Crafting and DIY projects have a way of igniting our imagination, especially when we mix different materials together. But what if you want to fuse fabric with PVC? Can these seemingly incompatible materials actually come together in perfect harmony? You bet they can. Join us on this thrilling journey as we dive into the captivating realm of gluing fabric to PVC and unlock the secrets to a flawless project.

Now, don’t let the idea of bonding fabric to PVC intimidate you. With the right techniques and a sprinkle of patience, you’ll be amazed at what you can achieve. In this blog post, we’re going to explore a treasure trove of tips, tricks, and insider knowledge that will take your crafting skills to new heights. So grab your trusty PVC pipes, choose your favorite fabric, and let’s embark on this adhesive adventure together.

What is PVC?

Contents

In this captivating journey, we will explore the durability, versatility, and affordability of PVC, shedding light on its potential in construction, automotive, healthcare, packaging, electronics, and even fabric gluing. Prepare to be amazed by the wonders of this extraordinary material.

The Mighty Properties of PVC:

- Durability: PVC is a warrior against the elements, bravely resisting moisture, chemicals, impact, and abrasion. Whether it’s enduring harsh weather conditions or battling corrosive substances, PVC stands strong.

- Versatility: The chameleon-like nature of PVC allows it to adapt to different forms. Rigid PVC (RPVC) possesses Herculean strength and unwavering rigidity, while flexible PVC (FPVC) showcases agility and adaptability.

- Affordability: PVC wins the crown for being one of the most cost-effective plastics on the planet. Abundant raw materials and efficient manufacturing processes make it accessible to all.

Applications that Redefine Industries:

- Construction Marvels: From pipes and fittings that channel life-giving water to gutters that bravely shield us from the rain, PVC proves its mettle in construction. Window frames stand tall against the wind, flooring materials withstand footfall battles, and electrical insulation ensures safety in every wire.

- Automotive Magic: Inside the realm of automobiles, PVC reigns supreme. Dashboards boast PVC’s resilience against wear and tear, seating upholstery wraps around its comfort like a warm embrace, door panels guard with unyielding strength, and floor coverings dance with every step.

- Healthcare Heroes: PVC plays a vital role in healthcare as it safeguards lives. IV tubing delivers hope, blood bags cradle precious life, and oxygen masks breathe life into the weary. PVC’s non-reactive nature and ease of sterilization make it a trusted ally in the medical field.

- Packaging Gems: PVC unveils its transparent magic in the packaging world. Blister packaging for pharmaceuticals and consumer goods ensures visibility while keeping tampering at bay. Trust in PVC to protect and showcase products with grace.

- Electrical Enigmas: Behind every flickering light or humming electronic device, PVC silently guards against electrical mishaps. Insulating wires and cables with its exceptional electrical properties, PVC ensures a safe and reliable connection.

Types of Fabric

Whether you’re looking to revamp old furniture or create unique accessories, this simple technique can turn ordinary materials into extraordinary creations. In this comprehensive guide, we will delve into the different types of fabric that interact with PVC when glued, uncovering the secrets to a successful bond.

Cotton: A Gentle Summer Breeze

Imagine the soft touch of a gentle summer breeze against your skin – that’s cotton. This natural fabric is breathable, soft, and oh-so-comfortable, making it perfect for clothing, home furnishings, and craft projects. When it comes to gluing cotton fabric to PVC, you’re in luck. Cotton is easy to work with and forms a strong bond with the plastic surface. However, it’s important to seal those fraying edges before you begin your gluing adventure – nothing should stand in the way of your creativity.

Polyester: Durability at Its Finest

When it comes to durability and resistance to wrinkles and shrinking, polyester is the superhero of fabrics. You’ll find this synthetic fabric in clothing, upholstery, and outdoor gear. When gluing polyester fabric to PVC, it’s crucial to choose the right adhesive that bonds well with both materials. Testing a small area beforehand ensures a secure bond, granting you the confidence to tackle your entire project with ease. With polyester by your side, your creations will withstand the test of time.

