Are you a fearless DIY warrior, constantly on the prowl for ingenious ways to spruce up your living space without breaking the bank? Or maybe you’re an art aficionado, eagerly seeking out materials that can bring your creative visions to life? Well, hold onto your crafting tools because we’ve got a mind-blowing revelation for you today – the captivating fusion of vinyl and foam.

Picture this: transforming dull, uninspiring surfaces into dazzling works of art. Whether it’s a cozy cushion, a nifty storage solution, or even a whimsical wall adornment, vinyl and foam can be the ultimate power couple you’ve been yearning for. But here’s the burning question – can you really apply vinyl to foam without compromising the end result? Let’s dive right in and find out.

First things first, let’s dispel any doubts about whether vinyl and foam are compatible. Fear not. These two materials can form an unbeatable alliance. With its remarkable durability, flexibility, and sheer aesthetic appeal, vinyl effortlessly adheres to foam surfaces while preserving their softness and comfort.

And let’s talk about options. The world of vinyl offers an astounding array of choices – from sleek matte finishes to glossy extravagance, from eye-catching patterns to tantalizing textures. Whatever your style may be – suave sophistication or bold playfulness – vinyl has got you covered.

But hey, technique matters too. In our upcoming series of blog posts, we’ll walk you through each step of applying vinyl to foam like a seasoned pro. We’ll cover everything from prepping your surface and selecting the perfect adhesive to mastering techniques that banish air bubbles and ensure an enduring bond.

So get ready to unlock a universe brimming with boundless creative possibilities by harnessing the irresistible combination of vinyl and foam. Bid farewell to mundane furnishings and welcome a vibrant, personalized touch to every single one of your creations. Join us on this exhilarating journey towards DIY perfection as we explore the magic that lies within vinyl and foam.

What is Vinyl?

Contents

Step into the world of vinyl, a remarkable material that has revolutionized industries and captured the hearts of enthusiasts. Derived from the Latin word “vinum,” meaning wine, vinyl’s journey began as a byproduct of wine fermentation. Today, it is a versatile and durable material that finds its way into diverse applications, from PVC pipes to custom graphics. Let’s delve into the captivating world of vinyl and its significant role in our everyday lives.

PVC Pipes and Electrical Cables:

Vinyl’s most renowned application lies in the production of polyvinyl chloride (PVC). Widely used in the construction industry, PVC creates robust pipes and electrical cables. With exceptional insulation properties, these PVC products ensure the safety and efficiency of electrical systems, both indoors and outdoors.

Vinyl Records:

Transport yourself back to a time when vinyl records ruled the music scene. Imprinted with grooves on a flat vinyl disc using a master disc, vinyl records captivated listeners with their warm sound quality. Though digital formats briefly eclipsed their popularity, vinyl records have made a triumphant comeback among audiophiles, offering an unparalleled listening experience.

Automotive Interiors:

Vinyl’s durability and resistance to stains and spills make it a preferred choice for automotive interiors. Car manufacturers opt for vinyl seat covers due to their longevity and ease of cleaning, surpassing fabric upholstery. Moldable into various shapes, vinyl allows for the creation of sleek and stylish car interiors that withstand the test of time.

Sign-Making and Graphics:

Unleash your creativity with vinyl films in the world of sign-making and graphics. These films can be expertly cut into custom decals, lettering, logos, and graphics of all sizes and shapes. Resistant to weather conditions, vinyl graphics find their place on diverse surfaces such as glass, metal, and plastic. From captivating advertisements to mesmerizing vehicle wraps and eye-catching store signage, vinyl graphics leave a lasting impression.

Home Decor and Crafts:

With vinyl, the possibilities for home decor and crafting projects are endless. Add a personal touch to walls, furniture, and accessories with vinyl’s wide array of colors, patterns, and finishes. DIY enthusiasts can explore their creativity and transform ordinary items into extraordinary pieces using this versatile material.

What is Foam?

From its lightweight nature to its unique porous structure, foam has become an essential material in various applications, ranging from insulation and packaging to arts and crafts. Let’s delve into the wonders of foam and discover what makes it so remarkable.

