Assembling these miniature marvels is an art form in itself, with enthusiasts constantly seeking out new ways to build their rockets with ease. And amidst the sea of adhesive options, one question burns brighter than the rest: Can hot glue hold its own in the realm of model rocket construction? Buckle up, my fellow rocketeers, as we embark on a thrilling journey through the captivating world of hot glue and model rockets.

Now, let’s be real – hot glue has always been a bit of a wild card when it comes to professional builders. Some swear by its speedy bonding powers, claiming it simplifies the assembly process like nothing else. But others raise an eyebrow and wonder if this sticky substance can withstand the forces of launch and flight.

So, here’s the deal: we’re going to dive headfirst into this debate, exploring both the casual DIY perspective and tapping into the wisdom of seasoned rocketry experts.

Get ready for some myth-busting action as we uncover the truth about using hot glue for model rockets. We’ll weigh up the pros and cons, separating fact from fiction along the way. Whether you’re just starting out on your rocket-building journey or you’ve been launching these bad boys for years, this exploration will leave no stone unturned. So buckle up tight, ignite your curiosity engines, and prepare to blast off into a world where hot glue becomes more than just a crafty tool – it becomes a potential game-changer for your next model rocket masterpiece.

What is Hot Glue?

Contents

- 1 What is Hot Glue?

- 2 Advantages of Hot Glue

- 3 Disadvantages of Using Hot Glue for Model Rockets

- 4 Alternatives to Hot Glue for Model Rockets

- 5 How to Choose the Right Adhesive for Your Model Rocket

- 6 Proper Surface Preparation for Model Rocket Assembly

- 7 Application Techniques for Adhesives on Model Rockets

- 8 Curing Times and Safety Considerations with Adhesives on Model Rockets

- 9 Conclusion

Hot glue, also known as hot melt adhesive, is a magical substance that has the power to bring your crafts and DIY projects to life. It’s like a secret weapon in the crafting world, ready to bond materials together with its incredible adhesive properties.

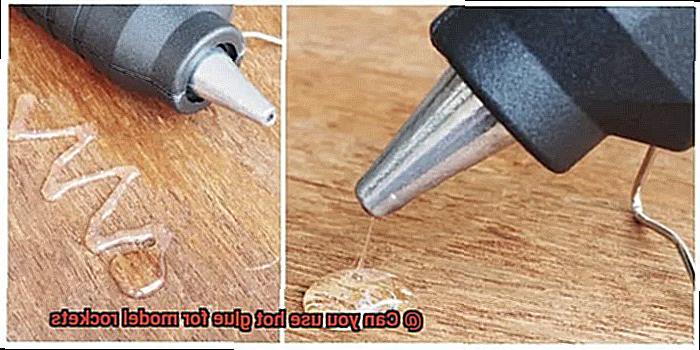

To unleash the power of hot glue, you’ll need a trusty hot glue gun. This little tool is a game-changer, equipped with a heating element that transforms solid glue sticks into a molten liquid. With a simple press of the trigger, the melted glue oozes out of the gun’s nozzle, ready to create a strong bond between your materials.

But what exactly makes hot glue so special? Well, it’s all about its thermoplastic nature. When heated, this adhesive superhero transforms from a solid into a liquid state, allowing it to flow and fill in every nook and cranny of your project. And when it cools down, it solidifies into a tough and sturdy bond that will withstand the test of time.

One of the most impressive features of hot glue is its lightning-fast setting time. Unlike other glues that take ages to cure, hot glue works its magic within seconds or minutes. The speed at which it bonds depends on the thickness of the layer applied, ensuring you can complete your projects with efficiency and precision.

Hot glue is also an incredibly versatile adhesive that can stick almost anything together. Whether you’re working with wood, fabric, plastic, or metal, hot glue will be your trusty sidekick. It forms strong bonds that are flexible and impact-resistant, perfect for materials that may experience stress or movement.

However, it’s important to note that not all projects are suitable for hot glue. For example, if you’re embarking on a journey to build model rockets that are meant to soar through the sky, you’ll need more specialized adhesives like epoxy or cyanoacrylate (super glue). These superhero adhesives are designed specifically for high-stress applications and will ensure your rockets stay intact during flight.

Advantages of Hot Glue

The world of model rocketry is filled with excitement, from the thrill of the launch to the satisfaction of a successful flight. But before you can experience those exhilarating moments, you need to construct your rocket with care and precision. And when it comes to choosing an adhesive, hot glue emerges as a true hero in the crafting realm. So, why should you consider using hot glue for model rocket construction? Let’s explore its advantages.

