Ever wondered if magnets and glue could join forces? Imagine this: You have a tiny but mighty magnet that you want to stick onto an object, whether it’s metal or plastic. But forget about nails or screws – is there a way to create a lasting bond using glue? Well, my friends, get ready to unravel the secrets of magnet-adhesive magic as we delve into the captivating world of gluing magnets to different surfaces.

In this intriguing blog post, we’ll explore the potential marriage between magnets and glue and find out if it’s truly possible. We’ll uncover the science behind their relationship, discuss which types of glue work best for different materials, and dive into the crucial role of surface preparation in achieving a successful bond.

But wait, there’s more. We’ll also venture into the realm of creativity and innovation, exploring practical applications where gluing magnets becomes a game-changer. From jaw-dropping DIY projects and mind-boggling crafts to groundbreaking advancements in engineering and technology, discover how this unconventional bonding method can revolutionize our interaction with magnetic objects.

So whether you’re an avid DIY enthusiast, a curious explorer, or an aspiring inventor, buckle up for an exhilarating journey through the world of magnetic adhesion. Get ready to challenge norms and unlock the potential of harmoniously combining magnets and glue. Prepare yourself for the astonishing power of an invisible bond that defies what we once believed was possible.

What Materials are Magnets Made Of?

Contents

- 1 What Materials are Magnets Made Of?

- 2 Why Glue a Magnet to Something?

- 3 What Type of Glue Should be Used for Gluing Magnets?

- 4 Preparing the Surface and Magnet for Gluing

- 5 Applying the Adhesive

- 6 Curing Time for Maximum Bond Strength

- 7 Factors That Can Weaken or Break the Bond Over Time

- 8 Using Additional Mechanical Means for Extra Support and Stability

- 9 Conclusion

Prepare to be captivated by the secrets of magnets and the materials that bring them to life. Delving into the world of magnetism, we will uncover the diverse materials used to create these mesmerizing objects and unravel their extraordinary properties.

At the heart of magnet production lies the most common type – the permanent magnet. Crafted from ferromagnetic materials, such as iron, nickel, and cobalt, these magnets possess a remarkable ability to become magnetized and retain their magnetic field. When exposed to a potent magnetic force, the very alignment of atoms within these materials undergoes a transformative shift, generating a magnetic field within the material itself.

The captivating phenomenon of magnets can be attributed to the alignment of atoms in ferromagnetic materials. Unlike their counterparts, these atoms remain steadfastly aligned even after separation from the external magnetic field. This unique characteristic allows permanent magnets to retain their magnetic allure, continuing to attract other magnetic materials long after their initial encounter.

Venturing further into the realm of magnets, we encounter electromagnets – a different breed altogether. These extraordinary creations require an external power source to awaken their magnetic potential. A core material serves as their foundation, encased by a coil of wire. When an electric current surges through this wire, it ignites a magnetic field around the core material, lending it a newfound magnetism.

The choice of core material for electromagnets is an art in itself, tailored to meet specific needs. From iron and steel to ferrite, each core material possesses distinct attributes that enhance the magnetic field generated by the electric current. The selection hinges upon factors such as desired strength and intended application, shaping the final character of these electrifying magnets.

Beyond the realms of traditional magnet materials lies a realm of rare-earth magnets – a testament to ingenuity and innovation. These remarkable specimens are forged from alloys containing rare-earth elements like neodymium and samarium. Renowned for their unparalleled magnetic strength, rare-earth magnets have cemented their place in various domains, from electronics to motors, leaving an indelible mark on the magnetic landscape.

It is crucial to acknowledge that not all materials possess the inherent qualities to become magnets. Only those with specific atomic structures and properties can be magnetized and retain their magnetism. This intricate dance of atomic alignment sets materials like iron, nickel, cobalt, and rare-earth elements apart, granting them the privilege of being the chosen ones in magnet production.

Why Glue a Magnet to Something?

In our previous discussions, we explored the fascinating properties and applications of magnets. Today, we delve into the intriguing question: Why glue a magnet to something? Prepare to be amazed as we unravel the hidden benefits of this simple yet powerful act.

