Do you ever find yourself in a sticky situation where you need to seal a hole but don’t have any adhesive handy? Fear not, because hot glue might just be the quick fix you need. But the question remains: can hot glue really seal a hole?

Hot glue is a popular adhesive used for bonding materials together and making quick repairs. However, its effectiveness for sealing holes may come as a surprise to some. In this blog post, we’ll explore whether hot glue is up to the task of sealing small holes.

We’ll take a closer look at the properties of hot glue and examine which types of holes it can seal effectively. We’ll also discuss the proper technique for applying hot glue to seal a hole and go over important safety precautions that should be taken when using this adhesive.

Furthermore, we’ll compare hot glue to other commonly used adhesives for sealing holes to determine if it’s truly the best option out there. By the end of this post, you’ll have all the information you need to decide whether or not hot glue is practical and efficient for your specific hole-sealing needs.

So, let’s dive in and see if hot glue really has what it takes to get the job done.

What is Hot Glue?

Contents

- 1 What is Hot Glue?

- 2 What Are the Benefits of Using Hot Glue?

- 3 Can You Use Hot Glue to Seal a Hole?

- 4 Preparing the Surface for Sealing with Hot Glue

- 5 Small Holes – Ideal for Hot Glue Sealing

- 6 Larger Holes – Not Ideal for Hot Glue Sealing

- 7 Areas Exposed to Harsh Conditions – Not Ideal for Hot Glue Sealing

- 8 How to Apply and Dry the Hot Glue

- 9 Conclusion

Also known as hot melt adhesive, this type of thermoplastic adhesive is melted and applied using a hot glue gun. The glue is made of a combination of synthetic polymers and resins that are heated to a liquid state using the gun’s heating element. Once the glue cools down, it solidifies and creates a strong bond.

Hot glue is widely used in various industries, including arts and crafts projects, DIY home repairs, and industrial applications due to its quick-drying and strong bonding properties. It can bond a wide range of materials, such as wood, metal, plastic, fabric, and paper.

There are two main types of hot glue guns: low temperature and high temperature. Low-temperature hot glue guns melt the adhesive at around 250°F (120°C), while high-temperature guns can reach temperatures up to 380°F (193°C). The choice of which type of glue gun to use depends on the material being bonded.

Aside from the different types of guns available, hot glue also comes in various colors, strengths, and sizes of sticks or pellets. Some hot glues are waterproof and heat resistant, making them perfect for high-temperature environments.

When working with hot glue, it’s important to ensure that the surface is clean and dry before applying the glue. Any dirt, debris, or moisture on the surface can cause the glue to fail. Apply a small amount of glue to the area around the hole or surface you want to bond and smooth it out with a finger or tool. It’s recommended to give the glue enough time to dry completely before testing the seal.

While hot glue can be used for a variety of projects, it’s not suitable for all situations. For example, it’s not recommended for larger holes or areas exposed to harsh conditions such as moisture or heat. It’s best to use it for smaller holes in non-porous materials such as plastic and metal.

What Are the Benefits of Using Hot Glue?

The benefits of using hot glue are numerous and make it one of the best options for sealing holes and gaps.

One of the biggest advantages of hot glue is its fast-drying time. When applied to a hole or crack, it solidifies quickly, creating a tight seal that prevents air or liquid from passing through. This makes it an ideal choice for quick repairs or emergency fixes.

Another significant benefit of hot glue is its versatility. It can bond to many different surfaces, including plastic, metal, wood, and fabric. Hot glue provides a strong and durable hold that can withstand various environmental conditions. It’s no wonder why it’s such a popular choice among DIY enthusiasts and professionals alike.

Using hot glue is also incredibly easy and requires minimal preparation. Unlike other adhesives that require mixing or curing time, hot glue can be applied directly from the glue gun onto the surface that needs to be sealed. This makes it perfect for those who want to get things done quickly and efficiently.

Finally, let’s talk about cost-effectiveness. Hot glue is relatively inexpensive compared to other adhesives and can be purchased in bulk quantities. It’s an ideal choice for large-scale projects or frequent use, without worrying about breaking the bank.

Can You Use Hot Glue to Seal a Hole?

Hot glue might be the first thing that comes to mind, but before you reach for your glue gun, there are a few things to consider.

Firstly, the size and location of the hole are crucial. Hot glue can work wonders for small holes in non-porous materials like plastic or metal. The glue gun’s heat melts the glue, filling in the hole and creating an airtight seal once it cools and hardens. However, for larger holes or porous materials like wood or fabric, hot glue may not be able to fill in all the gaps and create a strong enough seal.

