Picture the exhilaration of building a masterpiece, a piece of furniture or a structure that’s as solid as a rock. Whether you’re a DIY fanatic or a seasoned carpenter, plywood is your trusty sidekick. It’s affordable, versatile, and the go-to material for countless projects.

But here’s the burning question: Can you take two separate sheets of plywood and seamlessly fuse them into one unbreakable force? Is it possible to create an even stronger bond by joining these mighty pieces together?

Get ready for an epic adventure as we dive deep into the world of plywood, unraveling its adhesive secrets. Buckle up, because we’re about to explore the ins and outs, techniques and possibilities behind gluing two sheets of plywood together.

First things first, let’s uncover the different types of plywood adhesives at your disposal. From water-resistant wonders to heat-defying heroes, we’ll dig into which adhesives pack the most powerful bonding punch for your beloved plywood.

Once we’ve got that covered, we’ll delve into the nitty-gritty details and prep steps necessary for a successful bond. From cleaning surfaces like a pro to choosing clamping techniques with finesse, we’ll arm you with all the know-how needed to create an unbreakable connection.

But wait, there’s more. We’ll also explore various methods of applying adhesive to plywood. We’ll compare rolling it on like a boss versus brush or spray techniques so you can pick the method that suits your project and skills like a glove.

Last but not least, we’ll shed light on common mistakes that could sabotage your gluing success. By steering clear of these pitfalls, you’ll be well on your way to creating seamless connections that defy gravity.

Ready to unlock the full potential of merging two sheets of plywood into an unstoppable alliance? Let’s embark on this thrilling journey together and discover the secrets to crafting plywood structures that withstand the test of time.

What is Plywood?

Contents

Plywood, the unsung hero of construction and woodworking, is an engineered wood product known for its remarkable strength, stability, and versatility. This guide delves into the fascinating world of plywood, exploring its manufacturing process, the diverse range of wood species used, the crucial role of adhesive in bonding the layers together, and the multitude of advantages it offers over solid wood.

The Art of Plywood Production:

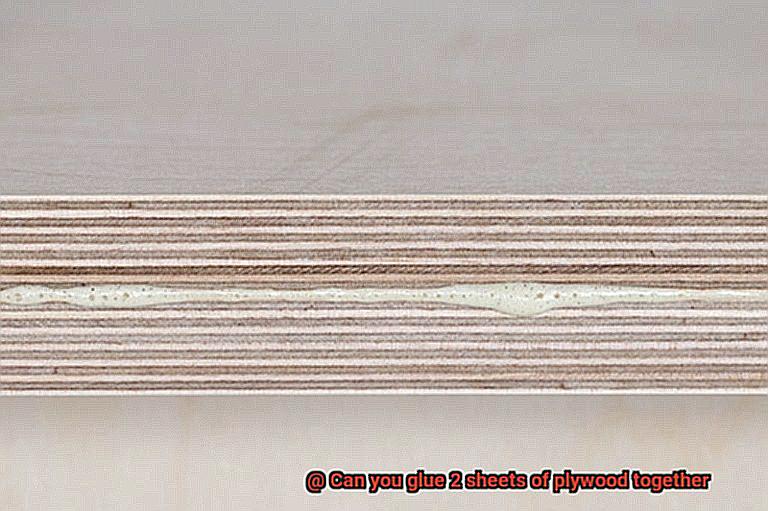

In this intricate dance of craftsmanship, thin layers of wood veneers or plies are meticulously bonded together. These layers are strategically arranged at right angles to one another, creating a symphony of strength and stability that surpasses solid wood. The choice between softwood or hardwood species, such as pine or oak, depends on the intended purpose and desired properties of the plywood.

The Glue that Holds It All Together:

Behind every successful plywood panel lies the secret ingredient – adhesive. Various types of adhesives make their mark in plywood production. From urea-formaldehyde (UF) to phenol-formaldehyde (PF), melamine-urea-formaldehyde (MUF), and isocyanate-based adhesives, each has its unique strengths and characteristics. Factors such as cost, environmental considerations, and intended applications determine the adhesive of choice.