Organization:

Imagine a clutter-free workshop or garage where every tool has its place. Gluing magnets to the wall provides a convenient solution for organizing tools. By attaching metal objects to these magnets, you can keep your workspace tidy, accessible, and efficient. No more fumbling through drawers or searching for misplaced tools – with glued magnets, everything is at your fingertips.

Decorative Delights:

Magnets come in various shapes, sizes, and designs, making them perfect for adding a touch of personalization and creativity. Whether it’s on your fridge, a whiteboard, or any magnetic-friendly surface, gluing decorative magnets can transform mundane spaces into visually appealing displays. Showcase your favorite photos, artwork, or inspirational quotes with ease.

Practical Bonding:

Sometimes traditional attachment methods like screws or nails are not feasible or desired. Gluing magnets offers a practical alternative for securing objects together. Crafters and DIY enthusiasts can now explore endless possibilities without the need for visible hardware. Delicate materials that could be damaged by drilling also find solace in the gentle embrace of glued magnets.

Mastering Magnetic Fields:

Strategically attaching magnets to specific areas of an object unlocks the power to manipulate its behavior when exposed to magnetic forces. This technique is particularly useful in engineering and scientific applications that demand precise control over magnetic interactions. With glued magnets, you can harness the power of attraction to achieve desired outcomes with finesse.

Choosing the Right Adhesive:

To ensure a successful bond, it’s crucial to select the appropriate adhesive. Regular household glue may not provide sufficient strength for magnets. Instead, opt for specialized adhesives designed specifically for bonding magnets. These adhesives possess the strength to withstand high temperatures and vibrations, guaranteeing a durable and long-lasting attachment.

What Type of Glue Should be Used for Gluing Magnets?

In this section, we will delve into the secrets of selecting the perfect glue for bonding magnets. Whether you seek to organize your tools, infuse your projects with creativity, or achieve precise control over magnetic interactions, choosing the ideal adhesive is vital for creating a bond that withstands the test of time. So, let’s embark on this journey and uncover the mysteries of gluing magnets.

When it comes to gluing magnets, the type of adhesive you choose depends on the specific application and the materials you are bonding. One highly recommended option is epoxy, a robust and resilient adhesive that creates an unyielding bond between surfaces. Epoxy works wonders when gluing magnets to metal or other magnets, providing exceptional strength and durability. For optimal results, opt for a two-part epoxy specifically designed for bonding magnets. These epoxies possess remarkable strength and can withstand the magnetic forces exerted by the magnets, guaranteeing a bond that endures.

