Glue is the backbone of any woodworking project. It’s what holds everything together and ensures that your masterpiece stands the test of time. But what happens when you don’t have clamps to keep your wood pieces in place? Is it possible to glue wood without clamping?

The answer is a resounding yes. As a carpenter, you don’t need to break the bank to get the job done. There are plenty of alternative methods that you can use to bond your wood pieces together. In this blog post, we’ll explore these methods in detail.

We’ve all been there – starting a project only to realize that we’re missing a crucial tool. Clamps can be expensive or not readily available, but fear not. We’ll show you how to achieve amazing results without them.

In this post, we’ll discuss commonly used adhesives and alternatives to clamps that you can use to bond wood pieces together. We’ll also go over the advantages and disadvantages of gluing without clamping, so you know exactly what you’re getting into.

Whether you’re a student trying to finish a school assignment or a DIY enthusiast looking for new techniques, this post has got you covered. So sit back, grab a cup of coffee, and let’s dive into the fascinating world of gluing wood without clamping.

What Types of Glue Work Best for Woodworking?

Contents

- 1 What Types of Glue Work Best for Woodworking?

- 2 What Are the Benefits of Clamping?

- 3 Is It Possible to Glue Wood Without Clamping?

- 4 Techniques To Minimize or Eliminate the Need for Clamping

- 5 Super Glue and Gorilla Glue: Pros and Cons

- 6 PVA (White Glue) and Epoxy: Pros and Cons

- 7 Tips For Gluing Wood Without Clamping

- 8 Conclusion

Woodworking is a craft that requires careful planning, precise measurements, and the right selection of materials. Among these materials, glue plays a crucial role in holding pieces of wood together. However, not all glue types work well for woodworking. To ensure a successful project, it’s important to choose the right glue for the job. In this article, we will explore the best types of glue for woodworking and their unique features.

PVA Glue: A Versatile and Easy-to-Use Option

Polyvinyl acetate (PVA) glue is a popular choice for woodworking due to its versatility and ease of use. It dries clear, making it an excellent option for visible joints. PVA glue has a strong bond and can be sanded or painted over once it has dried. However, it may not be suitable for non-porous surfaces like metal or plastic. Moreover, PVA glue struggles with oily or dense hardwoods, leading to weak joints.

Hide Glue: The Old-School Choice with Benefits

Hide glue is made from animal collagen and has been used in woodworking for centuries. It has a long open time, meaning it stays liquid for a longer period before drying, allowing for adjustments to be made before the bond sets. Hide glue is also reversible, meaning it can be easily removed if needed. Furthermore, hide glue works well with various types of wood and has high strength.

Epoxy: The Tough and Water-Resistant Choice

Epoxy is a two-part adhesive consisting of a resin and hardener that are mixed together before use. It provides an incredibly strong bond that can withstand stress and water damage, making it ideal for outdoor projects. Epoxy also fills gaps well, making it suitable for uneven surfaces. However, epoxy can be challenging to work with due to its longer drying time.

Polyurethane Glue: The Flexible and Gap-Filling Choice

Polyurethane glue is a good option for projects requiring flexibility, such as chair legs or curved pieces. As it dries, it expands, filling in gaps and creating a strong bond that can handle movement and stress. Polyurethane glue also works well with various types of wood. However, it can be messy to work with and requires clamping for at least an hour to ensure proper bonding.

CA Glue: The Quick Fix Choice

Cyanoacrylate (CA) glue, also known as super glue, is a fast-drying adhesive that creates a strong bond quickly. It works well for small repairs or quick fixes. However, it can be brittle and may not hold up well over time.

In conclusion, choosing the right type of glue is crucial for woodworking projects. PVA glue and hide glue are versatile options that work well with various types of wood. Epoxy is an excellent choice for outdoor projects or where water resistance is required. Polyurethane glue is ideal for flexible pieces and gap-filling.

What Are the Benefits of Clamping?

If so, you know that glue is a crucial component in creating strong and durable projects. But did you know that clamping is just as important? In fact, clamping is one of the most critical steps when joining two pieces of wood together, and it offers a host of benefits that can make or break your project’s success.

First and foremost, clamping applies pressure to the joint, ensuring a strong and secure bond between the pieces of wood. This pressure helps to push the glue into the pores of the wood, creating a deeper and more effective bond. Without clamping, the glue may not distribute evenly across the joint, resulting in weak spots and potential failure over time.

But that’s not all – using a clamp also allows the glue to dry evenly without any gaps or bubbles. It keeps the joint stable while the glue dries, preventing any movement or shifting that could compromise the bond. Plus, clamping ensures more precise and accurate alignment of the pieces of wood, resulting in a cleaner and more professional-looking finished product.

