Picture this: you’re knee-deep in a DIY project, trying to figure out how to seamlessly connect PVC and vinyl. It’s a head-scratcher, isn’t it? But fear not, my fellow crafters and home improvement enthusiasts – I’m here to demystify the art of bonding these two materials together flawlessly.

In this comprehensive guide, we’ll embark on an adventure into the realm of adhesive wonders, unraveling the secrets behind creating sturdy and long-lasting connections between PVC and vinyl. Whether you’re fixing a pesky leak in your vinyl pool liner, constructing an ingenious PVC-vinyl structure, or simply indulging in some creative crafting with these versatile materials, this guide is tailor-made just for you.

So grab your trusty safety goggles and slip on those gloves – we’re about to dive headfirst into the world of glue and innovation. Get ready to unlock the potential of PVC and vinyl as they join forces in perfect harmony.

What is PVC and Vinyl?

Contents

In the world of glue, PVC and vinyl have emerged as a powerful combination. These synthetic plastic polymers offer exceptional strength and versatility, making them go-to choices for various industries. This article delves into the properties, applications, and considerations when working with PVC and vinyl.

PVC: The Rigid Powerhouse

Polyvinyl chloride (PVC) is a renowned rigid plastic that boasts impressive strength and resilience. Its durability and resistance to harsh environments make it a staple in plumbing pipes, electrical conduits, window frames, and more. PVC is a reliable choice for applications that demand structural integrity.

Vinyl: The Flexible Marvel

Derived from PVC resin, vinyl is a flexible plastic that excels in diverse applications such as flooring, upholstery, signage, and beyond. With its water resistance and ease of maintenance, vinyl offers versatility without compromising strength. From hospitals to homes, vinyl finds its place in various settings.

Gluing PVC to Vinyl: The Perfect Combination

Bonding PVC to vinyl requires careful consideration of adhesive choices. Solvent-based adhesives are popular due to their ability to soften the plastics’ surfaces and create a strong bond upon re-solidification. However, proper ventilation is essential due to their strong odor and potential health hazards.

Specialized adhesives designed explicitly for PVC-vinyl bonding are also available. These adhesives offer reliable solutions for achieving durable bonds. Surface preparation plays a crucial role in adhesion quality: thorough cleaning and slight roughening with sandpaper enhance bonding performance.

Not all adhesives are suitable for PVC-vinyl bonding. General-purpose adhesives or super glues may not provide the desired strength or durability. Conducting a small-scale compatibility test before full application ensures optimal results.

Can You Glue PVC to Vinyl?

PVC and vinyl are versatile materials with a wide range of applications. PVC, known for its strength and durability, is commonly used in construction and plumbing. Vinyl, on the other hand, is a flexible material often found in flooring and upholstery. But can you glue PVC to vinyl? The answer is yes, but it requires the right adhesive and proper surface preparation.

When it comes to gluing PVC to vinyl, one common adhesive option is solvent-based PVC cement. This type of glue contains solvents that dissolve the surface of the PVC, allowing it to fuse with the vinyl when the solvents evaporate. Before applying the PVC cement, it’s important to clean the surfaces of both the PVC and vinyl thoroughly to remove any dirt or contaminants. You can use sandpaper or a fine-grit abrasive pad to slightly roughen the surfaces for better adhesion.

Another adhesive option for bonding PVC and vinyl is epoxy adhesive. Epoxy adhesives are known for their strong bonding capabilities and resistance to moisture, heat, and chemicals. However, not all epoxy adhesives are suitable for gluing PVC to vinyl, so it’s important to choose an epoxy adhesive that specifically mentions compatibility with these materials. Like with PVC cement, proper surface preparation is crucial when using epoxy adhesives.

Here are some key points to keep in mind when gluing PVC to vinyl:

- Choose the right adhesive: Look for solvent-based PVC cement or epoxy adhesive that specifically mentions compatibility with PVC and vinyl.

