If you’ve ever struggled to find effective ways to join PLA (Polylactic Acid), then this unconventional technique might just be the game-changer you’ve been waiting for.

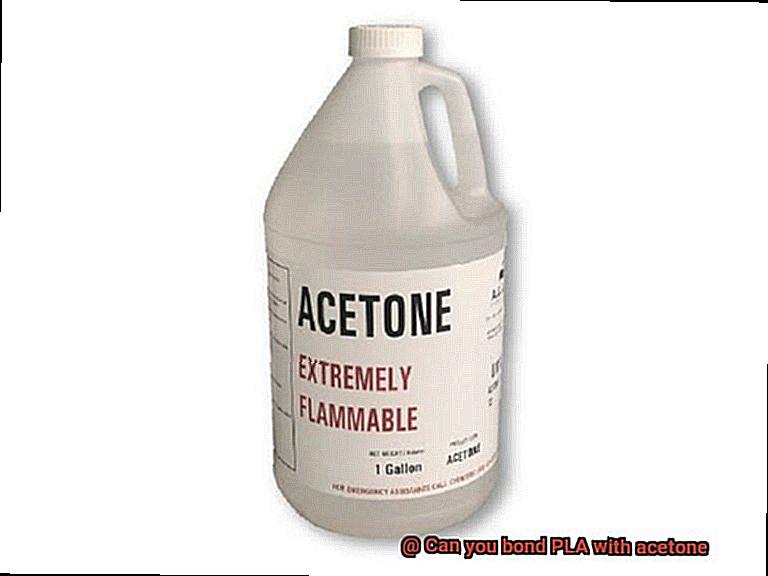

So, what’s the deal with bonding PLA using acetone? Picture this: acetone, a colorless and flammable liquid, swoops in like a chemical superhero and welds your PLA pieces together. When acetone meets PLA, it breaks down the surface of the material, causing it to partially dissolve. As the acetone evaporates, it leaves behind a bond that’s stronger than super glue.

The potential benefits of using acetone for bonding PLA are pretty enticing. Say goodbye to messy adhesives because this method offers a quick and straightforward solution for joining PLA parts. Plus, it creates a seamless finish as the dissolved PLA smooths out any rough edges between bonded pieces.

But hold on tight because there are some drawbacks to consider. Acetone is no joke – it’s a hazardous substance that requires caution. Inhaling its fumes can be harmful, so make sure you’re working in a well-ventilated area or wearing a respirator. Also, not all types of PLA play nice with acetone bonding, so don’t expect every print to be successful.

Now that we’ve got your interest piqued, let’s dive into the nitty-gritty details of bonding PLA with acetone. We’ll unravel its intricacies and reveal whether it truly lives up to its reputation as a 3D printing game-changer. So stick around because things are about to get exciting.

Is PLA Soluble in Acetone?

Contents

- 1 Is PLA Soluble in Acetone?

- 2 Vapor Smoothing with Acetone: How Does It Work?

- 3 Factors That Affect Bonding PLA with Acetone

- 4 Steps for Bonding PLA with Acetone

- 5 Advantages of Bonding PLA with Acetone

- 6 Disadvantages of Bonding PLA with Acetone

- 7 Alternatives to Bonding PLA with Acetone

- 8 Safety Precautions When Using Acetone for Bonding PLA

- 9 Conclusion

Step into the fascinating world of polylactic acid (PLA), the eco-friendly champion among plastics. As we embark on this journey, we shall unravel the enigma surrounding the solubility of PLA in acetone. Brace yourself for a captivating exploration of the intricate relationship between these two substances, as we delve into their solubility properties and unveil other remarkable aspects that lie beneath the surface.

Understanding Solubility:

In its pure form, PLA does not readily dissolve in acetone, setting it apart from other plastics like ABS or PVC. The chemical composition of PLA does not engage in the same molecular dance with acetone molecules that promotes dissolution. Hence, if you were to submerge a pristine piece of PLA into a container of acetone, it would remain steadfast and unperturbed by the solvent’s seductive allure.

Surface Effects:

Nevertheless, even though pure PLA does not dissolve in acetone, it is not immune to its charms. When acetone caresses the surface of PLA, it exudes an evanescent enchantment. With its rapid evaporation rate, acetone has the power to soften or confer a tacky texture upon the plastic’s exterior. This extraordinary property renders itself useful in various applications where bonding or smoothing PLA surfaces is desired.