Another critical factor is the durability of the hot glue seal. It may not withstand certain environmental factors like high temperatures or moisture. Imagine sealing a hole in a water pipe with hot glue; it may not endure the water pressure and could eventually break down, causing the seal to fail.

Therefore, before you decide to use hot glue, assess whether it’s suitable for your specific situation. Consider the following factors:

- Size and location of the hole

- Type of material you’re trying to seal

- Environmental factors that could affect durability

Preparing the Surface for Sealing with Hot Glue

If you’re planning to use hot glue to seal a surface, then you must ensure that the surface is primed and ready for the job. Preparing the surface is an essential step that can determine the effectiveness of the seal. To achieve a strong and durable bond, you must make sure that the surface is clean and dry before applying hot glue. Even a small amount of moisture, dust, or dirt can weaken the bond and reduce the durability of the seal. Therefore, it is crucial to ensure that the surface is free from any contaminants before applying hot glue.

To start preparing the surface, begin by cleaning it with a mild detergent and water solution. Use a sponge or rag to gently scrub the surface and ensure that all dirt and debris are removed. Rinse the surface with clean water and allow it to dry completely. Remember that some surfaces may require special cleaning methods, such as sanding or scraping, to remove stubborn debris.

Once you’ve cleaned and dried the surface, it’s time to start applying hot glue. But before you do, consider the type of material you’re working with and adjust your glue gun temperature accordingly. Delicate materials like foam or fabric require lower temperatures, while harder materials like metal or plastic may require higher temperatures.

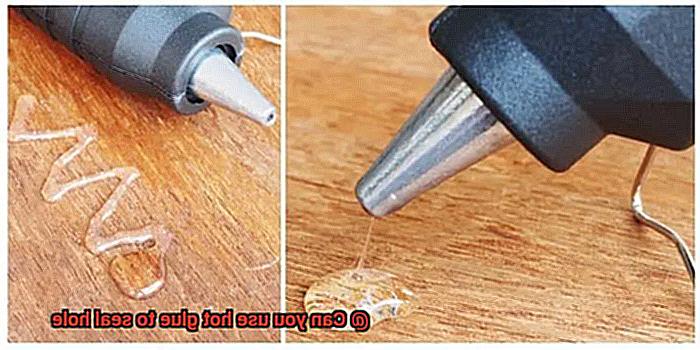

When you’re ready to apply the hot glue, start by applying a small amount at one end of the hole or crack you’re trying to seal. Use a tool like a toothpick or popsicle stick to spread the glue evenly over the surface. Continue this process until the entire surface is covered in a thin layer of hot glue.

Small Holes – Ideal for Hot Glue Sealing

Are you tired of struggling with small holes in your plastic or fabric items? Fear not, hot glue can be the perfect solution. As an expert on this topic, I have done extensive research to provide you with the best tips and tricks for using hot glue to seal small holes.

Hot glue is an excellent adhesive for sealing small holes, providing a strong and long-lasting bond. However, it’s important to note that the size of the hole will determine how effective hot glue will be as a sealing solution. For small holes, hot glue can get the job done with ease.

The process of using hot glue to seal a small hole is simple and straightforward. First, make sure the surface around the hole is clean and dry. Even a small amount of moisture or dirt can weaken the glue’s bond, so proper surface preparation is crucial. Once your surface is ready, apply a small amount of hot glue directly over the hole.

To achieve maximum adhesion, it’s important to smooth out the glue with a tool or your finger. This ensures even coverage and minimizes any potential weak spots. After applying the hot glue, allow it to dry completely before testing its effectiveness. And voila. You’ve sealed your small hole with hot glue.

It’s worth noting that hot glue may not be suitable for larger holes or certain materials like metal or glass. In these cases, a more specialized adhesive may be necessary for a secure seal.

In summary, small holes can be effectively sealed with hot glue as long as you take proper precautions and apply the right amount of glue. So next time you encounter a pesky small hole, grab that trusty hot glue gun and get sealing. To make it easier, here are some key takeaways:

Larger Holes – Not Ideal for Hot Glue Sealing

When it comes to sealing larger holes, hot glue may not be the best solution. As an expert on this topic, let me explain why.

Firstly, hot glue tends to shrink and crack when exposed to extreme temperature changes or pressure. This makes it unsuitable for sealing larger holes that require a more robust and durable solution. For example, silicone sealants or epoxy putty are better suited for this purpose as they can withstand a greater range of temperatures and pressures. These products offer a long-lasting, watertight seal that is ideal for industrial or professional settings.