Unveiling the Marvels of Plywood:

Plywood’s allure lies in its immense versatility. It comes in different grades and sizes, tailored to meet your specific project needs. With thicknesses ranging from a mere 1/8 inch to a robust 1-1/4 inches or even thicker, plywood knows no bounds. Its dimensions vary too, making it a perfect fit for an array of projects.

Triumph Over Solid Wood:

Plywood triumphs over solid wood on multiple fronts. Firstly, it delivers unbeatable cost-effectiveness. By utilizing thinner and lower-grade wood veneers, plywood not only becomes more affordable but also contributes to the conservation of precious timber resources. Secondly, plywood stands tall against the forces of nature, as it is less prone to warping, shrinking, or expanding thanks to its cross-grain construction.

What Type of Adhesive Can be Used for Gluing Plywood Together?

Plywood, a masterful combination of strength and versatility, owes its integrity to the adhesive that holds it together. With my expertise in woodworking, I’m here to unveil the secrets of gluing plywood. So, let’s embark on a journey through the realm of adhesives, where we’ll discover the ideal choices for creating a bond that will stand the test of time.

Polyurethane Glue: Unleashing Strength and Defying Water

Enter polyurethane glue, a crowd favorite in the world of plywood adhesion. This adhesive marvel boasts unparalleled bonding strength and water-resistant properties. As it cures, it expands, expertly filling any gaps or voids in the plywood, forging an unyielding bond. To unlock its full potential, moisten the surfaces before applying the glue to awaken its curing powers.

Epoxy Resin: The Dynamic Duo

Looking for an unbreakable bond that can weather any storm? Epoxy resin is your trusted ally. This two-part adhesive, consisting of a resin and a hardener, fuses together to create a bond of remarkable strength and durability. With its extraordinary gap-filling capabilities and resistance to moisture, epoxy stands tall as the go-to adhesive for plywood projects. But beware – working with epoxy demands precision in mixing ratios and patience during the curing process.

Wood Glue (PVA): Simplicity Meets Effectiveness

In the realm of plywood bonding, wood glue, also known as PVA (polyvinyl acetate) glue, emerges as a reliable choice. Its simplicity belies its effectiveness, providing a strong and steadfast bond when employed correctly. When venturing into outdoor projects or moisture-prone areas, select an exterior or waterproof variant specifically formulated for such applications.

Phenol Formaldehyde (PF) Resin Adhesive: Strength Personified

Yearning for an unyielding bond that surpasses all expectations? Enter phenol formaldehyde (PF) resin adhesive, the titan of structural applications. Often found in marine-grade plywood, this adhesive offers unparalleled strength and unwavering resistance to moisture. However, tread with caution, as PF resin adhesive emits formaldehyde gas during the curing process. Ensure proper ventilation becomes your guiding principle when working with this formidable adhesive.

Preparing the Plywood Surfaces

In our previous section, we unveiled the secrets of various adhesives, from the mighty polyurethane glue to the trusty wood glue. Now, let’s dive into the next crucial step in achieving plywood nirvana: preparing the plywood surfaces for gluing. Get ready to unlock the secrets of a flawless bond that will stand the test of time.

Step 1: Cleanliness is Next to Bondliness

Prepare for gluing greatness by ensuring your plywood surfaces are squeaky clean. Wipe away dirt, dust, and debris with a damp cloth or sponge, leaving no traces of hindrances. Patience is key here – allow the surfaces to dry completely before proceeding.

Step 2: Sanding – Roughing It Up

Time to rough up those plywood surfaces like a mini lumberjack. Grab your medium-grit sandpaper and sand away in the direction of the wood grain. Say goodbye to any smooth or glossy finishes that dare stand in the way of your strong bond.

Step 3: Imperfections Be Gone.

Inspect those plywood sheets with an eagle eye for imperfections that could weaken your bond. Smooth out knots, splinters, and any uneven spots using a chisel or sandpaper. Your goal is a clean and level surface that guarantees a flawless connection.

Step 4: Primetime Primer

Consider adding a touch of primer to your plywood surfaces for an adhesive boost. Let this magical elixir improve adhesion and give your bond extra strength. Follow the manufacturer’s instructions closely and allow ample drying time before moving forward.

