of installing PVC fittings, ensuring a strong bond and a watertight seal. From preparing the surfaces to joining the fittings, we’ve got you covered. Let’s dive in.

Tools and Materials:

Before you begin, gather the following tools and materials:

- PVC primer: Cleans and prepares the surfaces for bonding.

- PVC cement: Creates a strong and durable connection.

- Brush for application: Ensures even distribution of primer and cement.

- Clean cloth or rag: Removes any dirt, grease, or debris from the surfaces.

- Gloves: Protects your hands during the installation process.

- PVC fittings and pipes: The components that will be joined together.

Step 1: Prepare the Surfaces

To ensure a strong bond, start by meticulously cleaning both the fitting and pipe surfaces. Use a clean cloth or rag to eliminate any dirt, grease, or debris that could compromise the adhesion between the PVC components. This crucial step guarantees maximum contact between the primer and cement and the surfaces.

Step 2: Apply Primer

Using a brush, generously apply PVC primer to both the fitting and pipe ends. The primer not only cleans but also softens the surfaces, optimizing their ability to bond with the cement. Coat all areas evenly, ensuring complete coverage, and allow the primer to dry completely before proceeding.

Step 3: Apply Cement

Once the primer has dried, it’s time to apply a thin layer of PVC cement to both the fitting and pipe ends. It is essential to use cement that is compatible with PVC and specifically designed for your type of fitting. Be cautious not to over-apply the cement, as excessive amounts can result in messy joints and compromised connections.

Step 4: Joining the Fittings

Insert the pipe into the fitting, gently twisting it to achieve an even distribution of the cement. Hold the pipe in place for a few seconds to allow the cement to set. During this step, ensure proper alignment of the fittings to prevent leaks or other complications down the line. Accuracy is key when connecting PVC fittings.

Step 5: Allow Time for Curing

After joining the fittings, exercise patience and allow sufficient time for the cement to cure. Refer to the manufacturer’s instructions for the recommended curing time, as it may vary depending on the type of cement used. Avoid applying any pressure or force to the fittings until the cement has fully cured, ensuring a robust and durable connection.

Cleaning and Drying the Surfaces Before Installation

Properly cleaning and drying the surfaces before installation is essential for achieving a secure and long-lasting connection between PVC and brass fittings. Neglecting this step can result in weak joints and potential leaks, compromising the overall integrity of the installation. To ensure a successful bond, it is important to follow a few key steps.

Firstly, cleaning the surfaces is of utmost importance. Dirt, debris, and grease can hinder the adhesion between PVC and brass, preventing a strong connection. To effectively clean the surfaces, it is recommended to use a suitable cleaning agent specifically designed for PVC and brass materials. These cleaners are formulated to remove oils, residues, and contaminants from the surfaces.

Once you have the appropriate cleaner, take the time to scrub both the PVC and brass surfaces thoroughly. Use a cloth or brush to reach all areas, including inside the fittings, ensuring that every nook and cranny is cleaned. This meticulous cleaning process will help eliminate any potential obstacles to a solid bond.

After cleaning the surfaces, it is crucial to ensure that they are completely dry before proceeding with the installation. Moisture can compromise the adhesion between PVC and brass, leading to weakened joints or even leaks. To dry the surfaces effectively, use a clean cloth or towel to remove any excess moisture. Pay close attention to hard-to-reach areas such as threads or grooves. If time is of the essence, you may also utilize compressed air or a low-heat hairdryer to expedite the drying process. However, exercise caution to avoid overheating or damaging the materials.

It is important to note that Teflon tape should not be used as a substitute for proper cleaning and drying of surfaces before installation. While Teflon tape is commonly used for sealing threaded connections, it does not provide the necessary cleaning and bonding properties required for PVC to brass connections. Therefore, it is essential not to overlook this crucial step in favor of relying solely on Teflon tape.

Applying the Appropriate Glue According to Manufacturer’s Instructions

When it comes to joining PVC to brass, the glue you use plays a crucial role in creating a strong and secure connection. However, achieving optimal results requires more than just applying glue haphazardly. It’s essential to follow the manufacturer’s instructions meticulously. In this comprehensive guide, we will delve into the importance of adhering to these instructions and provide step-by-step guidance for applying the appropriate glue.

Choosing the Right Glue

- Different materials require different glues, so it’s important to select the correct one for PVC and brass connections.

- Manufacturers often provide specific recommendations for glue types suitable for joining PVC and brass.

- Solvent cement designed for PVC pipes is commonly used for this type of connection.

- This specialized cement chemically bonds PVC molecules together, ensuring a durable connection.

- Ensure that the solvent cement is compatible with both PVC and brass materials.

Proper Surface Preparation

- Before applying the glue, thoroughly clean and dry the surfaces to be joined.

- Remove any dirt, grease, or debris that could compromise the bond’s strength.

- Use a recommended cleaner or solvent from the manufacturer to prepare the surfaces adequately.

Applying the Glue

- Follow the manufacturer’s instructions precisely when applying the glue.

- Typically, a thin layer of glue is applied to both the PVC and brass surfaces.

- Avoid using excessive amounts of glue, as this can weaken the bond.

Joining the Parts Together

- Swiftly join the PVC and brass parts together while the glue is still wet.

- Ensure proper alignment and apply firm pressure when joining them.

- Hold the parts in place for the recommended curing time specified by the manufacturer.

Teflon Tape is Not Necessary

- Teflon tape is commonly used for threaded connections in plumbing applications but is unnecessary for joining PVC to brass with glue.

- Using Teflon tape can interfere with the adhesive properties of the glue, resulting in a weaker bond.