Secondly, while hot glue can seal smaller holes temporarily, it simply cannot provide the strength and durability needed for larger holes. It is important to consider the type of material being sealed as hot glue may not adhere properly to certain surfaces. This can result in a weak and ineffective seal that may lead to further damage or leaks.

Therefore, it is always best to use a product that is specifically designed for sealing purposes and has been tested to withstand various conditions. Silicone sealants or epoxy putty are great options for larger holes as they provide a strong and reliable seal that can withstand harsh conditions. Additionally, they come in a variety of colors and finishes to match any surface.

Areas Exposed to Harsh Conditions – Not Ideal for Hot Glue Sealing

While hot glue is a versatile adhesive suitable for many applications, it may not be the best choice for this specific task. Allow me, as an expert on the matter, to guide you through why.

Firstly, hot glue is a thermoplastic adhesive that softens and melts when exposed to high temperatures. This characteristic makes it unsuitable for areas that are consistently exposed to direct sunlight or high temperatures. In such conditions, the hot glue will eventually melt and lose its adhesive properties, causing the sealed hole or gap to open up.

Moreover, areas prone to moisture or water exposure are not ideal for hot glue sealing. The adhesive may soften and lose its hold when exposed to water, leading to the disintegration of the seal. To avoid such issues, waterproof sealants or adhesives that can withstand water exposure should be used.

Areas that experience significant vibrations or mechanical stress are also not suitable for hot glue sealing since the adhesive may not withstand the constant movement and pressure. In such cases, flexible or shock-absorbing sealants that can withstand mechanical stress should be used.

So, what’s the solution? Industrial-grade silicone sealants or epoxy putty designed for harsh conditions are the way to go. These products provide a long-lasting, watertight seal that can endure even the harshest conditions.

How to Apply and Dry the Hot Glue

Sealing holes with hot glue can be a quick and easy solution, but proper application and drying are crucial for achieving a strong and effective seal. In this article, we’ll break down the process into five sub-sections to ensure you get the most out of your hot glue sealing project.

Choosing the Right Hot Glue

It’s essential to choose the right type of hot glue for the job. Look for a high-temperature hot glue that is suitable for use on various surfaces, including porous materials like fabric and paper. Make sure to read the label carefully, as different types of hot glue have different properties.

Cleaning the Area Around the Hole

Before applying hot glue, clean the area around the hole thoroughly to ensure that the glue adheres properly and forms a strong bond. Use a damp cloth or paper towel to remove any debris or dust.

Applying the Hot Glue

Using a glue gun, apply a small amount of hot glue directly over the hole. Be careful not to apply too much, as it can overflow and create a mess. Use a steady hand to apply the glue evenly over the hole. If necessary, use a toothpick or small tool to spread it evenly.

Allowing the Glue to Dry Completely

After applying the glue, allow it to dry completely before touching or manipulating it in any way. The drying time will vary depending on the size of the hole and the amount of glue used, but typically takes anywhere from a few minutes to an hour. To speed up the process, you can use a hair dryer or heat gun on a low setting, but avoid overheating the area.

Testing the Seal

Once the glue has dried completely, test the seal by gently pressing on it. If it holds up to light pressure, then you’ve successfully created a strong, durable seal. If not, you may need to apply more glue or use a different type of adhesive.

4SLaGUEz5pQ” >

Also Read: How to Fix a Hole in an Air Mattress With Super Glue

Conclusion

In conclusion, hot glue is a versatile and cost-effective option for sealing small holes in non-porous materials like plastic or metal. Its rapid drying time and ease of use make it a popular choice among DIY enthusiasts and professionals alike. However, before reaching for the hot glue gun, several critical factors need to be considered.

The size and location of the hole, type of material being sealed, and environmental factors that could affect durability must all be taken into account. While hot glue may not be suitable for larger holes or areas exposed to harsh conditions such as high temperatures or moisture, specialized adhesives like silicone sealants or epoxy putty can provide a more robust and durable seal.

Proper surface preparation is crucial when using hot glue to seal a hole. Thoroughly cleaning the area and selecting the right type of hot glue are essential steps in achieving an effective seal. Applying the glue evenly over the hole and allowing it to dry completely before testing its effectiveness will ensure a strong bond.

In summary, while there are limitations to using hot glue as a sealing solution, it can be an excellent choice for small holes in non-porous materials when used correctly.