Are you ready to take your concrete projects to the next level with a touch of sleek stainless steel? If you’re wondering whether it’s possible to glue stainless steel to concrete, wonder no more. In this blog post, we’ll dive into the process of bonding these two materials together and provide you with a step-by-step guide for achieving a secure and long-lasting bond.

Stainless steel and concrete may seem like an unlikely pair, but with the right technique and adhesive, you can create a seamless connection that will stand the test of time. However, it’s important to note that gluing stainless steel to concrete comes with its own set of challenges due to their different properties.

So, let’s get started on this exciting journey as we uncover the secrets to successfully bonding stainless steel to concrete.

Step 1: Preparing the Surfaces

Contents

- 0.1 Step 1: Preparing the Surfaces

- 0.2 Step 2: Choosing the Right Adhesive

- 0.3 Step 3: Applying the Adhesive

- 0.4 Step 4: Joining the Surfaces

- 1 What is Stainless Steel?

- 2 What is Concrete?

- 3 Types of Adhesives Used for Bonding Stainless Steel to Concrete

- 4 Preparing the Surfaces for Bonding

- 4.1 Step 1: Thoroughly Clean the Surfaces

- 4.2 Step 2: Roughen the Stainless Steel Surface

- 4.3 Step 3: Etch the Concrete Surface

- 4.4 Step 4: Ensure Both Surfaces Are Dry

- 4.5 Step 5: Consider Using a Primer or Adhesive Promoter

- 4.6 Step 6: Check for Flatness and Evenness

- 4.7 Step 7: Follow Manufacturer’s Instructions for Adhesive Application

- 5 Applying Epoxy Adhesive

- 6 Factors that May Impact the Success of Bonding Stainless Steel to Concrete

- 7 Other Considerations for Bonding Stainless Steel to Concrete

- 8 Conclusion

Before diving into any gluing process, proper surface preparation is key. When working with stainless steel and concrete, it’s essential to thoroughly clean and degrease both surfaces. Grab some mild detergent and give them a good scrub. Then, use sanding or wire brushing techniques to remove any loose particles or contaminants. A clean and roughened surface will ensure optimal adhesive attachment.

Step 2: Choosing the Right Adhesive

Selecting the perfect adhesive is crucial for achieving a strong and durable bond. For gluing stainless steel to concrete, epoxy-based adhesives are highly recommended. These adhesives have excellent adhesion properties and are specifically designed for outdoor environments, making them ideal for this application.

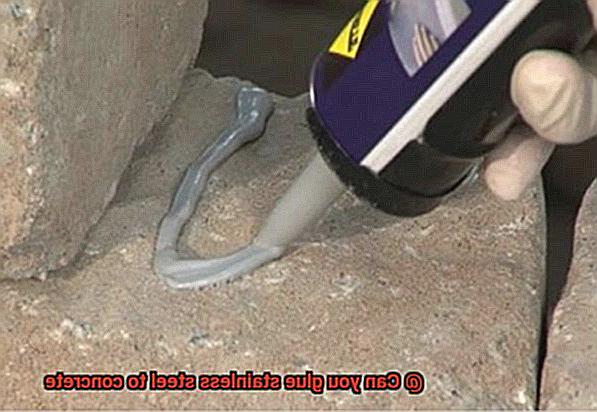

Step 3: Applying the Adhesive

Once you’ve found the right adhesive, follow the manufacturer’s instructions for mixing and application. Apply a thin, even layer of adhesive on both the stainless steel and concrete surfaces, ensuring complete coverage. Time is of the essence here as most epoxy-based adhesives have a limited working time, so work quickly but efficiently.

Step 4: Joining the Surfaces

Align the stainless steel piece with the concrete surface and press firmly to create sufficient contact between the two surfaces. To maintain pressure during the curing process, consider using clamps or other suitable tools. And don’t forget to remove any excess adhesive that squeezes out around the joint for a clean and professional finish.

By following these steps and taking on the unique challenges of gluing stainless steel to concrete, you’ll be able to achieve stunning results in your projects.

