Hey there, crafty folks.

Contents

- 1 How Does a Glue Gun Work?

- 2 Melting Point of Nylon

- 3 Risks of Using a Glue Gun on Nylon

- 4 Low-Temperature Glue Guns and Specialized Adhesives

- 5 Preparing the Surfaces for Bonding

- 6 Applying the Adhesive with a Glue Gun

- 7 Setting and Drying Time for the Bonded Areas

- 8 Strength of the Bond Created by a Glue Gun on Nylon

- 9 Conclusion

Got a hankering to whip up some awesome projects with nylon fabric? But hold up, can you actually use a glue gun on this stuff?

Fear not, my creative comrades. In this blog post, we’re gonna dig deep into the world of adhesives and figure out if a glue gun is the right tool for your nylon adventures.

Whether you’re sewing up stylish threads, fixing up bags, or constructing killer costumes, knowing which glues play nice with nylon is crucial. So grab that trusty hot glue gun and let’s find out if it’s gonna be BFFs with your nylon dreams or if you need to explore other options.

Let the crafting commence.

How Does a Glue Gun Work?

Glue guns, those versatile tools that make crafting and DIY projects a breeze, hold a certain mystique. But have you ever stopped to wonder about the intricate mechanisms that make them work? In this article, we will delve into the fascinating inner workings of a glue gun, exploring its components and how they seamlessly come together to create a powerful adhesive tool.

The Heating Element:

At the heart of every glue gun lies the mighty heating element, typically forged from either ceramic or metal. This crucial component is responsible for the magic of melting glue sticks. When plugged into an electrical outlet and switched on, the heating element gradually ignites, reaching scorching temperatures ranging from 250 to 400 degrees Fahrenheit (120 to 200 degrees Celsius).

Melting the Glue Sticks:

With the heating element ablaze, it begins its fiery dance by transforming solid glue sticks into molten goodness. These glue sticks, crafted from thermoplastic materials like EVA or polyamide, eagerly soften under the intense heat, becoming pliable and ready for action.

The Flow of Melted Glue:

Once the glue sticks surrender to the heat, their liquefied form embarks on a daring adventure. Through a narrow channel hidden within the glue gun’s innards, this molten adhesive journeys towards its destination.

The trigger mechanism, faithfully obeying your command, controls the flow of the melted glue with surgical precision. Squeeze the trigger, and like a graceful dancer, it dispenses the adhesive exactly where you desire. Release the trigger, and just like that, the flow stops; any remaining molten glue swiftly solidifies back into its former solid state.

Safety Features:

As we dance amidst the molten glory of a glue gun’s inner workings, we must not forget about safety. Many glue guns come equipped with built-in stands or kickstands, serving as loyal protectors against potential harm. These stands elevate the nozzle above the surface, preventing any accidental contact burns, and ensuring the safety of your fingers and work area.

Using a Glue Gun on Nylon:

Nylon, a delicate material with a melting point around 400 degrees Fahrenheit, requires special attention when using a glue gun. To safeguard the integrity of nylon, opt for a low-temperature glue gun or specialized adhesive formulated explicitly for nylon surfaces. Before applying the adhesive, cleanse the nylon surfaces thoroughly to ensure a robust bond. Apply the adhesive evenly, taking care not to go overboard and risk seepage through the fabric.

Firmly press the nylon surfaces together, following the manufacturer’s instructions for drying time. For even stronger bonds, consider alternative methods like sewing or utilizing specialized adhesives designed specifically for nylon.

Melting Point of Nylon

Nylon, a synthetic polymer renowned for its strength, durability, and versatility, boasts a melting point that sets it apart from other common materials. When it comes to applications requiring heat resistance, nylon stands firm. However, it is important to note that the exact melting point can vary depending on the specific type or grade of nylon being used.

In general, nylon melts between 180°C to 265°C (356°F to 509°F). This range provides a significant window of temperature tolerance, allowing nylon to withstand high levels of heat without losing its structural integrity. Nevertheless, it’s worth mentioning that the presence of additives or fillers in the material can influence the melting point.

When working with nylon and gluing it together, choosing the right adhesive is essential. Using a standard glue stick that melts at a lower temperature could compromise the bond or even damage the fabric. To address this challenge, glue sticks specifically designed for use on nylon are available in the market. These specialized glue sticks have a higher melting point, ensuring effective bonding without compromising the fabric’s integrity.

To ensure you’re selecting the appropriate glue stick for your project, check the packaging or product specifications to confirm its suitability for nylon. Additionally, before applying adhesive to larger areas, performing a test application on a small inconspicuous area of the nylon is recommended. This simple step allows you to assess compatibility and avoid any potential damage or undesirable results.