In short, the benefits of clamping are numerous:

- Strong and secure bond between pieces of wood

- Deeper and more effective bond due to pressure applied

- Even distribution of glue across joint

- Prevention of weak spots and potential failure over time

- Stable joint during glue drying process

- Accurate alignment of pieces for a cleaner finished product

Think of it this way: while clamping may seem like an extra step in the process, it can save time and effort in the long run. By using a clamp, you’re ensuring that the joint is secure and strong, reducing the likelihood of needing to repair or replace it later on.

Is It Possible to Glue Wood Without Clamping?

It is possible to glue wood without clamping. However, before you give up on clamping altogether, there are some important factors to consider.

First and foremost, the type of glue you use is paramount. For smaller pieces of wood, fast-drying glues like cyanoacrylate glue (also known as super glue) can hold the pieces together without the need for clamping, as they set quickly. However, for larger or heavier pieces, a polyurethane glue like Gorilla Glue may be more appropriate since it expands as it dries, filling any gaps between the pieces and creating a strong bond.

But here’s the catch: while it’s possible to glue wood without clamping, it’s not always the best idea. Clamping ensures that the pieces are held tightly together while the glue dries, resulting in a stronger and more secure bond. It also helps with precise alignment and even glue distribution, which can prevent weak spots and potential failure down the road.

If possible, always use clamps in your woodworking projects. However, if your project doesn’t allow for clamping due to size or shape restrictions, choose a strong adhesive and follow the manufacturer’s instructions carefully. Additionally, patience is key when gluing wood without clamps. Give the glue ample time to dry before moving or using your project to ensure a successful outcome.

Techniques To Minimize or Eliminate the Need for Clamping

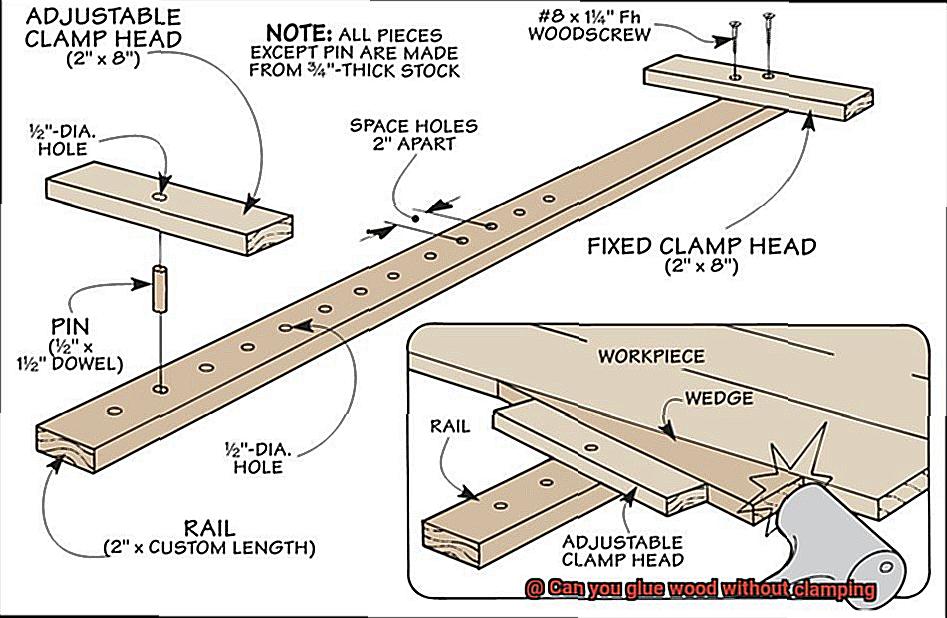

There are several techniques that can minimize or even eliminate the need for clamping altogether. Clamping has been a traditional method to ensure strong bonds between wood pieces, but it can be time-consuming and cumbersome.

One such technique is using adhesive films like double-sided tape, which provide a strong bond between the wood pieces. These tapes are especially handy for small or lightweight projects where clamps can be bulky and difficult to use. Bid farewell to the hassle of wrestling with clamps.

Another technique is using a vacuum press, which applies even pressure to the wood pieces, ensuring a strong bond without the need for clamps. This method is particularly useful for curved or irregularly shaped pieces that are challenging to clamp. The vacuum press ensures that each piece is held firmly in place.

If you’re looking for specialized glue types that don’t require clamping, cyanoacrylate glue (also known as super glue) is an excellent option. It sets quickly and creates a strong bond without needing any clamps. However, this type of glue may not be suitable for all types of wood and projects. Be sure to check the compatibility before use.

Polyurethane glue is another option that expands as it dries, creating a waterproof bond without requiring clamps. This makes it ideal for outdoor projects or anything that needs to withstand moisture. Polyurethane glue also fills gaps in the wood pieces, ensuring a more robust bond.