So, go ahead.

What is Stainless Steel?

Stainless steel, an alloy renowned for its impressive corrosion resistance and durability, has become an indispensable material in countless industries. From towering skyscrapers to sleek kitchen appliances, this versatile alloy offers exceptional value and performance. In this article, we will explore the captivating world of stainless steel, uncovering its remarkable properties and diverse applications.

Corrosion Resistance:

At the heart of stainless steel’s exceptional performance lies its unique composition. This alloy is primarily composed of iron, infused with chromium, nickel, and other elements. The addition of chromium forms a thin but mighty oxide layer on the surface of stainless steel, aptly named the passive layer. This layer acts as an impenetrable shield, safeguarding the material against rust and corrosion caused by moisture or harsh environments.

Strength and Durability:

Beyond its unrivaled corrosion resistance, stainless steel boasts extraordinary strength and durability. Its robust nature enables it to withstand heavy loads and extreme temperatures, making it an ideal choice for demanding applications in the construction and automotive industries. With stainless steel, you can rest assured that your structures will endure the test of time.

Hygiene Properties:

In industries where cleanliness is paramount, such as food and medicine, stainless steel shines. Its non-porous surface makes it effortlessly easy to clean and prevents the growth of bacteria or other harmful microorganisms. Whether it’s surgical instruments or kitchen countertops, stainless steel ensures impeccable hygiene standards.

Grades of Stainless Steel:

Not all stainless steels are created equal. Different grades offer distinct properties to suit specific applications. The most prevalent grades are 304 and 316, celebrated for their heightened resistance to corrosion due to elevated levels of chromium and nickel content. These grades find extensive use in marine environments, pharmaceutical equipment, and even jewelry.

Applications:

The versatility of stainless steel comes to life through its myriad applications across various industries. It graces our kitchens as elegant appliances, endures the challenges of marine structures, and guarantees the safety of medical instruments. From transportation to architecture and even fashion, stainless steel’s possibilities are limitless.

What is Concrete?

Concrete is a remarkable construction material that possesses unparalleled strength, durability, and versatility. It is composed of several key components that work together to create this superhero of the construction world.

First and foremost, we have cement – the mighty binder that holds everything together. Cement is produced by heating limestone and clay at high temperatures until they transform into a fine powder. When mixed with water, this powder undergoes a magical chemical reaction called hydration, causing it to harden and bind the other ingredients together.

But water isn’t just an innocent bystander in the concrete mixture; it plays a crucial role in activating the cement and enabling the hydration process to occur. However, it’s essential to find the perfect balance of water because too much or too little can affect the strength and workability of the concrete.

Now, let’s talk about aggregates – the rock stars of concrete. These are the materials that provide bulk to the mixture. Aggregates can be natural, such as sand and gravel, or manufactured, like crushed stone. The size and shape of these aggregates have a direct impact on the workability and strength of the final product.

But wait, there’s more. Concrete can also have additives or admixtures that give it special powers. These can include plasticizers, which make it easier to work with; accelerators that speed up curing time; retarders for those who like to take things slow; or even air-entraining agents that create microscopic air bubbles for extra freeze-thaw resistance.

Once all these ingredients are thoroughly mixed together, it’s time for the concrete to shine. It can be poured into molds or formwork and left to cure and harden over time. During this process, the hydration reaction continues, gradually strengthening the concrete until it reaches its full potential.

The advantages of concrete are numerous. Its high compressive strength allows it to withstand heavy loads without breaking or deforming. It also boasts excellent fire resistance, making it a safe choice for buildings. Additionally, concrete is durable, resistant to weathering and corrosion, and even provides good thermal insulation.

Types of Adhesives Used for Bonding Stainless Steel to Concrete

When it comes to attaching stainless steel to concrete, choosing the right adhesive is paramount. In this comprehensive guide, we’ll explore five different types of adhesives commonly used for bonding stainless steel to concrete. From the mighty bond of epoxy adhesives to the flexibility of polyurethane adhesives, we’ll cover it all. Get ready to tackle your stainless steel to concrete bonding projects with confidence.

