Prepare to be amazed as we unveil the unexpected partnership between these two seemingly mismatched materials. Yes, we’re diving into the captivating world of fiberglass and metal. If you’ve ever pondered whether fiberglass can be used on metal, get ready for a thrilling exploration that will ignite your curiosity.

In the pursuit of stronger, sturdier, and more resilient structures, engineers have left no stone unturned. And in their quest, they stumbled upon an engineering masterpiece – the combination of fiberglass and metal. So let’s uncover the functions, surprising applications, and benefits of using this dynamic duo.

First things first, fiberglass – a composite material with fine glass fibers embedded in resin – boasts exceptional qualities like its lightweight strength, corrosion resistance, and electrical insulation. On the other hand, metal brings to the table its unrivaled structural integrity and durability. When these two materials join forces, magic happens.

Throughout our captivating journey together, we’ll explore countless applications where fiberglass and metal elevate each other’s performance to new heights. From aerospace marvels to automotive innovations and even construction wonders, fiberglass-reinforced metal components have proven their mettle time and time again.

But how do we bring these unlikely partners together? Join us as we unravel the secrets behind effective adhesion and discover the various techniques employed to ensure a robust connection between fiberglass and metal. It’s a fascinating process that holds the key to unlocking their combined potential.

So whether you’re an engineering aficionado hungry for knowledge or simply someone intrigued by the world around us, come along as we delve into the extraordinary possibilities that arise when solid metals waltz with the versatile charms of fiberglass. Together, they create an unbeatable force that shapes our physical reality in ways we never imagined possible. Get ready to reimagine the unparalleled combination of fiberglass and metal.

What is Fiberglass?

Contents

- 1 What is Fiberglass?

- 2 Adhesion between Fiberglass and Metal

- 3 Preparing the Metal Surface for Fiberglass Application

- 4 Roughening the Metal Surface for Improved Adhesion

- 5 Applying an Adhesive or Bonding Agent to the Metal Surface

- 6 Different Types of Adhesives Suitable for Bonding Fiberglass to Metal

- 7 Properly Following Manufacturer’s Instructions Before Applying Adhesive

- 8 Laying Down the Fiberglass Material onto the Metal Surface

- 9 Conclusion

Prepare to be amazed by the incredible world of fiberglass. This composite material is a true marvel, known for its exceptional strength, durability, and versatility. It has become a go-to choice in a wide range of industries, from construction to automotive and marine. But what exactly is fiberglass? Let’s dive into the fascinating realm of this extraordinary material.

Unveiling the Creation Process:

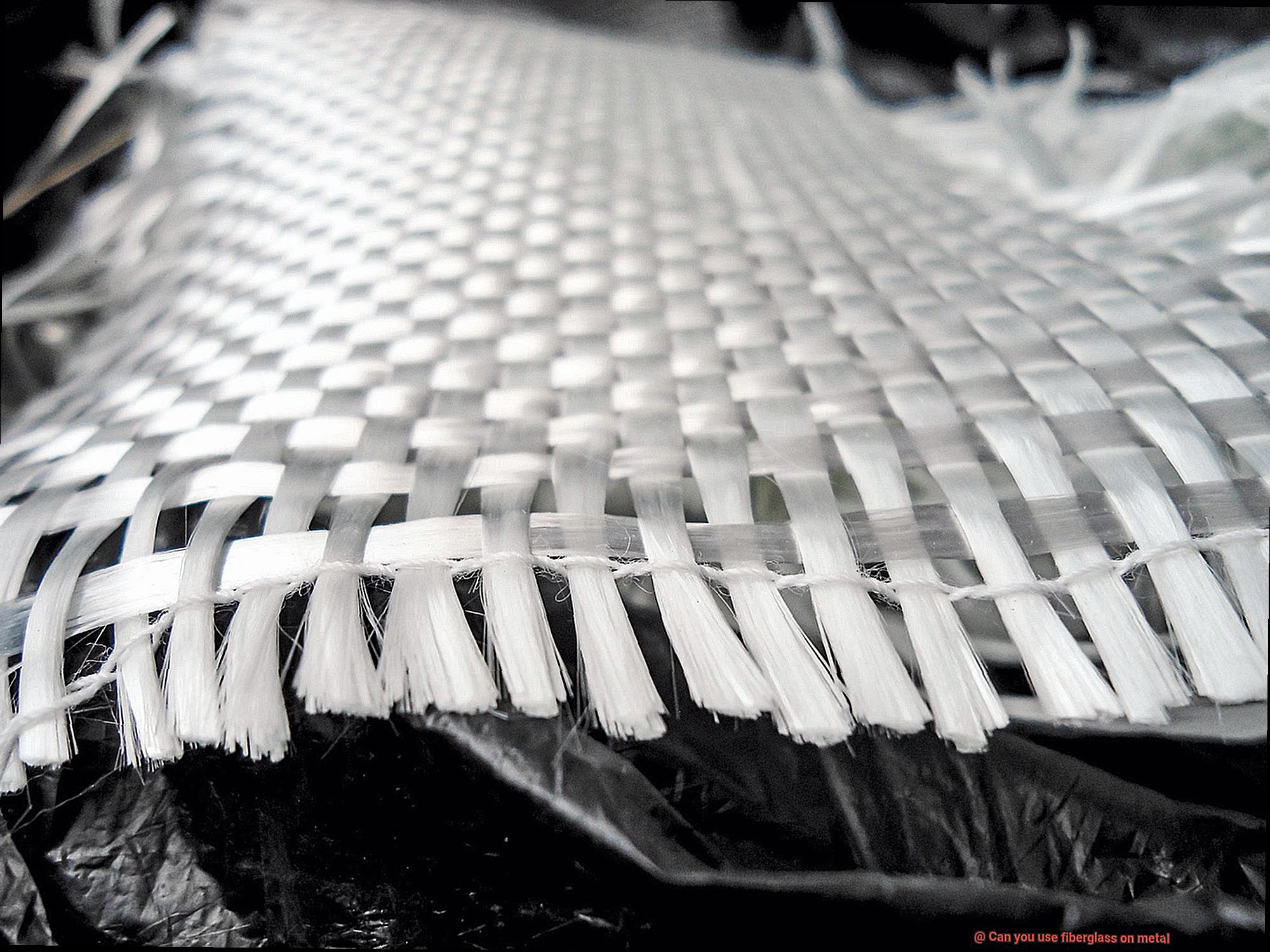

At the heart of fiberglass lies a magical combination of plastic and glass fibers. These fine strands of glass provide reinforcement, while the plastic matrix holds everything together and protects against external elements. The result is a lightweight yet incredibly strong material that can conquer any challenge it faces.

The Birth of a Legend:

Creating fiberglass is no simple task. It involves a carefully orchestrated series of steps that bring this material to life. First, glass fibers are born from the intense heat of melted glass. These molten strands are then extruded into delicate threads. To enhance their adhesion to the plastic matrix, they receive a special coating agent. Finally, these coated fibers are woven or arranged in specific patterns to form mats or fabrics.

The Art of Bonding:

A crucial aspect of working with fiberglass is bonding it to different surfaces. When it comes to metal, special considerations and preparations are required to ensure a strong and reliable bond. Let’s explore the best practices for using fiberglass on metal surfaces.

Preparing the Metal Surface for Greatness:

To pave the way for an unbreakable connection between fiberglass and metal, proper preparation is key. Start by giving the metal surface a thorough cleaning, banishing any hint of dirt, grease, or rust with suitable solvents or cleaning agents. This pristine canvas will lay the foundation for superior adhesion.

Roughening the Metal Surface:

To take adhesion to new heights, gently roughen the metal surface using fine-grit sandpaper or a wire brush. This seemingly small step creates a larger surface area for the fiberglass to cling onto, guaranteeing a bond that won’t be easily broken.

