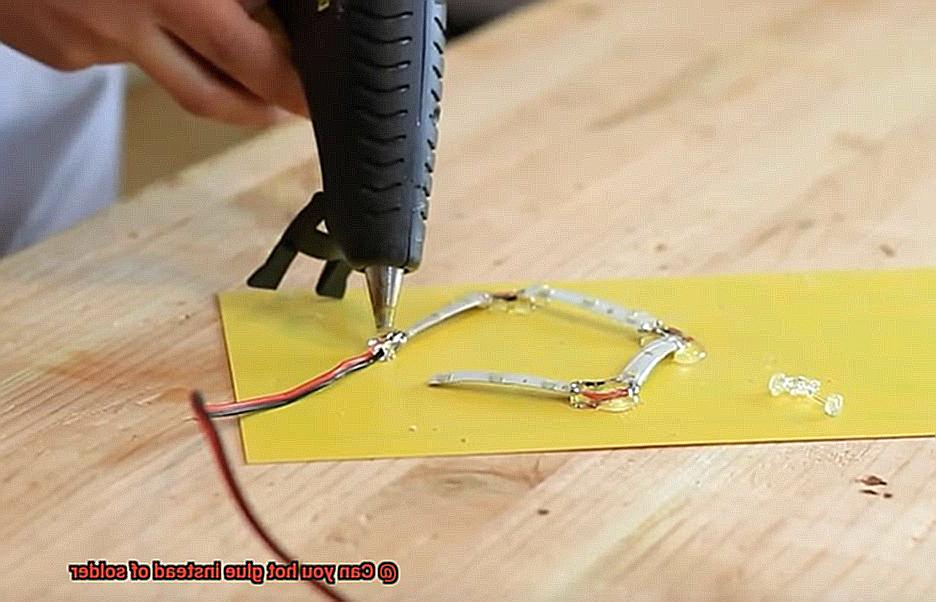

Picture this: you’re knee-deep in a DIY project, ready to join those electrical components and repair delicate circuits. But wait, the age-old question pops up – can you hot glue instead of solder? It’s a debate that has sparked fiery conversations among DIY enthusiasts and hobbyists alike. Today, we’re diving headfirst into the pros and cons of using hot glue as an alternative to soldering. Brace yourself for a battle of epic proportions.

Pros of Using Hot Glue:

- Easy-peasy lemon squeezy: Let’s face it, not all of us were born with a soldering iron in hand. Hot glue guns are the superhero sidekick for beginners, offering simplicity and ease of use. Just point that nozzle where you want it, squeeze that trigger, and voila. Your surfaces are bonded together.

- Shockingly non-conductive: Safety first, folks. One major advantage of hot glue is its non-conductive nature. Say goodbye to accidental short-circuits caused by exposed wires or components touching each other. Hot glue acts as an insulator, saving your circuits from going haywire.

- The art of reversibility: Unlike that pesky soldering iron, hot glue is all about second chances. Need to make modifications or repairs? No problemo. Simply heat up that trusty glue gun again and peel off the old glue without damaging a thing.

Cons of Using Hot Glue:

- Heat resistance? Not so much: Here’s the catch – hot glue isn’t exactly known for its tolerance to high temperatures like soldering is. While solder can handle the heat like a champ, hot glue starts melting around 120-140°F (49-60°C). So if your project involves extreme working conditions or intense heat, you might want to reconsider.

- The strength of a feather: Brace yourself for a potential weak link in the chain. Hot glue, though versatile, may not be the best choice when it comes to mechanical strength. Vibrations, mechanical stress, or the need for a secure connection can pose challenges that hot glue might struggle to overcome.

- Tiny electronics, big problems: Attention all precision seekers. Hot glue might not be your knight in shining armor for intricate electronic projects or small-scale circuitry. Its larger physical profile can get in the way of close component placement, hinder connections,

What is Hot Glue?

Contents

In this comprehensive guide, we will explore everything you need to know about hot glue. From its composition and applications to its advantages and limitations, we’ve got you covered. Whether you’re a seasoned crafter or just curious about this versatile adhesive, let’s dive in.

Composition and Application:

Hot glue is a thermoplastic adhesive made from polymer materials like ethylene-vinyl acetate (EVA) or polyamide. It comes in various sizes and formulations, including clear, colored, and even glitter-infused options. Its ability to bond materials such as wood, plastic, fabric, metal, and ceramics makes it perfect for arts and crafts projects, floral arrangements, minor repairs, and more.