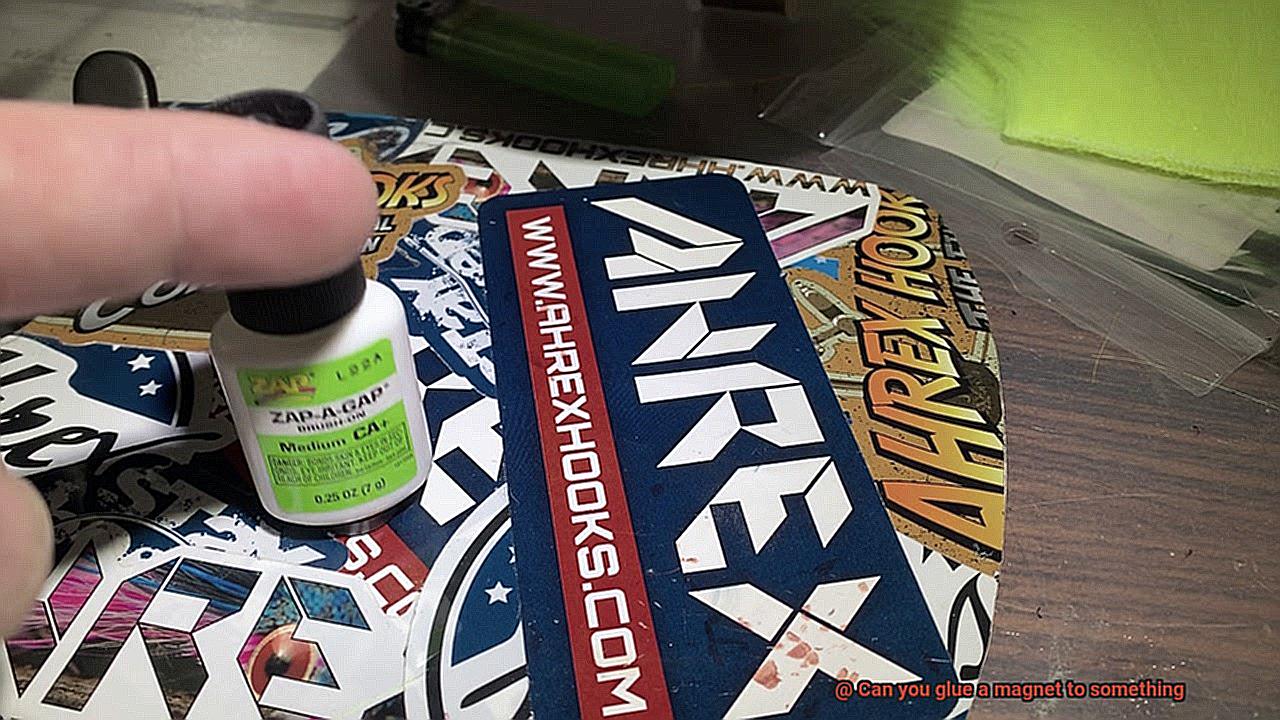

Another alternative for gluing magnets is cyanoacrylate, better known as super glue or instant glue. Cyanoacrylate dries rapidly and offers a powerful hold, making it suitable for smaller magnets or temporary applications. However, it may not match the long-term durability of epoxy. Thus, if you seek a permanent solution or need to bond larger magnets, epoxy reigns supreme.

Keep in mind that not all glues are suitable for bonding magnets. Adhesives containing solvents or that are water-based can degrade the magnet or weaken its magnetic properties. Therefore, it is crucial to steer clear of these types of adhesives when gluing magnets. Instead, opt for specialized adhesives like epoxy or cyanoacrylate that are tailor-made for this purpose.

Before applying the glue, it is essential to prepare the surfaces meticulously. This involves removing any dirt, oil, or residue from both the magnet and the material it will be bonded to. By doing so, you will pave the way for a strong and enduring bond between the two surfaces.

It is worth noting that some magnets come with adhesive backing, making them a breeze to attach to surfaces without the need for additional glue. However, this may not be suitable for all applications, especially if you require a stronger bond or specific positioning. In such cases, it is advisable to use a separate adhesive like epoxy or cyanoacrylate.

Preparing the Surface and Magnet for Gluing

Today, we’re delving into the fascinating world of preparing surfaces and magnets for gluing. Just like in any relationship, a strong bond is essential for a long-lasting connection between magnets and surfaces. So, let’s roll up our sleeves and create the perfect foundation for an unbreakable bond.

Step 1: Cleanliness is Next to Adhesiveness

To kick off our gluing adventure, cleanliness is key. Wipe away any dust, dirt, or oils using a clean cloth or a gentle detergent. Remember, a little cleanliness goes a long way in ensuring a solid connection.

Step 2: Roughing Up Non-Porous Surfaces

Smooth surfaces can be a challenge when it comes to gluing magnets. For non-porous materials like metal or glass, give them a light sanding with sandpaper or a file. This step creates an ideal grip for your glue, guaranteeing that your magnet will stay put.

Step 3: Priming Porous Surfaces

Ah, porous surfaces – they can be a bit finicky. But fear not. Apply a primer or sealant before gluing your magnet to seal those pesky pores and create a smoother surface. This sets the stage for optimal adhesion.

Step 4: Banishing Magnet Oils and Contaminants

Our magnets may be alluring, but they often come with an oily residue that hinders adhesion. Before getting down to glue business, wipe your magnet with rubbing alcohol or acetone to remove any oils or contaminants. Your adhesive will thank you.

