Today, we’re diving into the world of PVC pipes to answer a burning question: Can you unglue PVC and reuse it? We all know that PVC (polyvinyl chloride) is the go-to material for plumbing and construction because it’s tough as nails and won’t break the bank.

But what if you want to switch up your pipe layout or fix a busted section? Is it possible to undo those glued joints and salvage your PVC fittings?

Well, get ready because we’re about to spill the beans on the potential perks and pitfalls of ungluing PVC. And don’t worry, we’ll also dish out the step-by-step guide on how to do it safely and effectively.

So buckle up, folks, because we’re about to uncover the secrets behind PVC reusability.

How to Unglue PVC

Contents

- 1 How to Unglue PVC

- 2 Using Heat to Unglue PVC

- 3 Using Chemical Solvents to Unglue PVC

- 4 Combining Heat and Solvent for Effective Ungluing of PVC

- 5 The Risks of Reusing Unglued PVC

- 6 Inspecting the Pieces After Ungluing

- 7 When Should You Replace the Parts?

- 8 Tips for Successful Reuse of Unglued PVC

- 9 Conclusion

Well, today is your lucky day because we’re diving into the fascinating world of PVC glue and learning how to break those strong bonds. Whether you’re tackling a plumbing project or just want to reuse your PVC, we’ve got you covered. So, let’s roll up our sleeves and get started.

The Heat is On:

When it comes to ungluing PVC, heat can be your secret weapon. Grab a heat gun or a hairdryer set on high heat, and gently warm up the glued joint. As the adhesive softens, give those pipes a twist and a pull. Voila. They should come apart like magic. But tread carefully. Remember to keep the heat even and avoid overheating, or you might end up with melted PVC.

Power of the Saw:

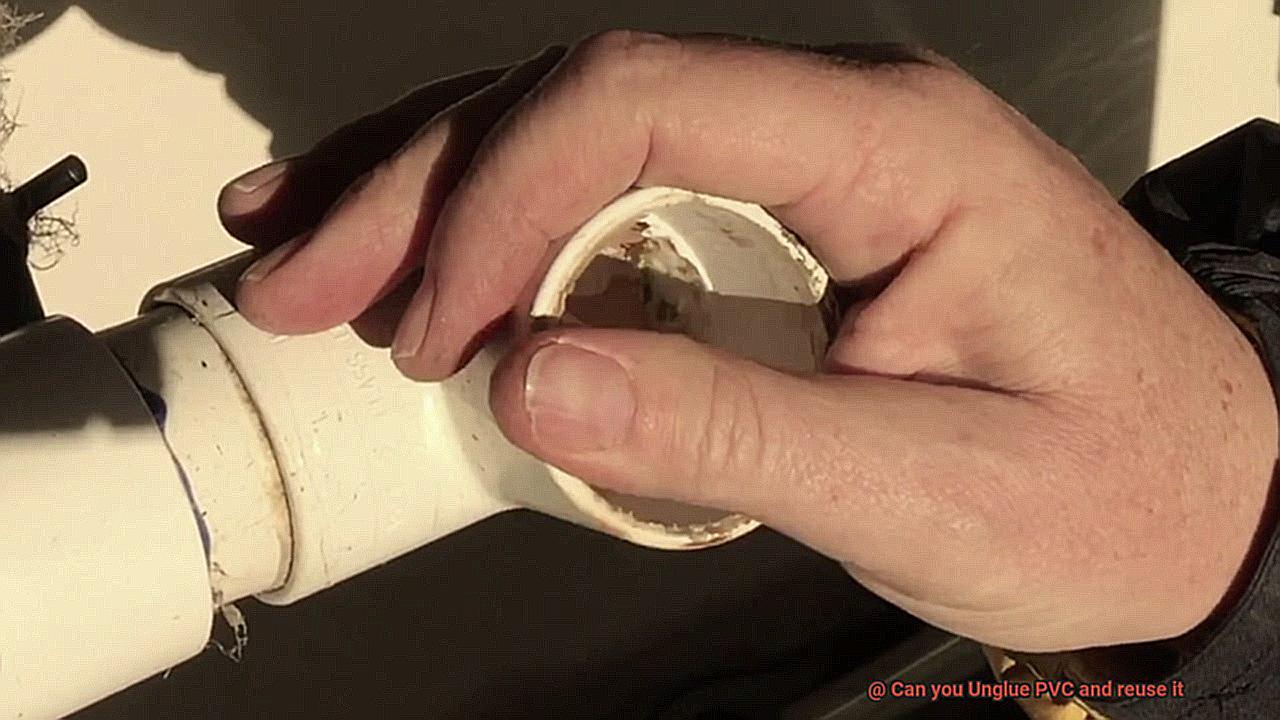

Sometimes, you need some mechanical muscle to separate those stubborn PVC pieces. Take out your trusty hacksaw or reciprocating saw, and carefully cut through the glued joint. Take your time and make sure not to damage the surrounding pipes or fittings. Once you’ve made that incision, grab your pliers or wrench and pry open the joint like a superhero. With a little determination and precision, those glued pieces will be no match for you.

The Magic of Solvents:

If heat and saws aren’t doing the trick, it’s time to bring in the solvents. Acetone, found in nail polish remover, can work wonders on PVC glue. Apply some acetone onto a cloth or sponge and rub it onto the glued joint. Let it sit for a few minutes, allowing the solvent to work its magic. Then, put those muscles to work and give those pipes a twist and a gentle pull. With a little bit of solvent sorcery, you’ll be able to unglue that PVC and give it a second life.

When in Doubt, Seek Help:

Sometimes, even the most determined DIYers need a helping hand. If all else fails or you’re unsure about ungluing PVC, it’s best to reach out to a professional plumber or contractor. They have the experience and knowledge to tackle those stubborn joints and can offer advice on the best course of action. Don’t be afraid to ask for help when you need it.

Conclusion:

Congratulations, DIY champs. You’ve now mastered the art of ungluing PVC and giving it a second life. Whether you used heat, saws, or solvents, your persistence paid off. Remember, safety first. Take precautions, be patient, and assess the condition of your PVC before attempting to reuse it. With these tips in your toolbox, you’re ready to tackle any PVC project that comes your way.

Using Heat to Unglue PVC

Imagine you’re knee-deep in a plumbing project, only to discover that you need to separate PVC joints that have been securely glued together. Don’t panic. In this comprehensive guide, we will delve into the fascinating world of using heat to unglue PVC joints. Get ready to become a master of ungluing as we uncover the secrets behind this superhero-like technique.

Safety First:

Before we embark on the thrilling process of heat ungluing, let’s prioritize our safety gear. Make sure you don your trusty safety goggles and gloves, protecting yourself from any potential mishaps during the process.

Choosing the Right Heat Source:

Now that we’re geared up, it’s time to select the perfect heat source. There are two popular options: the heat gun and the blowtorch. These tools can reach scorching temperatures, so handle them with caution and keep fire hazards at bay.

Applying Heat:

With our heat source in hand, point it towards the glued joint. Move it back and forth evenly, ensuring that the heat is distributed without overheating or damaging the PVC pipe. Our goal is to soften the adhesive without melting or compromising the integrity of the pipe itself – a delicate balance indeed.

Testing and Separating:

As the adhesive begins to yield under the heat’s gentle caress, apply gentle pressure to test if the joint starts to give way. Remember, patience is key here. If necessary, continue applying heat until the adhesive reaches that magical pliable state where the joint can be easily pulled apart.