Selecting the Perfect Adhesive:

Choosing the right adhesive is paramount in achieving a solid connection between fiberglass and metal. Several adhesives are specifically designed for this purpose, boasting phenomenal adhesion properties that will stand the test of time. Make sure to follow the manufacturer’s instructions meticulously, ensuring proper mixing and application within recommended temperature ranges.

Adhesion between Fiberglass and Metal

In the realm of materials, fiberglass stands as a true marvel, boasting unparalleled strength, durability, and versatility. However, when it comes to bonding fiberglass with metal surfaces, challenges arise. This article delves into the intricate world of adhesion between fiberglass and metal, exploring the key factors necessary for forging an unbreakable connection.

Challenges in Achieving Adhesion:

Surface Characteristics:

A chasm lies between fiberglass and metal in terms of surface characteristics. Metals flaunt smooth, non-porous exteriors, while fiberglass surfaces possess a rugged texture, thanks to embedded glass fibers. This disparity poses a formidable challenge for adhesives in establishing a robust bond.

Surface Preparation:

To overcome this disparity, meticulous preparation of both fiberglass and metal surfaces is paramount. Exquisite cleanliness graces the fiberglass surface, free from any dirt, dust, or oils that impede adhesion. Simultaneously, degreasing and cleansing the metal surface ensure optimal bonding. Various metals may demand specific cleaning methods such as etching or sanding to create a rougher texture that facilitates adhesion.

Choosing the Right Adhesive:

Epoxy Adhesives:

Renowned for their exceptional bonding strength and resistance to chemicals and moisture, epoxy adhesives reign supreme in bonding fiberglass to metal. Comprising two components requiring pre-application mixing, these adhesives create enduring connections capable of withstanding even the harshest environmental conditions.

Polyurethane Adhesives:

Polyurethane adhesives offer flexibility and impact resistance, rendering them ideal for applications involving movement or vibration. These adhesives boast remarkable water and chemical resistance, ensuring unwavering durability across diverse conditions.

Acrylic-Based Adhesives:

Acrylic-based adhesives shine with their swift curing time and user-friendly nature. Often employed for bonding lightweight fiberglass materials to metal surfaces, they may not match the strength of epoxy or polyurethane adhesives but still provide ample adhesion for specific applications.

Preparing the Metal Surface for Fiberglass Application

Today, we embark on a journey into the art of preparing a metal surface for the ultimate fiberglass application. Just like a painter meticulously primes their canvas before creating a masterpiece, we will guide you through the essential steps to ensure a strong and enduring bond between your metal surface and fiberglass material.

So, grab your gloves and let’s dive into the world of preparing the metal surface for fiberglass application.

Step 1: Thoroughly Cleanse and Degrease

In this first step, we must cleanse our metal surface of any dirt, oil, or contaminants that could hinder the perfect union between metal and fiberglass. With a solvent or degreaser recommended by the manufacturer, we gently wipe or brush away these unwanted particles. Remember, cleanliness is paramount to achieving flawless adhesion.

Step 2: Embrace the Roughness – Sanding

Having cleansed our metal surface, we now embark on adding some rough love. With fine-grit sandpaper or a sanding block in hand, we create a textured surface that acts as a welcoming mat for the fiberglass material. Carefully balancing between smoothness and roughness, we ensure that the metal remains undamaged and free from gouges.

Step 3: Banish Dust and Debris

Cleanliness remains at the forefront of our minds. After sanding, we diligently remove any lingering dust or debris from the metal surface. Whether blowing them away with compressed air or tenderly wiping them off with a clean, lint-free cloth, nothing should stand between your metal and fiberglass bonding bliss.

Step 4: Prime Time (Optional)

For those seeking an elevated level of adhesion prowess, consider applying a primer or epoxy-based coating. These champions provide an extra layer of protection and enhance the bond between metal and fiberglass. Following the manufacturer’s instructions, prime like a true professional.