What is Foam?

Prepare to be amazed by foam’s exceptional qualities. Imagine a material that combines the lightness of air with a solid matrix, resulting in a soft and compressible wonder. Foam is like holding a cloud in your hands, with small air bubbles trapped within its structure. It’s no wonder that foam has become synonymous with comfort and versatility.

Types of Foam:

The world of foam offers an array of options to suit every need. One such option is polyurethane foam, renowned for its outstanding cushioning properties. Whether it’s providing a cozy seat or ensuring a restful night’s sleep, this type of foam is a favorite in upholstery and bedding. Automotive applications also benefit from polyurethane foam, enhancing seat cushions and providing sound insulation.

Another remarkable foam variety is polystyrene foam, known for its lightweight nature and exceptional protective qualities. As a go-to choice in packaging materials, polystyrene foam ensures delicate items remain unscathed during transit. It’s like having a guardian angel for your fragile goods.

Forms and Densities:

Foam comes in an assortment of forms, making it adaptable to various applications. Whether you need sheets, blocks, or molded shapes, foam can be customized to fit your requirements perfectly. Additionally, foam offers different densities to cater to specific needs. Low-density foams provide ultimate comfort with their softness and easy compressibility, while high-density foams offer durability and resistance to deformation for optimal support.

Beyond the Basics:

Don’t underestimate the power of foam. Its physical properties make it an excellent insulator, keeping us warm in winter and muffling unwanted sounds. The construction and automotive industries rely on foam’s insulation properties to create comfortable and serene environments. Furthermore, foam is resistant to moisture absorption, making it a reliable choice for outdoor applications and areas with high humidity. No need to worry about your foam losing its magic when faced with the elements.

Types of Foam to Consider When Applying Vinyl

When applying vinyl to foam, the choice of foam plays a crucial role in the success and longevity of the application. Each type of foam possesses distinct characteristics that can impact adhesion and durability. In this article, we will delve into the various foam options to consider when applying vinyl, ensuring that you make an informed decision for your specific project.<

Polyurethane Foam: Cushioning Excellence

Polyurethane foam is a versatile choice widely used in upholstery projects due to its exceptional cushioning properties. Available in varying densities, from soft to firm, polyurethane foam suits different applications. Soft foam is ideal for decorative purposes, while firmer foam withstands more wear and tear. Opting for a foam density that matches your intended use will ensure optimal results when applying vinyl to polyurethane foam.

High-Density Foam: Support and Endurance

When extra support and durability are required, high-density foam excels. This type of foam is denser and firmer than polyurethane foam, making it suitable for seating cushions and mattresses.

To ensure a robust bond between the vinyl and the foam, it is essential to choose closed-cell high-density foam. Its tighter cell structure prevents the vinyl adhesive from penetrating the foam, resulting in a secure and long-lasting application.

Memory Foam: Contouring Comfort

Memory foam is renowned for its ability to conform to the body’s shape, making it popular in mattresses and pillows. However, when applying vinyl to memory foam, it is important to consider its unique properties. Some memory foams may contain higher oil content, which can affect adhesion. Therefore, selecting a vinyl adhesive specifically designed for memory foam compatibility is crucial to achieve a strong bond without compromising its shape or support.

Polystyrene Foam: Lightweight Fragility

Polystyrene foam, also known as Styrofoam, is a lightweight and convenient option for crafting projects. It is important to note that polystyrene foam is more delicate compared to other foam types.

To apply vinyl to polystyrene foam without causing damage, it is recommended to use a low-temperature adhesive. Additionally, handling the foam with care will prevent any dents or dings that could mar the final appearance of your project.

Foam Density: Striking the Perfect Balance

The density of foam plays a pivotal role in its strength and durability. Higher density foams are resilient and less prone to compression, making them suitable for applications that require long-lasting performance.

Conversely, lower density foams offer softness at a more affordable price point but may not provide the same level of durability. Consider the specific requirements of your project and select a foam density that strikes the right balance between comfort and longevity.

