Picture this: you’re waist-deep in a DIY project, scratching your head over how to seamlessly and securely connect those pesky wires. Well, hold onto your glue guns because we’ve got a surprising trick up our sleeves – hot glue. That’s right, that trusty adhesive we all know from our artsy endeavors might just be the secret weapon for wire connections.

In this blog post, we’re diving deep into the nitty-gritty of this sticky technique to find out if hot glue can truly hold its own. Get ready for an eye-opening journey through the uncharted territory where creativity meets practicality.

What is Hot Glue?

Contents

- 1 What is Hot Glue?

- 2 Can You Use Hot Glue to Connect Wires?

- 3 Advantages of Using Hot Glue for Wire Connections

- 4 How to Use Hot Glue to Connect Wires

- 5 Limitations of Using Hot Glue for Wire Connections

- 6 Alternatives to Using Hot Glue for Wire Connections

- 7 Safety Considerations When Using Hot Glue for Wire Connections

- 8 Conclusion

Hot glue, also known as hot melt adhesive, is a versatile and convenient adhesive that is widely used in crafts, DIY projects, and various other applications. Its fast-setting nature, strong bond strength, and resistance to moisture make it an essential tool for crafters, DIY enthusiasts, and professionals. In this article, we will explore the properties, uses, and limitations of hot glue.

Properties of Hot Glue:

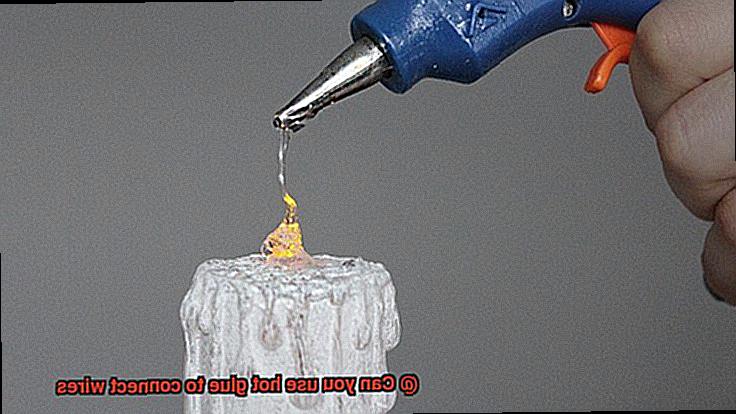

Hot glue is primarily composed of a synthetic polymer called ethylene-vinyl acetate (EVA), which has a low melting point ranging from 120 to 180 degrees Celsius (250 to 360 degrees Fahrenheit). This unique property allows it to be easily melted and applied using a hot glue gun. Other additives can be included in the formulation to enhance its adhesive properties, flexibility, or color.

Bonding Strength and Versatility:

Hot glue forms a strong and durable bond between various materials such as wood, fabric, metal, plastic, and even some electronic components when properly applied. Its ability to bond different materials together makes it a versatile choice for crafting, home repairs, packaging, floral arrangements, and even some industrial applications.

Resistance to Moisture and Temperature Variation:

One of the notable advantages of hot glue is its resistance to moisture. It can be used both indoors and outdoors without losing its adhesive properties. Additionally, hot glue can withstand moderate temperature variations without compromising its bonding strength. However, it should be noted that exposure to extreme temperatures or UV radiation may cause hot glue bonds to become brittle over time.

Uses of Hot Glue:

Hot glue finds its application in a wide range of projects. Crafters utilize it for attaching embellishments, creating 3D structures, and securing fabrics. DIY enthusiasts rely on hot glue for fixing loose items or bonding lightweight materials in home repairs. In packaging, hot glue is useful for sealing boxes or attaching labels. Its versatility makes it a go-to adhesive for various creative and practical endeavors.

Limitations of Hot Glue:

While hot glue offers numerous benefits, it does have limitations. It may not be suitable for applications requiring high heat resistance or long-term durability. For wire connections, hot glue can be used temporarily or for non-electrical purposes, but soldering is the preferred method for strong and reliable connections.

Can You Use Hot Glue to Connect Wires?