Step 5: Dry as a Desert

Moisture is the sworn enemy of fiberglass bonding, so let us ensure our metal surface is bone-dry before proceeding. Take a moment to ensure there is no trace of moisture lingering on your prepared surface. Your fiberglass will undoubtedly express its gratitude later.

Roughening the Metal Surface for Improved Adhesion

In the quest for flawless and long-lasting bonds between metal surfaces and fiberglass, the secret lies in roughening the metal surface. By creating a textured landscape, we unlock the potential for a robust and reliable connection.

In this captivating exploration, we will delve into a variety of methods for roughening metal surfaces to achieve superior adhesion for fiberglass. Prepare to be amazed as we uncover the secrets of this transformative process.

Method 1: Sanding – The Art of Abrasion

Embark on a classic journey with sanding, the tried-and-true method for roughening metal surfaces. Armed with sandpaper or a sanding disc, we enter a world of friction and motion. With each back-and-forth rub, we gradually sculpt a roughened landscape. Remember, the key to efficient roughening lies in selecting a coarse-grit abrasive material that can truly unleash the potential of the metal surface.

Method 2: Chemical Etching Agents – Unleashing the Beast Within

Prepare to witness the power of chemical etching agents as they transform metal surfaces into textured masterpieces. The realm of liquid-based agents beckons, offering phosphoric acid, hydrochloric acid, and sulfuric acid as potent allies. Applied with caution, these agents react with the metal’s topmost layer, revealing a landscape rich in texture and ready for adhesion. Safety precautions must be strictly adhered to when handling these chemical titans.

Method 3: Mechanical Methods – When Roughness Takes Flight

For those who seek more formidable means of roughening, mechanical methods stand tall as unwavering pillars of strength. Enter shot blasting, where tiny metallic particles soar through space at high velocities, relentlessly bombarding the metal surface with exhilarating force. Or witness the spectacle of sandblasting, where fine grains of sand or abrasive materials dance across the metal, leaving behind a landscape primed for fiberglass adhesion. Brace yourself for the sheer power of these mechanical marvels as they shape a rough surface layer on the metal, paving the way for an unbreakable bond.

Applying an Adhesive or Bonding Agent to the Metal Surface

Today, we embark on a new journey as we delve into the captivating realm of applying an adhesive or bonding agent to a metal surface. So, grab your tools and prepare to witness the transformative power of adhesion.

Preparing the Metal Surface: A Solid Foundation

Before we can dive into the world of adhesives, it is crucial to lay the groundwork for success. To ensure a strong bond, cleanliness is key. Rid the metal surface of any dirt, grease, or oxidation that might hinder adhesion. Give your metal a spa day it deserves.

Creating an Optimal Bonding Environment: The Art of Sanding

To welcome our adhesive superhero with open arms, we must create a rough texture on the metal surface. Armed with a medium-grit sandpaper, gently sand the metal to provide a stronger grip and guarantee a long-lasting bond. Transform your metal into a canvas ready for adhesion.

Cleaning and Priming: Preparing for the Grand Adhesive Dance

Bid farewell to any remnants of sanding past by wiping the metal surface with an appropriate solvent like acetone or isopropyl alcohol. This meticulous cleaning ensures a pristine canvas for our adhesive or bonding agent. Choose one designed specifically for metal surfaces and fiberglass – they’re an unbeatable team.

The Art of Application: Steady Hands and Even Layers

Now comes the moment of truth – applying the adhesive. Armed with a brush, roller, or spatula (depending on the adhesive’s consistency), let your steady hands guide you to success. Ensure an even layer across the entire metal surface – moderation is key. Avoid excessive adhesive that may lead to uneven bonding or unnecessary sanding.

Patience is a Virtue: Let the Adhesive Work its Magic

Once our adhesive masterpiece is complete, it’s time to let it work its magic. Follow the manufacturer’s instructions for drying time and allow the adhesive to bond properly with the metal surface. Patience is a virtue, my friends.

