Imagine this: you’re faced with a pesky rubber seal leaking on your basement floor, and you’re determined to take matters into your own hands. Armed with your trusty toolbox, you embark on a quest to find the perfect adhesive that can conquer the challenge of bonding rubber to cement. But here’s the burning question: is it even possible? Will your DIY fix stand strong against the test of time and moisture?

In this captivating blog post, we dive headfirst into the realm of adhesives, unraveling the mystery behind achieving a lasting bond between rubber and cement. Whether you’re an avid DIY enthusiast or simply intrigued by the enchanting world of glues, this question tugs at our curiosity with its enigmatic nature.

Join us as we unveil the secrets behind this sticky conundrum, debunking myths along the way and revealing a treasure trove of effective solutions. We’ll explore the science behind why rubber and cement seem like sworn enemies when it comes to sticking together, while sharing invaluable tips to ensure a job well done.

Within the depths of this blog post, prepare yourself for an array of high-strength adhesives and techniques that have proven their mettle where others have faltered. From mighty epoxy adhesives and polyurethane-based wonders to classic rubber cement and super glue heroes, we’ll sift through these options and assess their suitability for various applications.

But wait, there’s more. We’ll also guide you through crucial steps in preparing both the rubber and cement surfaces – ensuring they’re squeaky clean, bone dry, and free from any contaminants that could sabotage your bond.

So grab your favorite cuppa joe, brace yourself for an adventure into uncharted territory, and let’s uncover the thrilling world of bonding rubber to cement – one adhesive at a time.

Different Types of Adhesives for Bonding Rubber to Cement

Contents

- 1 Different Types of Adhesives for Bonding Rubber to Cement

- 2 Preparing the Surface for Glue Application

- 3 Applying the Adhesive to Bond Rubber and Cement

- 4 Benefits of Using Contact Cement for Rubber-to-Cement Bonding

- 5 Advantages of Using Epoxy Adhesive for Rubber-to-Cement Bonding

- 6 Considerations When Choosing an Adhesive for Gluing Rubber to Cement

- 7 Alternative Methods of Attaching Rubber to Cement

- 8 Factors Affecting the Strength and Durability of a Rubber-to-Cement Bond

- 9 Conclusion

When it comes to the challenge of bonding rubber to cement, choosing the right adhesive is essential. Rubber and cement may seem like an odd pairing, but with the right adhesive, they can form a strong and lasting bond. In this comprehensive guide, we will explore the different types of adhesives available for this purpose and delve into their unique advantages and considerations. So let’s dive in and discover the secrets to successful rubber-to-cement bonding.

Contact Cement – The Mighty Instant Bond:

Contact cement is a superhero in the world of adhesives when it comes to bonding rubber to cement. This solvent-based adhesive is applied to both surfaces, allowing it to dry before pressing the two together. The result? An instant bond that is strong and durable. Contact cement’s quick drying time makes it a popular choice, but be aware of its toxicity and ensure proper ventilation during application. With contact cement, you can achieve a swift and reliable connection between rubber and cement.

Epoxy Adhesive – The Unyielding Strength:

When strength and durability are paramount, epoxy adhesive steps up to the challenge. Comprised of two components – resin and hardener – epoxy adhesive requires careful mixing before application. Once applied, it forms an unbreakable bond that can withstand heavy loads and extreme temperatures. However, working with epoxy adhesive demands precision in mixing and application. Follow the instructions diligently, and you’ll have a bond between rubber and cement that can handle anything.

Polyurethane Adhesive – The Flexible Warrior:

For applications requiring flexibility and resilience, polyurethane adhesive emerges as the hero of choice. Its unique characteristic allows it to move and stretch along with the bonded materials, making it ideal for situations where movement is expected.

Additionally, polyurethane adhesives exhibit excellent resistance to water, chemicals, and temperature fluctuations. Simply apply the adhesive directly to the rubber and cement surfaces, wait for it to cure (typically within 24 hours), and revel in the flexibility and durability of your bond.