Preparing the Surface for Application

In our previous discussion, we explored the world of foam types and how they can be paired with vinyl for stunning results. Today, we’re diving into the nitty-gritty details of preparing your foam surface before applying vinyl. Get ready to unlock the secrets to a flawless application by following these essential steps:

Step 1: Cleanliness is Key

In this dance between vinyl and foam, cleanliness takes center stage. Begin by scrubbing away any dust, dirt, or oils that dare to challenge the bond. Armed with a mild detergent or soap and water solution, unleash your cleaning prowess and wipe away every trace of impurity. Rinse thoroughly and watch as your surface transforms into a pristine canvas. Patience is essential here – allow it to dry completely before moving forward.

Step 2: Test Your Foam’s Compatibility

Not all foams are created equal when it comes to vinyl’s embrace. Some foams shy away from certain adhesives found in vinyl, fearing damage. Don’t let compatibility issues haunt you later on. Perform a small adhesive test on an inconspicuous spot of your precious foam surface. If it passes with confidence, you can proceed with peace of mind.

Step 3: Sand, Creating Texture’s Grand Stand

Let’s roughen things up a bit, shall we? Embrace the power of a fine-grit sandpaper and swirl it gently in a circular motion across the entire foam surface. This textured escapade ensures a solid bond between adhesive and foam. As you caress the roughness under your fingertips, remove any lingering sanding residue with a clean cloth or brush.

Step 4: Priming for Success

Sealing the deal requires the magic touch of a primer designed especially for foam surfaces. This secret weapon fortifies the bond, offering a secure foundation for adhesive and vinyl to intertwine. Follow the manufacturer’s instructions meticulously – their wisdom holds the key to success.