Step 5: A Test Fit for a Perfect Fit

Before you embark on your gluing adventure, take a moment for a test fit. Place the plywood sheets together without adhesive to ensure a perfect alignment and snug fit. Don’t overlook any gaps or misalignments – make necessary adjustments now for a seamless bond later.

Step 6: Choosing Your Adhesive Sidekick

Select your adhesive sidekick wisely, as it holds the key to a successful plywood bond. Wood glue, epoxy, or construction adhesive – the choice is yours. For most plywood projects, wood glue reigns supreme with its strong holding power and moisture resistance. However, consult professionals or follow manufacturer recommendations for specific applications or different materials.

Applying the Glue

Plywood, the chameleon of woodworking materials, possesses the power to elevate your projects from ordinary to extraordinary. But let’s face it, slapping two sheets together won’t cut it. No, my friend, there’s a secret to creating a bond that defies time, and it all begins with choosing the right glue.

So, grab your drink of choice, put on your thinking cap, and immerse yourself in the world of gluing plywood sheets.

Step 1: Cleanliness Breeds Glue-liness

Before even contemplating the glue bottle, take a moment to ensure your plywood sheets are pristine. Dust, dirt, and pesky contaminants can sabotage the adhesive properties of the glue. Think of it as priming a canvas before creating a masterpiece – a clean surface is essential to success.

Step 2: Choosing Wisely

Wood glue or carpenter’s glue reign supreme when bonding plywood sheets. Tailored specifically for wood surfaces, these formidable adhesives possess the strength and durability to make your project beam with pride.

Be sure to read labels carefully, considering factors such as drying time, strength, and resistance to moisture. The right glue can make all the difference.