Bonding with Acetone:

Despite PLA’s resistance to acetone’s dissolving prowess, a symbiotic bond can be formed between them. Behold the solvent adhesive capability of acetone. By judiciously applying a minute quantity of acetone to the surfaces to be united and gently pressing them together, the acetone deftly softens the plastic, forging an unbreakable bond. As the acetone gracefully evaporates, leaving behind solidified bonds, the once-disparate parts meld into one harmonious entity.

Considerations and Recommendations:

Caution must be exercised, for the efficacy of acetone bonding relies on multiple factors. The precise formulation of the PLA, the surface area being bonded, and the applied pressure all partake in this intricate dance.

Hence, it is prudent to embark on a preliminary courtship by testing this bonding technique on a diminutive sample before committing to more grandiose or mission-critical projects. Furthermore, depending on the project’s requirements and constraints, alternative methods such as specialized adhesives or mechanical fasteners may warrant consideration.

Vapor Smoothing with Acetone: How Does It Work?

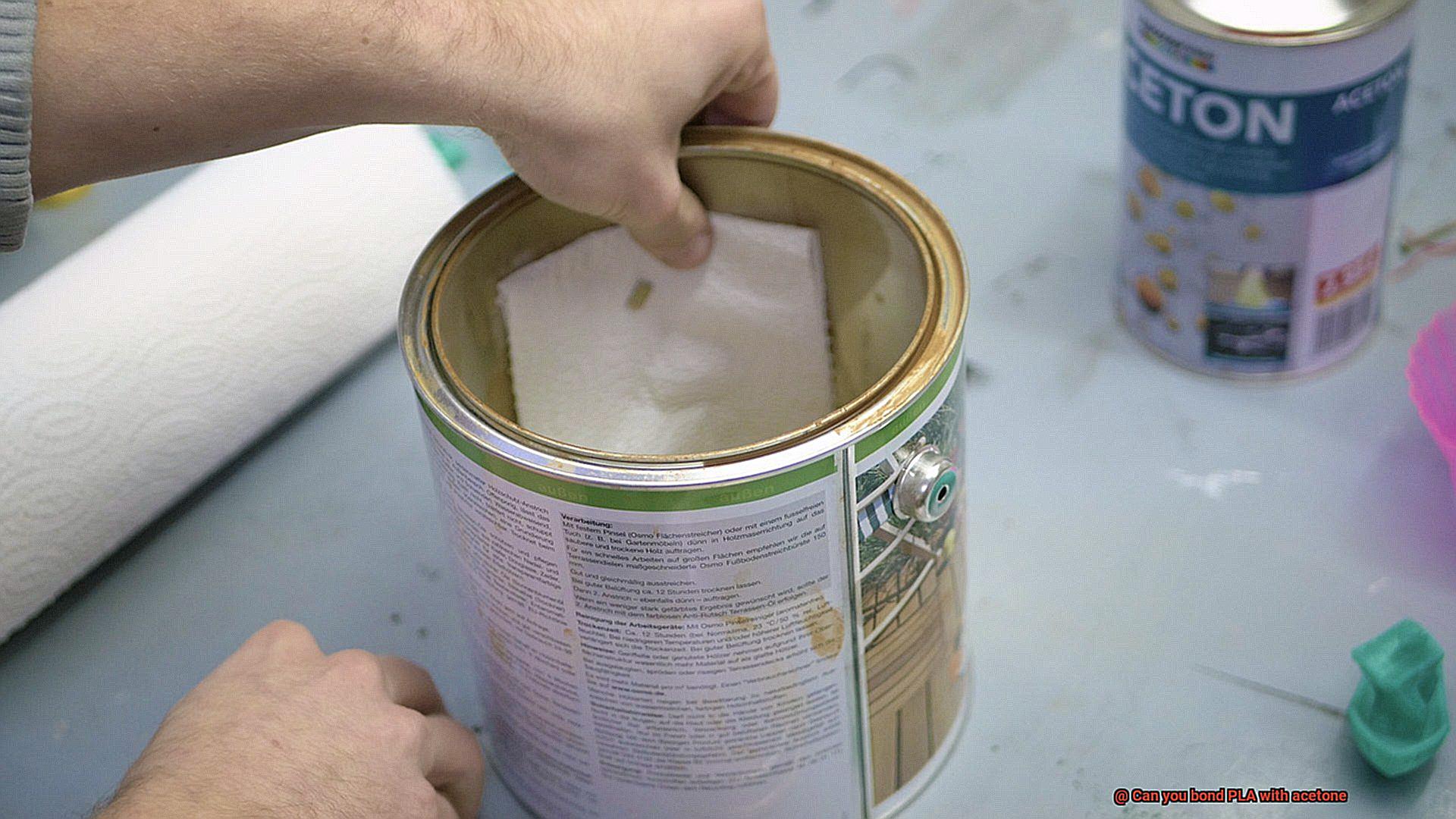

To get started, you’ll need a sealed container and some acetone. Place your PLA print inside the container, ensuring a tight seal to minimize airflow. Now, add a small amount of acetone and let the magic begin.

