Are you itching to finish up your PVC project but dreading the thought of waiting a whole two hours for that glue to dry?

I’ve got the inside scoop on this sticky situation. As someone who knows PVC like the back of their hand, I totally get the frustration that comes with being in the middle of a project.

Waiting for glue to dry is about as exciting as watching paint dry – or so they say. But here’s the burning question: do we really have to endure a mind-numbing two-hour wait for PVC glue to set?

So, grab yourself a cuppa joe and prepare to be wowed by the science behind PVC glue drying.

What Factors Affect the Drying Time of PVC Glue?

Contents

- 1 What Factors Affect the Drying Time of PVC Glue?

- 2 How Long Does It Take for PVC Glue to Dry?

- 3 Is It Necessary to Wait 2 Hours for PVC Glue to Dry?

- 4 What Happens if I Don’t Wait for the Recommended Drying Time?

- 5 How Can I Ensure Maximum Strength and Durability of a Joint?

- 6 What Are Some Tips for Working with PVC Glue?

- 7 What Are the Benefits of Waiting for PVC Glue to Fully Cure?

- 8 How Can Environmental Conditions Affect the Drying Time of PVC Glue?

- 9 Conclusion

In this article, we will explore the science behind PVC glue drying time and delve into the key factors that affect this process.

Temperature and Humidity: The Dynamic Duo

The first and most crucial factor that affects the drying time of PVC glue is temperature. Higher temperatures accelerate the drying process, while lower temperatures slow it down. Extreme temperatures, whether scorching or freezing, can adversely affect both the drying time and the overall bond strength.

Humidity levels also play a significant role in PVC glue drying time. High humidity slows down solvent evaporation, prolonging the drying process. Conversely, low humidity levels facilitate faster evaporation and consequently faster drying. Therefore, it is crucial to consider both temperature and humidity when using PVC glue.

Thickness Matters

The thickness of the glue application is another critical factor affecting drying time. Applying a thicker layer of PVC glue will take longer to dry compared to a thin layer. This is because a thicker layer requires more time for solvents to evaporate fully. To ensure optimal results, follow the manufacturer’s instructions regarding the appropriate amount of PVC glue to apply.

The Type of PVC Glue Matters Too

Different types of PVC glues have varying compositions and formulas, resulting in differences in their drying times. Some glues are designed for faster drying, while others may require more time to set and cure properly. It is important to choose a PVC glue that suits your specific needs and project requirements.

Joint Design and Fit: A Hidden Factor

The design and fit of the joint being glued together can also affect the drying time. Tight-fitting joints allow less air circulation, resulting in slower drying times compared to loosely fitting joints. Additionally, complex joint designs with multiple angles or tight corners may require more time for the glue to reach and bond all the surfaces properly.

Ventilation: The Breath of Fresh Air

Adequate ventilation is essential during the drying process of PVC glue. Good airflow helps in the evaporation of solvents and promotes faster drying. Poor ventilation can prolong the drying time and may even affect the quality of the bond. It is recommended to work in a well-ventilated area or use additional fans to facilitate air circulation.

Surface Preparation: The Foundation for Success

Proper surface preparation is crucial for achieving optimal drying time and bond strength. The surfaces being glued should be clean, dry, and free from any contaminants such as dust, oil, or grease. Any residue on the surface can interfere with the adhesive properties of the PVC glue and prolong the drying time.

Curing Time: The Waiting Game

While PVC glue may appear dry to the touch within a specific timeframe, it is important to note that complete curing takes longer. Curing refers to the process where the PVC glue reaches its maximum bond strength. Most PVC glues require at least 24 hours for full curing, even if they seem dry before that. Restraint is key when it comes to applying pressure or stress to a joint that is not fully cured.

How Long Does It Take for PVC Glue to Dry?

If you’re embarking on a DIY project that involves joining PVC pipes or fittings together, you’ll likely be using PVC glue, also known as solvent cement. But the burning question is, how long does it take for this glue to dry? Well, buckle up because we’re about to dive into the world of PVC glue drying time and give you all the information you need.