Nylon: Lightweight Warrior

Nylon is the lightweight warrior of fabrics – strong, resistant to abrasion, and perfect for sportswear and swimwear. When it comes to gluing nylon fabric to PVC, you’ve got an ace up your sleeve. Nylon boasts excellent adhesive properties that create a super-strong bond with the plastic surface. Get ready to experience the sheer power of sticking as your creations come to life.

Vinyl: The Waterproof Wonder

Vinyl fabric is like a superhero cape – it’s waterproof, durable, and easy to clean. No wonder it’s the go-to choice for upholstery and outdoor applications. When it comes to gluing vinyl fabric to PVC, you’re in for smooth sailing. Both materials share similar compositions, making it a breeze to find an adhesive that bonds them together seamlessly. Prepare to embark on a journey of crafting excellence and create some stunning projects that will leave everyone in awe.

Adhesives for Bonding Fabric to PVC

When it comes to bonding fabric to PVC, choosing the right adhesive is crucial for a strong and durable bond. There are several types of adhesives available for this purpose, each with their own unique properties and applications. In this comprehensive guide, we’ll explore the different types of adhesives and provide tips on how to properly prepare surfaces for application.

- Solvent-based adhesives: These adhesives are known for their strength and durability, making them a popular choice for industrial applications. They work by chemically dissolving the PVC and fabric surfaces, allowing them to fuse together when the solvent evaporates. However, it’s important to note that these adhesives can be flammable and have strong fumes, so proper ventilation and caution should be taken when using them.

- Water-based adhesives: If you’re looking for a safer alternative, water-based adhesives are a great option. These adhesives are less toxic and have lower fumes, making them more suitable for home use. They work by forming a bond through the evaporation of water, leaving behind a strong adhesive layer. Water-based adhesives can be used for various applications, including upholstery and crafting projects.

- Contact adhesives: Another popular choice for bonding fabric to PVC is contact adhesive. These adhesives come in two parts: one is applied to the fabric, and the other is applied to the PVC surface. Once both surfaces are dry, they are pressed together, creating an instant bond. Contact adhesives are known for their strength and flexibility, making them ideal for applications where the fabric may need to stretch or move.

Before applying any adhesive, it’s important to properly prepare the surfaces that will be bonded. Both the PVC and fabric should be clean and free from any dust, dirt, or grease. Using a mild detergent or rubbing alcohol can help remove any contaminants. Additionally, roughening the surface of the PVC with sandpaper can enhance the adhesive’s grip.

When applying the adhesive, it’s crucial to follow the manufacturer’s instructions. This includes applying the adhesive evenly and allowing it to dry or cure for the recommended amount of time. Applying too much adhesive or not allowing enough drying time can result in a weak bond.

It’s also important to consider the specific application and requirements of the bonded fabric to PVC. For example, if the fabric will be exposed to moisture or extreme temperatures, a waterproof or temperature-resistant adhesive may be necessary.

Lastly, it’s always a good idea to test the adhesive on a small, inconspicuous area before applying it to the entire surface. This will allow you to assess the bond strength and compatibility with both the fabric and PVC.

Preparing Surfaces for Adhesion

In this comprehensive guide, we’ll walk you through the essential steps to ensure your fabric sticks to PVC like a champ. So, grab your glue and let’s dive in.

Step 1: Cleanliness – A Spotless Start

To lay the foundation for a strong bond, cleanliness is key. Before delving into the adhesive world, make sure both your fabric and PVC surfaces are squeaky clean. Dust, dirt, and grease can be major adhesion killers. For the fabric, gently scrub it with a soft brush using a mild detergent or soap solution. As for the PVC, wipe it clean using a cloth dampened with isopropyl alcohol. Start with spotless surfaces for optimal results.