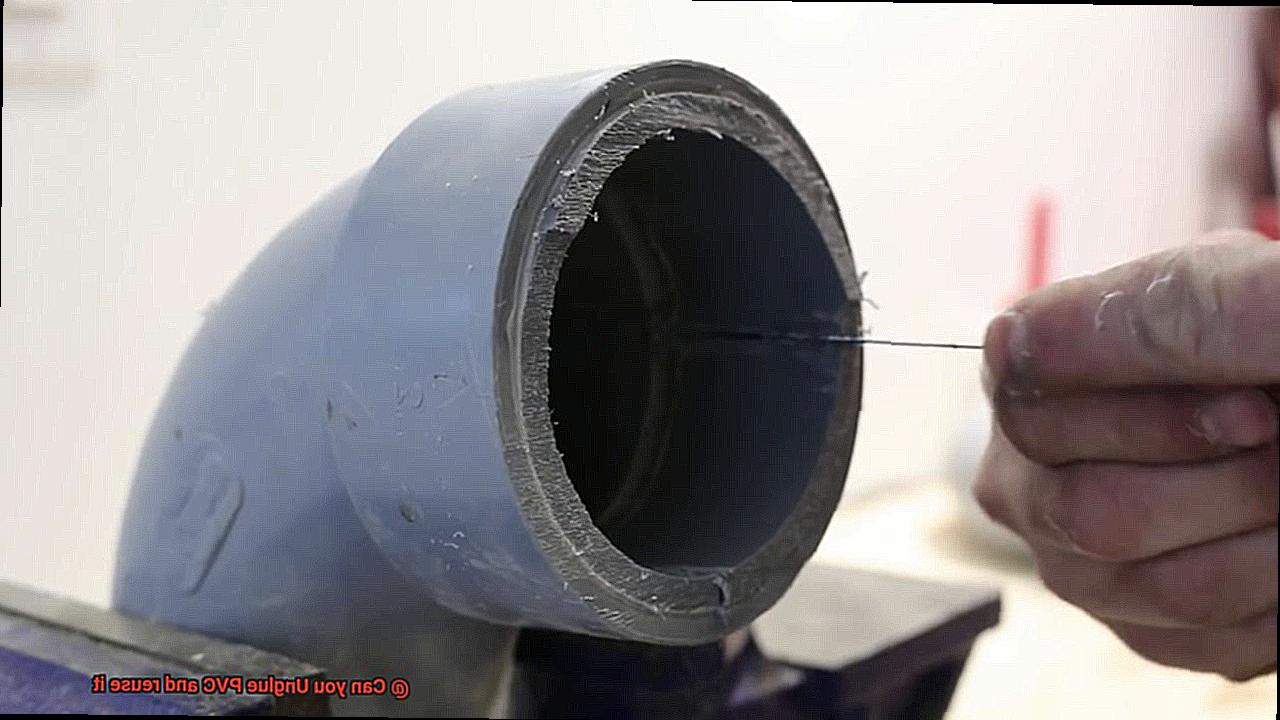

Adhesive Removal:

Once you’ve successfully separated the joint, it’s time for some cleanup. Use a plastic scraper or putty knife to scrape off any remaining adhesive. Avoid using metal tools to prevent scratching or damaging the PVC pipe – our goal is restoration, not destruction.

Cleaning and Rejoining:

Before rejoining the PVC pipes with new adhesive, ensure that both ends are thoroughly cleaned. Use a PVC pipe cleaner to remove any residue from the old glue, leaving you with a fresh canvas for your next masterpiece of plumbing.

Using Chemical Solvents to Unglue PVC

In this comprehensive guide, we will explore the process of using chemical solvents to break down PVC cement and free your components. So, gear up and get ready for an exciting adventure.

Step 1: Prioritize Safety:

Ensure your safety by wearing gloves and eye protection. Work in a well-ventilated area to avoid inhaling any fumes. Remember, safety is the key to success.

Step 2: Acetone – The Mighty Solvent:

Start by applying acetone directly to the glued joint. Let it penetrate the bond for a few minutes. Acetone, readily available at hardware stores, is a powerful solvent against PVC cement.

Step 3: Gentle Separation:

Tap the joint with a rubber mallet or use a pipe wrench to twist and separate the pieces. The weakened bond should make them come apart easily. If not, it’s time for reinforcements.

Step 4: Repeat and Pry:

If the pieces refuse to budge, repeat the acetone application process and allow it to soak for longer. Use a scraper or putty knife to carefully pry apart stubborn joints.

Step 5: Alternative Solvents:

In some cases, acetone might not be enough. Enter methyl ethyl ketone (MEK) and tetrahydrofuran (THF), alternative solvents more effective in breaking down stubborn bonds. Handle these chemicals with care and follow safety guidelines.

Step 6: Cleanse and Renew:

After successfully ungluing PVC, thoroughly clean the components to remove any residue before regluing or reusing them. This ensures a strong bond and a fresh start.

Combining Heat and Solvent for Effective Ungluing of PVC

Polyvinyl chloride (PVC) is a tough plastic widely used in construction and plumbing. Its strong bond can be quite a challenge to break. But fear not, we have the perfect solution. In this article, we will delve into the powerful combination of heat and solvents to effectively unglue PVC and restore your components to their former glory.