Acetone, a powerful solvent with impressive dissolving abilities, starts to evaporate inside the container. As it does, it releases vapors that interact with the surface of your PLA print. These vapors dissolve a thin layer of the PLA material, which then re-condenses onto the surface, effortlessly filling in any imperfections along the way. It’s like giving your print a luxurious spa treatment.

But before you go dunking all your prints into an acetone bath, there are some essential things to keep in mind. Vapor smoothing with acetone is specifically designed for PLA filament only. So, double-check that your print is made from this material. Other filaments like ABS or PETG won’t respond well to acetone and could end up damaged.

Timing is key in this process. The duration of vapor smoothing depends on the size and complexity of your print. Typically, it takes around 30 minutes to an hour for the acetone vapors to work their magic. However, it’s crucial to closely monitor the process to avoid over-smoothing or potential damage.

Safety should always be a top priority. Acetone is highly flammable, so make sure you’re working in a well-ventilated area away from any open flames or ignition sources. Don’t forget to protect yourself with gloves and goggles because direct contact with acetone is a big no-no.

To achieve optimal results, use a sealed container that restricts airflow, allowing the acetone vapors to concentrate and work their magic on the surface of your print. It’s also a good idea to rotate or move the print during the process to ensure even exposure to the acetone vapors.

Factors That Affect Bonding PLA with Acetone

Look no further. In this blog post, we will delve into the factors that significantly impact the bonding process and share some expert tips to help you achieve impressive results.

- PLA Composition: Not all PLAs are created equal. Different brands or formulations may have variations in their chemical makeup, which can greatly influence their bonding ability with acetone. So, it is crucial to consider the specific type of PLA you are using, as it can make a world of difference in achieving a strong and lasting bond.

- Acetone Concentration: The concentration of acetone used is a critical factor for successful bonding. Acetone is a powerful solvent that excels at dissolving various types of plastics, including PLA. However, using too high or too low of an acetone concentration can lead to subpar bonding results. To strike the perfect balance, it is generally recommended to use a moderate concentration of acetone, typically around 10-20% by volume.

- Surface Preparation: The key to achieving a strong bond lies in proper surface preparation. Before attempting to bond PLA with acetone, ensure that the surfaces you intend to join are clean and free from any contaminants such as dust, oils, or residues. A gentle wipe with a clean cloth or mild detergent solution will do wonders. Moreover, roughening the surface slightly with sandpaper or a similar abrasive material can enhance bonding by increasing the contact area between PLA and acetone.

- Temperature and Time: Heat things up. Applying heat to the bonding area significantly enhances the effectiveness of acetone in dissolving PLA and promoting bonding. However, it is vital to exercise caution not to overheat and deform your precious PLA prints. Additionally, allowing sufficient contact time is crucial for optimal bonding. A few minutes of contact time should suffice to achieve the desired strength.

- Surface Area and Geometry: More contact points mean better bonding. A larger surface area provides ample opportunities for acetone to interact with PLA, resulting in improved bonds. Conversely, intricate designs or complex geometries may have hard-to-reach areas for acetone, leading to weaker bonds in those regions. Hence, it is essential to consider these factors during the printing process to ensure successful bonding.

Steps for Bonding PLA with Acetone

Bonding PLA with acetone is a game-changer when it comes to creating strong and durable connections between PLA surfaces. Whether you’re working on 3D printed parts or crafting intricate designs, this bonding method will revolutionize your projects.

First things first, let’s talk about surface preparation. The key to a successful bond is starting with clean surfaces. You want to make sure there’s no dirt or oils getting in the way. So grab some soap and water or isopropyl alcohol, and give those surfaces a good scrub. We want them sparkling clean. And don’t forget to let them dry completely before moving on.