Epoxy Adhesives: The Superheroes of Adhesion

When it comes to bonding stainless steel to concrete, epoxy adhesives are the undisputed champions. These superheroes offer a combination of exceptional bond strength, durability, and resistance to chemicals and moisture. With the ability to withstand high temperatures and provide great flexibility, epoxy adhesives are the go-to choice for projects big and small. Whether you’re working on a construction site or a DIY project, epoxy adhesives have got your back.

Polyurethane Adhesives: Flexibility at its Finest

If you’re looking for an adhesive that can handle impact and vibration, polyurethane adhesives are the way to go. These bad boys offer not only good adhesion but also unmatched flexibility. Perfect for both indoor and outdoor environments, polyurethane adhesives resist moisture to keep your bond strong even in damp conditions. Don’t let anything shake your stainless steel to concrete bond with these flexible warriors.

Acrylic Adhesives: Fast and Furious

When time is of the essence, acrylic adhesives come to the rescue. Known for their fast curing time and strong bond strength, these adhesives are ideal for quick projects that require immediate results. They adhere well to both stainless steel and concrete surfaces and can withstand exposure to chemicals and UV radiation. Whether you’re working on an outdoor installation or a time-sensitive project, acrylic adhesives will get the job done in no time.

Cyanoacrylate Adhesives: The Quick Fixers

Need a quick fix for bonding small stainless steel parts to concrete surfaces? Look no further than cyanoacrylate adhesives, also known as super glue. These fast-curing adhesives provide instant bond strength, making them perfect for small-scale projects. However, keep in mind that while they offer immediate results, they may not provide the same long-term durability as other adhesive options. When time is of the essence, cyanoacrylate adhesives are the ultimate quick fixers.

Structural Adhesive Systems: The Heavy-Duty Warriors

For heavy-duty applications that demand exceptional strength and durability, structural adhesive systems like methacrylate adhesives are your best bet. These heavy-duty warriors can handle extreme temperatures, resist chemicals and moisture, and provide a bond that will stand the test of time. When you need a bond that’s built to last, turn to these structural adhesive systems for the ultimate strength and reliability.

Preparing the Surfaces for Bonding

Achieving a strong and durable bond between stainless steel and concrete requires proper surface preparation. In this comprehensive guide, we will walk you through the essential steps to ensure successful adhesion. Whether you’re a DIY enthusiast or a professional, these steps will equip you with the knowledge and skills needed to confidently tackle your stainless steel to concrete bonding projects.

Step 1: Thoroughly Clean the Surfaces

Begin by cleaning both the stainless steel and concrete surfaces using a mild detergent and water solution or a specialized cleaner suitable for the materials. Eliminate any dirt, dust, grease, or contaminants that could hinder the bonding process. Remember, cleanliness is key to achieving a reliable bond. Ensure that the surfaces are completely clean and dry before moving on to the next step.

Step 2: Roughen the Stainless Steel Surface

Stainless steel’s smooth surface can pose challenges for effective adhesive bonding. To overcome this, use sandpaper, a wire brush, or a grinder to create a rough texture on the stainless steel. By roughening the surface, you increase its surface area, providing more grip for the adhesive and enhancing adhesion.

Step 3: Etch the Concrete Surface

Improving adhesion on concrete involves using a concrete etching solution or acid wash to open up the material’s pores. This process enables the adhesive to penetrate into the concrete substrate, resulting in a stronger bond. Follow the manufacturer’s instructions for the etching solution, ensuring that you take necessary safety precautions.

Step 4: Ensure Both Surfaces Are Dry

Moisture can compromise the adhesive’s ability to bond effectively. After thoroughly cleaning and roughening both surfaces, it is crucial to ensure they are completely dry before proceeding with bonding. Eliminate any moisture or humidity present as they can negatively impact the bond’s quality.