Pressing the Fittings Together Securely

Pressing fittings together securely is a crucial step in ensuring a leak-free connection between PVC and brass pipes. It’s like the final touch that brings everything together. If you’re wondering how to do it right, I’ve got you covered. Let’s dive into the steps necessary to securely press fittings together.

First things first, cleanliness is key. Before pressing the fittings together, make sure to clean the surfaces of both the PVC and brass pipes. Nobody likes a dirty connection. Use a clean cloth or brush to remove any dirt, debris, or grease that could interfere with a secure bond.

- Next, it’s time to bring out the secret weapon – the adhesive. Using an appropriate adhesive can enhance the strength and durability of the connection. Look for adhesives specifically designed for PVC to brass connections. These adhesives come in the form of solvent cements or primers that soften the PVC and create a strong bond.

- Now comes the important part – following the manufacturer’s instructions. Different types of fittings may have specific instructions on how to press them together securely. Take a moment to read and follow these instructions carefully. They might mention specific pressure requirements or techniques for optimal results.

To apply the necessary force, you may need some tools on hand. Clamps or wrenches can help ensure a tight and secure connection. Just make sure you’re using the correct tools for the job and handle them properly to avoid any damage to the fittings or pipes.

Last but not least, always double-check for leaks. Apply water or another suitable test medium to the connection and keep a close eye out for any signs of leakage. If you spot any leaks, don’t fret. It might just mean that you need to tighten the fittings a little further or reapply adhesive.

Remember, Teflon tape is commonly used for sealing pipe threads, but it’s not usually required or recommended for PVC to brass connections. The adhesives used in this process are usually sufficient to create a tight seal without the need for additional tape.

Allowing Sufficient Time for the Adhesive to Cure

When it comes to bonding PVC to brass, using adhesive is a popular and effective method. However, simply applying the adhesive is not enough. The crucial step that should never be overlooked is allowing sufficient time for the adhesive to cure. This process is what transforms the liquid or semi-liquid adhesive into a solid state, creating a strong and durable bond between the PVC and brass surfaces.

The curing time of the adhesive can vary depending on several factors. One such factor is the type of adhesive being used. Different adhesives have different chemical compositions and curing mechanisms. It is essential to carefully read and follow the manufacturer’s instructions regarding curing time for the specific adhesive being used. This will ensure that you allow enough time for the adhesive to fully cure and reach its maximum strength.

Environmental conditions also play a significant role in the curing process. Temperature and humidity can greatly influence how quickly or slowly the adhesive cures. Higher temperatures generally accelerate curing, while lower temperatures can slow it down. Similarly, high humidity levels can prolong curing time, while low humidity can expedite it. When planning for sufficient curing time, it is crucial to consider these environmental factors.

During the curing process, it is vital to avoid any movement or stress on the bond. Premature handling or disturbance can weaken or break the bond before it has fully cured, compromising its strength and durability. To prevent this, it is recommended to secure the bonded components in place using clamps or other appropriate tools during the curing period. This ensures that the bond remains undisturbed and reaches its full strength.

Rushing the curing process or not allowing enough time for complete curing can result in weak bonds that may fail under stress or over time. It is therefore advisable to avoid subjecting the bonded PVC-to-brass joint to any stress or load until the adhesive has fully cured. This includes avoiding movement, pressure, or exposure to water or other fluids that could compromise the bond.

Iim6vW-Bzsg” >

Conclusion

When it comes to connecting PVC to brass, the use of Teflon tape can be a game-changer. This simple yet effective solution ensures a tight and secure seal between the two materials. By wrapping the threads of the PVC fitting with Teflon tape before attaching it to the brass fitting, you create a barrier that prevents leaks and enhances the overall durability of the connection.

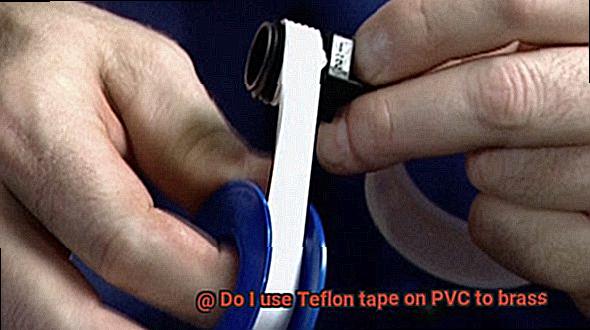

Teflon tape, also known as plumber’s tape or thread seal tape, is made from polytetrafluoroethylene (PTFE), a high-performance material known for its nonstick properties. Its unique composition allows it to effectively fill any gaps or irregularities in the threaded connection, creating a watertight seal that withstands pressure and resists corrosion.

Using Teflon tape on PVC to brass connections is particularly crucial because these two materials have different expansion rates. PVC tends to expand and contract more than brass due to temperature changes. Without proper sealing, this difference in expansion can lead to leaks and weakened connections over time.

To apply Teflon tape correctly, start by wrapping it clockwise around the male threads of the PVC fitting. Ensure that each wrap overlaps slightly with the previous one but does not cover the opening of the fitting. Continue wrapping until you have covered all exposed threads with at least two layers of tape.

Once wrapped, firmly screw the PVC fitting into the female threads of the brass fitting. The Teflon tape will compress as you tighten, creating a tight bond between the two materials. Be careful not to overtighten, as this can damage both fittings.

In conclusion, using Teflon tape on PVC to brass connections is highly recommended for ensuring leak-free and long-lasting connections. It provides an extra layer of protection against leaks caused by temperature variations and helps maintain the integrity of your plumbing system. So next time you’re working on such a connection, don’t forget to reach for that trusty roll of Teflon tape.