Hot glue is a versatile adhesive commonly used in crafts and DIY projects. Its quick-drying and strong bonding properties make it a popular choice for various applications. However, when it comes to connecting wires, hot glue may not be the best option. Let’s dive into the advantages and disadvantages of using hot glue for wire connections.

Advantages:

- Ease of use: Hot glue is easy to apply and requires minimal tools or equipment. It can be melted with a glue gun and quickly solidifies upon cooling.

- Availability and affordability: Hot glue and glue guns are widely available at craft stores, hardware stores, and online retailers. They are also relatively inexpensive compared to other wire connection methods.

Disadvantages:

- Lack of conductivity: Hot glue is not designed for electrical connections and does not conduct electricity. This means it does not allow electrical current to flow through it, making it unsuitable for wire connections.

- Heat damage: The high temperature of the glue gun can melt the insulation of the wires, leading to short circuits or other electrical problems. This can be a safety hazard and may cause damage to the wires or connected devices.

- Lack of long-term reliability: Hot glue tends to become brittle over time, especially when exposed to temperature changes or mechanical stress. This can result in the wires becoming loose or disconnected, leading to intermittent or faulty connections.

Alternatives:

- Soldering: Soldering is a popular method for connecting wires. It involves melting a metal alloy called solder onto the wires, creating a strong bond and ensuring good conductivity. Soldered connections are durable, resistant to temperature changes and mechanical stress, and provide reliable electrical connections.

- Crimping: Crimping involves using specially designed connectors that securely hold the wires together without damaging their insulation. This method is commonly used in electrical installations and provides secure and reliable wire connections.

- Wire nuts, terminal blocks, and connectors: These are alternative methods specifically designed for wire connections. They provide secure and reliable electrical connections and are available in a variety of sizes and types to suit different applications.

Advantages of Using Hot Glue for Wire Connections

Today, we embark on an exciting journey into the realm of hot glue and its incredible advantages when it comes to wire connections. Whether you’re a seasoned pro or just starting your creative adventure, hot glue can be your ultimate sidekick, offering a secure bond, flexibility, insulation, ease of use, quick drying time, and even a touch of reversibility. Let’s delve into why hot glue is the perfect choice for connecting wires.

Advantage 1: A Bond that Can’t be Broken

Hot glue creates an unbreakable bond between wires when applied correctly. Say goodbye to loose connections and embrace the security and durability of a joint that ensures optimal conductivity. With hot glue, your hard work won’t fall apart.

Advantage 2: Embracing Flexibility in Motion

Unlike other adhesives, hot glue possesses a unique flexibility. This means that even if your wires experience movement or vibration, the adhesive won’t crack or break. It’s like giving your wires the freedom to dance without compromising their connection. Now that’s cool.

Advantage 3: The Magic of Insulation

Hot glue acts as a protective shield around wire connections, safeguarding them from moisture, dust, and other contaminants. This insulation property becomes particularly valuable when working outdoors or in humid environments where corrosion poses a threat to your connections. Keep those wires safe and sound.

Advantage 4: Simplicity at Its Finest

Hot glue is a DIYer’s dream come true because it’s incredibly simple to use. Armed with just a hot glue gun, you can apply the adhesive quickly and effortlessly. No need for specialized tools or equipment – it’s all about convenience and accessibility.

Advantage 5: The Need for Speed

Time is of the essence, my friend, and hot glue understands that perfectly. Unlike other glues that take ages to dry, hot glue dries within minutes. This means you can complete your wire connection projects in record time and get back to enjoying the fruits of your labor. Efficiency at its finest.

Advantage 6: Reversibility for the Win

We all make mistakes, and sometimes adjustments or repairs are necessary for our wire connections. Fear not, because hot glue offers a degree of reversibility. If needed, you can remove or reposition the adhesive without causing damage to the wires or other components. It’s like having a safety net for your DIY adventures.