First and foremost, hot glue boasts a lightning-fast drying time. While other adhesives may demand hours or even days to fully set, hot glue bonds within mere seconds. Picture this: you can build your rocket in a fraction of the time it would take with other adhesives. This quick-drying feature not only speeds up assembly but also reduces waiting time, allowing you to get closer to your launch sooner.

But speed isn’t the only advantage of hot glue. It also creates a bond that is strong, sturdy, and reliable. The adhesive properties of hot glue ensure that every component of your rocket remains securely attached, even when subjected to the stresses of flight. No need to worry about structural failures – hot glue has got you covered.

Versatility is another feather in the hot glue’s cap. It effortlessly bonds a wide range of materials commonly used in model rocket construction, including plastic, wood, foam, and cardboard. Whether you’re attaching fins or securing the engine mount, hot glue is your go-to adhesive. Say goodbye to the hassle of finding different adhesives for different materials – hot glue simplifies your building process.

When it comes to ease of use, hot glue guns take the spotlight. Simply plug in the gun, let it heat up, and you’re good to go. The controlled dispensing through a nozzle ensures precise application without any mess or excess adhesive. Whether you’re a seasoned hobbyist or a beginner in the world of model rocketry, hot glue offers a user-friendly experience.

But what if you make a mistake or need to make adjustments? Fear not – hot glue is reversible. Despite creating a strong bond, it can be easily softened and peeled off by applying heat with a heat gun or hairdryer. No need to start from scratch when making repairs or adjustments; hot glue allows for flexibility and convenience.

Apart from its practical advantages, hot glue also offers cost-effectiveness. It is an affordable adhesive option compared to specialized adhesives available in the market. Craft stores and online retailers stock hot glue sticks in bulk, providing a pocket-friendly solution for multiple projects. You can build more rockets without breaking the bank.

Safety is always a prime concern when working with adhesives, and hot glue ensures your well-being. The glue guns come equipped with features like insulated nozzles and trigger mechanisms to prevent accidental burns. Adhering to manufacturer’s instructions and using caution are essential for safe handling and application.

Disadvantages of Using Hot Glue for Model Rockets

When it comes to model rocket building, hot glue may seem like a quick and easy solution, but it has several disadvantages that should not be overlooked. Let’s take a closer look at why hot glue may not be the best choice for your beloved rockets.

First and foremost, hot glue simply isn’t as strong as other adhesives commonly used in model rocket construction. It’s like the middle child of adhesives – it gets the job done, but it’s not the best. If you’re looking for a rock-solid bond, you might want to consider alternatives like epoxy or cyanoacrylate (super glue), which are known for their superior strength and durability.

Another drawback of hot glue is its tendency to become brittle over time, especially when exposed to extreme temperatures. This means that your rocket’s joints could become weak and prone to failure. Imagine the disappointment of watching your rocket fall apart mid-flight or shatter upon impact – not exactly the outcome you were hoping for.

Speaking of extreme temperatures, hot glue has a relatively low melting point. Picture this: you’ve painstakingly assembled your rocket, only to have the heat from the engine soften or melt your glue, compromising the stability of the entire structure. It’s a recipe for disaster.

Moisture is another enemy of hot glue. If your rocket gets wet or is exposed to humid conditions, the hot glue may lose its grip and fail to hold everything together securely. And let’s face it – rockets and water don’t mix well anyway.

Now let’s talk about time. Hot glue takes longer to cure compared to other adhesives. If you’re an impatient rocketeer who wants to get your creation off the ground as soon as possible, you might want to consider a faster-drying alternative.

And what about aesthetics? Hot glue can be messy and difficult to work with, especially when you’re aiming for precision or intricate assembly. Uneven spreading or visible residue can put a damper on your rocket’s visual appeal – not exactly the sleek and polished look you were going for.

Lastly, hot glue isn’t easily reversible. Once it’s applied and cured, it’s tough to remove without damaging your rocket. This limits your ability to make adjustments or perform repairs if needed.

Alternatives to Hot Glue for Model Rockets

When it comes to building model rockets, finding the right adhesive is crucial for a successful launch and flight. While hot glue may be convenient, it’s worth exploring alternatives that offer superior strength, durability, and versatility. In this blog post, we will delve into the world of alternative adhesives for model rockets and explore their benefits and drawbacks.