Step 2: Roughening the Surface – Embrace Imperfections

PVC surfaces are notoriously smooth and nonporous, which can make them resistant to adhesion. Fear not. Embrace imperfection by lightly sanding the PVC with fine-grit sandpaper. This process creates tiny abrasions that give the adhesive more surface area to grip onto. By roughening the surface, you’re setting the stage for an unbreakable bond.

Step 3: Primer Application – The Magic Touch

For an extra boost in adhesion power, consider applying a primer specifically designed for fabric and PVC. Think of it as the magic touch that creates a chemical bond between the two surfaces, making them inseparable. Before diving into priming, carefully read the manufacturer’s instructions to ensure proper application. With the right primer, you’ll be one step closer to adhesive perfection.

Step 4: Testing Compatibility – A Match Made in Adhesive Heaven

Don’t leave things up to chance. Before committing to gluing your fabric to PVC, conduct a compatibility test. Take small samples of both materials and apply a small amount of adhesive, following the curing instructions provided by the manufacturer. Once the bond has cured, put it to the ultimate test by applying force or pulling at the bonded area. If it holds strong, congratulations. You’ve found your adhesive soulmate.

Step 5: Adhesive Selection – Finding “The One”

Choosing the right adhesive is like finding “the one” for your project. Consider factors such as intended use, flexibility requirements, and durability. Solvent-based adhesives, epoxy adhesives, and specialized fabric adhesives are all viable options. Seek guidance from adhesive manufacturers or industry professionals if you find yourself unsure. With the perfect adhesive in hand, you’re ready for a bond that can conquer any challenge.

Applying Adhesive to Fabric and PVC

Get ready for an exhilarating ride as we delve into the art of gluing fabric to PVC. Whether you’re a seasoned glue aficionado or just a curious DIY enthusiast, this comprehensive guide is tailor-made for you.

Step 1: The Perfect Adhesive

The secret to a successful bond lies in selecting the right adhesive. You have two main options at your disposal: solvent-based adhesives and water-based adhesives. Solvent-based adhesives work their magic by dissolving surfaces, creating an unbreakable bond. On the other hand, water-based adhesives are less toxic and easier to work with. Take a moment to consider your project’s needs before making your choice.

Step 2: Prepare for Glory

No bond can be achieved without proper preparation. Start by meticulously cleaning both the fabric and PVC surfaces. Wave goodbye to any dust, dirt, or grease using a mild detergent or rubbing alcohol. Patience is key here – allow them to dry completely before proceeding to the next step.

