If you’ve ever found yourself anxiously waiting for your Sugru creation to dry, prepare to have your mind blown. We’re about to reveal the hidden techniques that will have your squishy masterpiece transformed into a solid wonder in record time. Buckle up as we dive deep into the science behind Sugru’s curing process and share some genius tips and tricks. Get ready to become a speed demon in the world of Sugru.

Details:

Contents

Sugru, that magical moldable glue, gradually turns into durable silicone rubber when exposed to air. Normally, it takes around 24 hours for it to dry completely. But who has time for waiting? Fear not. There are ways to turbocharge this process without sacrificing quality. One method involves maximizing airflow around your Sugru creation by placing it near a fan or using a hairdryer on low heat. This encourages moisture evaporation and speeds up the curing process. Another option is utilizing gentle heat from an oven set on low, but beware of potential damage and keep a close eye on it. You can also divide Sugru into smaller portions or spread it out thinly for faster drying due to increased surface area exposure. Just remember to protect unused Sugru from premature drying.

Potential Benefits:

Imagine the possibilities that come with cutting down drying time. From quick fixes to supercharging your creative projects, saving precious hours could mean instant gratification instead of impatiently staring at wet glue. Whether you’re repairing a frayed cable, customizing your beloved gadget, or crafting a one-of-a-kind masterpiece, knowing how to make Sugru dry faster will revolutionize your productivity and ignite new waves of inspiration.

Tips and Tricks:

This blog post isn’t just about speeding things up; we’ve got some nifty tricks up our sleeves too. From applying thinner layers of Sugru to mixing it with faster-drying additives, we’ll show you how to achieve lightning-fast results. And don’t worry, we haven’t forgotten about storage. We’ll share valuable insights on how to keep your Sugru fresh and pliable for future projects.

Conclusion:

Prepare to unlock the secrets of Sugru’s lightning-fast drying and take your creativity to new heights. With our expert advice and insider tips, you’ll become a master of time-saving DIY solutions in no time. So, get ready to leave waiting in the dust

What is Sugru?

Imagine having a glue that can repair anything, modify everyday objects, and unleash your creativity all at once. Look no further than Sugru, the revolutionary moldable glue that has taken the DIY world by storm. Created by product design student Jane ni Dhulchaointigh, Sugru is a silicone-based substance that starts off as a pliable putty and transforms into a durable rubber-like material. In this article, we will delve into the wonders of Sugru, its versatile applications, and techniques to speed up the drying process for those times when you need it fast.

Versatile Applications:

Sugru’s versatility knows no bounds. From fixing broken objects to modifying and improving everyday items, Sugru offers endless possibilities. Its adhesive properties allow it to bond to metals, plastics, ceramics, glass, wood, and fabrics. Whether you want to repair a frayed cable, reinforce weak spots in your shoes, or create custom grips for your tools, Sugru has got you covered.

Impressive Properties:

What sets Sugru apart from traditional glues is its ability to cure into a strong and resilient rubber-like material. Once applied, Sugru takes approximately 24 hours to fully cure at room temperature. During this time, it transforms from a malleable putty into a tough and durable substance that can withstand various environmental conditions. It is waterproof, heat-resistant (up to 180°C/356°F), and electrically insulating, making it suitable for a wide range of applications.

Accelerating the Drying Process:

While Sugru’s curing time is relatively quick compared to other adhesives, there may be instances where you need it to dry faster. Here are some techniques you can use:

- Applying Heat: Gently warming the surface with a hairdryer or heat gun can accelerate the chemical reaction that causes Sugru to cure. Be cautious not to overheat the material.

- Reducing Thickness: Thicker layers of Sugru take longer to dry. Spreading it out into thinner layers or using smaller amounts at a time will speed up the drying process.

- Increasing Airflow: Adequate ventilation helps dissipate moisture from the surface, allowing for faster curing. Place your project in a well-ventilated area or near a fan.

- Controlling Humidity: High humidity can slow down the curing process. Use dehumidifiers or air conditioning to lower the humidity in the environment for faster drying.

Applying Heat to Speed Up Drying

Introduction:

Welcome, fellow enthusiasts of the adhesive world. Today, we embark on an exciting journey into the realm of expediting the drying process of Sugru by harnessing the power of heat. If you’re an avid user of this versatile moldable glue and yearn for quicker project completion, this article is tailor-made for you. So, let’s dive in.