Epoxy – The Powerhouse:

One alternative to hot glue is epoxy. This versatile adhesive offers exceptional bonding strength and durability. With a longer drying time than hot glue, epoxy provides a reliable bond that can withstand high temperatures. It is especially suitable for joining metal components or reinforcing critical structural areas of your rocket.

Cyanoacrylate Glue – The Quick Fixer:

Super glue, also known as cyanoacrylate glue, is a fast-drying adhesive that forms an instant and strong bond. While it may lack the flexibility and impact resistance required for certain rocket parts, super glue is ideal for smaller components or quick fixes during the build process.

Foam-Safe Adhesives – Lightweight Bonding:

For lightweight materials like foam or balsa wood, foam-safe adhesives such as foam glue or white craft glue are excellent choices. These adhesives are specifically formulated to bond porous materials without causing damage or melting. Although they have a longer drying time, they provide a reliable bond for lightweight components.

Mechanical Fasteners – Easy Modifications:

In some cases, mechanical fasteners like screws or bolts can be used as an alternative to adhesives. This method allows for easy disassembly and reassembly of rocket components, making it convenient for modifications or repairs. However, keep in mind that mechanical fasteners may add weight to your rocket, so they may not be suitable for all applications.

Choosing the Right Adhesive:

Selecting the best alternative adhesive for your model rocket depends on various factors, such as weight, strength, flexibility, and temperature resistance. Consider the specific requirements of your rocket and the materials being used to make an informed decision.

Safety First:

Regardless of the adhesive you choose, it’s crucial to follow the manufacturer’s instructions and work in a well-ventilated area. Adhesives can emit fumes or heat during the curing process, so taking necessary safety precautions is essential.

How to Choose the Right Adhesive for Your Model Rocket

Embarking on a model rocket building adventure is an exciting endeavor. To ensure the success of your project, it is vital to choose the right adhesive that will provide structural integrity. In this article, we will guide you through the process of selecting the perfect glue for your model rocket.

Understand the Materials:

To begin, it is crucial to understand the materials you will be working with. Different adhesives are designed to bond specific materials such as plastic, wood, or metal. Checking labels and choosing an adhesive compatible with your model rocket’s materials is essential for a strong bond.

Consider Strength Requirements:

Model rockets experience high levels of stress and pressure during flight. Therefore, selecting an adhesive that provides a strong and durable bond is crucial. Epoxy is an excellent choice due to its exceptional bonding strength, making it ideal for securing parts together. For attaching small or lightweight components, cyanoacrylate (super glue) may be suitable.

Factor in Drying Time:

The drying time of your chosen adhesive can impact your building process. Some adhesives require longer drying times, which can slow down progress. If you prefer a quicker bonding solution, opt for an adhesive with a faster drying time.

Safety Precautions:

Safety should always be a top priority when working with adhesives. Read and follow the manufacturer’s instructions carefully to ensure proper usage. Wearing gloves and working in a well-ventilated area will protect you from potential hazards.

Experimentation:

Finding the perfect adhesive may require some experimentation. Don’t hesitate to try different adhesives and techniques to achieve desired results. Keep track of your experiments and take notes on their effectiveness to refine your process over time.

Proper Surface Preparation for Model Rocket Assembly

Proper surface preparation is key to ensuring a sturdy and secure model rocket. Let’s dive into the world of surface preparation, focusing specifically on the glue aspect of the process. Trust me, this is one step you don’t want to skip if you want your rocket to soar.

First things first, cleanliness is crucial. Before applying any adhesive, make sure your surfaces are squeaky clean. Grab a clean cloth and wipe away any dirt or grease that may be lurking on your rocket parts. If you’re dealing with plastic surfaces, use a mild detergent that won’t damage the material. We want our rockets to shine like the stars they are.

Now that we’ve got clean surfaces, let’s rough things up a bit. Gently scuff the surfaces with sandpaper or an abrasive pad. This creates a rough texture that gives our adhesive something to hold onto. Just remember, we’re looking for a light scuff, not a complete makeover.

Next up, primetime. Apply a primer or bonding agent designed specifically for model rockets. This extra layer of bonding goodness will give your rocket assembly some serious strength. Follow the manufacturer’s instructions on how to apply it, whether it’s brushing or spraying it onto the prepared surfaces.

While we’re on the topic of strength, let’s not forget about temperature and humidity conditions. Different adhesives have specific temperature ranges at which they perform best, so work within those ranges for optimal results. Keep an eye on the humidity too – high humidity can throw a wrench in our adhesive plans, so try to work in a dry environment whenever possible.