Risks of Using a Glue Gun on Nylon

Nylon is a versatile material known for its strength and durability, making it a popular choice for various projects. However, when it comes to gluing nylon, caution is key. In this article, we will delve into the potential risks of using a glue gun on nylon and explore alternative bonding methods that can ensure success without compromising the integrity of your project.

Melting and Damage:

Nylon’s low melting point makes it susceptible to damage when exposed to high temperatures. Glue guns typically operate above 200 degrees Celsius, posing a significant risk of warping, burning, or even melting the nylon fabric. Without proper precautions, irreversible damage can occur.

Poor Adhesion:

Nylon’s smooth and slippery surface presents a challenge for glue to adhere effectively. While some glues claim to work on nylon, the bond may not be strong enough to withstand stress or movement. This can result in parts detaching and your project falling apart at the seams.

Discoloration and Staining:

The intense heat from glue guns can cause dyes or pigments in nylon fabric to transfer or bleed, leaving unsightly marks or ruining the appearance of your project. Avoiding gluing mishaps is crucial to maintain the visual appeal of your beautiful creation.

Voiding Warranties:

Using a glue gun on nylon may void warranties or guarantees provided by manufacturers. Following proper care instructions is essential to retain warranty coverage for your nylon products. Deviating from recommended adhesives can have costly consequences.

Alternative Bonding Methods:

Fortunately, there are alternative methods for bonding and repairing nylon fabrics that offer superior results compared to glue guns. Sewing or utilizing specialized fabric adhesives designed for nylon can provide stronger and more durable bonds without the associated risks.

Low-Temperature Glue Guns and Specialized Adhesives

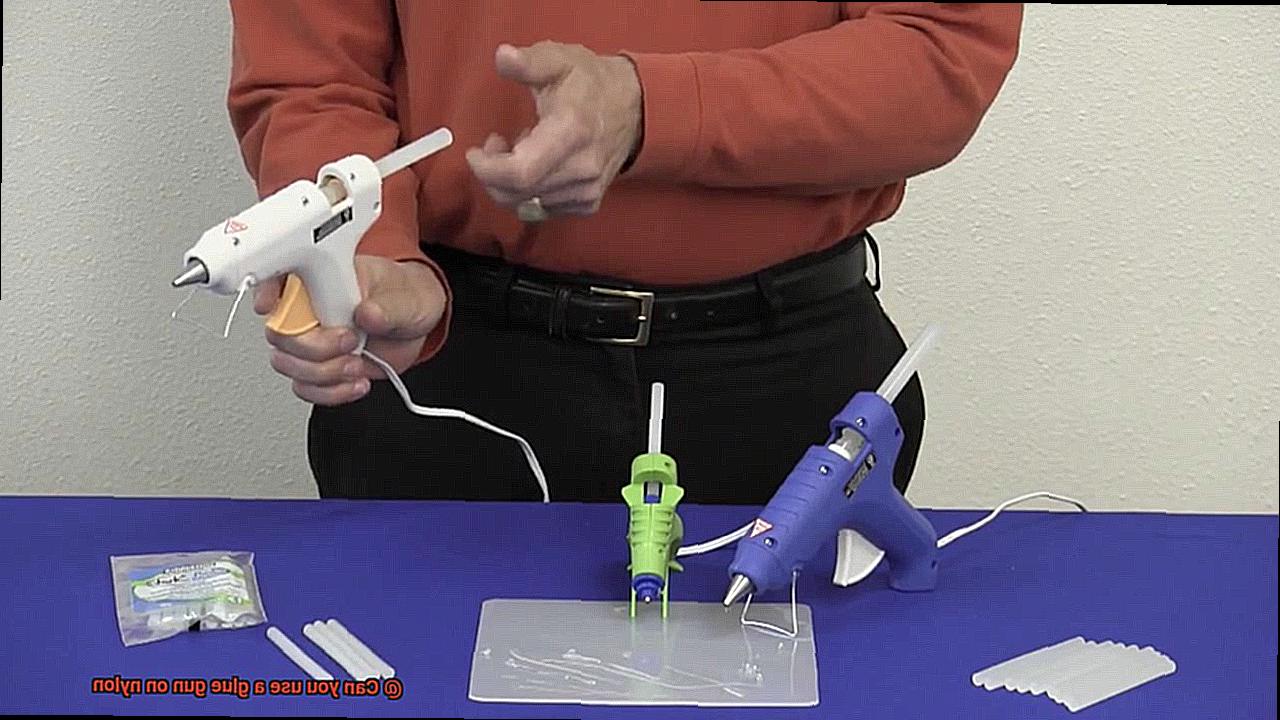

Nylon, the resilient and heat-resistant synthetic polymer, demands a delicate touch when it comes to bonding. Fear not. Low-temperature glue guns come to the rescue. Operating at around 250°F or lower, these magical tools ensure that your precious nylon remains unscathed, untouched by the fiery wrath of melting glue.