The Science Behind It:

Why does heat prove to be a valuable ally in speeding up Sugru’s drying time? Well, my curious comrades, when heat is applied, it ignites a chemical reaction that propels the drying process into overdrive. The molecules within Sugru become infused with heightened kinetic energy, causing them to zip around at an accelerated pace and collide more frequently. These frenzied encounters facilitate the vital cross-linking of polymer chains within Sugru, resulting in a swift and efficient cure.

Practical Methods:

Now that we’ve unraveled the scientific magic behind it, let’s delve into some practical methods that can be employed to apply heat and expedite drying. Firstly, one popular option is utilizing a hairdryer or heat gun. By directing a stream of hot air onto the Sugru-coated surface, you’re effectively ushering the heat deep into its core, thereby turbocharging the curing process. However, exercise caution and initiate with low heat settings, gradually increasing if necessary to avoid any unfortunate mishaps like burnt or brittle Sugru.

Another technique involves placing your Sugru-clad masterpiece in a warm environment. Seek solace near a radiator or even in an oven set at a low temperature. The gentle warmth enveloping your creation will work its enchantment and accelerate the drying process.

Thickness Considerations:

Ah, but wait. Let us not forget the crucial factor of thickness when it comes to Sugru application. Thicker layers naturally demand more time to dry, even with the application of heat. Thus, dear readers, adjust your expectations accordingly and summon patience when dealing with generous amounts of this wondrous glue.

Manufacturer’s Instructions:

Furthermore, it is imperative to note that different types of Sugru may possess specific optimal temperatures for drying. To ensure success, consult the manufacturer’s instructions for comprehensive guidance on temperature ranges and drying times.

Reducing Thickness of Sugru

Reducing the thickness of Sugru is a challenge that many users face when working with this versatile material. Achieving a thin layer or precise application can be tricky, but fear not. There are effective techniques that can help you conquer this obstacle and achieve a faster drying time.

First and foremost, it’s crucial to understand the impact of thickness on drying time. Thicker layers of Sugru naturally take longer to cure compared to thinner layers. Therefore, if you’re looking to speed up the process, it’s essential to apply a thin layer of Sugru.