Advantages of Hot Glue:

- Quick Bonding: Hot glue sets rapidly once applied, making it ideal for projects that require immediate bonding or tacking.

- Ease of Use: With a simple trigger mechanism on a glue gun, hot glue is easy to handle and apply without the need for complex tools or techniques.

- Versatility: Hot glue’s compatibility with different materials makes it suitable for a wide range of projects.

- Safety: Hot glue has a low odor and is non-toxic, ensuring safety when used in well-ventilated areas or around children.

Limitations of Hot Glue:

- Durability: While hot glue provides a strong bond for many materials, it may not be as durable as other adhesives in high-temperature or heavy-load applications.

- Heat Sensitivity: Hot glue can soften or melt when exposed to heat, so it may not be suitable for projects that require heat resistance.

Hot Glue vs. Soldering:

In certain cases where soldering may not be practical or suitable, hot glue serves as a convenient alternative. However, for electrical connections or joining metal components that require conductivity and durability, soldering is typically preferred.

What is Solder?

The answer lies within the captivating realm of solder. Prepare to embark on a journey where we unravel the secrets of this extraordinary material and explore its myriad applications.

Solder is a transformative metal alloy that performs wonders in joining metal components. Typically composed of tin and lead, though lead-free alternatives exist for the environmentally conscious, solder possesses a low melting point.

When heated, it metamorphoses into a malleable liquid that can flow and create robust bonds between metals.

Soldering – The Art of Connection

Imagine a steady hand clutching a soldering iron or gun in one palm and a spool of solder in the other. Soldering is an art form where this mystical alloy truly comes alive. As the solder liquefies and adheres to the surfaces being joined, it weaves a conductive path, enabling the smooth flow of electricity or heat between the connected components.

Marvels of Solder’s Superpowers

Solder possesses extraordinary properties that make it the preferred choice for professionals and hobbyists alike. Its innate ability to wet and adhere to metal surfaces ensures solid bonds, boosting strength and durability. Moreover, solder boasts exceptional thermal and electrical conductivity, facilitating efficient transfer of heat or electrical signals.

Beyond Electronics and Plumbing

While solder is most commonly associated with electronics and plumbing, its versatility extends far beyond these domains. In the hands of jewelry makers, solder gracefully connects metal components, resulting in stunning pieces that dazzle the eye. Creative souls also employ solder for decorative purposes in artistic projects, adding an extra touch of charm to their creations.

Electrical Conductivity: Hot Glue vs. Solder

From their composition to their ability to conduct electricity, we will delve into the unique properties of these materials and shed light on their use in electrical connections.

The Lowdown on Solder:

Let’s begin with solder, the hero of electrical connections. Imagine a remarkable metal alloy composed of tin and lead that transforms from a solid to a liquid state when heated. This molten magic then solidifies upon cooling, creating robust and reliable bonds between electrical components.

With its exceptional electrical conductivity, solder is the go-to conductor for electronic devices, circuit boards, and even plumbing applications.

Hot Glue: A Dazzling Dilemma:

Now let’s turn our attention to hot glue—a versatile thermoplastic adhesive renowned for bonding materials together. While not designed specifically for electrical connections, hot glue does possess some level of electrical conductivity. However, it falls short in comparison to solder when it comes to reliability and efficiency.

The Heat Is On:

One crucial difference lies in stability under high temperatures. Solder, being a metallic alloy, withstands heat like a champion while maintaining its conductivity. Conversely, hot glue can become unstable and lose its conductivity when exposed to extreme temperatures or mechanical stress.

Resistance vs. Conductivity:

Another key distinction is resistance—the ability of a material to hinder or allow the flow of electric current. Solder offers a low-resistance pathway due to its metallic properties, ensuring a smooth flow of electricity. In contrast, hot glue generally exhibits higher resistance, making it less reliable for conducting electricity.

The Choice is Clear:

For applications demanding top-notch electrical conductivity—such as circuit boards and electronic devices—solder reigns supreme. Its ability to create robust, long-lasting connections is unmatched. However, hot glue does have its place in certain low-voltage applications or as a temporary connection when electrical conductivity is not paramount.

The Best of Both Worlds:

But wait. There’s more. Enter the realm of conductive adhesives—a delightful fusion of hot glue and solder. These special adhesives contain conductive particles that enhance their electrical conductivity while still maintaining some of the flexibility and ease of use associated with hot glue. Talk about a winning combination.

