Are you a miniature hobbyist always on the lookout for the perfect glue to make your crafting projects stand out? Or are you just starting out in the miniature-making world and wondering which adhesive will give you the best results? Look no further than Gorilla Glue, a product that has been gaining popularity in the crafting industry for its impressive strength and versatility.

But why is choosing the right glue so important in miniature-making? Well, it’s simple: miniatures are delicate and require an adhesive that can hold small pieces together without damaging them. The quality of your glue can make or break your project, so it’s essential to choose wisely.

Enter Gorilla Glue, with its unique chemical composition that creates a strong, waterproof bond – perfect for miniature crafting. This versatile glue works on various materials such as wood, foam, fabrics and metals. Its expandable properties make it ideal for filling gaps and creating seamless joints.

However, before you rush out to buy Gorilla Glue for your next project, let’s take a closer look at whether it is truly the best option for miniature-making. Are there any potential downsides to using this popular adhesive? Keep reading to find out.

What is Gorilla Glue?

Contents

- 1 What is Gorilla Glue?

- 2 Is Gorilla Glue Suitable for Miniatures?

- 3 Advantages of Using Gorilla Glue on Miniatures

- 4 Disadvantages of Using Gorilla Glue on Miniatures

- 5 Alternatives to Gorilla Glue for Miniatures

- 6 How to Choose the Right Adhesive for Your Miniature Project

- 7 Tips for Applying and Working with Adhesives on Miniatures

- 8 Conclusion

Gorilla Glue is a revolutionary adhesive that has taken the DIY world by storm since its inception in 199This polyurethane-based glue is known for its robust adhesive properties and versatility in bonding different types of materials together. The Gorilla Glue Company, based in Sharonville, Ohio, produces various forms of Gorilla Glue, including the original foaming adhesive and the fast-drying, clear Gorilla Super Glue. Additionally, there are variants of Gorilla Glue that cater specifically to wood, metal, and plastics.

One of the unique features of Gorilla Glue is its ability to expand and foam up as it dries. This makes it ideal for larger-scale projects where a stronger bond is required. The expanding quality fills any gaps or cavities in the materials being bonded, creating a robust bond that withstands even the most challenging conditions.

However, when it comes to miniature projects, Gorilla Glue may not be the best option due to its expanding nature. The excess foam can make it challenging to apply the glue precisely, leading to unsightly bulges or bumps on the miniature’s surface. Additionally, the dried foam can be challenging to remove if adjustments or repairs are necessary.

Another consideration when using Gorilla Glue for miniatures is its yellowish-brown color when dry. Certain projects may require a clear or translucent finish which can be difficult to achieve with this glue. Furthermore, the strength of the bond created by Gorilla Glue may not be suitable for miniatures that require frequent handling or assembly. Disassembling parts without causing damage can be challenging due to the expanding nature of the glue.

Despite these limitations, Gorilla Glue remains a versatile and strong adhesive option for many DIY projects. It is an excellent choice for larger projects that require a robust bond capable of withstanding harsh conditions. In contrast, Gorilla Super Glue is perfect for precise applications where a clear bond is necessary.

Is Gorilla Glue Suitable for Miniatures?

While it’s a popular adhesive known for its strength and versatility, it’s important to consider some key factors before diving in.

One of the main challenges with Gorilla Glue is its expanding nature. While it’s great for larger projects that require a strong bond, it can be problematic when working with small miniatures. As the glue dries, it tends to push out from the joints, creating a messy appearance that’s tough to clean up. The excess glue can even damage delicate miniatures, which is the last thing you want.

Another factor to keep in mind is that Gorilla Glue requires moisture to activate its bonding properties. This may not be an issue for larger surfaces, but applying moisture to tiny and delicate miniature pieces can be tricky without causing damage. You want your miniatures to look beautiful and precise, not warped and deformed.

Lastly, if you’re working with polystyrene foam, it’s best to steer clear of Gorilla Glue altogether. This adhesive can melt and deform foam, completely ruining your miniature terrain or props.

Advantages of Using Gorilla Glue on Miniatures

As an expert in this field, I have researched and compiled a list of the many advantages of using Gorilla Glue on miniatures.

Firstly, Gorilla Glue boasts an incredibly strong bond that ensures your miniature remains secure, even after rough handling. This is crucial for those who display or play with their miniatures often.

Secondly, one of the most significant advantages of using Gorilla Glue is its versatility. It can bond a wide range of materials such as plastic, metal, and wood. This makes it a go-to choice for many miniature hobbyists who work with different types of miniatures.