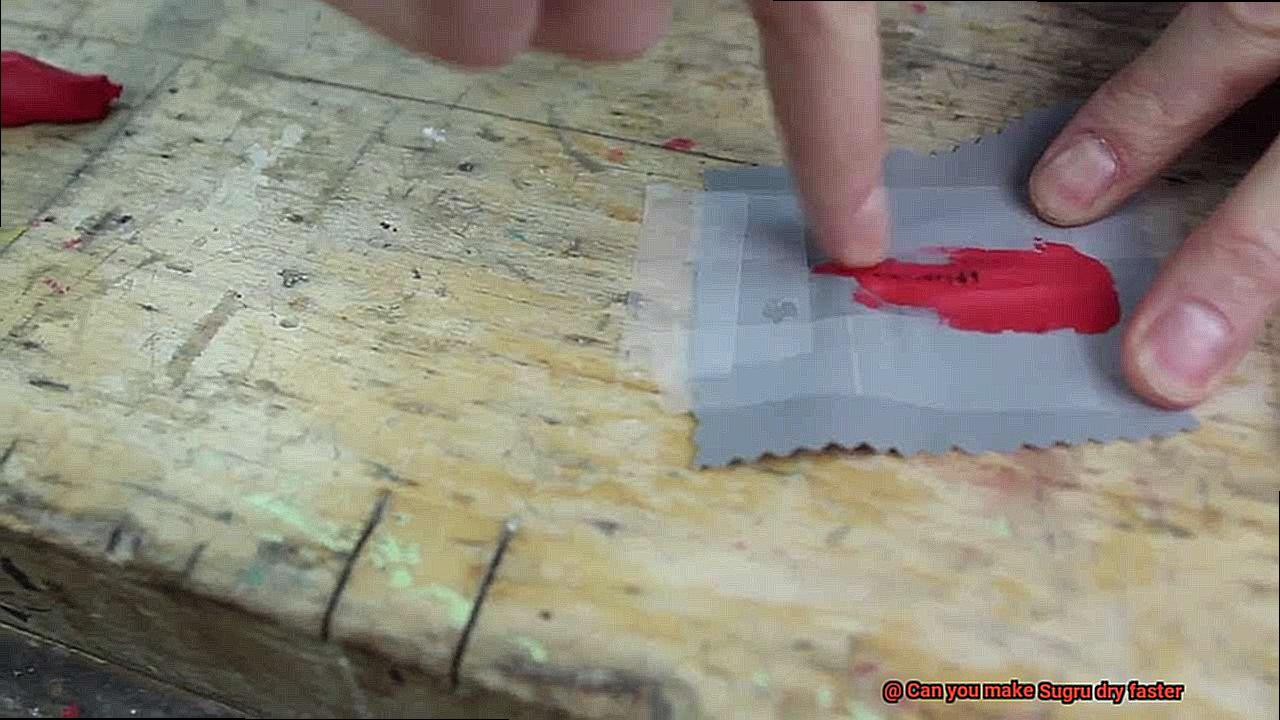

One technique that works wonders is stretching the Sugru before application. Start by tearing off a small piece of Sugru and roll it into a ball. Then, gently stretch and pull the Sugru between your fingers. As you do so, you’ll notice it becoming thinner and more pliable. This stretched-out Sugru is now ready to be applied in a thin layer onto your desired surface.

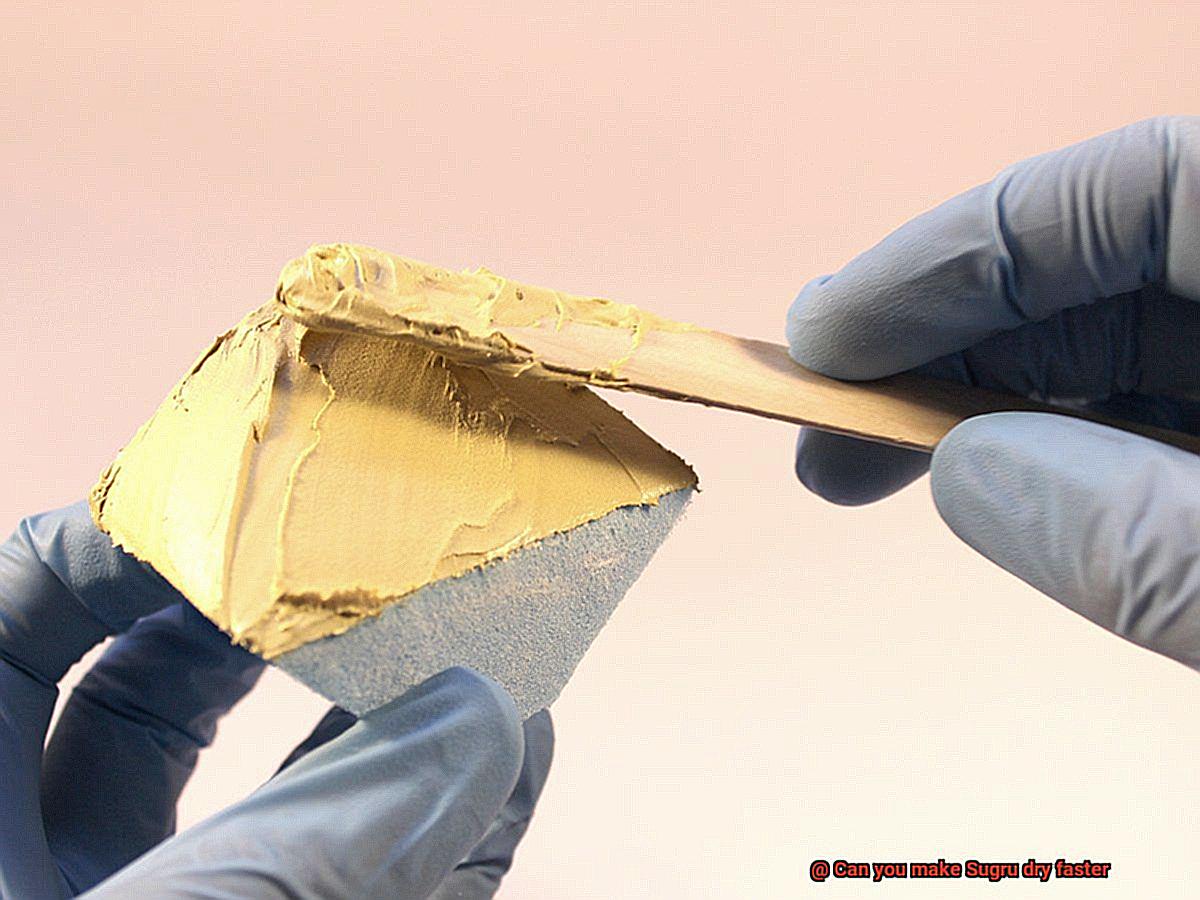

Alternatively, you can roll out the Sugru using a rolling pin or any similar tool. Begin by placing the desired amount of Sugru on a clean surface. Then, confidently roll it out into a thin sheet, just like you would with dough. This method gives you complete control over the thickness of your Sugru and ensures an even application.