Now, it’s time for the magic ingredient – acetone. Acetone is like a superhero for bonding PLA. It softens and partially melts the PLA, allowing it to bond with other PLA surfaces. So take a brush or a cotton swab, and apply a small amount of acetone evenly on both surfaces. We don’t need to go crazy with the acetone – a little goes a long way.

With the acetone applied, it’s time to bring those surfaces together. Carefully align them and press them firmly. We want even pressure across the entire bonding area. This is where the real magic happens – creating a bond that’s as strong as steel (well, maybe not steel, but you get the idea).

But wait. We’re not done yet. Now comes the waiting game. Patience is key here. Let your bonded surfaces sit undisturbed, allowing the acetone to evaporate and the PLA to bond properly. It’s like watching a pot of water boil – except we’re waiting for the bond to cure. Give it at least 24 hours, but feel free to check on it periodically during this time.

And now, for the big reveal – testing the bond strength. Gently try to separate the bonded surfaces and see if there are any signs of weakness or detachment. If everything holds up well, congratulations. You’ve successfully bonded PLA with acetone.

Just keep in mind that not all PLA formulations are created equal. Some may not respond well to acetone. So it’s always a good idea to test a small area or consult the manufacturer’s recommendations for bonding with acetone. And remember, safety first. Use acetone in a well-ventilated area and take the necessary precautions.

Advantages of Bonding PLA with Acetone

Today, we’re diving into the world of bonding PLA with acetone. If you’ve ever wondered how to create strong and durable connections between PLA surfaces, look no further. Acetone is here to save the day. In this post, we’ll explore the advantages of using acetone as your go-to adhesive for all your PLA projects. So, let’s get started.

Advantage 1: Strength and Durability

Acetone is a superhero when it comes to bonding PLA. It effectively melts the surface of the PLA, allowing it to fuse together seamlessly with another piece. The result? A bond that’s as robust as the original material itself. Say goodbye to weak adhesives and hello to a bond that can withstand the test of time.

Advantage 2: Simplicity and Accessibility

Forget about hunting down specialized adhesives or spending a fortune on bonding methods. Acetone is your friendly neighborhood solution. It’s readily available at most hardware stores, pharmacies, and beauty supply shops. Plus, it won’t break the bank. Easy to find and affordable – what more could you ask for?

Advantage 3: Versatility in Application

Whether you’re working on small intricate parts or larger PLA pieces, acetone has got you covered. Its versatility allows for seamless bonding in a wide range of projects. From 3D printing wonders to DIY repairs or crafts, acetone offers a solution for all your bonding needs.

Advantage 4: Aesthetically Pleasing Finish

We all want our creations to look flawless, right? Well, bonding PLA with acetone provides just that. Unlike traditional adhesives that might leave visible marks or uneven surfaces, acetone ensures a clean and polished finish. Your projects will look professional and seamless, even without post-bonding finishing processes.

Advantage 5: Environmental Sustainability

Let’s not forget about Mother Earth. Both PLA and acetone are biodegradable substances, making them an eco-friendly choice for bonding plastics. By opting for acetone, you’re not only creating strong connections but also promoting environmental sustainability. Go green with your bonding choices.

Advantage 6: Easy Disassembly

Life happens, and sometimes we need to make modifications or repairs. With acetone bonding, that’s not a problem. Unlike some strong adhesives that permanently bond materials together, acetone bonds can be reversed by applying heat. This means you can separate and rework your PLA pieces without compromising their integrity.

Disadvantages of Bonding PLA with Acetone

When it comes to bonding PLA plastics, acetone often takes center stage as the go-to solvent. Its ability to dissolve and soften PLA surfaces for a strong bond makes it a popular choice. However, before you dive headfirst into this seemingly perfect solution, it’s important to understand the disadvantages associated with using acetone as a bonding agent for PLA.

Warping and Deformation:

Acetone’s rapid evaporation rate can be a double-edged sword. While it dries quickly, this can cause the PLA to shrink or warp during the bonding process. This is especially problematic with larger or more complex PLA objects, as uneven drying can lead to structural instability and compromise the overall integrity of the bond.

Limited Bond Strength:

While acetone can create a temporary bond between PLA pieces, it falls short in terms of long-term durability. The bond formed using acetone is more prone to cracking or breaking under stress compared to other adhesive methods. This limitation makes it unsuitable for applications that require robust and enduring bonds.