- Clean the surfaces: Thoroughly clean both the PVC and vinyl surfaces to remove any dirt or contaminants that may interfere with bonding.

- Roughen the surfaces: Use sandpaper or a fine-grit abrasive pad to slightly roughen the surfaces for better adhesion.

- Apply the adhesive: Follow the manufacturer’s instructions for applying the adhesive, ensuring an even and thin layer on both PVC and vinyl surfaces.

- Press and cure: Press the PVC and vinyl surfaces together firmly and allow sufficient time for the adhesive to dry and cure.

It’s worth noting that the bond strength may vary depending on factors such as the specific adhesive used, surface preparation, and application of the materials. To be safe, it’s always a good idea to test the adhesive on a small, inconspicuous area before attempting to glue PVC to vinyl on a larger scale. Additionally, consult with the manufacturer of the PVC and vinyl materials for their recommendations on adhesive compatibility and best practices for bonding these materials together.

Adhesive Options for Bonding PVC to Vinyl

Well, you’re in luck because I’m here to give you the full scoop on adhesive options that will get the job done. Whether you’re tackling a construction project or revamping some upholstery, finding the perfect adhesive is crucial for creating a strong and long-lasting bond.

Let’s start with solvent-based adhesive, a popular choice among many. These adhesives contain powerful solvents that dissolve the surfaces of the PVC and vinyl, allowing them to fuse together as the solvents evaporate. Known for their exceptional strength and durability, solvent-based adhesives are ideal for projects that demand a permanent bond. Just keep in mind that they can emit potent fumes during application, so make sure to work in a well-ventilated area.

If you prefer a less toxic alternative, water-based adhesive might be the answer. These adhesives work by creating a chemical reaction with moisture present in the air or on the surfaces being bonded, resulting in a strong connection between the PVC and vinyl. Water-based adhesives are particularly suited for applications where flexibility is key, such as upholstery or fabric projects. Not only do they emit fewer fumes compared to solvent-based options, but they also provide a safer choice for indoor use.

For those seeking convenience and speed, adhesive tapes specially designed for bonding PVC to vinyl are readily available. These tapes feature a robust adhesive backing that instantly bonds the two materials together. No drying time or special surface preparation is needed, making them an excellent choice for small projects or quick repairs. However, it’s important to note that their strength may not match that of solvent-based or water-based adhesives.

When selecting an adhesive, consider factors such as cost, strength, and ease of use. Additionally, take into account the environment in which the bonded materials will be used and any specific requirements of your project.

Proper surface preparation is crucial for achieving a strong bond. Ensure that both surfaces are thoroughly cleaned, dried, and free from any dirt, dust, grease, or other contaminants. Consider using a mild detergent or alcohol-based cleaner to clean the surfaces before applying the adhesive.

Lastly, compatibility is key. Not all adhesives may bond well with certain types of PVC or vinyl, so it’s always a good idea to perform a test on a small, inconspicuous area before applying it to the entire surface.

Preparing the Surfaces for Bonding

Achieving a strong and durable bond between PVC and vinyl materials requires meticulous surface preparation. The key to success lies in the details – the thoroughness of your cleaning, the finesse of your sanding, and the precision of your primer application. So, buckle up and get ready for a bonding adventure like no other.

First things first, you need to banish any trace of dirt, dust, grease, or other contaminants from the surfaces. Imagine wielding a mighty sword made of a mild detergent or cleaning solution, accompanied by a soft cloth or sponge as your trusty sidekick. Together, you will embark on a crusade to scrub away every last particle of impurity. Rinse them thoroughly, allowing the cleansing water to wash away any remnants of grime. And then, let patience be your virtue as you wait for the surfaces to dry completely, like a desert longing for rain.