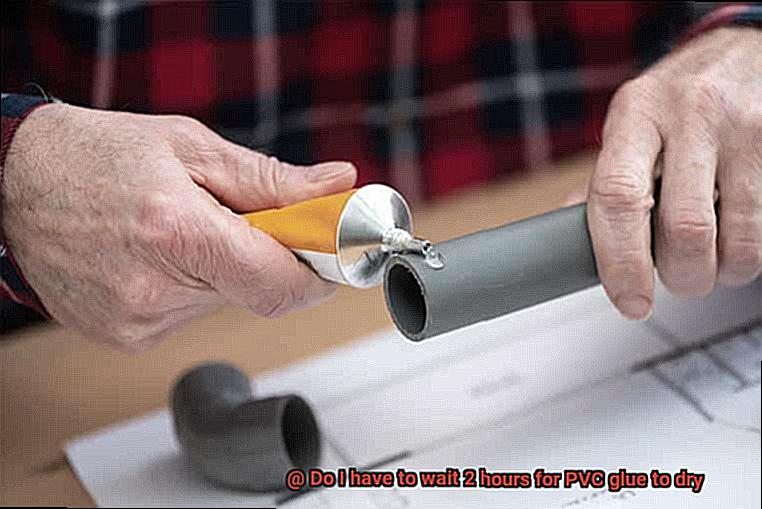

PVC glue is a powerful adhesive specifically designed for bonding PVC surfaces together. It creates a permanent bond that is strong and durable, making it ideal for plumbing projects and other applications. But when it comes to drying time, things aren’t as straightforward as we’d like them to be.

The drying time of PVC glue can vary depending on several factors, including temperature, humidity, and the type of PVC cement used. As a general rule of thumb, it’s recommended to wait at least two hours for the PVC glue to dry before applying any pressure or stress on the joint. This allows enough time for the solvent in the glue to evaporate and the bond to fully set.

However, keep in mind that this two-hour guideline is just an estimate and may not apply in all situations. Why? Because temperature and humidity play a significant role in the drying time of PVC glue. In warmer and drier conditions, the glue may dry faster, while in colder and more humid environments, it may take longer to fully dry. So, it’s essential to take these factors into account when estimating drying time.

But wait, there’s more. Before you start putting pressure on that joint after two hours, there’s one more thing you need to know – curing time. While the surface may feel dry to the touch after a couple of hours, it is highly recommended to wait at least 24 hours before subjecting the joint to any pressure or stress.

Why? Because even though the glue may appear dry, it still needs time to cure fully. Curing is the process during which the bond reaches its maximum strength and durability. Rushing this step can result in a weak bond, leakage, or even failure of the joint over time.

To speed up the drying process, some manufacturers offer fast-drying PVC glues that can dry within minutes. These can be convenient for quick projects, but it’s crucial to carefully read and follow the instructions provided with these products to ensure proper usage and optimal results.

In summary, while waiting for two hours is a general guideline for PVC glue to dry, the actual drying time can vary depending on temperature, humidity, and other factors. It’s crucial to consider these variables and follow the manufacturer’s instructions for the specific PVC glue being used. Additionally, allowing sufficient curing time of at least 24 hours before applying any pressure or stress on the joint is essential for a strong and durable bond.

Is It Necessary to Wait 2 Hours for PVC Glue to Dry?

Joining PVC pipes and fittings requires the use of PVC glue, also known as solvent cement. But how long should you wait for the glue to dry? Is it really necessary to wait a full 2 hours? In this blog post, we’ll explore the science behind PVC glue drying time and explain why waiting is essential for a strong and durable bond.

Understanding PVC Glue Drying Time:

- The Importance of Curing: PVC glue needs time to cure, or harden, before it can withstand pressure or stress. Waiting for a minimum of 2 hours allows the glue to fully bond and create a solid connection that won’t fail over time.

- Factors Affecting Drying Time: Several factors influence the drying time of PVC glue. These include the type of glue used, ambient temperature, humidity levels, and the size of the joint being glued.