But wait, there’s more. The adhesive you choose is equally vital for a bond that withstands the test of time. Specialized adhesives formulated for nylon bonding are designed to cling to this material with unwavering strength. Weak joints be gone – reliable adhesion is here to stay.

Now, when handling low-temperature glue guns on nylon, remember this golden rule: apply the adhesive evenly, avoiding excess like an artist with a discerning eye. Too much adhesive spells disaster – messiness and bulkiness that won’t suit your project’s needs. Remember, less can be more when it comes to glue.

Before committing to the entire surface, take a moment to test the adhesive on a small, inconspicuous area of the nylon fabric or material. This simple precaution ensures compatibility and prevents any unfortunate discoloration or damage from befalling your prized creation.

Ah, low-temperature glue guns are fantastic companions for nylon bonding, but they’re not your only option. For those intricate or detailed projects that require finesse, let specialized liquid adhesives grace your work with their brush or dropper application. These liquid wonders often forge even stronger bonds than their gun-wielding counterparts, leaving your projects intact and visually appealing.

Remember that different applications may call for higher temperatures or specific adhesive types. When uncertainties arise, seek the wisdom of professionals or embark on a research quest to find the perfect solution for your unique project.

Preparing the Surfaces for Bonding

Before embarking on the exciting journey of nylon bonding, it is essential to properly prepare the surfaces for bonding to ensure a strong and durable bond. The process involves several important steps that contribute to the overall success of the project.

The first step in preparing the surfaces is to ensure they are clean and free from any dirt, dust, or debris. Imagine trying to bond two surfaces together with particles getting in the way – it would be a disaster. To avoid this, use a clean cloth to wipe down the surfaces and remove any unwanted substances. If there are any grease or oil stains, a mild detergent can come to the rescue.

Once the surfaces are clean, it’s time to roughen up the surface of the nylon. This may seem counterintuitive, but trust me, it’s crucial. By lightly sanding the nylon with fine-grit sandpaper or using a nylon brush, you create more surface area for the adhesive to bond to. Think of it as providing a rough texture for the adhesive to grip onto tightly.

After roughening the surface, it’s important to clean it again. This step ensures that any loose particles created during the roughening process are removed. You want a smooth and clean surface for optimal bonding – no stray particles interfering with your masterpiece.

Now let’s talk about temperature. Different adhesives have different temperature requirements for optimal bonding. It’s crucial to choose an adhesive that is compatible with both nylon and your trusty glue gun. Additionally, check the recommended temperature range for your adhesive. You want that bond to hold up under various conditions, whether it’s freezing cold or scorching hot.

Lastly, let’s consider flexibility and movement. Nylon has a tendency to expand and contract with changes in temperature and humidity. To accommodate this movement without compromising bond strength, choose an adhesive that can handle these fluctuations. And if you’re feeling extra cautious, design your joint with some flexibility in mind. This will help prevent stress concentrations and potential failure points.

Applying the Adhesive with a Glue Gun

Whether you’re a seasoned pro or just starting out, this guide will equip you with the knowledge and techniques needed to apply adhesive with a glue gun on nylon like a true expert. So, grab your glue gun and let’s dive in.

Step 1: Selecting the Right Adhesive

Not all adhesives are created equal, especially when it comes to bonding nylon. Hot melt adhesives reign supreme in this realm due to their versatility and exceptional bond strength. Look for hot melt adhesives specifically designed for nylon to ensure optimal compatibility.

Step 2: Preparing the Nylon Surface

Before embarking on the bonding process, it is crucial to properly prepare the nylon surface. Start by meticulously cleaning the surface to eliminate any dirt, dust, or grease that may hinder the effectiveness of the adhesive. Once clean, gently sand or roughen up the surface to create minute grooves that enhance adhesion.

Step 3: Applying the Adhesive

Now it’s time to unleash the power of your trusty glue gun. Remember, less is more when it comes to applying adhesive. Work swiftly and meticulously, ensuring a thin and even layer of melted adhesive is applied to both surfaces being bonded. Avoid excessive buildup or dripping, as this can compromise both appearance and bond strength.

Step 4: Bonding Like a Pro

With the adhesive expertly applied, bring the surfaces together swiftly but firmly while the glue is still hot. This guarantees maximum contact between the adhesive and nylon, resulting in an indomitable bond. Keep in mind that nylon boasts flexibility and movement, so allow for some give in your bond to accommodate these innate characteristics.