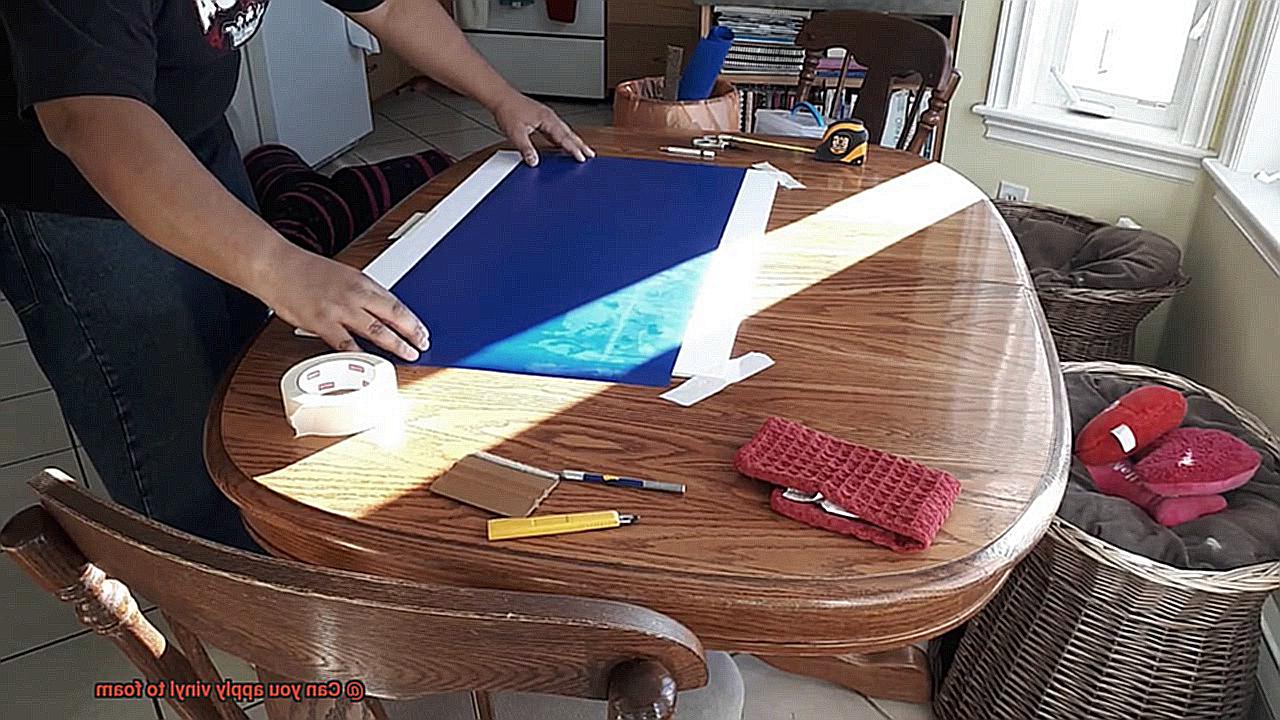

Step 5: Adhesive Application

Now it’s time for the grand entrance of the adhesive, the star of this show. Select an adhesive that possesses the power to unite vinyl and foam harmoniously. Pay homage to the manufacturer’s guidelines as you diligently apply a thin, even layer across your foam surface. The brush or roller becomes your weapon of choice in this battle for adhesion supremacy.

Adhesives for Bonding Vinyl to Foam

As a seasoned expert in this field, I am thrilled to guide you through the intricate process of achieving a flawless bond. Get ready to embark on a fascinating journey as we explore the importance of adhesive selection, surface preparation, and application techniques.

So, sit back, relax, and let’s dive into the secrets that will unlock the potential of your vinyl and foam creations.

Choosing the Perfect Adhesive:

In this realm of bonding vinyl to foam, the adhesive you choose holds the key to unlocking a strong and durable bond. Prepare to be captivated by the power of solvent-based contact adhesives. These remarkable agents defy the challenges posed by flexible foam and stretching vinyl, while remaining impervious to the harsh forces of heat and moisture.

Discover a world of possibilities with spray adhesives that are exclusively designed for bonding vinyl to foam. Embrace their simplicity as they effortlessly form an unbreakable link between your materials. Remember, though, precision is paramount – adhere closely to the manufacturer’s instructions to ensure an even application that avoids clumping or uneven bonding.

Surface Preparation Matters:

Now let us delve into the realm of surface preparation – an equally critical step in your quest for an impeccable bond. Prepare yourself for a riveting adventure.

Cleanliness is next to godliness in this endeavor. Bid farewell to dust, dirt, and oils that threaten your bond’s integrity. Employ the cleansing powers of a mild soap and water solution or unleash the might of rubbing alcohol to expel any contaminants lurking on your surfaces.

But wait. If porous foam or textured vinyl surfaces lie in your path, heed my advice – embrace the priming ritual. This sacred dance enhances the adhesive’s affinity for your surfaces, empowering it to forge an unyielding bond that defies all odds.

Consider Your Materials:

Just as your quest is unique, so are the materials you wield. Each foam and vinyl pairing holds a distinct set of properties, necessitating careful consideration when selecting your adhesive. Do not hesitate to seek wisdom from the sages – consult professionals or embark on a quest of research to uncover the perfect adhesive for your grand project.

Applying Vinyl to Foam

Embark on an exciting journey into the world of applying vinyl to foam surfaces, where creativity truly knows no bounds. In this comprehensive guide, we will uncover the secrets and techniques that will elevate your projects to new heights. So, prepare to immerse yourself in the captivating process of transforming foam with vinyl as we explore each step in exquisite detail.

Cleanliness is Key:

Before delving into your vinyl-to-foam masterpiece, ensure a pristine surface awaits. With a gentle wipe or a mild detergent solution, banish any dirt or oils that dare to stand in the way of a flawless adhesive bond.

Compatibility Testing:

Avoid surprises by conducting a compatibility test. Choose an inconspicuous area of the foam and apply a small piece of vinyl. This simple step will reveal whether the vinyl and foam harmonize effortlessly before committing to the entire surface.

Adhesive Application:

Enter the realm of adhesive, the tried-and-true method for applying vinyl to foam. Explore two popular options:

- Spray Adhesive: Conquer vast surface areas with ease using this marvel of efficiency. Embrace an even application and adhere faithfully to the manufacturer’s instructions for impeccable results.