Silicone Adhesive – The Water-Wise Champion:

When moisture poses a challenge, silicone adhesive rises to the occasion. This adhesive boasts exceptional waterproofing properties, ensuring a strong bond even in wet conditions. Perfect for outdoor projects or areas prone to moisture, silicone adhesives can be applied directly to the rubber and cement surfaces. Curing usually takes between 24 to 48 hours, providing you with a reliable and long-lasting bond that can withstand the elements.

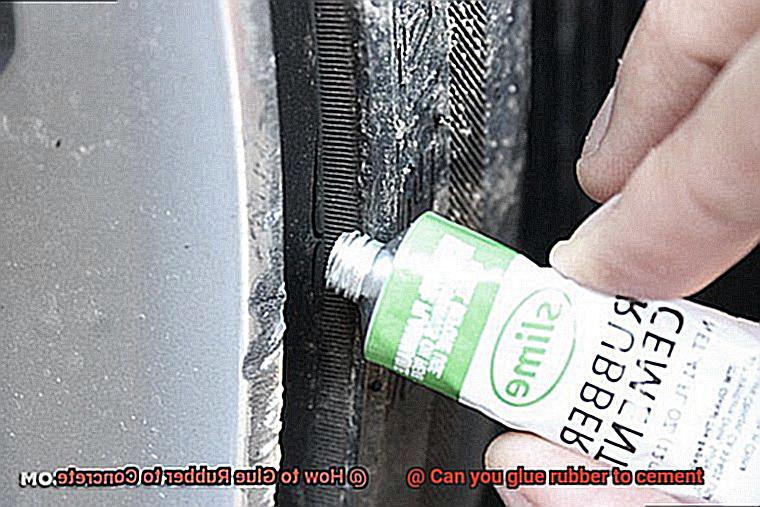

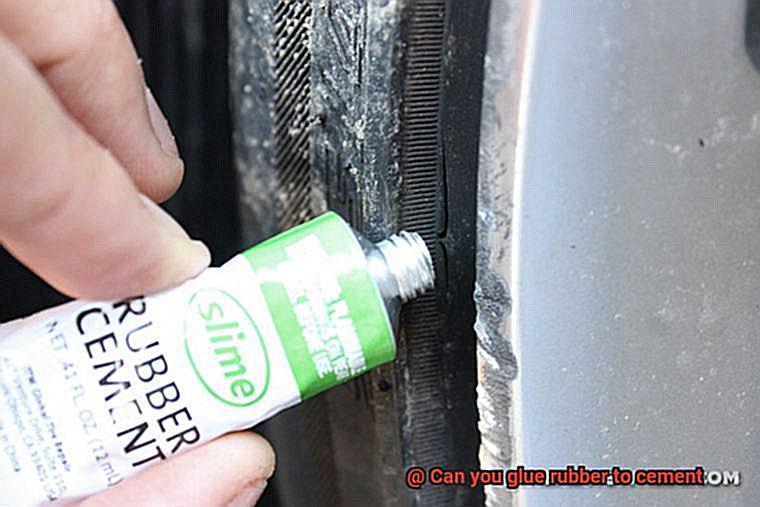

Rubber Cement – The Versatile Companion:

When it comes to temporary or light-duty bonding, rubber cement is the trusty companion you need. Designed specifically for bonding rubber materials, this type of adhesive offers flexibility and easy repositioning if necessary. Apply the rubber cement to both surfaces, let it dry, and bring them together.

Preparing the Surface for Glue Application

We’re about to reveal the key to preparing the surface for glue application between rubber and cement. Get ready to take your DIY projects to the next level.

- Step one: cleanliness reigns supreme. Don’t let dirt, dust, or grease stand in the way of a powerful bond. Grab a mild detergent or soap and water solution, and give those surfaces a thorough scrubbing. Rinse them off until they’re squeaky clean, leaving no residue behind. We want nothing but pristine surfaces here.

- Step two: roughen things up, but with finesse. Use sandpaper or a wire brush to create a gently textured surface on the cement. This helps the rubber grip onto the cement like a flexible warrior ready for battle. Be cautious not to go too far and damage the integrity of the cement. We’re aiming for a balanced texture here.

- Step three: unleash the power of primers and bonding agents. Take your bond to superhero levels by applying a primer or bonding agent designed specifically for rubber-to-cement adhesion. These products work their magic through a chemical reaction that enhances adhesion. Follow the manufacturer’s instructions diligently and allow ample drying time. Patience is key here, my friends.