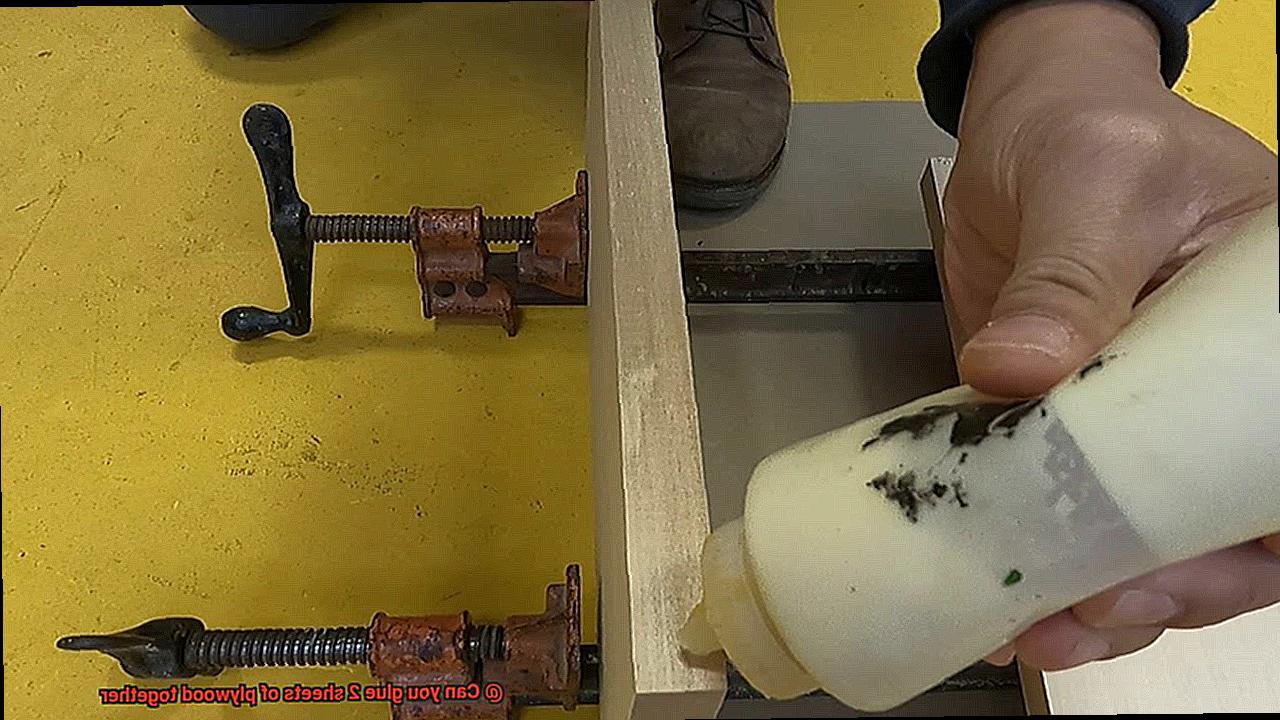

Step 3: Spreading the Love

Now comes the enjoyable part – applying the glue. Armed with a brush or roller, spread that sticky elixir evenly on both surfaces of your plywood sheets. Attention to detail is paramount; ensure every crevice receives a generous coat of glue. It’s like embracing your project with a warm, gooey hug.

Step 4: Pressing for Perfection

It’s time to bring those plywood sheets together and forge a bond that evokes envy among woodworkers. Exert firm pressure as you join the sheets, employing clamps or weights to secure them in place.

This ensures maximum contact between the glue and surfaces, creating a bond as robust as Hercules himself. But remember, moderation is key – we’re aiming for a sturdy connection, not a flattened pancake.

Clamping and Drying Time

So, grab your favorite cup of coffee and prepare to embark on this fascinating exploration.

The Mighty Clamp: Harnessing the Power of Pressure

Picture yourself as a virtuoso painter, armed with the perfect brush. Clamping, my friends, is that brush in our woodworking masterpiece. It ensures an even distribution of pressure across every inch of your plywood sheets.

To achieve this symphony of strength, we turn to bar clamps or pipe clamps – the guardians of uniform pressure distribution.

There’s more to this masterpiece. Strategically place these clamps every 6-8 inches along the edges of your plywood sheets. This meticulous arrangement guarantees a bond that can weather any storm.

And don’t forget the cauls – those straight wooden warriors placed on top and bottom. They shield against warping and bowing, adding that final touch that elevates your creation to excellence.

The Art of Waiting: Drying Time as a Test of Patience

Let’s embrace patience – a virtue that separates amateurs from true masters. Drying time is where we unleash our inner Picassos. Different glues boast varying curing times, so heed the manufacturer’s instructions for guidance. As a rule, most wood glues demand a minimum of 30 minutes to an hour under clamping before disturbance.

Clamping time alone may not suffice for full curing. Remember, we aspire for greatness. The glue craves sufficient time to dry and harden, a process that spans from 24 hours to several days, influenced by environmental factors. So, masters of the craft, exercise patience and allow that bond to reach its zenith.

Ventilation: Breathing Life into the Artwork

In any artistic pursuit, proper ventilation acts as the breath of fresh air. Gluing plywood is no exception. Bequeath your creation with good airflow, enabling swift drying and thwarting moisture buildup that threatens the bonding process. Open those windows, let nature’s breeze dance through your masterpiece,

Other Types of Adhesives for Gluing Plywood Together

When it comes to joining plywood together, traditional wood glue is not the only option. There are several other adhesives available that offer unique advantages for specific applications. In this article, we will explore five different types of adhesives that can be used to effectively bond plywood sheets together.

Polyurethane Adhesive – Strength that Defies the Elements:

Polyurethane adhesive is a popular choice for plywood bonding due to its exceptional strength and resistance to moisture and temperature changes. This adhesive forms a robust bond that can endure heavy loads and external forces. Furthermore, as it cures, polyurethane adhesive expands, expertly filling any gaps or voids between the plywood sheets.

Whether you’re constructing outdoor furniture or tackling marine projects, polyurethane adhesive guarantees a long-lasting bond that can withstand the harshest conditions.

Epoxy Adhesive – The Impenetrable Shield:

For a bond that is not only strong but also waterproof, epoxy adhesive reigns supreme. Comprising two components, resin and hardener, epoxy adhesive must be mixed before application.