Different Types of Adhesives Suitable for Bonding Fiberglass to Metal

The bond between fiberglass and metal requires an adhesive that can withstand a multitude of challenges. In this comprehensive guide, we will explore the diverse world of adhesives and unveil five distinct types that are perfect for bonding fiberglass to metal. By delving into their unique properties and applications, you’ll gain a deeper understanding of which adhesive is best suited for your project.

Epoxy Adhesive: The Titan of Bonding Strength

Epoxy adhesives stand tall as the go-to choice for bonding fiberglass to metal. Their unparalleled strength and durability make them versatile for various applications. Available in different formulations, such as two-part epoxy or one-part epoxy, these adhesives create a formidable bond when mixed or cured at room temperature. Whether you’re constructing a masterpiece or repairing a marine vessel, epoxy adhesives guarantee a secure and long-lasting connection.

Polyurethane Adhesive: Flexibility Meets Resilience

When it comes to accommodating movement or stress on the bond, polyurethane adhesives steal the show. Their exceptional flexibility and resistance to impact and vibration ensure a reliable bond when bonding fiberglass to metal. These adhesives also boast remarkable water resistance, making them ideal for applications exposed to moisture or outdoor conditions.

Acrylic Adhesive: The Indomitable Guardian

If harsh environments or extreme temperatures are your adversaries, acrylic adhesives will have your back. With their outstanding chemical resistance and high temperature resilience, they forge an unyielding bond between fiberglass and metal surfaces. Whether in liquid or film form, acrylic adhesives offer versatility in application methods, ensuring optimal performance.

Cyanoacrylate Adhesive: Super Glue for Swift Solutions

When time is of the essence, cyanoacrylate adhesives, fondly known as super glue, come to the rescue. While they may not possess the same level of strength and durability as other adhesives, their quick bonding and curing times allow for rapid assembly. Perfect for lightweight applications or temporary bonds, cyanoacrylate adhesives offer a fast and reliable solution.

Silicone Adhesive: The Champion of Flexibility

For applications demanding flexibility and resistance to extreme temperatures, silicone adhesives reign supreme. Their exceptional thermal stability enables them to withstand high temperatures without compromising their bonding properties. Additionally, they exhibit remarkable resistance to moisture and chemicals, making them an excellent choice for outdoor or marine applications.

Properly Following Manufacturer’s Instructions Before Applying Adhesive

Well, buckle up because today we’re diving into the essential step of properly following the manufacturer’s instructions before applying adhesive to fiberglass and metal surfaces. Trust me, this step is the secret sauce to a bond that’s unbreakable.

Now, I know what you might be thinking. Reading instructions? Piece of cake. But my friend, it’s not just about reading them; it’s about truly understanding and flawlessly executing them. So, let’s break it down and discover why this step is so vital.

First and foremost, different adhesives have different powers and demand specific application techniques. Just like superheroes with their unique abilities, adhesives have their own specialties too. That’s why it’s absolutely crucial to use the adhesive that is specifically recommended for bonding fiberglass to metal surfaces. Don’t go rogue and use any random adhesive you find lying around.

Once you’ve got the right adhesive in your grasp, it’s time to prepare those surfaces. Think of it as priming the canvas before creating a masterpiece. Both the fiberglass and metal surfaces must be clean, dry, and completely free from any dirt, dust, grease, or other sneaky contaminants that could jeopardize your bond. We’re aiming for a bond that stands the test of time, not one that crumbles at the first sign of trouble.

- Now here’s a little secret technique – roughen things up a bit. Yes, you heard that right. Sometimes, the manufacturer’s instructions may recommend sanding or roughening the surfaces. It may seem counterintuitive, but trust me on this one. By creating a rough surface, you’re actually giving the adhesive something to cling onto, enhancing its super glue-like abilities. It’s like giving it a little extra oomph.