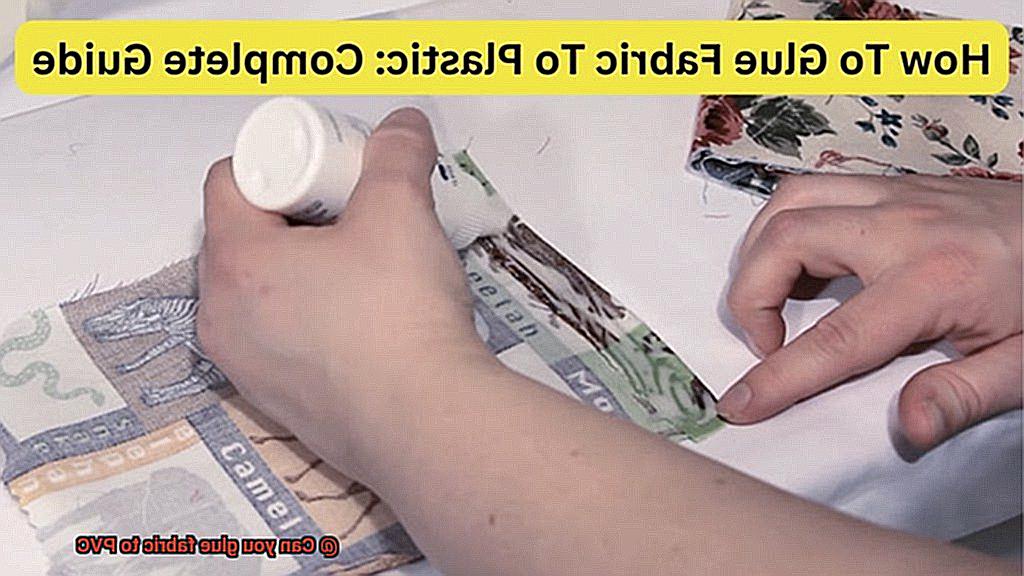

Step 3: Apply with Finesse

Now it’s time to get down and dirty with the adhesive. Armed with a brush or roller, apply the adhesive evenly and in thin layers. Remember, less is more. Applying too much adhesive can lead to unwanted seepage or unsightly lumps.

Step 4: Place and Press

With the adhesive applied, delicately place the fabric onto the PVC surface. Pay close attention to alignment, ensuring there are no wrinkles or bubbles in sight. To guarantee an ironclad bond, apply pressure evenly across the entire surface.

Step 5: A Test of Patience

Now comes the ultimate test – letting your bond cure. Follow the manufacturer’s instructions religiously and grant your adhesive the time it needs to dry and set fully. This crucial step ensures a connection between fabric and PVC that will withstand the test of time.

Step 6: Reinforcements, Activate.

Depending on your project’s demands, additional reinforcements may be necessary. Consider stitching or using reinforcing tapes for that extra boost in strength. Especially if your bond will face extreme conditions like moisture or temperature fluctuations, these reinforcements will ensure an unbreakable connection.

Factors That Affect the Durability of the Bond

Embark on this journey with me as we delve into the captivating world of glues, meticulous preparation techniques, formidable environmental conditions, artful application methods, the unsung hero of flexibility, and the harmony of compatibility tests. Prepare to unlock the secrets to forging a bond that will triumph against the relentless test of time.

The Mighty Glue:

Glues are not created equal. Selecting a glue designed exclusively for bonding fabric and PVC is paramount to achieving a durable bond. These specialized glues possess extraordinary adhesive properties that ensure an enduring connection.

Prepping for Success:

Disregarding this essential step is not an option. Before applying any glue, meticulously cleanse both fabric and PVC surfaces. The presence of dust, dirt, or grease can hinder adhesion and weaken the bond. For an extra boost, the PVC surface can be invigorated by the gentle abrasion of sandpaper, reinforcing bond strength.

Battling Environmental Factors:

Mother Nature can be an adversary in our bonding endeavors. Extreme temperatures and humidity levels interfere with the adhesive properties of glue, compromising bond durability. To achieve optimal results, adhere to temperature and humidity guidelines outlined by the manufacturer.

Artful Application Techniques:

Become a glue virtuoso. Applying an even layer of glue on both fabric and PVC surfaces is vital for proper adhesion. Utilize brushes or rollers to achieve uniformity in application. Remember, patience is key – allowing sufficient drying or curing time as directed by the glue manufacturer leads to a robust and unyielding bond.

Flexibility: The Unsung Hero:

Acknowledge the might of flexibility. Fabric and PVC often experience varying levels of movement and flexibility in their applications. Select a glue capable of accommodating these variations without succumbing to cracks or breaks, ensuring the bond remains steadfast even under relentless stress or strain.

Compatibility: A Match Made in Heaven:

Consider the fabric-PVC compatibility factor. Certain fabrics may not adhere well to PVC due to chemical composition or surface texture. Before committing to full application, test a small, inconspicuous area to avoid adhesion issues and potential disappointment.

Pros and Cons of Gluing Fabric to PVC

Gluing fabric to PVC might just be the solution you’ve been searching for. This innovative technique opens up a whole new world of creative possibilities. Let’s dive in and explore the pros and cons of this exciting combination.