Step 5: Positioning and Orientation

Now that we have pristine surfaces and magnets ready, let’s consider positioning and orientation. Mark the spot where you want your magnet to reside before applying any glue. This ensures perfect alignment and attraction.

Step 6: Magnetic Polarity Matters

Magnetic fields have their rules, so it’s crucial to understand the polarity and magnetic field orientation of your magnet before gluing. Incorrect positioning can affect the functionality of your magnet, so take a moment to familiarize yourself with its magnetic personality.

Applying the Adhesive

In our previous sections, we explored the essentials of surface preparation and magnet positioning. Now, get ready to dive into the captivating world of applying adhesive when gluing magnets. Together, we will unravel the secrets behind achieving flawless and unyielding bonds. So grab your magnets and let’s embark on this adhesive adventure.

Choosing the Right Adhesive:

In the realm of magnet gluing, selecting the ideal adhesive is paramount. Seek out an adhesive with exceptional bonding capabilities that can adhere seamlessly to both the magnet and the target surface. Among the top contenders, epoxy reigns supreme – a versatile adhesive renowned for its ability to forge robust connections. Remember, adhere closely to the manufacturer’s instructions as different epoxy types may require specific curing times or application methods.

Surface Preparation:

Before we venture into the realm of adhesive application, let us first delve into the realm of surface preparation. To ensure an unbreakable bond, both the magnet and the surface must be pristine – free from any dirt, oils, or residue that might undermine their union. A thorough cleansing with rubbing alcohol will work wonders, bestowing upon your glue job a touch of perfection.