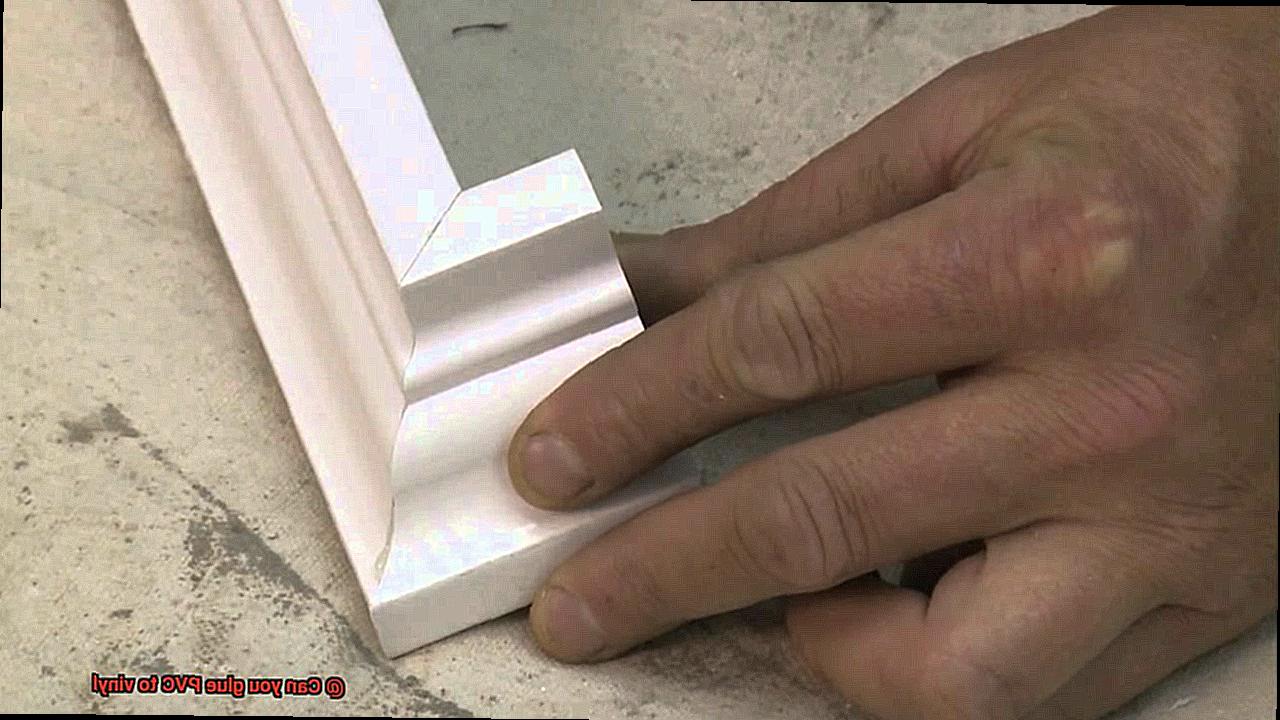

Now that your surfaces are pristine, it’s time to add some texture to their smooth canvas. Picture yourself as an artist armed with sandpaper or a sanding block with a fine grit. With meticulous circular motions, you gently roughen the surfaces, creating tiny grooves that provide a foothold for the adhesive about to join them. But remember, subtlety is key – too much roughening can backfire.

As with any masterpiece in progress, there may be stray particles left behind from the sanding process. Fear not. Armed with a clean cloth or compressed air, you swiftly sweep away any remnants of dust or debris. With each stroke or blast, you ensure that nothing stands in the way of the impending bond.

Now it’s time to bring out the big guns – the primer. This magical elixir specially designed for PVC and vinyl materials creates a chemical bond between the adhesive and the surface. Like an alchemist carefully blending ingredients, you follow the manufacturer’s instructions to apply an even and thin layer of primer over both surfaces. This potion requires time to work its magic, so allow it to dry completely before proceeding.