- Quick-Drying Formulas: Some PVC glues offer quick-drying formulas that can reduce waiting time to as little as 15 minutes. However, these formulas are best suited for smaller, low-pressure joints and may not provide the same strength for larger or high-pressure applications.

- Manufacturer’s Instructions: It is crucial to read and follow the manufacturer’s instructions for the specific PVC glue being used. Different brands and types of glue may have varying curing times and application instructions.

- Temperature and Humidity Effects: Temperature and humidity play significant roles in drying time. Higher temperatures accelerate drying, while lower temperatures slow it down. Similarly, high humidity levels can prolong curing time.

Why Waiting Matters:

- Joint Integrity: Rushing the drying process can result in a weak bond that may fail under pressure or over time. Waiting for the recommended curing time ensures the integrity of the joint.

- Critical Applications: If the joint will be used in a critical application or subjected to high pressure or stress, it is advisable to wait the full recommended curing time before putting it into service.

- Undisturbed Joint: During the curing process, it’s essential to keep the joint undisturbed. Any movement or stress can compromise the bond and result in a weaker connection.

What Happens if I Don’t Wait for the Recommended Drying Time?

Imagine you’ve just completed a project involving PVC pipes, and you’re eager to test your handiwork. However, before you start celebrating, it’s crucial to understand the consequences of not waiting for the recommended drying time when using PVC glue. Failing to allow sufficient drying time can lead to various issues that extend beyond a simple leaky pipe. This article explores the potential problems that arise from not waiting for the recommended drying time when working with PVC glue.

Weak Connections and Leaks:

Rushing to use or handle glued PVC parts before they are fully dry can result in weak connections prone to breaking and leaking. The recommended drying time allows the glue to bond completely, ensuring a strong and durable connection capable of withstanding the test of time.

Loss of Adhesion:

Disturbing glued joints prematurely can lead to a loss of adhesion. This means that the glue may not stick as effectively, compromising the joint’s integrity and increasing the risk of leaks or failures. Don’t let impatience jeopardize the strength of your connections.

Inadequate Curing:

Curing is a chemical process where the glue transitions from a liquid to a solid state. By not adhering to the recommended drying time, the glue may not have enough time to cure properly. As a result, it could remain tacky or soft, making it vulnerable to damage and deformation.

Compromised Structural Integrity:

Rushing the drying process weakens the overall strength of the bond. The recommended drying time ensures sufficient bonding, enabling joints to withstand pressure, temperature changes, and other environmental factors. Ignoring this time frame risks compromising the structural integrity of your connections.

Difficulty in Adjustments and Modifications:

Once the glue has fully cured, it forms a strong and rigid bond that is challenging to undo without damaging the pipes or fittings. Failing to wait for the recommended drying time can turn adjustments or modifications to your PVC installation into a nightmare.

How Can I Ensure Maximum Strength and Durability of a Joint?

Before you dive in, let’s uncover the secrets to creating joints that are not only strong but also built to withstand the test of time. In this article, we’ll explore the key steps and considerations that will ensure maximum strength and durability of your joints when using PVC glue. From surface preparation to curing time, we’ve got you covered.

Step 1: The Power of Cleanliness

To create a rock-solid bond, start by ensuring your PVC surfaces are pristine. Wipe away any dirt, grease, or contaminants using a solvent such as acetone or isopropyl alcohol. This seemingly small step makes a world of difference in the strength of your joint.

Step 2: Liberally Apply the Glue

Don’t hold back when it comes to glue. Apply a generous amount to both surfaces that will be joined. Using a brush or applicator, spread the glue evenly across the surfaces. Leave no corner untouched to maximize bonding strength.

Step 3: Firmness is Key

Now that the glue is applied, firmly press the two surfaces together. Applying pressure ensures proper adhesion between the PVC pieces. Hold the joint in place for at least 2 hours to allow the glue to set and cure. Patience is a virtue in this step.

Step 4: Primer for Power

For an extra boost in strength and longevity, consider using a primer before applying the PVC glue. Primers soften the PVC surface, allowing for better penetration and adhesion of the glue. This simple step can make a significant difference in the long run.