- Step four: moisture, be gone. Moisture is the nemesis of glue application. Before you begin, ensure that both surfaces are completely dry. If there’s any lingering moisture, grab a clean cloth or paper towel and wipe it away. Trust me, this step is crucial for a bond that stands the test of time.

- Step five: it’s glue time. Apply the glue evenly and in just the right amount. Don’t be stingy, but also avoid creating a mess by going overboard. Devour the instructions provided by the glue manufacturer like your life depends on it (well, maybe not that dramatic), and pay attention to the recommended drying times. This is where the rubber meets the cement, my friends.

Applying the Adhesive to Bond Rubber and Cement

In our previous section, we revealed the secrets to achieving a powerful bond between rubber and cement. Now, let’s dive into the nitty-gritty details of applying the adhesive like a pro. Get ready to unleash your inner warrior and create bonds that will withstand the test of time.

Step 1: Choose the Right Adhesive

In this battle for a lasting bond, selecting the right weapon is crucial. Not all adhesives are created equal when it comes to bonding rubber and cement. Arm yourself with an adhesive specifically designed for this purpose. Look for those that proudly mention rubber and cement bonding on their packaging or consult with a professional to ensure you’re equipped with the correct adhesive.

Step 2: Clean and Prepare the Surfaces

Before engaging in this battle, both the rubber and cement surfaces need to be cleaned and prepared. Dirt, dust, and grease can be formidable foes, hindering the bonding process. Conquer them by scrubbing away any debris from the surfaces using a mild detergent or cleaner. Rinse them thoroughly with water and allow ample time for them to dry before proceeding.

Step 3: Use a Primer (If Required)

Sometimes, even warriors need reinforcements. In cases where extra strength is needed, a primer can come to your rescue. This mighty ally enhances the bonding strength by promoting adhesion between the rubber and cement surfaces. If your chosen adhesive recommends using a primer, follow the instructions provided and allow it to dry completely before proceeding.

Step 4: Apply the Adhesive Evenly

Now it’s time for the main event – applying the adhesive. Follow your instincts and pay close attention to the manufacturer’s instructions for your specific adhesive. With a steady hand, apply a thin and even layer of adhesive on both the rubber and cement surfaces. Remember, precision is the mark of a true warrior.

Step 5: Allow Proper Curing Time

In this battle, patience is key. After applying the adhesive, it’s crucial to allow sufficient time for curing. Curing time refers to the duration required for the adhesive to set and create a strong bond between the rubber and cement surfaces. Follow the manufacturer’s instructions regarding curing time, as it may vary depending on the specific adhesive used.

Benefits of Using Contact Cement for Rubber-to-Cement Bonding

Prepare to embark on an extraordinary journey into the realm of rubber-to-cement bonding. Brace yourself for the ultimate secret weapon that will elevate your bonding skills to new heights – behold, the mighty contact cement. This formidable adhesive is hailed by experts far and wide for its unparalleled properties and benefits. Allow me to unveil the captivating advantages of using contact cement for rubber-to-cement bonding.

First and foremost, contact cement wields a bond so powerful it could rival the grip of a seasoned warrior. When applied with precision, it forges an almost indissoluble connection between rubber and cement surfaces. Bid farewell to nagging concerns about detachment – with contact cement, your materials will remain steadfastly united.

Yet, strength alone does not define the essence of contact cement. Its inherent flexibility mirrors the grace and agility of a master martial artist. Rubber materials often endure movements, vibrations, or stretching, but fear not – contact cement can withstand these stresses without wavering. Whether you’re dealing with rubber flooring, resilient gaskets, or other vital rubber components, contact cement emerges as your unwavering ally.

The capricious nature of temperature fluctuations can pose a formidable challenge to rubber-to-cement bonding. But fret not, for contact cement emerges as your valiant savior. It fearlessly endures extreme heat or chilling cold without relinquishing its adhesive prowess. Whether you toil under blistering summer suns or endure bone-chilling winters, your rubber-to-cement bond shall stand resolute, akin to a warrior in the throes of battle.