Strength of the Bond: Hot Glue vs. Solder

When it comes to bonding materials, two popular contenders enter the ring: hot glue and solder. Each has its own strengths and weaknesses, so understanding their properties is key to determining which adhesive will come out on top. Get ready to witness an adhesive showdown.

Strength:

Hot Glue:

- Versatile adhesive for wood, plastic, fabric, and some metals.

- Ideal for crafts, DIY projects, and quick repairs.

- Provides sufficient strength for lightweight applications.

- Adheres well to porous surfaces like fabric or wood.

Solder:

- Melts a filler metal onto metal surfaces to create a strong and permanent bond.

- Perfect for electronics and plumbing applications.

- Offers high tensile strength and excellent electrical conductivity.

- Creates strong bonds between different metals.

Weaknesses:

Hot Glue:

- Lower tensile strength than soldered joints.

- Not suitable for heavy-duty or load-bearing tasks.

- May not form a strong bond on smooth or non-porous materials like metal or glass.

- Softens or melts under high heat conditions.

Solder:

- Requires specialized equipment (soldering iron) and skills for proper execution.

- Not suitable for bonding non-metallic materials.

- High melting point limits use in temperature-sensitive applications.

Precision and Control: Hot Glue vs. Solder

In the realm of adhesives, two contenders stand tall: solder and hot glue. In one corner, solder takes the stage with its precise connections and strong bonds. In the other corner, hot glue shows off its versatility and ease of application. As we enter the ring, let’s explore the differences between these adhesive heroes and see which one will save the day in terms of precision and control.

Round 1: Precision

Solder emerges as the undisputed champion in precision. It excels in joining small components and creating exact connections, making it the go-to technique for delicate electronic work and intricate circuitry. The controlled application of filler metal ensures a reliable connection. On the other hand, hot glue lags behind in this round. Its melted state poses challenges in controlling the amount and placement, resulting in less tidy connections.

Round 2: Control

Once again, soldering takes the lead in control. The heat from the soldering iron can be directed precisely to specific areas, allowing for accurate soldering without damaging nearby components. This level of control is crucial when working with delicate electronic parts. Conversely, hot glue falls short in precision and control. The adhesive tends to spread out upon application, making it difficult to achieve precise results.

Round 3: Strength and Durability

In terms of strength and durability, solder emerges as the heavyweight champion. Soldered joints are generally stronger and more durable than hot glue bonds. By forming a metallurgical bond with the metal components being joined, solder creates a secure connection capable of withstanding stress and vibration. This makes soldering ideal for heavy-duty applications or situations involving extreme temperatures. On the other hand, while hot glue bonds are strong for many materials, they may not hold up under intense conditions.

Round 4: Versatility

When it comes to versatility, hot glue takes the spotlight. It can bond a wide range of materials, including wood, fabric, plastic, and even glass. Its quick-drying time makes it convenient for immediate assembly in various projects. Additionally, hot glue offers the advantage of easy removal or repositioning if needed, providing flexibility for temporary or experimental projects. In contrast, solder is primarily used for metal components and electronic applications.

When to Use Hot Glue Instead of Solder

Today, we embark on a quest to uncover the perfect time to wield the mighty hot glue gun instead of the tried-and-true soldering iron. In this epic battle of precision versus versatility, strength against control, we shall explore when hot glue emerges victorious.

Let us first pay homage to solder, the reigning champion of adhesive supremacy. This noble warrior is the go-to choice for precise and robust connections in electronic circuits. With its remarkable ability to forge low-resistance electrical links, solder guarantees unwavering performance. It’s as if solder were a superhero, seamlessly bonding minuscule components and intricate circuitry.

But what about hot glue? Ah, this versatile adhesive possesses its own set of superpowers. While it may lack the precision and strength of solder, hot glue shines brightly in specific scenarios. Brace yourselves, for here are the moments when hot glue can save the day:

- Temporary Fixes: When you find yourself in need of a quick patch-up or temporary solution, hot glue springs into action. Whether it’s holding wires in place or securing a loose connection, hot glue’s rapid drying nature makes it a convenient savior for on-the-spot repairs.

- Heat-Sensitive Components: Imagine delicate electronic components or materials that crumble under the scorching heat of soldering. Fear not. Hot glue emerges as a non-destructive alternative, providing insulation and support while safely protecting these heat-sensitive wonders.