But wait, there’s more. Different adhesives may have additional surface preparation steps specific to their application. Some may need mixing, while others may require a specific temperature or humidity range for optimal bonding. Take heed of the adhesive manufacturer’s instructions and be sure to follow them meticulously.

Lastly, remember that even the environment plays a role in this bonding symphony. The temperature and humidity levels can either harmonize with the adhesive or throw it off-key. Ensure that the surfaces bask in the recommended temperature range, and that the humidity levels dance in sync with the adhesive’s desires.

Not All Adhesives are Suitable for Bonding PVC to Vinyl

Today, we delve into the intricacies of bonding PVC to vinyl, a task that requires meticulous attention to detail and a touch of adhesive artistry. Join us as we unveil the secrets behind choosing the right adhesive for this unique challenge.

Understanding the Differences:

To comprehend why not all adhesives can successfully bond PVC to vinyl, we must first recognize the distinct properties of these materials. PVC, a rigid thermoplastic commonly found in construction applications, stands tall and strong, while flexible vinyl gracefully embraces upholstery and flooring, bending and stretching with ease. These differences pose a significant challenge when it comes to creating a strong and durable bond.

The Quest for Compatibility:

One of the key hurdles in bonding PVC to vinyl lies in bridging the flexibility gap between these two materials. The chosen adhesive must possess the remarkable ability to accommodate their differing movements without compromising the bond’s integrity. Furthermore, as PVC and vinyl may have different chemical compositions and additives, it becomes essential to select an adhesive that exhibits compatibility with both materials.

The Right Tools for the Job:

Thankfully, our adhesive arsenal provides a range of suitable options. Solvent-based adhesives, such as those containing volatile organic compounds (VOCs), evaporate during the bonding process, resulting in a robust connection. Epoxy adhesives boast exceptional strength and durability, while urethane adhesives offer flexibility and moisture resistance – ideal for PVC-vinyl bonding.

Mastering the Craft:

To achieve an impeccable bond, it is paramount to adhere to the adhesive manufacturer’s instructions diligently. Proper surface preparation involves thorough cleaning and removal of any contaminants or residues that could mar the bonding process. Applying the adhesive evenly and allowing ample curing time are essential steps in attaining a lasting connection.

Strength in Numbers:

In some cases, mechanical fasteners like screws or rivets can supplement adhesive bonding, reinforcing joints that may face excessive stress or movement. This combination of mechanical and adhesive strength is particularly crucial in outdoor or structural applications, where durability is paramount.

Choosing Wisely:

While numerous adhesives claim to bond PVC to vinyl, not all possess the reliability and longevity required for a successful union. Opting for adhesives that have been tested and proven specifically for PVC-vinyl bonding ensures optimal results.

Mechanical Fasteners as an Alternative Option

When it comes to the task of joining PVC and vinyl materials, glue is often the default choice. However, there are situations where glue simply doesn’t cut it or isn’t the preferred option. In such cases, mechanical fasteners come swooping in as the ultimate problem solvers. In this captivating blog post, we will delve into the remarkable advantages of using mechanical fasteners over glue when it comes to attaching PVC to vinyl.

Swift and Simple Installation:

The beauty of mechanical fasteners lies in their simplicity and speed of installation. Unlike glue, which demands meticulous surface preparation and tedious drying time, mechanical fasteners can be effortlessly inserted into the materials with lightning speed. This makes them an ideal choice for time-sensitive projects or situations requiring frequent disassembly.

Unparalleled Adjustability and Flexibility:

Mechanical fasteners bring a whole new level of adjustability and flexibility to the table. Whenever precise alignment becomes paramount or adjustments are needed after installation, screws or rivets can be loosened or tightened with ease. This level of flexibility proves invaluable in construction or fabrication projects where measurements may demand fine-tuning during the assembly process.