Step 5: Climate Considerations

Temperature and humidity play a vital role in the drying and curing process of PVC glues. Ensure that your work environment falls within the recommended range provided by the manufacturer. Extreme temperatures or high humidity can compromise the strength and durability of the joint.

Step 6: Timing is Everything

While some glues may dry quickly, curing takes time. Wait at least 24 hours before subjecting the joint to significant stress or load. This allows the glue ample time to fully cure and ensures maximum strength.

What Are Some Tips for Working with PVC Glue?

Working with PVC glue can be tricky, but with the right tips and techniques, you can get the job done. Here are some important things to keep in mind when working with PVC glue:

Preparation is key

Before applying PVC glue, it’s crucial to clean the surfaces to be bonded thoroughly. Use a PVC cleaner and primer specifically designed for PVC pipes to remove any dirt, debris, or moisture. This step ensures a clean surface for optimal adhesion. Make sure to follow the manufacturer’s instructions for cleaning and priming.

Apply the glue evenly

When applying PVC glue, remember that less is more. Apply an even and thin layer of glue on both surfaces that will be joined together. Avoid applying too much glue as it can result in messy joints and weak bonds. Use the appropriate size of applicator or brush that comes with the PVC glue for even application.

Join the pieces immediately

Once you’ve applied the glue, join the pieces together immediately. PVC glue works through solvent welding, where the solvents melt the surfaces of the PVC, creating a strong bond as they cool and solidify. Waiting too long before joining the pieces can weaken the bond. Align the pipes or fittings correctly before the glue sets, as it sets quickly.

Use clamps or supports

To ensure a secure bond, use clamps or supports to hold the pieces together while the glue dries. This prevents any movement or shifting that could compromise the bond. Adjust and align the pieces before the glue sets to ensure proper positioning.

Allow proper drying time

While PVC glue sets quickly, it’s important to allow at least 24 hours for the bond to fully cure before subjecting it to pressure or stress. This ensures maximum strength and durability. Be patient and avoid rushing this crucial step.

In addition to these tips, it’s important to consider temperature and humidity levels when working with PVC glue. Higher temperatures and lower humidity can accelerate drying time, while lower temperatures and higher humidity can slow it down. Keep these factors in mind and plan your project accordingly.

Safety is also important when working with PVC glue. Always follow the manufacturer’s instructions and use protective gear such as gloves and eye protection. Work in a well-ventilated area to avoid inhaling the fumes.

What Are the Benefits of Waiting for PVC Glue to Fully Cure?

In this blog post, we will explore the benefits of allowing PVC glue to fully cure before using it. Patience truly is a virtue when it comes to creating strong and reliable connections in your pipe system.

So, grab a cup of coffee and let’s dive into the art of waiting.

Strong and Durable Connections:

By waiting for PVC glue to fully cure, you ensure that the adhesive reaches its maximum strength. This translates into stronger and more durable connections between your PVC pipes or fittings. After all, who wants weak joints that might leak or fail over time? Not you. Take pride in knowing that your pipe system will stand the test of time.

Leak Prevention:

Rushing the curing process can lead to weak joints that are prone to leaks. By giving the glue enough time to cure completely, you minimize the risk of leaks in your pipe system. Trust us, preventing leaks now will save you a lot of headaches in the future. Enjoy peace of mind knowing that your pipes are watertight.

Resistance to Pressure and Stress:

Fully cured joints can withstand higher levels of pressure and stress. Whether you’re dealing with plumbing, irrigation, or industrial systems, waiting for PVC glue to fully cure ensures that your connections can handle the demands of everyday use. No need to worry about unexpected bursts or failures. Feel confident in the strength and reliability of your pipe system.

Avoidance of Chemical Reactions:

PVC glue often contains solvents that help with adhesion. Waiting for full curing time allows these solvents to evaporate completely, reducing the risk of chemical reactions with the PVC material. This ensures a secure bond without any unwanted side effects. Eliminate any concerns about potential damage or degradation caused by chemical interactions.