- Alright, now it’s time for the grand finale – applying the adhesive. But hold your horses. Don’t just slap it on willy-nilly. The manufacturer’s instructions will specify whether you should use a brush, roller, or spreader. So, make sure to follow their expert advice and apply an even and consistent layer of adhesive. We’re aiming for a bond that’s as sturdy as a fortress, not one that’s flimsy and weak.

Laying Down the Fiberglass Material onto the Metal Surface

Prepare to embark on an exhilarating journey into the world of fiberglass and metal fusion. Today, we reveal the secrets of laying down fiberglass material onto a metal surface, creating a bond as unbreakable as Mjolnir. Get ready to wield your tools and witness the magic unfold.

Preparing the Metal Surface:

Cleanliness is paramount in our quest. Like a knight’s shining armor, the metal surface must be free from dirt, grease, and rust. Armed with sandpaper or a wire brush, we shall vanquish any loose paint or coatings, ensuring a smooth canvas that will eagerly embrace our fiberglass.

Applying the Bonding Agent:

Enlist the aid of our secret weapon – the bonding agent. This mighty elixir enhances the connection between fiberglass and metal, just as Captain America’s shield strengthens his resolve. Choose a bonding agent tailored to your metal type or opt for a versatile one capable of bonding various metals. Follow the manufacturer’s instructions meticulously, for we must honor their wisdom.

Choosing the Right Fiberglass Material:

Assembling our Avengers team requires careful consideration. Sheets, mats, or woven fabric – each possesses its unique power. For grand endeavors encompassing vast areas or intricate shapes, unleash the might of sheets or mats. When facing smaller repairs or delicate details, call upon the resilience of fiberglass fabric. The path you choose shall determine your success.

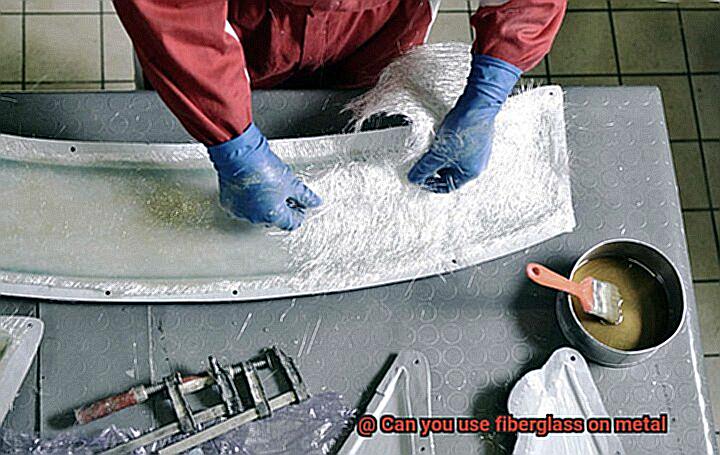

Laying Down Fiberglass Material:

Now, it is time to summon your inner Black Widow and work swiftly and skillfully. Position the fiberglass material with precision, obliterating any air bubbles or wrinkles that dare challenge its strength and beauty. Employ a roller or squeegee to press the material firmly against the metal surface, banishing excess resin like a superhero dispatching villains.

The Power of Curing:

Our mission remains incomplete until we harness the formidable power of curing. This process solidifies the resin in the fiberglass material, transforming it into an indomitable force. The duration of this metamorphosis hinges upon the type of resin and ambient temperature. Observe the manufacturer’s instructions diligently, including any post-curing rituals like sanding or finishing.

Zp5gmDC7KQI” >

Conclusion

Yes, fiberglass can indeed be used on metal surfaces.

It is a versatile material that can adhere to various substrates, including metal. By applying a layer of fiberglass over the metal, you can enhance its strength, durability, and resistance to corrosion.

Moreover, the combination of fiberglass and metal creates a lightweight yet sturdy composite material that is commonly used in industries such as automotive manufacturing and construction.