Unyielding Strength and Unmatched Durability:

While glue can provide a solid bond between PVC and vinyl, it may not always hold up against certain forces or stresses over time. Mechanical fasteners, on the other hand, step up to the plate by distributing loads more effectively and creating a connection that can withstand tension, compression, and shear forces like champions. They offer an unparalleled level of strength and durability compared to adhesive bonding alone.

Embracing Varying Thicknesses:

Another feather in the cap for mechanical fasteners is their ability to handle varying thicknesses of PVC and vinyl materials with grace. Glue may stumble when it comes to bonding materials with significant differences in thickness. In stark contrast, mechanical fasteners effortlessly penetrate through different layers, ensuring a secure attachment that leaves no room for doubt.

Safety First:

In certain applications where PVC and vinyl components are exposed to heavy loads or vibrations, the use of mechanical fasteners may even be required for safety reasons. These fasteners become the ultimate guardians, providing additional reinforcement and warding off failure to ensure the integrity of the structure.

Testing the Adhesive Before Applying it

When it comes to joining different materials, testing the adhesive before applying it is absolutely vital. In this article, we will explore the importance of testing, outline the necessary steps for a successful bonding process, and highlight key factors to consider. Get ready to unlock the secrets to achieving a strong and durable bond.

Step 1: Determining Compatibility

To ensure a successful bond, it is essential to test the adhesive’s compatibility with the materials you are working with. Apply a small amount of adhesive onto scrap pieces of each material and allow them to dry or cure as per the manufacturer’s instructions. Next, try to separate the two pieces. A strong bond indicates that the adhesive is suitable for gluing those specific materials together.

Step 2: Evaluating Durability

Materials may encounter various environmental conditions such as temperature changes, moisture, or UV rays. The adhesive must withstand these factors without compromising the bond’s strength. To test durability, subject the bonded samples to simulated environmental conditions like extreme temperatures or humidity levels. Examine the bond afterward for any signs of deterioration or weakening.

Step 3: Considering Aesthetics

Nobody wants an adhesive that ruins their project’s appearance. To ensure colorfastness and surface integrity, apply a small amount of adhesive on an inconspicuous area of both materials. Let it dry completely and observe for any changes in color or texture. If there are no noticeable alterations, it means that the adhesive is suitable for gluing the materials together without affecting their appearance.

uGdr6UFAB2g” >

Also Read: How to Glue Vinyl to PVC?

Conclusion

In conclusion, the possibility of gluing PVC to vinyl is not just a far-fetched idea—it’s a reality with the right adhesive and proper surface preparation. These two materials may have different properties, but when bonded together correctly, they can create connections that are not only strong but also built to last.

When it comes to finding the perfect adhesive for this task, there are a couple of options that stand out. Solvent-based PVC cement and epoxy adhesive have proven themselves time and time again in the world of PVC-vinyl bonding. The solvent-based adhesives work their magic by softening the surfaces of both materials, allowing them to fuse together seamlessly once the solvents evaporate. On the other hand, epoxy adhesives offer incredible strength and resistance against moisture, heat, and chemicals—making them ideal for long-lasting bonds. Just remember to choose adhesives that explicitly state their compatibility with PVC and vinyl.

However, it’s important to note that adhesive selection is just one part of the equation. Proper surface preparation plays a pivotal role in achieving successful bonding. Before applying any adhesive, make sure to thoroughly clean both surfaces of dirt or contaminants that could hinder their union. To enhance adhesion even further, consider giving the surfaces a gentle roughening using sandpaper or an abrasive pad. And don’t forget: always follow the manufacturer’s instructions for applying the chosen adhesive—this will ensure an even and thin layer on both PVC and vinyl.

It’s worth mentioning that not all adhesives are cut out for PVC-vinyl bonding. To avoid any mishaps or disappointments down the line, conducting a small-scale compatibility test before going all-in is highly recommended.

All in all, with careful consideration in selecting your adhesive weapon of choice, meticulous surface preparation, and adherence to best practices—you can confidently glue PVC to vinyl like a pro.