Let’s start with heat. By directing heat onto the glued joint using a heat gun or hairdryer, you can soften the adhesive and make it easier to separate the pieces. Begin with low heat and gradually increase if needed, taking care not to damage the plastic. Picture the adhesive melting away under the gentle warmth, giving way to freedom.

But why stop there? Solvents are the secret weapon in this ungluing battle. Acetone and methylene chloride are renowned for their adhesive-dissolving prowess. Apply these solvents directly to the glued joint, allowing them to seep into the adhesive for a few minutes. The solvents work their magic, breaking down the bond further. Remember, safety first. Don your protective gloves and eye gear as you handle these potent chemicals.

It’s important to note that not all solvents are compatible with PVC. Some can harm or degrade the plastic. To be safe, always test a small, inconspicuous area before applying solvents to the glued joint. Be patient, my friend. Successful ungluing may require multiple applications of solvent and heat.

Once you’ve triumphantly unglued your PVC components, it’s time for a thorough cleaning. Use a solvent or abrasive pad to eradicate any remnants of adhesive residue. This step is crucial for ensuring a strong bond when re-gluing the PVC.

However, before diving into re-gluing, take a moment to assess the condition of your PVC and the strength of its original bond. If the ungluing process caused damage or weakened the PVC, it might not be suitable for reuse. And if that original bond was as solid as a rock, achieving a secure bond during re-gluing may prove challenging.

The Risks of Reusing Unglued PVC

Working with PVC can be a testament to its strength and durability. However, when the bond is broken and you consider reusing unglued PVC, there are several risks that must be taken into account.

- Structural Weakness: Unglued PVC may have weakened or damaged sections that compromise its structural integrity. Wear and tear over time can make the pipe or fitting less reliable, leading to potential leaks or even catastrophic failures depending on the application.

- Contaminants: If the PVC was previously used for specific purposes like plumbing or electrical work, it could contain residue or contaminants that pose a risk to a new project. This becomes particularly concerning when dealing with potable water or sensitive electronic equipment.

- Challenging Process: The process of ungluing PVC can be challenging and may result in further damage to the pipe or fitting. The use of solvents or heat to remove the adhesive can release harmful fumes, posing health risks and potentially causing burns if mishandled.

- Insecure Fit: Even if you successfully unglue the PVC, there is no guarantee that it will fit together securely again. The adhesive was designed to create a permanent bond between the pipe and fitting, and reusing unglued PVC disregards this intended purpose. This significantly increases the risk of leaks or failures, especially in critical applications involving high pressure or temperature.

Inspecting the Pieces After Ungluing

Now, before you jump back into the glue game, it’s crucial to inspect those pieces thoroughly. We want our projects to be safe and secure, don’t we? So, grab a cup of coffee and let’s dive into the world of inspecting PVC pieces after ungluing them.

First and foremost, examine the surfaces of your PVC pipes or fittings. Look closely for any cracks, breaks, or warping. These imperfections could be signs that your PVC has seen better days and might not be suitable for reuse. After all, nobody wants a leaky mess ruining their hard work.

Next, let’s focus on those edges. Take a close look and ensure they are clean and free from any rough or jagged bits. It’s essential to maintain the integrity of your joint when putting everything back together.

Now, let’s talk about leftover adhesive residue. Make sure that stuff is completely gone before attempting to reuse your PVC. Trust me, you don’t want any sticky surprises down the line.

Moving on to threads and connectors – these little guys play a big role in creating a tight and leak-free connection. Take a good look at them and make sure they’re intact and undamaged. Give them some extra attention because even the smallest flaw could compromise the joint.

And here’s a pro tip: whip out that measuring tape. Check the dimensions of your unglued PVC pieces. Any significant changes in size could indicate weakness or deformation during the ungluing process.

Now, I know this might seem overwhelming, but if you’re unsure about the condition of your unglued PVC pieces, don’t hesitate to consult with a professional or an expert in PVC materials. They have the knowledge and experience to give you the best advice for reusing your PVC.

So there you have it, folks. Inspecting your unglued PVC pieces is crucial before diving back into the glue game. Stay safe, stay secure, and happy DIYing.

When Should You Replace the Parts?

PVC pipes and fittings quietly perform the essential task of carrying water and waste throughout our homes. However, like all things, they have a lifespan. In this comprehensive guide, we will explore when it is necessary to replace PVC pipes and fittings, with a particular focus on the use of glue. Let’s dive in and uncover the signs that indicate the need for replacements.