The application of contact cement is a veritable breeze – even for those who are new to the craft. Its liquid form allows for meticulous application on both rubber and cement surfaces. And once applied, it demands no interminable waiting period. A brief drying time suffices before pressing the two surfaces together in harmonious unity, much like the grandest champion embracing victory.

Moisture and chemicals may pose as formidable foes to adhesive bonds, but contact cement scoffs in the face of adversity. This indomitable adhesive showcases impressive resistance to the ravages of moisture and chemicals, ensuring that your rubber-to-cement bond remains unyielding even in the harshest environs. So go forth and employ it in the bonding of rubber materials that may encounter water, oils, or other substances that could potentially undermine the bond’s integrity.

Advantages of Using Epoxy Adhesive for Rubber-to-Cement Bonding

Get ready to be amazed as we uncover the incredible advantages that epoxy adhesive brings to the table. From its Herculean bonding strength to its superhero-like resistance, this adhesive is a game-changer in the world of construction and industrial applications.

- Unbreakable Bond: When it comes to bonding rubber materials to cement surfaces, epoxy adhesive is the undisputed champion. With its exceptional tensile strength, it forms a bond so strong it could make Hercules jealous. Whether you’re working on a construction project or an industrial application, rest assured that this adhesive will deliver a durable and long-lasting bond that can withstand the test of time.

- Defying Mother Nature: Environmental factors can be quite unforgiving, but epoxy adhesives fear no elements. Moisture, heat, chemicals, UV radiation – you name it, epoxy can handle it. It’s like having a shield against the unpredictable forces of nature. No matter what harsh conditions your project faces, you can trust that epoxy adhesive will keep your rubber-to-cement bond intact and reliable.

- The Versatility Wonder: Epoxy adhesive is the embodiment of versatility. It has the power to bond different types of rubber materials to various cement surfaces, including concrete, masonry, and stone. Talk about a match made in adhesive heaven. From automotive to construction and electronics industries, this adhesive suits a wide range of applications. Whatever your project demands, epoxy is up for the challenge.

- Conquering Corrosion: Rubber materials can often come into contact with aggressive substances, but fear not. Epoxy adhesives have a secret weapon – their incredible chemical resistance. Oils, solvents, acids – you name it, they won’t stand a chance against the mighty epoxy. It remains robust and unyielding, even when faced with corrosive materials commonly found in industrial environments. Your rubber-to-cement bond will stay strong and secure.

Considerations When Choosing an Adhesive for Gluing Rubber to Cement

Today, we embark on an epic journey into the realm of rubber-to-cement bonding. But be warned, this is no task for ordinary adhesives. We need a glue that can conquer the elements, defy wear and tear, and create an unbreakable union. So, don your lab coats and safety goggles as we delve into the key considerations when selecting the ultimate adhesive for gluing rubber to cement.

Consideration 1: Rubber Compatibility

Just as superheroes have their unique powers, rubber comes in various forms too. Natural rubber, synthetic rubber, and blends of both grace our world. Each type possesses its own distinct properties and surface characteristics. Therefore, it is imperative to choose an adhesive that harmonizes perfectly with your specific rubber companion. Remember, compatibility is the secret to a successful bond.

Consideration 2: Cement Surface

Now let us shift our gaze to the very foundation of our adhesive conquest – the cement surface. Cement can be as smooth as a silk ribbon or as rough as a rugged mountain range. Some surfaces even mimic the porosity of a thirsty sponge. Different adhesives thrive on different textures and porosities. Thus, understanding your cement surface is an essential step in selecting your adhesive ally.

Consideration 3: Temperature Resistance

Our adhesive superhero must withstand the harshest temperatures thrown its way – scorching heat or freezing cold alike. Some adhesives may falter under extreme conditions, losing their power or deteriorating over time. To ensure a bond that stands the test of time, choose an adhesive that fearlessly endures the temperature fluctuations your glued rubber shall face.

Consideration 4: Flexibility Matters

Like any true hero, our adhesive partner must possess unparalleled flexibility. Rubber materials possess inherent elasticity, demanding an adhesive that can adapt to their every move. We seek a bond that withstands stress and movement, refusing to relinquish its grip. Thus, select an adhesive that embraces the twists and turns of gluing rubber to cement without breaking a sweat.