If you prefer a more hands-on approach, grab a spatula or any similar tool after stretching or rolling out the Sugru. Use its flat edge to spread the Sugru evenly onto your intended surface. This technique guarantees a thin and smooth layer of Sugru that will dry in no time.

However, it’s important to note that thinner layers may have reduced adhesive strength compared to thicker ones. To reinforce them, consider using additional support like tape or wire if needed. By taking this extra step, you can ensure that your thin layers of Sugru stay firmly in place.

Increasing Airflow Around Sugru

Sugru is a versatile and moldable adhesive used for DIY projects and repairs. While it offers convenience, waiting for it to dry can sometimes feel like an eternity. Fortunately, there are effective ways to speed up the drying process, such as increasing airflow around Sugru. In this blog post, we will explore how improving airflow can help expedite Sugru’s drying time, providing valuable tips and techniques for faster results.

Understanding the Science Behind Drying:

When exposed to air, Sugru forms a thin skin on its surface, initiating the drying process. By enhancing airflow, you facilitate the evaporation of moisture from Sugru, leading to faster drying times. The movement of air helps carry away moisture content from the material, allowing it to dry more quickly.

Harnessing the Power of Fans:

Placing a fan near the area where Sugru is applied can significantly increase airflow and expedite the drying process. Experiment with different fan speeds and positions to find the optimal setup for your project. Be mindful not to position the fan too close to the Sugru, as excessive drying may cause cracks or uneven drying.

Utilizing Hairdryers Strategically:

Another method to enhance airflow is by using a hairdryer on a low or cool setting. Direct the airflow towards Sugru to speed up drying. However, maintain an appropriate distance between the hairdryer and Sugru to prevent overheating or damage to the material.

Positioning Objects for Improved Airflow:

Strategically placing objects near Sugru can increase airflow and speed up drying. Consider placing your project near an open window or using a desk fan in close proximity to circulate fresh air. This technique is particularly useful for larger or bulkier applications of Sugru, ensuring all areas receive adequate airflow.

Patience is Key:

While increasing airflow accelerates the drying process, it’s important to allow sufficient time for complete curing. Rushing the process may result in weaker bond strength or reduced durability. Always follow the manufacturer’s instructions regarding drying and curing times for optimal results.

Controlling Humidity Levels for Faster Drying

Well, I’ve got great news for you – controlling humidity levels can be the secret to speeding up the drying process of this magical glue. Let’s dive into the details of how humidity affects the drying time of Sugru, and explore practical methods to control humidity and supercharge your drying experience.

Humidity is all about moisture in the air, and it plays a significant role in how quickly adhesives like Sugru dry. High humidity levels can slow down the process because excess moisture hinders the evaporation of water in the adhesive. On the flip side, low humidity levels can help accelerate drying by allowing water to evaporate more efficiently.

So, how can you control humidity levels and turbocharge the drying time of Sugru? Here are some practical methods:

- Dehumidifiers: These handy devices are specifically designed to suck out excess moisture from the air. By using a dehumidifier in your drying area, you can create a drier environment and promote faster drying of Sugru.

- Fans and ventilation: Increasing airflow around your Sugru can work wonders. Utilize fans or ventilation systems to improve air circulation, facilitating quicker evaporation and drying.

- Desiccants: Ever seen those small silica gel packets that come with new shoes or electronics? Well, they’re actually desiccants. Placing these moisture-absorbing materials near your drying area can help remove excess moisture from the air and speed up the drying process.

Remember, it’s all about finding the right balance. While controlling humidity can accelerate drying, excessively dry conditions may cause other issues like premature curing or cracks. So, aim for an optimal humidity level rather than going to extremes.

By mastering the art of controlling humidity levels with methods like dehumidifiers, fans, and desiccants, you’ll be well on your way to faster drying of Sugru. Just remember to exercise a little patience too, as quality bonding and durability are worth the wait.