Damaged or Cracked Parts:

The most obvious sign that you need to replace PVC pipes and fittings is visible damage. Cracks, breaks, and leaks are clear indicators that your plumbing system needs attention. Ignoring these issues can lead to further damage, costing you more in the long run.

Aging Pipes:

While PVC is known for its durability, older pipes may start showing signs of wear and tear. Brittle and cracking PVC can increase the risk of leaks and water damage. If your system is several decades old, it may be wise to consider replacing the parts as a preventative measure, ensuring your plumbing system remains reliable.

Changes in Plumbing Regulations:

Plumbing codes are regularly updated to ensure safety and efficiency. If your current PVC system does not meet the latest code requirements, it is essential to replace the outdated parts to comply with regulations. This ensures your system operates optimally while keeping you and your home safe from potential hazards.

Advancements in Technology:

The plumbing industry constantly evolves, offering improved materials and technologies that enhance performance and longevity. Upgrading your PVC system may be beneficial if there have been advancements that make your system more efficient or durable. Embracing these advancements can save you money on maintenance and repairs in the future.

Remodeling or Renovation Projects:

If you’re planning any remodeling or renovation projects that involve altering or extending your plumbing system, it might be necessary to replace some or all of the PVC parts involved. Ensuring compatibility and proper integration with the existing system will help maintain optimal functionality, preventing potential issues down the line.

Tips for Successful Reuse of Unglued PVC

Reusing PVC pipes and fittings not only saves money but also helps reduce waste. However, ungluing PVC can be a challenging task that requires proper techniques and precautions. In this comprehensive guide, we will provide you with essential tips and guidelines for successfully reusing unglued PVC.

Thorough Inspection:

Before attempting to unglue PVC, carefully inspect the pipes for any cracks, chips, or breaks. Damaged PVC may compromise its structural integrity and render it unsuitable for reuse. Additionally, check for remnants of glue or adhesive on the pipe, as they can hinder the effectiveness of new adhesive.

Protect Yourself:

Always prioritize safety by wearing protective gear such as gloves and safety goggles when working with PVC and adhesives. This ensures that you are shielded from potential chemical reactions or accidents during the ungluing process.

Choose the Right Technique:

There are various methods to unglue PVC, but one common approach is using heat. Apply heat to the glued joint using a heat gun or a hairdryer to soften the adhesive, making it easier to separate the pipes. Remember not to overheat the PVC, as excessive heat can cause damage.

Opt for Solvent Solutions:

Another effective method involves using a solvent specifically designed for PVC pipes. These solvents dissolve the adhesive, allowing for easy separation of the pipes. Follow the manufacturer’s instructions carefully and ensure proper ventilation in your workspace.

Thorough Cleaning:

After successfully ungluing the PVC pipes, clean them thoroughly before reuse. Remove any leftover adhesive or residue using a solvent or suitable cleaning agent. This step guarantees proper adhesion when reassembling the pipes.

Select Appropriate Adhesive:

Choose an adhesive specifically designed for bonding PVC pipes back together. Consider the type of PVC and the intended application when selecting the adhesive. There are various types available, so make sure to choose one suitable for your specific needs.

HuWuxVfHJ6o” >

Conclusion

Yes, it is possible to unglue PVC and reuse it. PVC, or polyvinyl chloride, is a type of plastic commonly used in plumbing and construction projects. While PVC glue forms a strong bond when initially applied, there are methods to break the bond and separate the pieces.

One method involves using heat to soften the PVC adhesive. By applying heat from a heat gun or hairdryer to the glued joint, the adhesive can be softened and loosened. Once softened, the pieces can be carefully separated without causing damage.

Another method involves using a solvent specifically designed for PVC glue removal. These solvents work by dissolving the adhesive, allowing for easy separation of the glued parts. It is important to follow the instructions provided with the solvent and take necessary safety precautions when using chemicals.

However, it’s important to note that while it is possible to unglue PVC and reuse it, there may be some limitations. The strength of the bond may be compromised after ungluing, so it’s essential to assess whether the material is still suitable for its intended purpose.

In conclusion, with proper techniques such as applying heat or using solvent-based products, PVC can be unglued and reused. However, caution should be exercised as there might be some loss in strength after ungluing.