Minimized Risk of Joint Movement:

During installation or subsequent use, pipes may be subjected to external forces like vibration or temperature changes. By allowing PVC glue to fully cure, you minimize the risk of joint movement or displacement. Say goodbye to wobbly connections. Experience the stability and reliability of firmly secured joints.

Convenience and Peace of Mind:

Following the manufacturer’s recommended curing time offers convenience and peace of mind. By patiently waiting for the glue to cure, you can proceed with further installation or use knowing that your PVC joints are secure and reliable. Now that’s a load off your mind. Embrace the freedom to move forward confidently in your project.

How Can Environmental Conditions Affect the Drying Time of PVC Glue?

The drying time of PVC glue is a delicate dance influenced by a myriad of environmental conditions. In this captivating exploration, we will dive into the scientific intricacies of how temperature, humidity, and airflow can sway the drying time of PVC glue. So, grab your lab coat and prepare to be enthralled as we unravel the secrets behind this captivating phenomenon.

Temperature: Igniting the Flames of Drying

Temperature takes center stage in determining the drying time of PVC glue. Like a fiery conductor, higher temperatures intensify the process by accelerating solvent evaporation. If you’re in a hurry, creating a warm environment becomes a game-changer. But beware. Excessive heat can cause uneven drying or even compromise the integrity of the glue itself.

Humidity: The Stealthy Saboteur

Humidity lurks in the shadows, ready to sabotage the drying time of PVC glue. High humidity saturates the air with moisture, hindering solvent evaporation and prolonging drying time. Conversely, low humidity creates an ideal habitat for swift and efficient drying. So, if you reside in a humid climate, consider employing dehumidifiers or air conditioners to expedite the process.

Airflow: The Whirlwind Beneath the Wings

Did you know that airflow can impact how swiftly PVC glue dries? Adequate airflow acts as a gentle whirlwind, whisking away evaporating solvents and propelling faster drying. However, stagnant air stifles evaporation and drags out the drying time. Yet tread carefully – excessive airflow may lead to uneven drying or even premature curing.

Putting it All Together:

To master the art of optimizing PVC glue’s drying time, one must harmonize these environmental factors. For those in a rush, a slight increase in temperature or the cautious use of a heat gun can prove instrumental. Combatting high humidity becomes a breeze with the aid of dehumidifiers or air conditioning units. And let us not forget the power of airflow – proper ventilation ensures smooth and seamless progress.

Conclusion:

wxTq_5szm4g” >

Also Read: How Long Does PVC Glue Take to Dry?

Conclusion

According to conventional wisdom, it is recommended to wait for approximately 2 hours for PVC glue to dry. However, this waiting period can vary depending on various factors such as the type of glue used, environmental conditions, and the size of the project. It’s important to note that rushing the drying process may compromise the effectiveness and durability of the bond. So, while waiting for two hours might seem like a long time, it’s crucial to exercise patience and allow ample time for the glue to set properly.

Why is this waiting period necessary? Well, PVC glue typically contains solvents that need time to evaporate completely. These solvents play a vital role in creating a strong bond by softening and melting the PVC surfaces before they harden together. Rushing this process could result in weak joints or even complete failure of the bond.

Imagine spending hours meticulously assembling your PVC project only to have it fall apart because you didn’t give the glue enough time to dry properly. Patience truly is a virtue when it comes to working with PVC adhesive.

Now, I know waiting around for two hours can feel like an eternity, especially when you’re eager to see your finished project come together. But trust me when I say that taking shortcuts in this process will only lead to disappointment in the long run.

So, what can you do during these seemingly endless two hours? Use this time wisely. Double-check your measurements, tidy up your work area, or maybe take a well-deserved break and grab a cup of coffee. Remember, good things come to those who wait (and properly adhere their PVC joints).

In conclusion, while waiting for two hours may seem like an eternity when using PVC glue, it is essential for ensuring a strong and durable bond between your materials. By exercising patience and allowing ample drying time, you’ll be rewarded with a sturdy finished product that will stand the test of time.