Once cured, epoxy offers outstanding bonding strength and remarkable resistance to moisture, chemicals, and temperature fluctuations. It is the ideal choice for outdoor projects or scenarios where the bonded plywood may come into contact with water.

Construction Adhesive – The Versatile Warrior:

Construction adhesive is a versatile option that can be employed in various applications, including plywood bonding. Available in different formulations such as solvent-based or water-based, construction adhesive delivers reliable bonding strength. It is easy to apply and dries relatively quickly, making it an efficient choice for projects that demand a rapid turnaround time.

Contact Cement – Instantaneous Fusion:

When immediate bonding is required, contact cement emerges as the adhesive of choice. This type of adhesive creates a strong and durable bond when two surfaces coated with it come into contact.

Contact cement is often used for laminating plywood sheets or attaching veneer to plywood surfaces. While it offers quick bonding, it necessitates careful application due to its rapid-setting nature.

Structural Adhesive – Empowering Plywood Bonds:

For projects that demand heavy-duty bonds, structural adhesive is the ultimate solution. Designed specifically to provide high-strength bonding between different materials, including plywood, structural adhesives possess exceptional load-bearing capabilities and exhibit resistance to impact and vibration. These adhesives find common usage in construction and engineering endeavors where strong and long-lasting bonds are prerequisites.

Epoxy Adhesive

Unlock the full potential of your plywood projects with the superhero of glues – epoxy adhesive. This powerhouse adhesive not only creates an impenetrable bond between two sheets of plywood but also empowers your creations with unyielding strength and durability.

So, how does this magic glue work? Epoxy adhesive is a dynamic duo made up of two components: a resin and a hardener. These components must be mixed in precise proportions to unleash their superpowers. Once combined, the epoxy adhesive forms a chemical bond that is strong enough to withstand anything thrown its way.

But before we dive into the gluing process, let’s make sure our plywood surfaces are prepared for this heroic bonding experience. Make sure they are clean and free from any contaminants like dust or grease. To maximize the adhesive’s strength, consider giving the surfaces a rough texture by sanding them.

Now it’s time to apply the epoxy adhesive and witness its transformative abilities. Grab a brush or spatula and apply an even layer of adhesive to both plywood surfaces. Don’t be shy – be generous with the amount of adhesive applied to ensure complete coverage.

Once the adhesive is applied, press the two plywood sheets together with all your might. You can even call in reinforcements like clamps or weights to hold them in place while the adhesive works its magic. Keep in mind that curing time for epoxy adhesives may vary depending on environmental factors like temperature and humidity. Always follow the manufacturer’s instructions to achieve optimal results.

Once fully cured, your bonded plywood sheets will become invincible against moisture, heat, and chemicals. This means your plywood project will stand strong through any challenge it faces.

Now, it’s important to note that this superhero glue may come with a slightly higher price tag than other glues. However, its unparalleled bonding strength and durability make it well worth considering, especially when joining two sheets of plywood together.

O0ipjo0CJug” >

Conclusion

Yes, you can definitely glue two sheets of plywood together. It is a common practice in woodworking and construction projects. By using the right adhesive and following proper techniques, you can create a strong and durable bond between the two sheets.

To begin, make sure the surfaces of the plywood are clean and free from any dust or debris. This will ensure better adhesion between the layers. Next, apply a generous amount of wood glue evenly onto one sheet of plywood.

Now, carefully place the second sheet on top of the glued surface, ensuring that the edges align properly. Apply pressure evenly across the entire surface to ensure maximum contact between the two sheets. You can use clamps or weights to hold them together while the glue dries.

It’s important to note that not all adhesives are suitable for gluing plywood. It is recommended to use a high-quality wood glue specifically designed for bonding wood surfaces. These glues have strong bonding properties and provide excellent strength.

Once the glue has fully cured according to the manufacturer’s instructions, you will have a solid and secure bond between your plywood sheets. This method is commonly used in various applications such as furniture making, cabinetry, flooring, and even in constructing wooden structures.

In conclusion, gluing two sheets of plywood together is an effective way to create a larger and stronger panel for your woodworking projects. With proper preparation, quality adhesive, and careful application techniques, you can achieve a reliable bond that will withstand the test of time.