Construction adhesive might just be your new best friend. Whether you’re giving your bathroom a facelift, upgrading your kitchen, or transforming any space in your home, FRP panels are the way to go.

They’re tough, water-resistant, and easy to maintain. But here’s the real kicker: when used correctly, construction adhesive can work wonders in securely attaching those FRP panels to almost any surface.

In this blog post, we’ll take a deep dive into the exciting world of using construction adhesive for FRP panels. We’ll spill all the secrets, share some do’s and don’ts, and give you everything you need to know for a successful installation.

So, grab a cup of joe, get comfy, and let’s embark on this adhesive adventure together.

What is Construction Adhesive?

Contents

- 1 What is Construction Adhesive?

- 2 What are FRP Panels?

- 3 Factors to Consider When Using Construction Adhesive for FRP Panels

- 4 Types of Construction Adhesives Suitable for Bonding Plastics

- 5 Benefits of Polyurethane Adhesives for Bonding FRP Panels

- 6 Preparing the Surfaces Before Applying the Construction Adhesive

- 7 How to Apply the Construction Adhesive to the FRP Panels

- 8 Alternative Options for Bonding FRP Panels

- 9 Conclusion

In the realm of construction, where strength and durability are paramount, construction adhesive reigns supreme. Known interchangeably as construction glue or construction adhesive sealant, this powerful bonding agent plays a pivotal role in the industry. Its ability to securely unite a plethora of materials makes it indispensable for both builders and DIY enthusiasts. In this comprehensive guide, we will delve into the world of construction adhesive, exploring its remarkable features, diverse applications, and essential tips for achieving optimal results.

Features and Types:

Construction adhesive takes on various forms, including liquid, gel, or paste, catering to the unique needs of different projects. Its exceptional initial tackiness allows surfaces to bond immediately upon application, providing an instant stronghold. Furthermore, construction adhesive boasts long-term strength that ensures a robust bond capable of resisting formidable forces and stresses. Formulated to withstand moisture, heat, cold, and other environmental factors, it guarantees unwavering performance under challenging conditions.

Applications:

- Framing: Construction adhesive fortifies the structural integrity of frames by providing an additional layer of support.

- Drywall Installation: By eliminating the need for mechanical fasteners, construction adhesive securely fastens drywall panels to studs or other surfaces.

- Flooring Installation: This versatile adhesive is indispensable for attaching flooring materials such as tiles or planks to subfloors.

- Tile Setting: With its reliable adhesion properties, construction adhesive ensures tiles remain firmly affixed to walls or floors for years to come.

- General Repairs: When it comes to fixing broken objects or reattaching loose parts, construction adhesive proves invaluable in restoring functionality.

Tips for Successful Use:

- Thoroughly clean and dry the surfaces that require bonding.

- Ensure surfaces are free from dust and debris to optimize adhesion.

- Apply the adhesive evenly and generously onto one surface, ensuring complete coverage.

- Firmly join the surfaces together and apply sufficient pressure until the adhesive dries and sets.

- Adhere to manufacturer instructions regarding curing time and temperature for the best results.

What are FRP Panels?

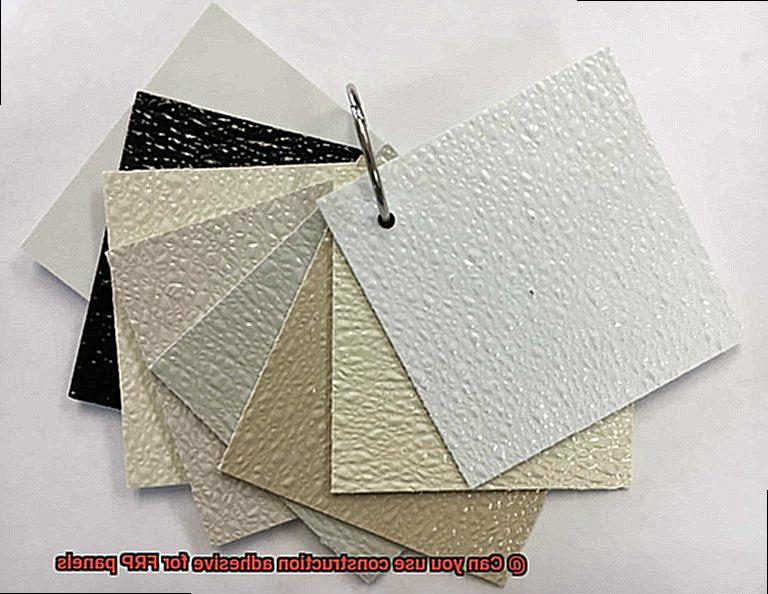

When it comes to construction, FRP panels are the true superheroes of building materials. Also known as fiberglass reinforced plastic panels, these powerhouses are created by combining polyester resin with reinforced fiberglass, resulting in an unstoppable product that can conquer any challenge.