Step 5: Consider Using a Primer or Adhesive Promoter

For an added boost in adhesion, consider utilizing a primer or adhesive promoter specifically designed for bonding stainless steel and concrete. These products create a chemical bond between the two materials, further enhancing the overall strength of the bond. Follow the manufacturer’s instructions for proper application.

Step 6: Check for Flatness and Evenness

To ensure a high-quality bond, it is important that both surfaces are flat and even. Imperfections or unevenness in either the stainless steel or concrete can affect the bond’s integrity. Use a level or straight edge to assess flatness and make any necessary adjustments before applying the adhesive.

Step 7: Follow Manufacturer’s Instructions for Adhesive Application

Different adhesives have varying application methods and curing times. To achieve optimal results, it is crucial to follow the manufacturer’s instructions precisely. Take into consideration factors such as temperature and humidity during application and curing.

Applying Epoxy Adhesive

In this comprehensive guide, we will take you through the step-by-step process of applying epoxy adhesive to create a bond that is as strong as it is durable.

First and foremost, let’s emphasize the significance of surface preparation. Prior to applying epoxy adhesive, it is crucial to ensure that both the stainless steel and concrete surfaces are meticulously cleaned and free from any contaminants. Use a degreaser to eliminate any oils or grease from the stainless steel, while ensuring that the concrete surface is devoid of loose particles.

To optimize the adhesion between the stainless steel and epoxy adhesive, it is imperative to roughen the stainless steel surface. This can be achieved by using sandpaper or a wire brush, creating more surface area for the adhesive to intimately bond with. This step is pivotal in maximizing the strength of the bond.

Now that your surfaces are properly prepared, it’s time to mix the epoxy adhesive. Typically comprising of two parts – resin and hardener – it is imperative to diligently follow the manufacturer’s instructions and mix these components in the correct ratio. This meticulous process ensures that the adhesive cures effectively, attaining its maximum strength.

Once adequately mixed, it’s time to apply the epoxy adhesive. Employ a brush, roller, or spatula to evenly distribute the adhesive on both the stainless steel and concrete surfaces. It is essential to apply enough adhesive to ensure complete contact between the two materials.

Now comes the moment of anticipation – bonding the stainless steel to the concrete. Firmly press the stainless steel onto the concrete surface, guaranteeing full contact between these materials. This action plays a pivotal role in establishing a robust and trustworthy connection.

Do not forget to promptly clean up any surplus adhesive before it cures. Epoxy can be quite challenging to remove once hardened, so it is best to wipe away any excess immediately.

The final step is to allow sufficient curing time for the epoxy adhesive. Curing times may vary depending on the brand and type of epoxy used, making it crucial to adhere to the manufacturer’s guidelines. Exercise patience and let the adhesive work its magic.

Once fully cured, you will have a bond that is not only strong but also durable. Your stainless steel and concrete will be securely joined, providing a reliable connection capable of withstanding the test of time.

Factors that May Impact the Success of Bonding Stainless Steel to Concrete

The secret lies in a strong and durable bond created through the right adhesive. In this comprehensive guide, we’ll explore the factors that can impact the success of bonding stainless steel to concrete, ensuring a reliable and long-lasting connection.

Surface Preparation:

Proper surface preparation is paramount for a successful bond. Both stainless steel and concrete surfaces should be immaculately clean, free from dirt, dust, and grease. To enhance the bonding area, roughening the surfaces is vital. In the case of stainless steel, removing any passive layer is essential to improve adhesion.

Type of Adhesive:

Selecting the right adhesive is key to achieving a successful bond. Epoxy adhesives are highly regarded due to their exceptional bonding strength and durability. However, polyurethane and acrylic adhesives are viable alternatives worth considering as well. Always opt for an adhesive specifically designed for bonding stainless steel to concrete and strictly adhere to the manufacturer’s instructions.

Compatibility:

Stainless steel and concrete possess different physical properties, such as expansion rates. Ensuring compatibility between these materials requires choosing adhesives with flexibility that can accommodate differential movements between stainless steel and concrete.