Step 5: Patience is Key

After the bonding process, resist the temptation to rush. Allow ample time for the adhesive to cool and set, adhering to the specific drying time recommended by the manufacturer. This crucial step ensures a robust and enduring bond that can withstand any challenge.

Setting and Drying Time for the Bonded Areas

If you’re curious about the setting and drying time for bonded areas when using a glue gun on nylon, you’ve come to the right place. In this guide, we’ll delve into the nitty-gritty details, so grab your favorite beverage, sit back, and let’s dive in.

Choosing the Right Glue Stick:

When bonding nylon with a glue gun, opt for high-temperature glue sticks designed specifically for materials like nylon. Ensure you select a high-quality glue stick that meets your project requirements.

Setting Time:

The setting time refers to how long it takes for the glue to bond the nylon surfaces together. Depending on the type of glue stick used, setting times can range from a few seconds to several minutes. Follow the manufacturer’s instructions for accurate setting time.

Pressure is Key:

To achieve a quicker set, apply gentle pressure on the bonded areas immediately after bonding them. This helps create a secure bond and reduces the setting time.

Drying Time:

Once the bonded areas have set, allow them to dry completely. Drying times can be influenced by temperature, humidity, and the thickness of the glue applied. As a general rule of thumb, wait at least 24 hours before subjecting the glued nylon to any stress or strain.

Patience is Virtuous:

During the drying process, resist the temptation to touch or manipulate the bonded areas. Let them dry undisturbed to ensure a strong and durable bond.

Manufacturer’s Recommendations:

Different glues may have varying drying times due to their unique formulations. Some glues may dry faster with heat or air circulation. Always refer to the manufacturer’s recommendations for specific drying times.

Strength of the Bond Created by a Glue Gun on Nylon

The strength of the bond created by a glue gun on nylon is influenced by various factors that must be taken into consideration. By understanding these factors, you can ensure a strong and durable bond that meets your specific application requirements.

The type of glue you choose is crucial in determining the strength of the bond. Glue guns typically use hot melt adhesives, which are solid at room temperature and melt when heated. These adhesives can be made from different materials such as thermoplastic polymers or synthetic resins. It is important to select a hot melt adhesive specifically designed for bonding nylon. These adhesives are formulated to have excellent adhesion properties to nylon and provide a strong bond.

Surface preparation also plays a vital role in achieving a strong bond between the glue gun adhesive and nylon. The surface of the nylon must be clean, dry, and free from any contaminants that may hinder the adhesion process. If necessary, roughening the surface with sandpaper or using a primer specifically designed for nylon can enhance the bond strength.

External factors such as temperature and humidity can also impact the strength of the bond. Extreme temperatures or high levels of humidity may affect the performance and durability of the adhesive bond. Thus, it is essential to consider the intended application and environmental conditions when selecting a glue gun adhesive for bonding nylon.

To ensure that the chosen adhesive provides the desired level of bond strength, it is recommended to test it on a small, inconspicuous area of the nylon material before applying it to the entire surface. This will help determine if the adhesive is suitable and meets your specific requirements.

Conclusion

Using a glue gun on nylon can be quite the challenge, but fear not. With the right approach and some expert tips, you can create a bond that’s as strong as Hercules himself.

Nylon is a delicate fabric with a low melting point, so it’s important to choose your glue gun wisely. Opt for a low-temperature glue gun or better yet, get your hands on a specialized adhesive made specifically for nylon surfaces. This way, you’ll avoid any unwanted fabric-frying mishaps.

But wait, there’s more. Prepping the surface is crucial when working with nylon. Give it a thorough cleaning and roughen it up with sandpaper or a trusty nylon brush. This creates more grip for the adhesive to hold onto tightly, ensuring your bond won’t go down without a fight.

When it comes time to apply the glue, remember: less is more. A thin and even layer of melted adhesive on both surfaces is all you need. Don’t go overboard with excessive buildup or dripping – we don’t want any unsightly messes ruining our masterpiece.

Patience is key in this game. Allow ample time for the adhesive to cool and set before putting any strain on your creation. Follow the drying time recommended by the manufacturer to guarantee a bond that can stand up to anything life throws its way.

Now, let’s talk about risks because knowledge is power, my friend. Using a glue gun on nylon does come with some potential pitfalls – melting or damaging the fabric, poor adhesion, discoloration or staining – just to name a few. If you want to play it safe (and who doesn’t?), consider alternative bonding methods like sewing or using specialized fabric adhesives designed exclusively for nylon.

In essence, while using a glue gun on nylon may require some finesse and know-how, it’s totally doable. So unleash your inner artist and tackle those fabulous nylon projects with confidence.