One of the remarkable superpowers of FRP panels is their ability to resist water and chemicals. Like an impenetrable fortress, these panels shield against moisture, making them perfect for areas that require frequent cleaning or endure harsh conditions. They even possess the incredible ability to repel the growth of mold and mildew, ensuring a healthy indoor environment.

But that’s not all – FRP panels are also unmatched in strength and durability. With their reinforced fiberglass, they can take a beating without cracking or breaking. Imagine them as the Hulk of construction materials, capable of withstanding heavy use and impacts effortlessly. And the best part? They require minimal effort to keep them looking fresh and brand new.

Installation is where FRP panels truly shine, acting as fast as the Flash himself. They can be easily cut to size using common tools and installed using adhesive bonding or mechanical fastening. This means you can save time and labor costs, giving you more freedom to focus on other aspects of your project.

And let’s not forget about their style. FRP panels come in a wide range of colors, patterns, and finishes, making them the Iron Man of aesthetic appeal. Whether you desire a sleek modern look or a more traditional style, there’s an FRP panel option that will suit your preferences perfectly.

Factors to Consider When Using Construction Adhesive for FRP Panels

When using construction adhesive for FRP panels, there are several factors that need to be considered to ensure a successful and long-lasting bond. These factors include the type of adhesive, surface preparation, environmental conditions, application technique, curing time, and accommodation for expansion and contraction.

Firstly, it is important to select the right type of adhesive. Not all adhesives are suitable for bonding FRP panels, so it is crucial to choose a high-strength, waterproof adhesive specifically designed for this purpose. This ensures that the adhesive can withstand the strength required for bonding FRP panels effectively.

Secondly, proper surface preparation is essential. The surface of the FRP panels must be clean, dry, and free from any dirt, dust, or grease. Any contaminants on the surface can interfere with the bonding process and compromise the integrity of the adhesive bond. It is recommended to use a mild detergent or solvent to clean the surface thoroughly before applying the adhesive.

Next, consider the environmental conditions during installation. Different adhesives have specific temperature and humidity ranges in which they perform optimally. It is important to check the manufacturer’s instructions for the recommended installation conditions and ensure that these conditions are met during the application of the adhesive. This helps maximize the adhesive’s performance and effectiveness.

Proper application technique is also crucial for a strong bond. The adhesive should be applied evenly and in the correct amount as instructed by the manufacturer. Using a notched trowel or spreader can help ensure proper coverage of the adhesive on both the panel and substrate surfaces.

Allowing sufficient curing time is another important factor. Adhesives require time to cure and reach their maximum strength. It is recommended to follow the manufacturer’s instructions regarding curing time before subjecting the bonded panels to stress or load. The curing time may vary depending on the type of adhesive used.

Lastly, consider accommodating for expansion and contraction of FRP panels. These panels can expand and contract with changes in temperature, which can put stress on the adhesive bond. To prevent damage to the bond, it is advisable to leave a small gap between the panels during installation and use a flexible adhesive that can withstand the movement without compromising the bond.

Types of Construction Adhesives Suitable for Bonding Plastics

Here, we will explore the different types of adhesives available and provide examples of each type. Whether you’re working on a DIY project or a professional construction job, understanding the right adhesive for plastics is crucial for creating strong and durable bonds.

Epoxy Adhesives:

Epoxy adhesives are like the superheroes of the adhesive world, combining two components – a resin and a hardener – to create an incredibly strong bond. These adhesives can withstand moisture, chemicals, and temperature fluctuations, making them ideal for bonding FRP panels in various environments. They are also great for bonding uneven or irregular surfaces due to their excellent gap-filling properties.

Polyurethane Adhesives:

For applications that require flexibility, polyurethane adhesives are the go-to choice. They offer exceptional flexibility and bond strength, making them suitable for areas with movement or vibration. These adhesives also have excellent resistance to moisture and chemicals, ensuring durability in outdoor or high humidity environments.