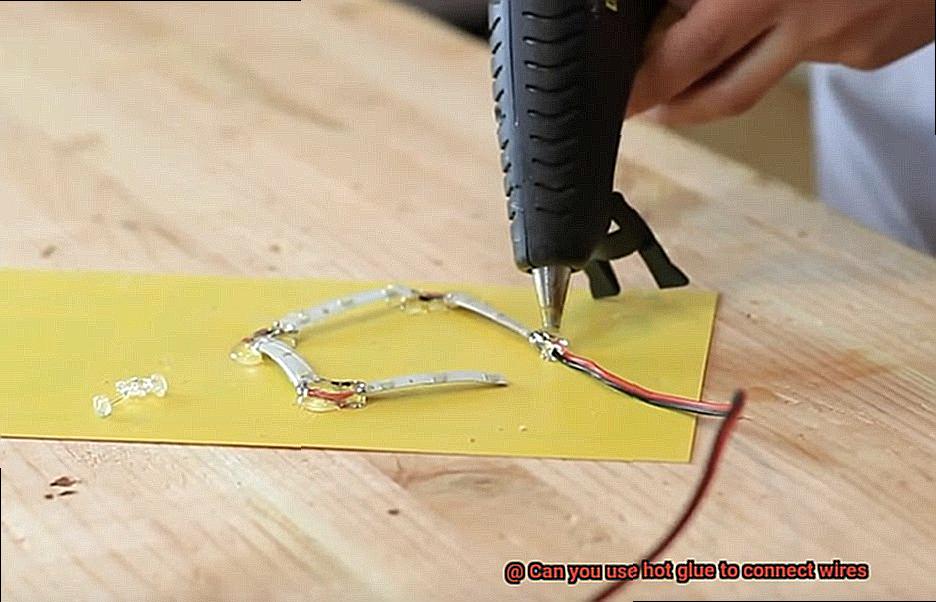

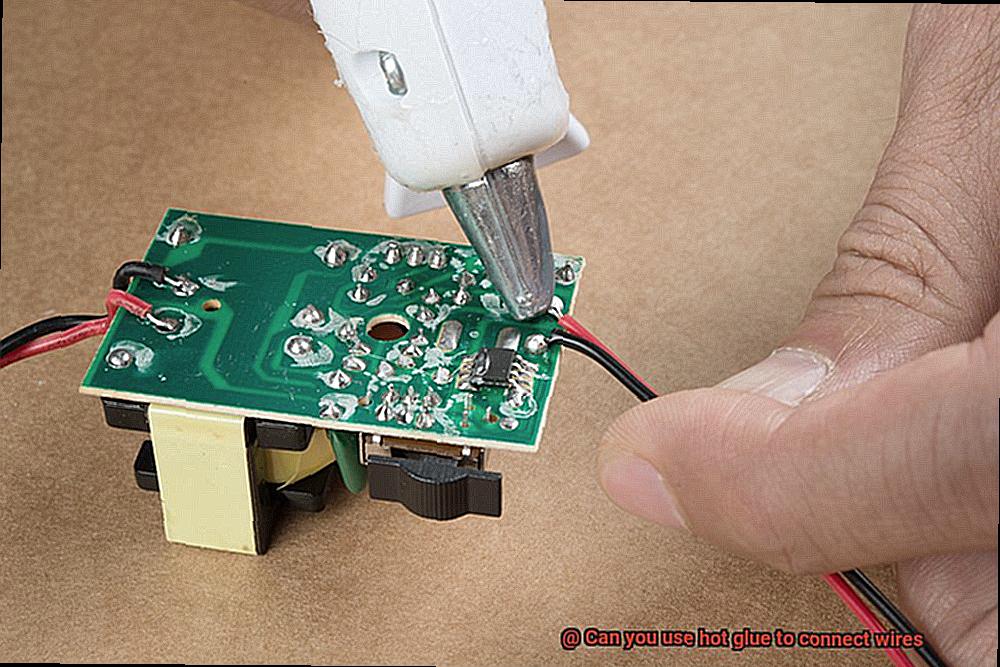

How to Use Hot Glue to Connect Wires

Hot glue is a versatile adhesive that can be found in many craft rooms and DIY toolboxes. While it’s commonly used for sticking things together, it can also be used to connect wires. This blog post will guide you through the process of using hot glue to connect wires, discussing its advantages, limitations, and safety considerations.