Following Manufacturer’s Instructions and Guidelines

Today, we embark on a journey into the captivating world of Sugru—an extraordinary adhesive that possesses remarkable capabilities when used correctly. However, to truly unlock its full potential and ensure a successful project, it is paramount to adhere meticulously to the manufacturer’s instructions and guidelines. Within this blog post, we shall delve into the reasons why following these instructions is not merely recommended but absolutely essential, particularly when it comes to controlling the drying time of Sugru.

The Thickness Factor:

Influencing Sugru’s drying time lies an often overlooked aspect—the thickness of the applied layer. It is a well-established fact that thicker layers demand more time to dry in comparison to their thinner counterparts. As such, expediting the process requires the application of a thin layer of Sugru. Not only does this facilitate faster drying, but it also guarantees superior adhesion and longevity.

The Temperature Tango:

Ambient temperature plays a pivotal role in dictating Sugru’s drying time. Higher temperatures tend to accelerate the process, while lower temperatures have an inhibitory effect. Therefore, for optimal results, it is advisable to work within moderate temperature conditions. Remember, exercising patience becomes imperative when allowing Sugru to dry in colder environments.

Humidity Hurdles:

Another influential factor impacting Sugru’s drying time is humidity levels. Low humidity proves ideal for swift drying, whereas high humidity can significantly prolong the process. If you find yourself working within a humid environment, consider employing dehumidifiers or fans to enhance air circulation and expedite drying time.

The Airflow Advantage:

To achieve even and thorough drying of Sugru, proper air circulation assumes paramount importance. The manufacturer strongly advises leaving your project undisturbed during the drying process, allowing air to reach all sides of the applied Sugru. This ensures consistent drying and minimizes the likelihood of potential issues arising.

The Heat Hazard:

In the pursuit of expediting the drying process, it might be tempting to employ external heat sources such as hairdryers or ovens. However, this approach is not recommended. Uneven drying may occur, jeopardizing the adhesive bond and potentially leading to project failure. It is always in your best interest to trust the manufacturer’s instructions and guidelines for optimum results and safety.

Balancing Speed with Proper Curing

Balancing speed with proper curing is a delicate dance that requires finesse and careful consideration. When it comes to using Sugru, a remarkable moldable glue that can fix, bond, and create wonders, finding the perfect balance between speed and curing is essential for achieving optimal results.

Let’s start by exploring the role of temperature in speeding up the drying process. Heat is the catalyst that can accelerate chemical reactions and expedite the cross-linking process of Sugru. By increasing the temperature in the curing environment, you can harness the power of thermal energy to your advantage. However, caution must be exercised as excessive heat can lead to premature drying or even degradation of the material. It’s like walking on a tightrope – finding that sweet spot where you apply just enough heat to speed things up without compromising the integrity of your creation.

Now, let’s delve into the realm of thickness. It’s a simple equation – thinner layers dry faster than thicker ones. The less material there is to cure, the quicker it will dry. So if time is of the essence, apply a thin layer of Sugru and watch it transform before your eyes. But don’t be fooled by its rapid transformation – even in its thin state, Sugru still maintains its incredible adhesion and strength.

But what about humidity? Ah, the invisible force that can either hinder or hasten the curing process. Higher humidity levels slow down drying time, while lower humidity levels promote faster curing. To harness the power of humidity to your advantage, consider curing Sugru in a well-ventilated area with controlled humidity or utilize a dehumidifier to regulate moisture content in the air.

But hold your horses. Before you embark on a speedy journey to completion, remember that proper curing is vital for optimal performance. Rushing the process may compromise adhesion strength and durability. So exercise patience and allow sufficient time for Sugru to cure fully before subjecting it to any stress or load. It’s like waiting for a delicate flower to bloom – the beauty lies in the patience and the reward is worth the wait.

G-NVfe58htU” >

Conclusion

When it comes to drying time, Sugru can be a bit of a waiting game.

However, there are a few tricks you can try to speed up the process and get your project finished faster. First off, make sure you’re working in a warm and dry environment.

Sugru loves heat, so if you can find a spot with some extra warmth, like near a heater or in direct sunlight, that will help it dry quicker. Secondly, consider using a hairdryer on low heat to gently blow air over your Sugru creation.

This can help evaporate the moisture and speed up the drying process. Just be careful not to get too close or use high heat, as this could damage your project.

This method should only be used as a last resort and with caution, as excessive heat can cause Sugru to become brittle or even burn.