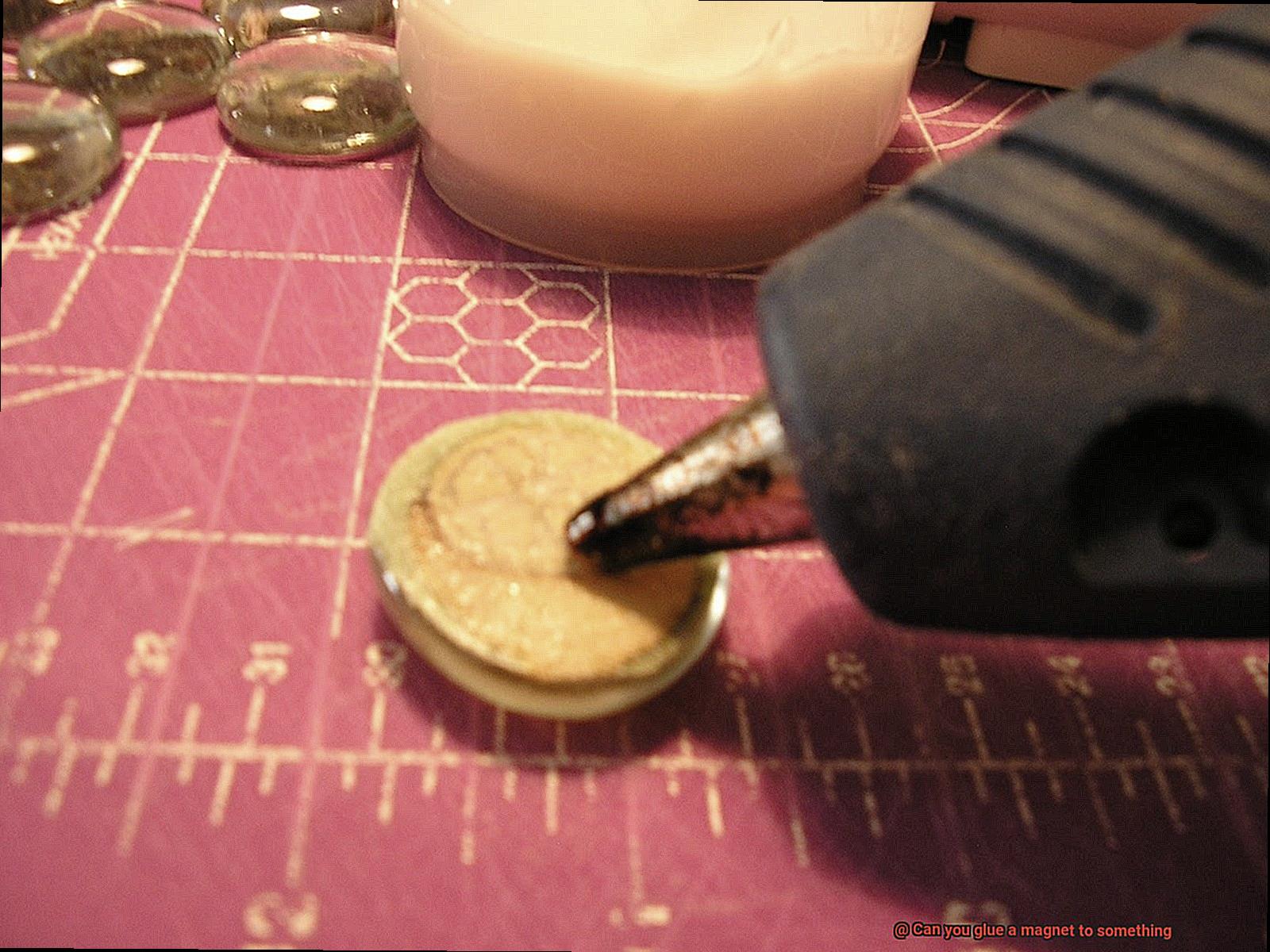

Applying the Adhesive:

Now, let us turn our attention to the main event – applying the adhesive. Begin by using a modest amount of adhesive and evenly distribute it across the surface area of the magnet that will make contact with its counterpart. This meticulous approach prevents excessive adhesive from causing a chaotic mess. Remember, when it comes to glue, less is more.

Securing the Bond:

Having applied the adhesive with precision, it is time to secure the bond. Press the magnet firmly onto its designated surface and maintain this pressure for several minutes. This crucial step allows the adhesive to bond effectively, resulting in a connection that knows no weakness. Depending on the adhesive chosen, additional pressure or clamps may be necessary to hold the magnet in place during the curing process. Such an extra safeguard guarantees a bond that can withstand the test of time.

Curing Time for Maximum Bond Strength

We’ve explored the wonders of adhesives from selection to application, but one crucial element remains unexplored – curing time. Today, we embark on a captivating journey into the world of bond strength maximization. So fasten your lab coats and secure your safety goggles as we plunge into the depths of this enchanting adhesive adventure.

Understanding Curing Time:

Imagine this – you’re bonding a magnet to something extraordinary, brimming with potential. But hold your excitement. Before you envision the magic, let’s unravel the significance of curing time. In simple terms, it’s the period required for the adhesive to fully bond and unleash its maximum strength. It’s the secret elixir that transforms ordinary glue into an unyielding force.

Different Adhesives, Different Cure Times:

Just like superheroes with distinct abilities, different adhesives possess varying cure times. Take cyanoacrylate adhesives, for instance – these mystical potions (known as super glue) can cure within seconds or minutes. But beware. This swift initial cure doesn’t guarantee maximum bond strength. To unlock its true power, allow a minimum of 24 hours for the adhesive to cure before subjecting it to any stress.

Now, let’s delve into epoxy adhesives – the Hulk of the adhesive world. Comprising a resin and a hardener, they demand more time for curing. We’re talking hours or even days, depending on the specific product and environmental conditions. Patience here is rewarded with a bond that can withstand the mightiest forces.

The Manufacturer Knows Best:

To achieve unparalleled bond strength, heed the wisdom of adhesive manufacturers. They’ve toiled tirelessly in their hidden laboratories, concocting the perfect formulas and determining optimal curing times. So follow their instructions diligently – it may involve leaving your creation undisturbed for a specified period or even harnessing external factors like heat or UV light to expedite the curing process.