Super Glue and Gorilla Glue: Pros and Cons

First up, Super Glue, aka cyanoacrylate glue. This fast-drying adhesive reacts with moisture in the air to form a bond, making it easy to use without any special tools or equipment. Plus, it can bond wood in just a few seconds. However, due to its lower strength and brittleness, it may not be suitable for larger or more complex projects. So, if you’re looking for a quick fix for a small or simple project, Super Glue may be the way to go.

Now, let’s talk about Gorilla Glue. This polyurethane-based adhesive requires moisture to activate and expand, creating a tight bond between pieces of wood. It’s waterproof, can withstand heat and cold, and provides a strong permanent bond. However, it does have some drawbacks. It dries slowly and requires several hours of clamping for a strong bond. And, it can be messy to work with and requires some skill to apply evenly. Nevertheless, if you’re working on a larger or more complex project that requires a strong bond, Gorilla Glue may be your best bet.

But what if you need both speed and strength? In that case, consider using both Super Glue and Gorilla Glue together. For example, use Super Glue for quick initial bonding while applying Gorilla Glue for added strength and durability.

PVA (White Glue) and Epoxy: Pros and Cons

PVA (white glue) and epoxy are here to save the day. But which adhesive is the best for your project? As an expert in this field, I have compiled a list of pros and cons for each adhesive to help you make the best decision.

Firstly, let’s talk about PVA. This water-based adhesive is widely available and affordable, making it a popular choice for many DIYers. One of the biggest advantages of PVA is its easy cleanup – any excess glue can be wiped away with a damp cloth while it’s still wet. It also has a relatively long open time, giving you more time to adjust the pieces before the glue sets.

However, PVA requires pressure to create a strong bond, which means that clamping is usually necessary. Without clamping, the bond may not be as strong and the wood may shift or move during the drying process. Additionally, PVA has limited resistance to moisture and heat, which can weaken the bond over time.

Next up is epoxy. This two-part adhesive consists of resin and hardener and forms a strong bond with almost any material, including wood, metal, and plastic. It also has excellent resistance to moisture and heat, making it ideal for outdoor or high-temperature applications.

When it comes to gluing wood without clamping, epoxy has some advantages over PVA. Firstly, it does not require pressure to form a strong bond – simply applying the adhesive and holding the pieces together for a few minutes is enough. Secondly, epoxy has a shorter drying time than PVA, so you do not need to wait as long before handling the glued pieces.

However, epoxy can be more expensive than PVA and requires careful mixing of the resin and hardener to ensure a proper bond. Additionally, any excess epoxy must be cleaned up with solvents, which can be messy and time-consuming.

In summary, both PVA and epoxy have their pros and cons when it comes to gluing wood without clamping. PVA is affordable and easy to clean up but requires pressure and has limited resistance to moisture and heat. Epoxy forms a strong bond without pressure and has excellent resistance to moisture and heat but can be more expensive and requires careful mixing and cleanup. Ultimately, the choice between the two will depend on the specific application and personal preference.

Tips For Gluing Wood Without Clamping

First and foremost, it is essential to choose the right type of glue for the job. While PVA glue is great for woodworking projects, it may not be the best choice for gluing without clamping. Instead, opt for a more flexible adhesive like polyurethane glue or epoxy. These adhesives allow for some movement without compromising the strength of the bond.

Another crucial factor in successful wood gluing is surface preparation. To ensure a strong bond, make sure to clean, dry, and sand the surfaces to be glued. This will create a rougher texture and provide more surface area for the glue to adhere to.

Using weight or pressure can also help create a strong bond without the need for clamps. For instance, placing heavy objects on top of the glued pieces can apply enough pressure to hold them in place while the glue dries. This technique works particularly well for small projects or when working with thin pieces of wood.

Timing is also key when gluing without clamps. You must work quickly and efficiently to apply the glue and join the pieces before it starts to dry. This may require some practice and experimentation to find the right amount of glue and working speed that works best for you.

LLQa_koALNA” >

Conclusion

In conclusion, the art of gluing wood without clamping is not an impossible feat. However, it requires a keen understanding of the type of adhesive used and proper surface preparation. There are several options available for bonding wood pieces together including PVA glue, hide glue, epoxy, polyurethane glue, and cyanoacrylate glue. Each has its own set of advantages and disadvantages depending on the size and requirements of the project at hand.

While clamping provides even pressure to ensure a strong bond between wood pieces while allowing precise alignment and even glue distribution, there are techniques that can minimize or eliminate the need for clamping altogether. For instance, using adhesive films or a vacuum press can prove useful in certain situations.

When it comes to achieving successful gluing without clamps, choosing the right adhesive type for the job and working quickly are crucial factors. It’s worth noting that although clamping may seem like an extra step in the process, it ultimately saves time and effort by ensuring a secure joint that will stand the test of time.

By keeping these tips and techniques in mind, carpenters can achieve amazing results without breaking the bank on expensive clamps.