Advantages of Using Hot Glue:

Using hot glue to connect wires offers several advantages. Firstly, it’s a simple and fast method that requires only a hot glue gun and glue sticks. Secondly, hot glue provides a strong bond, especially for low voltage or temporary connections. Lastly, it acts as a protective layer, safeguarding the connection from moisture and other environmental factors.

Limitations and Safety Considerations:

Despite its benefits, hot glue does have limitations. It is not conductive, so it should only be used for low voltage applications or non-critical connections. Additionally, hot glue has limited temperature resistance and may not hold up well in high heat or high current situations.

Using Hot Glue to Connect Wires:

To use hot glue for wire connections, start by stripping the insulation off the ends of the wires to expose the bare metal conductors. Apply a small amount of hot glue to one of the exposed conductors while it’s still warm and pliable. Then quickly press the other wire’s exposed conductor onto the hot glue. Hold the wires together until the glue cools and hardens, creating a secure connection.

When to Consider Other Methods:

It’s important to assess your project’s specific needs before deciding to use hot glue as a wire connector. If you require a more durable or reliable connection, soldering or using wire connectors may be a better option. These methods provide stronger electrical connections and can withstand higher temperatures and current flow.

Limitations of Using Hot Glue for Wire Connections

Hot glue is often hailed as the superhero of the crafting world, with its versatility, quick application, and strong bond. However, when it comes to wire connections, this trusty sidekick has its limitations. In this blog post, we will delve into the world of hot glue and explore why it may not be the best choice for wire connections. Prepare yourself for an electrifying adventure as we uncover the drawbacks of using hot glue in this captivating journey.

The Non-Conductive Conundrum:

One of the major limitations of hot glue is its lack of electrical conductivity. Being an insulator, hot glue hinders the flow of electricity. When used to connect wires, it can disrupt the transmission of electrical signals or power. Therefore, if you are working with wires that require efficient electricity transfer, hot glue might not be the optimal option.

Melting and Brittle Bonds:

Another limitation of hot glue is its vulnerability to heat. While it is designed to melt at high temperatures and solidify quickly upon cooling, this property can backfire when exposed to heat generated by the wires themselves or in high-temperature environments. In such instances, hot glue may soften or even melt, resulting in loose or unstable wire connections. Conversely, in colder temperatures, hot glue becomes brittle and prone to cracking, weakening the connections.

Lackluster Mechanical Strength:

Although hot glue is excellent for crafts, it falls short when it comes to providing mechanical strength for wire connections. If there is movement or stress on the connections, hot glue may not offer sufficient support or stability. This can lead to loose or detached wires, potentially causing malfunctions or safety hazards in electronic devices.

Irreversible Wonders:

Once applied, hot glue becomes a permanent fixture. This lack of reversibility poses challenges during repairs or modifications. Removing hot glue without damaging the wires or components can be a daunting and time-consuming task, making it less than ideal for situations that require flexibility.

Not a One-Size-Fits-All Solution:

Lastly, hot glue may not be suitable for all types of wires or applications. When wires are exposed to moisture or chemicals, hot glue may not provide adequate protection against corrosion or contamination. In such cases, alternative methods like soldering or using specialized connectors may be more appropriate.

Alternatives to Using Hot Glue for Wire Connections

While hot glue may be your go-to sidekick for many projects, prepare to be astonished by a host of alternatives that will take your wire connections to new heights. So buckle up and get ready to unleash the power of these captivating alternatives.

Electrical Tape:

Imagine a superhero cape for your wires – that’s electrical tape. This flexible and easy-to-use option is specifically designed to insulate and protect electrical wires. It wraps around your wires, providing a secure connection while keeping them safe. Just remember, it may not have the super strength for high-stakes projects.

Heat Shrink Tubing:

Prepare to witness a magical transformation with heat shrink tubing. This thermoplastic material tightens around your wires when heated, creating a protective seal that shields against moisture and abrasion. With a flick of a heat gun or lighter, you’ll witness its superpower in action.