Moisture Content:

Excess moisture in concrete can impede adhesion, leading to weak bonds or potential failure over time. Therefore, it is crucial to ensure proper curing and desired moisture content before attempting to bond stainless steel.

Temperature Conditions:

Extreme temperatures can significantly impact adhesive performance. Considering temperature conditions during installation is essential. Selecting an adhesive suitable for the expected temperature range will help maintain its integrity under various environmental conditions.

Load-Bearing Requirements:

When selecting an adhesive and designing the bond, it is imperative to consider the intended use of the bonded assembly. Factors such as weight, expected loads, and environmental conditions must be taken into account to ensure a strong and durable bond.

Testing and Quality Control:

Conducting adhesive-specific tests, such as pull-off or shear strength tests, is highly recommended to determine suitability. Regular quality control checks during installation facilitate early issue identification and ensure a successful bonding process.

Other Considerations for Bonding Stainless Steel to Concrete

Bonding stainless steel to concrete is a delicate art that requires more than just slapping some glue on and hoping for the best. To achieve a strong and long-lasting bond, several crucial considerations must be taken into account. In this article, we will explore these considerations, focusing on the role of adhesive, to ensure successful bonding of stainless steel to concrete. So, put on your hard hat and get ready for an engaging dive into the world of stainless steel and concrete bonding.

Surface Preparation: Cleaning and Roughening for Optimal Adhesion

The foundation of a successful bond lies in proper surface preparation. Thoroughly cleaning both the stainless steel and concrete surfaces is essential to remove any contaminants that might hinder adhesion. Say goodbye to dirt, debris, and oils. Additionally, the stainless steel surface may need to be roughened or etched to enhance adhesion. This can be achieved through mechanical methods like sandblasting or chemical solutions. Remember, safety should always be a top priority when working with chemicals or abrasive materials.

Choosing the Right Adhesive: A Bond That Holds Strong

Not all adhesives are created equal when it comes to bonding stainless steel to concrete. You need an adhesive specifically designed for this application. Options like epoxy-based adhesives, polyurethane adhesives, and hybrid adhesives are commonly used. Consider factors such as desired bond strength and environmental conditions before making your choice. Each adhesive has its own unique properties that can contribute to a successful bond.

Temperature and Humidity: Battling the Elements

The elements also play a role in the bonding process. Adhesive curing is influenced by temperature and humidity levels, so it’s crucial to follow the manufacturer’s instructions regarding recommended ranges for optimal curing. Extreme temperatures or high humidity can compromise bond strength and durability. It’s important to create the perfect environment for adhesive curing to ensure a strong and reliable bond.

Mechanical Fasteners: Reinforcing the Connection

In some cases, relying solely on adhesives may not provide enough strength and stability. This is where mechanical fasteners come into play. Using screws or anchors in conjunction with adhesives can reinforce the bond, especially for heavy or load-bearing applications. By combining the strength of adhesives with the reliability of mechanical fasteners, you can create a bond that withstands even the toughest conditions.

Long-Term Maintenance: Keeping the Bond Intact

Bonding stainless steel to concrete is not a “set it and forget it” situation. Regular inspection and maintenance are essential to ensure the bond remains intact and address any potential issues promptly. Corrosion and deterioration can occur over time, so proactive maintenance is necessary to extend the lifespan of the bonded assembly and ensure its continued performance.

sMrY7_V0I5A” >

Conclusion

Yes, it is possible to glue stainless steel to concrete.

The key is to use a high-quality adhesive that is specifically designed for bonding metal to concrete surfaces. These adhesives are typically epoxy-based and offer excellent strength and durability.

They create a strong bond between the stainless steel and the concrete, ensuring a secure and long-lasting connection. Gluing stainless steel to concrete can be a practical solution for various applications, such as attaching handrails or fixtures to concrete walls or floors.

However, it is important to follow the manufacturer’s instructions carefully and ensure proper surface preparation for optimal adhesion.