One of the major advantages of gluing fabric to PVC is its incredible versatility. By incorporating fabric, you can instantly transform a plain PVC surface into a visually appealing masterpiece. Whether you’re revamping furniture, creating a unique bag, or designing a one-of-a-kind costume, fabric allows for endless customization options. With a vast array of colors, textures, and patterns to choose from, you can truly express your personal style and make your PVC creations stand out from the crowd.

In addition to its aesthetic benefits, gluing fabric to PVC also enhances durability. The fabric acts as an extra layer of protection against pesky scratches, harmful UV rays, and general wear and tear. This added durability ensures that your PVC creations will withstand the test of time and continue to look fabulous for years to come.

Comfort is another incredible advantage of gluing fabric to PVC. If you’re tired of uncomfortable seating options, adding fabric can provide a softer and more cushioned surface to sit or lean on. Say goodbye to those uncomfortable PVC chairs and hello to a whole new level of comfort.

However, it’s important to consider the potential challenges that come with gluing fabric to PVC. Achieving a strong bond between the two materials can be a bit tricky. The adhesive used must be specifically designed for both fabric and PVC and applied correctly for optimal results. Without proper bonding, the fabric may peel or detach over time, leaving you with a less-than-desirable outcome.

Another downside is the limited heat resistance of PVC. It’s important to keep in mind that excessive heat can weaken or even melt the glue used to attach the fabric, resulting in separation. If your project is likely to be exposed to high temperatures, it’s crucial to carefully consider this aspect and take necessary precautions.

Cleaning glued fabric-PVC items may also require special care, depending on the type of fabric used. Some fabrics may be more prone to staining or discoloration when exposed to certain cleaning agents or methods. It’s important to follow the manufacturer’s instructions and use appropriate cleaning techniques to ensure that your fabric-PVC creations stay looking pristine.

Lastly, while gluing fabric to PVC can enhance visual appeal, it may not always result in a seamless or professional finish. Uneven glue application or visible glue residue can detract from the overall aesthetics of the item. Taking the time to ensure a clean and neat application is crucial for achieving a polished final product.

xQgTwsRdfwI” >

Conclusion

Yes, it is possible to glue fabric to PVC. This combination can be achieved by using the right adhesive specifically designed for bonding these two materials together. The key lies in selecting a high-quality adhesive that is strong enough to create a lasting bond between the fabric and PVC. When applying the adhesive, make sure to follow the manufacturer’s instructions carefully for optimal results.

Gluing fabric to PVC opens up a world of possibilities for various projects. Whether you’re looking to create custom upholstery, repair outdoor gear, or add decorative elements to your PVC structures, this technique allows you to seamlessly integrate fabric into your designs.

The process starts with preparing both surfaces before applying the adhesive. Clean the PVC thoroughly, removing any dirt or debris that could interfere with adhesion. Similarly, ensure that the fabric is clean and free from any coatings or finishes that may hinder bonding.

Once both surfaces are prepped, apply an even layer of adhesive onto the PVC surface using a brush or applicator recommended by the manufacturer. Take care not to apply too much adhesive as it may seep through the fabric or cause unwanted bulges.

Next, carefully place the fabric onto the glued surface of the PVC, ensuring proper alignment and smooth application. Apply pressure evenly across the entire bonded area using a roller or your hands. This step helps eliminate air bubbles and ensures maximum contact between the two materials.

Allow sufficient drying time as per the adhesive manufacturer’s instructions. It is crucial not to rush this step as premature handling can compromise the bond strength.

Once fully dried and cured, test the bond by gently pulling on both materials. If they remain firmly attached without any signs of separation or weakening, congratulations – you have successfully glued fabric to PVC.

However, it’s important to note that different types of fabrics and PVC may require specific adhesives tailored for their unique properties. Therefore, it’s always advisable to consult with experts or conduct thorough research before embarking on your fabric-to-PVC bonding journey.

In conclusion, gluing fabric to PVC is indeed possible with the right adhesive and proper technique. This versatile combination opens up a world of creative opportunities, allowing you to bring your unique ideas to life.