Don’t Rush the Magic:

Impatience may serve us well in certain endeavors, but not when it comes to adhesive bonding. Even if an adhesive appears dry or solid after a shorter curing time, it may not have reached its full internal strength. Waiting for the recommended curing duration ensures that chemical reactions occur, forming robust molecular bonds between the magnet and the substrate.

Factors That Can Weaken or Break the Bond Over Time

In our previous adventure, we uncovered the secrets of curing time and its role in creating unbreakable bonds between magnets and substrates. Today, we’re delving into the darker side of adhesive longevity. Yes, even the mightiest bonds can weaken or break over time. So, grab your adhesive cape and let’s explore the five factors that can pose a threat to the strength and durability of your magnet’s bond.

Moisture and Humidity: The Silent Saboteur

Imagine this: a magnet, happily bonded to its surface, bravely facing the world. But lurking in the shadows is moisture and humidity, ready to pounce. Excessive exposure to these elements can cause the glue to degrade over time, weakening the bond. Water-based adhesives are particularly susceptible. To combat this villain, consider the environment where your magnet will reside. Opt for an adhesive that resists moisture for long-term durability.

Temperature Fluctuations: The Fiery Foe

Extreme temperatures can turn even the most powerful bond into a brittle nightmare. Picture a magnet glued with an adhesive that can’t handle the heat (or cold). With exposure to scorching or freezing conditions, the adhesive may soften or become brittle, leading to bond failure. To defeat this formidable enemy, choose an adhesive that can withstand the temperature range of your magnet’s environment. Only then can you be sure your bond will remain unbreakable.

Chemical Exposure: The Corrosive Culprit

Beware of chemicals and solvents that can wreak havoc on your magnet’s bond. These villains are corrosive and reactive with adhesives, leading to weakened or broken bonds over time. Consider the potential exposure your magnet and adhesive will face in their intended environment. Choose an adhesive with chemical resistance properties or add a protective coating to shield your bond from these harmful adversaries.

Using Additional Mechanical Means for Extra Support and Stability

Today, we embark on an exciting journey to discover the secrets of using additional mechanical means for unparalleled support and stability when gluing magnets. Brace yourselves as we unveil the key to a rock-solid attachment.

The Dynamic Duo: Glue and Screws/Bolts

When dealing with heavy or large magnets, relying solely on glue may leave you wanting more. To achieve an unyielding bond, consider employing screws or bolts alongside adhesive. By drilling holes in the surface, you can insert screws or bolts through the magnet and into those holes. The glue then acts as a powerful reinforcement, adding an extra layer of adhesive strength. This method proves invaluable for magnets that exert significant force.

Brackets: Trusty Sidekicks for Unmatched Support

Brackets emerge as another formidable option for providing additional support and stability. These trusty sidekicks can be attached to both the magnet and the desired surface, forging a robust connection. Equipped with adhesive backing, brackets stay firmly in place while allowing for effortless attachment. Industrial applications and vehicle installations benefit greatly from this method’s ability to securely mount magnets in specific positions.

Magnetic Mounting Systems: Embrace Flexibility at Its Finest

For those yearning for flexibility and convenience, magnetic mounting systems present a game-changer. These ingenious systems feature a metal plate embedded with mighty magnets, offering secure attachment while facilitating effortless detachment when needed. Whether you’re mounting magnets on walls or frequently switching them between surfaces, magnetic mounting systems provide unmatched support and versatility.

Preserving Magnetic Field Integrity

While additional mechanical means enhance strength and stability, it is vital to select non-magnetic materials for these supports. Certain metals or materials can disrupt the magnet’s magnetic field, jeopardizing its functionality. By mindfully considering the materials used, you can achieve a secure attachment without compromising the magnet’s magnetic field.

cdmTX3-0e5M” >

Conclusion

The answer to the question “Can you glue a magnet to something” is a resounding yes.

Gluing a magnet to an object is not only possible, but it can also be quite effective. By using the right adhesive and following proper techniques, you can securely attach a magnet to almost anything.

Whether it’s for craft projects, DIY home improvements, or even industrial applications, gluing magnets opens up a world of possibilities.