Health and Safety Concerns:

Working with acetone requires caution. It is highly flammable, so proper handling and storage are essential. Adequate ventilation is necessary to prevent inhalation of fumes that can cause respiratory irritation or dizziness. Furthermore, direct contact with acetone can irritate the skin and eyes, necessitating the use of protective gloves and goggles.

Limited Availability:

While acetone is commonly found in hardware stores and beauty supply shops, its availability may vary depending on your location. This can pose an inconvenience for users who don’t have easy access to acetone or prefer not to work with potentially hazardous solvents.

Precise Application Required:

Bonding PLA with acetone demands careful application and precision. Excessive use or incorrect application can weaken the bond or even damage the material itself. Following proper instructions and guidelines is crucial to ensure successful bonding without compromising the integrity of your PLA object.

Alternatives to Bonding PLA with Acetone

If you’re tired of the limitations and potential hazards of using acetone to bond your PLA (polylactic acid) 3D prints, then I have great news for you. Today, we embark on a thrilling journey into the realm of alternative bonding methods that will bid farewell to acetone once and for all.

- Super Glue (Cyanoacrylate Adhesive): This trusty adhesive creates a formidable bond when it encounters moisture in the air. To ensure optimal adhesion, make sure your surfaces are squeaky clean and free from oils or debris.

- Epoxy Adhesives: These powerful two-part wonders consist of resin and hardener that must be mixed together before application. Once cured, they form a rock-solid bond capable of withstanding high temperatures and challenging chemical environments.

- Flexible Friend – Polyurethane Adhesives: When flexibility is paramount, turn to polyurethane adhesives. They excel at bonding PLA prints that may face stress or movement.

- Get Your Heat On: For the tinkering enthusiasts among us, wielding a heat gun or soldering iron can create a fusion between PLA pieces. By melting the surface and pressing it against another melted surface, a robust bond is achieved. Remember to work in a well-ventilated area.

- Specialized PLA Bonding Adhesives: Don’t fancy experimentation? No worries. There are adhesives specifically formulated for bonding PLA available on the market. These treasures offer faster curing times and enhanced flexibility, taking away the guesswork.

These five alternatives to bonding PLA with acetone will transform your printing experience. Each method boasts its own unique benefits and considerations, so select the one that best suits your project’s needs. Prepare for impeccable bonding, where your PLA prints stick together like glue.

Safety Precautions When Using Acetone for Bonding PLA

When it comes to bonding PLA prints, acetone has long been a popular choice. But before you dive into using this powerful chemical, it’s crucial to understand the necessary safety precautions that should be taken. By following these guidelines, you can ensure a safe working environment and protect yourself and those around you.

- Work in a well-ventilated area: Acetone is highly volatile and can release harmful fumes. Always work in a space with proper air circulation, such as opening windows or using a fan. Never work in a confined or poorly ventilated space.

- Personal Protective Equipment (PPE): Wear gloves, safety goggles, and a lab coat to shield your skin and eyes from potential splashes or spills. Acetone is not something you want coming into contact with your bare skin or eyes.

- Store and handle acetone properly: Keep acetone away from heat sources and store it in a cool, dry place. It is highly flammable and can easily ignite. Use tightly sealed containers to prevent accidents.

- Use acetone sparingly: Less is more when using acetone for bonding PLA. Apply it only to the areas that require bonding. Using excessive amounts can increase the risk of accidents or damage to the PLA material.

- Use a dedicated workspace or protective surface: Acetone can damage certain materials like wood or plastic, so be mindful of where you’re working. Have a dedicated workspace or use a surface that can be easily cleaned.

- Be cautious when handling acetone-soaked parts: Acetone-soaked PLA parts can become slippery, increasing the risk of accidental drops or injuries. Use proper gripping techniques or tools to ensure a secure hold.

- Proper disposal of waste acetone: Do not pour acetone down the drain or toss it in regular trash bins. Check local regulations for appropriate disposal methods or consider recycling options.

- In case of accidental skin or eye contact: If there is any accidental skin contact, wash the affected area immediately with soap and water. In case of eye contact, flush with water for at least 15 minutes and seek medical attention if irritation persists.

1xdcF2n1T6w” >

Conclusion

Yes, you can bond PLA with acetone.

Acetone acts as a solvent for PLA, causing it to soften and partially dissolve. When the softened PLA is pressed together with another piece of PLA, the acetone evaporates, leaving behind a strong bond between the two pieces.

It’s important to note that while acetone can effectively bond PLA, it may not work well with other types of plastics.