- Strain Relief: Have you ever grappled with wires that incessantly get tugged or yanked? Fear not. Hot glue shall be your secret weapon in this battle. By applying it around the wires, you create a strain relief effect that alleviates stress on the solder joint, safeguarding against damage.

- Easy Removal or Rework: Unlike solder, which clings stubbornly until heated for removal, hot glue can be softened with heat and peeled away without causing harm. This makes it a valuable asset in situations where connections may need reworking or removal.

However, it is crucial to note that hot glue should never substitute solder in critical applications or those requiring high levels of conductivity. Solder provides an unwavering and reliable electrical connection that hot glue simply cannot match.

Therefore, when deliberating whether to employ hot glue instead of solder, carefully assess the specific demands of your project. Take into account factors such as durability, electrical conductivity, heat resistance, and the permanence of the connection. With these considerations in mind, you shall discern whether hot glue is your loyal sidekick or if it’s time to summon the trusty soldering iron.

Advantages and Disadvantages of Using Hot Glue Instead of Solder

When it comes to bonding materials, two contenders stand in the ring – hot glue and solder. While soldering is known for its precision and durability, hot glue guns offer convenience and versatility. In this battle of adhesives, we’ll compare their advantages and disadvantages to help you make an informed choice for your projects.

Advantages of Hot Glue:

- Ease of Use: Hot glue guns are a DIY enthusiast’s best friend. They require no specialized skills or training, making them accessible to anyone. This ease of use makes hot glue an excellent choice for quick repairs or craft projects.

- Versatility: Hot glue can bond a wide range of materials, including wood, plastic, fabric, and even certain metals. Its flexibility makes it a fantastic option for various applications, from arts and crafts to household repairs.

- Quick Bonding: Time is precious, especially when working on time-sensitive projects. Hot glue bonds quickly upon application, allowing you to move forward without delay. This speed is particularly advantageous when working with delicate materials that can be damaged by excessive heat from soldering.

- Reversible: Mistakes happen, but with hot glue, they’re easily fixable. If you need to separate glued parts or correct errors, simply apply heat or solvents to soften the glue and start over. This reversible feature offers greater flexibility and reusability compared to soldering.

Disadvantages of Hot Glue:

- Limited Strength: While hot glue provides a decent bond, it is generally not as strong as soldered connections. Solder creates durable and conductive joints that can withstand mechanical stress and vibrations better than hot glue. Therefore, if your project requires a strong bond, such as in structural or heavy-load applications, soldering is the better choice.

- Temperature Sensitivity: Hot glue has its limitations when it comes to extreme temperatures. High heat can cause it to soften or melt, while low temperatures can make it brittle and prone to cracking. Solder, on the other hand, remains stable under extreme conditions. Therefore, if your project will be exposed to temperature fluctuations, soldering is the more reliable option.

- Conductivity Issues: If your project involves electrical conductivity, hot glue falls short. Unlike solder, which is an excellent conductor of electricity, hot glue does not have this property. So, for circuit boards or wiring projects, where electrical connections are critical, soldering is the way to go.

- Aesthetics: Hot glue leaves visible glue lines, which may not be desirable for projects where aesthetics matter. This is particularly true for crafts or projects where a neat and clean appearance is desired. Soldering creates seamless joints that exude a professional and clean appearance.

e4vjxc0Gkr8″ >

Conclusion

Hot glue may seem like a convenient alternative to soldering, but it falls short when it comes to reliability and durability. While hot glue can bond materials together temporarily, it lacks the strength and conductivity of soldered connections. Soldering creates a secure and long-lasting joint that ensures electrical continuity, while hot glue may fail under stress or high temperatures.

Additionally, hot glue does not provide the same level of precision as soldering. Soldering allows for precise placement of components and ensures proper electrical contact, which is crucial in many electronic applications. Hot glue, on the other hand, can be messy and imprecise, making it unsuitable for intricate projects or delicate circuitry.

Furthermore, hot glue is not designed to withstand the same environmental conditions as soldered connections. Soldered joints are resistant to heat, moisture, and vibration, making them ideal for applications that require reliability and longevity. Hot glue, however, can melt or become brittle over time when exposed to extreme temperatures or humidity.

In conclusion, while hot glue may have its uses in certain non-critical applications or temporary fixes, it cannot fully replace soldering in terms of reliability and performance. Soldering remains the preferred method for creating strong and durable electrical connections that stand the test of time.