Wire Nuts or Connectors:

In the realm of wire connections, wire nuts or connectors are the unsung heroes. With their internal threads and plastic caps, they twist onto your wires, creating a bond that’s as strong as family ties. However, they may need some extra space due to their bulkiness.

Crimp Connectors:

Enter the arena of strength and security with crimp connectors. These connectors feature metal sleeves that crimp onto your wires, ensuring excellent conductivity and durability. But beware, you’ll need the right tools and skills to master this technique.

Soldering:

Prepare to wield the power of fire and metal with soldering. This method creates an unbreakable bond by melting solder onto your wires, guaranteeing exceptional conductivity and durability. However, it requires skill and specialized equipment, making it the secret weapon for the crafting elite.

Alligator Clips or Banana Plugs:

For temporary connections in the world of prototyping or testing, alligator clips and banana plugs are the trusty sidekicks you need. Alligator clips clamp onto your wires with their tooth-like jaws, while banana plugs securely insert into a banana-shaped socket. However, keep in mind that they may not be suitable for permanent installations.

Safety Considerations When Using Hot Glue for Wire Connections

Hot glue is a popular choice for wire connections in craft and DIY projects, but it’s important to prioritize safety. In this article, we will explore the safety considerations involved when using hot glue for wire connections.

By following these guidelines, you can ensure successful and secure wire connections while keeping yourself safe. So, let’s dive in and discover the key safety considerations when working with hot glue.

Electrical Shorts and Fires:

- Hot glue is not conductive, so it doesn’t provide electrical insulation.

- Insulate wires properly with electrical tape or heat shrink tubing to prevent potential pathways for current flow.

- This reduces the risk of electrical shorts and fires.

Temperature Hazards:

- Hot glue guns operate at high temperatures (200 to 400°F).

- Avoid touching hot glue directly or getting too close to the nozzle to prevent burns.

- Handle the gun with caution and prioritize safety while working with hot glue.

Ventilation Matters:

- Hot glue emits fumes that can irritate the respiratory system.

- Work in a well-ventilated area or use a fan to dissipate fumes and minimize health risks.

- Let fresh air flow through open windows during your crafty adventures.

Precision and Accuracy:

- Excessive amounts of hot glue result in messy and bulky wire connections.

- Aim for a thin and even layer of hot glue to secure wires without excessive buildup.

- This ensures both functionality and aesthetics of your project remain top-notch.

Not a Permanent Solution:

- Hot glue may weaken over time, leading to loose or unstable wire connections.

- Regularly inspect and maintain connections made with hot glue, especially for vibrating or moving applications.

- Consider alternative methods for more secure and durable solutions if deterioration or instability is observed.

kFG8LIXTEDw” >

Also Read: Is Hot Glue Conductive?

Conclusion

In conclusion, while hot glue may seem like a convenient solution for connecting wires in DIY projects, it falls short in several important aspects. Sure, hot glue has its merits – it’s easy to use, widely available, and won’t break the bank. It forms a sturdy bond and provides insulation to safeguard wires from moisture and unwanted substances. Plus, it dries in a jiffy and can be undone if needed.

But let’s not overlook its limitations when it comes to wire connections. The truth is, hot glue isn’t conductive. That means it won’t allow electricity to flow through it efficiently – not exactly ideal for applications that require smooth electrical current transfer.

And here’s another setback: hot glue doesn’t play well with heat. Expose it to high temperatures generated by the wires or place it in a scorching environment, and you might find yourself dealing with a gooey mess as the glue softens or melts away.

That’s not all – hot glue lacks the mechanical strength necessary for wire connections that experience movement or stress. Over time, this adhesive can become brittle, leading to loose or unstable connections that put your project at risk. And let’s not forget how tricky removing hot glue can be without causing damage to your precious wires or components.

There are alternative methods that can save the day. Soldering, crimping, wire nuts or connectors, electrical tape, heat shrink tubing – these options offer stronger electrical connections and greater durability in various applications.

Ultimately, choosing the right method for your wire connections boils down to your project’s specific needs. Take into account factors like conductivity requirements, temperature resistance, mechanical stability, and ease of reversibility or repairability before making your decision.