Acrylic Adhesives:

When speed and aesthetics matter, acrylic adhesives deliver. These adhesives cure quickly and leave behind no trace, making them ideal for fast-paced projects. The transparency of acrylic adhesives also allows for a clean and seamless finish. If you want a bond that sets fast and looks good doing it, acrylic adhesives are your best bet.

Cyanoacrylate Adhesives:

Commonly known as super glue or instant glue, cyanoacrylate adhesives provide fast curing times and high bond strengths. While they are great for bonding small areas or temporary bonds, they may not be suitable for long-term bonding of large plastic surfaces like FRP panels. Consider these adhesives for quick fixes or small-scale projects.

Specialty Adhesives:

For specific plastic materials like polycarbonate or PVC, specialized adhesives are available. These adhesives are formulated to provide optimal bonding strength and compatibility with these particular plastics. They ensure a secure and lasting bond between FRP panels made from these materials.

Benefits of Polyurethane Adhesives for Bonding FRP Panels

First and foremost, polyurethane adhesives are known for their superior strength and durability. When you bond FRP panels with polyurethane adhesives, you can trust that the bond will last for a long time and withstand any challenge. No need to worry about your panels coming loose or breaking apart.

But it’s not just strength – polyurethane adhesives also have exceptional resistance to heat, moisture, and chemicals. FRP panels often face extreme temperature variations, water exposure, and chemical contact. With polyurethane adhesives, your bond remains intact even in these harsh environments.

Flexibility is another key benefit of polyurethane adhesives. Unlike some other adhesives, they have a certain degree of elasticity, allowing them to absorb vibrations and movements without compromising bond strength. So if your FRP panels are subjected to frequent movements or vibrations, polyurethane adhesives are the way to go.

Polyurethane adhesives offer excellent adhesion properties too. They can bond well to a wide range of substrates, including FRP panels, without the need for additional surface preparation or primers. This saves you time and effort during the bonding process.

Additionally, polyurethane adhesives have good gap-filling capabilities. They can fill in small gaps or irregularities between the FRP panels, ensuring a smooth and even bond. This is particularly useful when working with large panels or surfaces that may have slight imperfections.

If speed is a priority for your project, polyurethane adhesives won’t disappoint. They have a relatively fast curing time, typically within a few hours. This allows for faster assembly and installation of your FRP panels, saving you valuable time.

And here’s a bonus advantage: some polyurethane adhesives even have fire-resistant properties. This is crucial for applications where fire safety is a concern, such as in buildings or transportation vehicles.

Preparing the Surfaces Before Applying the Construction Adhesive

To create a sturdy bond between Fiber-Reinforced Polymer (FRP) panels and construction adhesive, proper surface preparation is crucial. Just like building a solid foundation for a house, preparing the surfaces sets the stage for a strong and durable bond that can withstand the test of time, temperature changes, moisture, and more. In this article, we will explore the importance of surface preparation and reveal the secret to achieving a powerful adhesive bond.

Step 1: Cleanliness is Next to Bond-iness

The first step in surface preparation is thorough cleaning. Any dirt, dust, grease, or contaminants can hinder the adhesive’s ability to form a strong bond. Use a mild detergent or specialized cleaner recommended by the adhesive manufacturer to ensure a clean slate. Don’t forget to remove any residue from previous adhesives or sealants as well.

Step 2: Roughen Up for Better Grip

To enhance the adhesive’s grip, lightly sand the surfaces with fine-grit sandpaper. The aim is not to remove excessive material but to create a slightly rough texture that allows the adhesive to penetrate and bond effectively. This roughening process improves the overall strength of the bond.

Step 3: Dry as a Bone

Moisture is the enemy of adhesive bonding. Ensure that the surfaces are completely dry before applying the adhesive. Use a clean cloth or towel to remove any residual moisture, paying attention to hard-to-reach areas. This step guarantees optimal adhesion and prevents any potential weakening of the bond due to moisture.

Step 4: Prime Time

Priming is your secret weapon for improving adhesion. It creates a uniform surface and promotes better penetration of the adhesive. Consult with the adhesive manufacturer for specific primer recommendations suitable for FRP panels. Choosing the right primer ensures that the adhesive bonds securely to both the panels and the substrate.