Thirdly, waterproof properties are essential for miniatures that may be exposed to water or moisture. Gorilla Glue excels in this area and does not break down or weaken when it comes into contact with water. This ensures that your miniature remains intact when subjected to wet conditions.

Fourthly, Gorilla Glue dries clear, making it ideal for use on miniatures with intricate details. You no longer have to worry about any pesky residue or visible glue marks detracting from your masterpiece.

Lastly, Gorilla Glue’s expandability is another major benefit. As it dries, the glue expands and fills any gaps or cracks in the miniature’s structure. This helps to create a more secure bond between the different parts of the model.

Disadvantages of Using Gorilla Glue on Miniatures

While Gorilla Glue may seem like a strong and reliable adhesive, it comes with some disadvantages that you should be aware of.

One major issue with using Gorilla Glue on miniatures is its foaming action. While this expanding quality might be useful for filling gaps in larger projects, it can be disastrous for miniatures that require precise and clean details. The glue can foam out of joints and create a messy appearance, making your carefully crafted work look like a chaotic science experiment.

In addition to foaming, the color of Gorilla Glue can also be problematic for miniature enthusiasts. It dries to a yellowish-brown hue, which doesn’t always match the color of your model. This can be especially noticeable on light-colored or white miniatures, detracting from the overall appearance of your work.

Another disadvantage of Gorilla Glue is its longer drying time. Assembling miniature models can be a time-consuming process, and waiting for glue to dry can feel like an eternity. Plus, the longer drying time makes it more difficult to adjust or fix mistakes during assembly.

Finally, Gorilla Glue’s strong bond can also be a double-edged sword. It may not be ideal for use on small or delicate parts since the bond created by the glue can cause parts to break or snap off when trying to remove them. This can be frustrating for miniature enthusiasts who want to make adjustments or changes to their work.

Alternatives to Gorilla Glue for Miniatures

As a miniaturist, finding the perfect adhesive is essential to ensure that your creations last for years to come. While Gorilla Glue is a well-known choice, it’s not the only option available. Luckily, there are several alternatives to consider when it comes to gluing miniatures.

First on the list is super glue, also known as cyanoacrylate glue. This adhesive is perfect for small and delicate miniatures because of its strong and quick-drying properties. Its quick action makes it an ideal choice for those who don’t have much time to spend on their projects. Super glue can also be used in combination with other adhesives such as epoxy or PVA glue for added strength.

If you’re working with larger miniatures or those that require extra stability, epoxy resin is worth considering. This two-part adhesive creates a durable and robust bond that can withstand wear and tear. Epoxy resin also dries clear, making it an excellent choice for transparent or translucent miniatures.

For those who want a more versatile adhesive, PVA glue is a great option. Also known as white glue or school glue, PVA glue is water-soluble and easy to work with. It’s perfect for attaching larger pieces or filling gaps in miniatures. While it may not be as strong as some other adhesives, it can be used in combination with other types of glue for added durability.

When deciding which adhesive to use for your miniature project, keep in mind several factors such as the size and material of the miniatures, the level of detail required, and your personal preferences. Experimentation is key in finding the perfect adhesive for your miniature masterpiece.

How to Choose the Right Adhesive for Your Miniature Project

Creating miniatures is not just a hobby but an art form that requires precision and attention to detail. The right adhesive is crucial to ensure that your hard work does not go to waste. With so many adhesives available in the market, it can be challenging to choose the right one. However, by considering a few key factors, you can confidently select the perfect adhesive for your miniature project.

Materials Matter

One of the most critical factors to consider when choosing an adhesive is the materials you will be working with. Different adhesives work better with specific materials, and choosing an adhesive that works well with your materials will ensure a strong and lasting bond. For example, plastic cement adhesive is ideal for plastic miniatures, while metal miniatures require super glue or epoxy adhesive.

Strength and Durability

Miniature projects require delicate and intricate pieces that need to withstand handling and potential wear and tear over time. Therefore, choosing an adhesive that is strong and durable enough to hold up to these conditions is crucial. Consider the strength and durability of the adhesive before making your final decision as it will determine how long-lasting your miniature project will be.

Drying Time and Flexibility

Miniature projects often involve small and intricate pieces that require precision when applying the adhesive. A quick-drying adhesive may not provide enough time to properly position pieces before it sets. On the other hand, a slow-drying adhesive may not be practical for projects that require multiple steps or layers. Additionally, consider the flexibility of the adhesive as some miniatures may require movement or bending.