Lastly, remember that different materials may require different approaches. Plastic surfaces might need special adhesives designed specifically for plastics, while metal surfaces could benefit from the strength of epoxy-based adhesives. Do your research and understand the specific requirements for the materials you’re working with to ensure a successful bond.

Application Techniques for Adhesives on Model Rockets

Building and launching model rockets is an exhilarating hobby that requires attention to detail and the right tools. One crucial tool in your rocket-building arsenal is adhesive. Adhesives play a vital role in securing the different parts of your rocket together, ensuring a safe and successful flight.

When it comes to choosing the right adhesive, hot glue may be your go-to for crafting projects, but it may not be the best choice for model rockets. Hot glue has a low melting point, which can cause it to soften or melt during high-temperature rocket launches. This can lead to weakened bonds and potential damage to your rocket. Instead, opt for specialized adhesives like epoxy or cyanoacrylate (super glue).

Epoxy is renowned for its excellent bonding strength and resistance to high temperatures, making it an ideal choice for securing rocket components. Cyanoacrylate, also known as super glue, is also popular in rocketry due to its fast-drying and strong bonding properties. These adhesives are specifically designed for model rockets and will ensure a reliable bond between your rocket’s components.

Now that you have chosen the right adhesive, let’s discuss application techniques. Start by ensuring that the surfaces you are bonding are clean and free from any dust or grease. A quick wipe-down with a clean cloth should suffice. If you are working with plastic parts, use a mild detergent to gently clean them.

Next, lightly roughen the bonding surfaces with sandpaper or an abrasive pad. This will create a rough texture that helps the adhesive grip better. Be careful not to overdo it – a light scuff is what we’re aiming for, not a complete overhaul.

When it’s time to apply the adhesive, remember that less is more. Apply it sparingly but evenly onto one of the surfaces. Excessive adhesive can add unnecessary weight and create a messy situation. Firmly press the surfaces together and hold them in place until the adhesive has completely cured. The curing time can range from a few minutes to several hours, depending on the adhesive used. Be patient and allow sufficient time for the adhesive to set before subjecting your rocket to any stress or pressure.

Always adhere to the manufacturer’s instructions and safety guidelines when working with adhesives. Some may require proper ventilation or the use of protective equipment. Additionally, remember that different materials may require different adhesives, so do your research and choose accordingly.

Curing Times and Safety Considerations with Adhesives on Model Rockets

Today, we embark on a journey to explore a vital aspect of rocket building – the curing times and safety considerations when using adhesives. These factors not only determine the strength and reliability of your rocket but also ensure the well-being of everyone involved. So, let’s strap in and ignite our knowledge about adhesives.

Curing times are the superheroic minutes that transform ordinary adhesives into mighty bonds. Different adhesives possess their own unique curing times, so it’s crucial to follow the manufacturer’s instructions for the specific adhesive you’re working with. This adherence to guidelines ensures that your rocket components are securely fused together, ready to withstand the forces of flight.

Now, let’s address the safety aspect. As we venture into the realm of adhesives, it’s essential to equip ourselves with knowledge to protect both ourselves and those around us. Firstly, choose a well-ventilated work area or don a respiratory mask to shield yourself from inhaling any potentially harmful fumes that may waft from the adhesive. Safety should always be our North Star.

Moreover, take a moment to acquaint yourself with the safety data sheet (SDS) provided by the adhesive manufacturer. This treasure trove holds valuable information about potential hazards, handling precautions, and first aid measures in case of accidental exposure or ingestion. Following these guidelines is not just important; it’s vital for safeguarding your personal well-being.

Speaking of safety, let us not overlook our precious skin. Some adhesives can cause skin irritation or provoke allergic reactions. To outsmart such adversaries, it’s wise to don protective gloves when handling adhesives. In case of contact with your delicate skin, rinse the affected area immediately with generous amounts of water and mild soap.

Last but not least, let’s delve into the realm of storage. Just like superheroes, adhesives need a safe hideout to maintain their powers and prevent mishaps. Keep them in their original containers, sealed tightly to preserve their effectiveness. Store them in a cool, dry place, away from the scorching glare of sunlight and the fiery heat of other sources.

znZa_du7JT8″ >

Conclusion

Yes, you can use hot glue for model rockets.

It is a versatile adhesive that can be used to secure various components together. Its quick-drying nature makes it convenient for assembling small-scale models.

Additionally, the weight of the hot glue could affect the overall performance and stability of the rocket.