Step 5: Temperature Matters

Both the FRP panels and the substrate should be at room temperature before applying construction adhesive. Extreme temperatures can affect the adhesive’s curing time and overall performance. Store both the adhesive and panels at room temperature prior to installation for optimal results.

Step 6: Smooth Operator

When it’s time to apply the adhesive, use a suitable applicator like a caulking gun or trowel. This ensures an even application of the adhesive onto one surface, spreading it out with a notched trowel if necessary. Apply the adhesive in an even layer, ensuring it’s evenly distributed without any gaps or voids. Attention to detail during this step ensures a consistent and reliable bond.

How to Apply the Construction Adhesive to the FRP Panels

If you’re ready to install FRP (Fiberglass Reinforced Plastic) panels, it’s crucial to understand how to apply construction adhesive correctly. This step-by-step guide will walk you through the process, ensuring a strong and durable bond that will withstand the test of time.

Step 1: Prepare the Surface

Before applying construction adhesive, ensure that the surface of your FRP panels is clean and free from any dirt, dust, or grease. Wipe down the panels with a damp cloth and allow them to dry completely. This step is essential for achieving optimal adhesion.

Step 2: Apply Adhesive Along Edges and Corners

Using a caulk gun or trowel, generously apply a bead of construction adhesive along the edges and corners of the FRP panels. This ensures a robust bond between the panels and the wall. Don’t be shy with the application; remember, more adhesive means a stronger attachment.

Step 3: Apply Adhesive in Zigzag Pattern

After covering the edges and corners, apply construction adhesive in a zigzag pattern across the back of the panel. This even distribution of adhesive will provide a secure bond between the panel and the wall. Think of it as creating a web of adhesive for maximum strength.

Step 4: Press Panel Firmly onto Wall

With the adhesive applied, firmly press the FRP panel onto the wall, starting from one corner and working your way to the opposite corner. Apply even pressure across the entire surface of the panel using a roller or a block of wood. This ensures that every inch of the panel makes full contact with both the adhesive and the wall, leaving no room for weak points.

Step 5: Leave Gap Between Panels

If you’re installing multiple FRP panels, remember to leave a small gap between each panel to allow for expansion. This gap can be filled with caulk or sealant after installation, providing a clean and finished look. This step is crucial to accommodate any movement or shifting without compromising the integrity of the adhesive bond.

Step 6: Allow Adhesive to Dry Completely

To achieve a strong bond, allow the adhesive to dry completely according to the manufacturer’s instructions. This may take several hours or even a full day, so exercise patience and avoid any unnecessary disturbances. Rushing this step could compromise the overall strength and effectiveness of the adhesive bond.

Alternative Options for Bonding FRP Panels

When it comes to bonding FRP panels, construction adhesive might not always be the best choice. That’s why we’re here to explore alternative options that will ensure a strong and durable bond for your FRP panels. From epoxy adhesives to double-sided tapes and mechanical fasteners, we’ve got you covered.

Epoxy Adhesive:

Epoxy adhesives are the superheroes of bonding non-porous surfaces like FRP panels. With their exceptional strength and durability, they provide a long-lasting bond that can withstand the toughest conditions. To ensure optimal adhesion, thoroughly clean the panel surface before applying the epoxy.

Double-Sided Adhesive Tapes:

For an instant bond without the hassle of curing or drying time, double-sided adhesive tapes are your go-to option. These versatile tapes come in various types, including acrylic foam and high-strength adhesive tapes. Look for tapes specifically designed for non-porous surfaces like FRP panels, and you’ll have a reliable bond in no time.

Mechanical Fasteners:

Sometimes, the old-fashioned way is the best way. Mechanical fasteners, such as screws or nails, provide a strong and reliable bond for your FRP panels. They excel at handling heavy loads or external forces that may be present in your project. Remember to pre-drill holes in the panels and use corrosion-resistant fasteners for maximum durability.

GqrD_G1W4-4″ >

Conclusion

In conclusion, it is not recommended to use construction adhesive for FRP panels.

While construction adhesive may seem like a convenient option, it is not designed to adhere to the specific needs of FRP panels. FRP panels require a specialized adhesive that can withstand the unique challenges of their composition and installation.

It’s essential to choose an adhesive specifically formulated for FRP panels to ensure a secure and long-lasting bond.