Experimentation is Key

There is no one-size-fits-all solution when it comes to choosing the right adhesive for your miniature project. Experimenting with different options is crucial to finding the perfect fit. It’s best to test new adhesives on scrap pieces of your materials before using them on your actual project. This will give you a sense of how well they work with your materials and how they perform during the drying process.

Consider Safety

Safety should always be a priority when working on any project, including miniatures. Consider choosing adhesives that are non-toxic and safe to use. Some adhesives may emit harmful fumes, and it’s important to use them in a well-ventilated area or wear protective equipment such as gloves or masks.

Tips for Applying and Working with Adhesives on Miniatures

Creating miniature models is a fascinating hobby that requires precision and attention to detail. Applying and working with adhesives on miniatures can be challenging, but with the right tips and tricks, it can be an enjoyable experience. Here are five sub-sections that will help you master the art of miniature assembly.

Choose the Right Adhesive

Choosing the right adhesive is crucial when it comes to working with miniatures. Some adhesives work better for specific materials than others, such as super glue for plastic or epoxy for metal. Consider factors such as drying time, strength, and color before choosing an adhesive. It’s best to do some research and experiment with different adhesives to find the one that works best for your project.

Apply Carefully

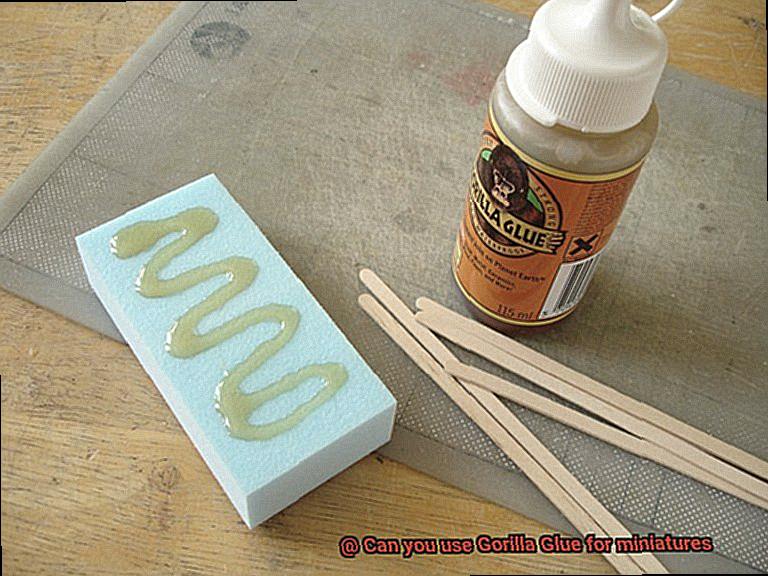

Applying glue carefully is crucial when working on miniatures. A small amount of glue should be applied to one surface and then pressed together firmly for several seconds. If you’re using Gorilla Glue specifically, remember that it expands as it dries, so use a minimal amount to avoid unwanted bulging or distortion.

Use Masking Tape

Holding pieces together while the glue dries can be challenging, and that’s where masking tape comes in handy. Use masking tape to hold pieces together while the glue dries. This can help ensure that the pieces stay in place and don’t shift or move during the drying process.

Use Small Tools

Using small tools can make applying glue to hard-to-reach areas or small details easier without making a mess. Toothpicks are great for precise application, while brushes can be used to spread glue over larger areas.

Clean Up Excess Glue

Excess glue can leave behind unsightly marks or residue that can ruin the look of your miniature model. Be sure to clean up any excess glue as soon as possible with a damp cloth or paper towel, being careful not to disturb the glued pieces.

Conclusion

In conclusion, Gorilla Glue proves to be a formidable adhesive option for miniature enthusiasts. Its exceptional strength and versatility make it an ideal choice for filling gaps and creating seamless joints in small-scale models. Moreover, its waterproof properties ensure that your miniature will remain intact even when exposed to wet conditions.

However, before deciding on using Gorilla Glue for miniatures, it’s essential to weigh the potential downsides. The expanding nature of the glue can make it tricky to apply precisely, resulting in unsightly bulges or bumps on the miniature’s surface. Additionally, removing dried foam can prove challenging if adjustments or repairs are necessary.

Fortunately, there are several alternatives available when choosing an adhesive for your miniature project. Super glue, epoxy resin, and PVA glue are some options worth considering based on factors like materials used, strength and durability required, drying time and flexibility.

When applying glue to miniatures, precision is key. Small tools can help with accuracy while masking tape can hold pieces together while the glue dries. Cleaning up excess glue is crucial in ensuring a clean and professional-looking finished product.