Alternative Methods of Attaching Rubber to Cement

We’ve explored the traditional methods of attaching rubber to cement, but now it’s time to venture into the realm of alternative techniques. Get ready for a thrilling journey that will challenge convention and revolutionize rubber-to-cement attachment.

First up on our list of alternative methods is the ingenious adhesive tape. These specially-designed tapes create an unbreakable bond between rubber and cement, thanks to their robust adhesive backing. No need for extra tools or equipment – just apply the tape to both surfaces and witness a secure connection materialize before your eyes. Convenience at its finest.

But wait, there’s more. Enter the world of contact adhesives, formulated specifically for bonding rubber to cement surfaces. These liquid marvels demand a bit of patience – apply the adhesive to both materials, allow it to dry for a specified time, and then press the rubber onto the cement surface. The result? A bond so powerful it will leave you in awe.

If you’re seeking an adhesive with unparalleled strength, look no further than epoxy adhesives. Renowned for their durability, these mighty warriors conquer even the most challenging bonding tasks. Just ensure that your chosen epoxy adhesive is compatible with both the rubber and cement surface – nobody likes a compatibility clash.

But what if you require some additional firepower? Fear not. Mechanical fasteners – screws or nails – come to the rescue. Combine these fasteners with adhesive materials, and you’ll forge a bond that screams “strength” and “stability.” This technique proves invaluable in heavy-duty industrial settings where endurance is paramount.

Before you embark on your alternative methods adventure, heed this word of caution: success may vary depending on factors like the type of rubber, condition of the cement surface, and specific application requirements. Always test your chosen method in a small inconspicuous area before going all-in. Safety first, my friends.

Speaking of safety, let’s not forget about the manufacturer guidelines and precautions. Respect the instructions provided by the adhesive or bonding material – wear protective gear, work in a well-ventilated area, and handle unused materials with care.

Factors Affecting the Strength and Durability of a Rubber-to-Cement Bond

In our quest for adhesive excellence, we have explored the realm of rubber-to-cement bonding, seeking the secrets to a bond that defies all odds. We’ve dabbled in the wonders of adhesives, from contact marvels to steadfast epoxies. But now, let us embark on a thrilling expedition into the very heart of the matter – the factors that determine the strength and durability of a rubber-to-cement bond. Brace yourselves for an adhesive odyssey like no other.

Factors that Forge or Shatter a Rubber-to-Cement Bond:

- Surface Preparation: The cornerstone of any successful relationship lies in preparation. Before embarking on this bonding journey, it is paramount to ensure pristine surfaces. Bid farewell to oil, dust, and loose particles that could sabotage your bond. Embrace a thorough cleansing ritual with suitable solvents, removing existing coatings or residues that dare to challenge your quest for an unyielding bond.

- Adhesive Selection: Ah, the hero of our tale. The choice of adhesive is pivotal in achieving a triumphant rubber-to-cement bond. Seek an adhesive specially crafted for such unions, bearing in mind their unique properties and compatibility with rubber and cement surfaces. An adhesive boasting exceptional adhesion properties, flexibility, and resistance to environmental adversaries like moisture and temperature fluctuations shall be your trusted ally.

- Adhesive Application: Like a master weaver, the artful application of adhesive knits strength into every fiber of your bond. Employ suitable tools, such as applicators or brushes, to ensure even application on both rubber and cement surfaces. Adhere diligently to the manufacturer’s instructions regarding adhesive thickness and curing time – for hastiness has no place in forging an unbreakable alliance.

- Curing Time: Ah, the sweet anticipation. Time stands as your steadfast companion, enabling the adhesive to entwine with the rubber and cement surfaces. Bestow upon it ample curing time, as recommended by the adhesive’s creator. Patience becomes your virtue, allowing the adhesive to penetrate deeply, weaving an interlocking bond that can withstand the ravages of time.

WyM9JtRZuvc” >

Conclusion

Yes, you can indeed glue rubber to cement.

The bond between rubber and cement can be strong and durable when the right adhesive is used. There are specific adhesives available in the market that are designed to adhere rubber to cement surfaces effectively.

These adhesives are formulated to provide excellent bonding strength, ensuring that the rubber stays firmly attached to the cement surface.