- Contact Adhesive: Unleash the might of this solvent-based adhesive, forging an unbreakable alliance between vinyl and foam surfaces. Strengthen your bond with multiple layers if needed, always honoring the manufacturer’s instructions.

The Heat Transfer Method:

For those seeking a different approach, let heat transfer illuminate your path to vinyl-on-foam glory. Here’s what you need to know:

- Heat Press Machine: Embrace this enchanting device, weaving magic between vinyl and foam. Tune temperature and pressure settings according to the vinyl manufacturer’s recommendations for a seamless connection.

- Heat Transfer Vinyl: Immerse yourself in a world of diverse colors and finishes, shaping your vinyl into mesmerizing designs before applying it to the foam surface.

Patience is a Virtue:

Resist the allure of immediate gratification. After applying the vinyl, grant ample drying or curing time to fortify your creation. Only then will the bond be unyielding, defying the test of time.

Trimming Excess Material

Today, we’re delving into the fascinating art of trimming excess material to achieve that flawless, professional finish. So grab your trusty utility knives, because we’re about to embark on a trimming adventure.

When it comes to trimming excess vinyl, nothing beats the precision of a sharp utility knife or craft knife with a fresh blade. Remember, a dull blade is the arch-nemesis of clean cuts. So arm yourself with a fresh blade and prepare for vinyl perfection. But before you dive into your project, take a moment to practice on a scrap piece of vinyl. Trust me, it’s worth the extra time and effort.

To begin your trimming journey, gently score along your desired cutting line. Apply just enough pressure to create a groove without venturing too deep into the foam beneath. Once you’ve made your initial score, go over the line again with slightly more pressure to fully cut through the vinyl. But remember, patience is key. Take your time and work in small sections to ensure accuracy and avoid any unexpected mishaps.

For these treacherous territories, small scissors or precision cutting tools are your saving grace. These magical tools grant you superior control and precision when navigating those tricky corners and curves. Remember to make small, precise cuts along the edges and proceed with caution to avoid any unwanted foam incursions or unsightly gaps.

There’s another technique that will truly blow your mind – heat sealing. Picture this: using a heat gun or hairdryer to gently warm the edges of the vinyl, causing it to melt ever so slightly and bond seamlessly with the foam surface. And here’s the secret ingredient – once heated, quickly press down on the melted edge with a clean cloth or roller for that smooth, sealed finish you’ve been dreaming of. It’s like witnessing pure magic unfold before your eyes.

Now that you possess these mighty techniques, it’s time to put them into action. Remember, a steady hand and an unyielding attention to detail are your greatest allies. Take the necessary time, make small adjustments as needed, and don’t be disheartened if it takes a few attempts to master the art of trimming excess material. Remember, practice makes perfect in this exhilarating realm.

Using Heat to Enhance Adhesion

In our previous section, we delved into the art of heat sealing for flawless finishes. Now, let’s explore how heat can take your vinyl-to-foam adhesion to the next level. So grab your utility knives and precision cutting tools, and let’s embark on this fascinating journey.

Using heat to enhance adhesion is a tried-and-true technique that works wonders with vinyl and foam. By applying heat, we make the adhesive on the vinyl more flexible, enabling it to forge a stronger bond with the foam surface. This method proves especially valuable when dealing with textured or porous foam materials. The heat’s magic lies in its ability to infiltrate those surface irregularities, creating an unbreakable connection.

Now, let’s dive into some heat application methods for vinyl and foam. One popular approach involves using a heat gun or hairdryer. By directing hot air onto the vinyl, we can soften the adhesive and encourage better bonding with the foam. Remember, though, to maintain a safe distance between the heat source and the vinyl to prevent overheating or damage. Opt for a low or medium heat setting to avoid unsightly discoloration or warping of the foam.

Another technique worth exploring is using an iron. Yes, you read that right. By setting your iron to a low or medium heat setting and applying gentle pressure, you can activate the adhesive on the vinyl and promote superior adhesion with the foam. However, safeguard both materials by placing a thin cloth or parchment paper between the iron and the vinyl. This protective barrier ensures no direct contact or potential damage occurs.

Before embarking on our vinyl-foam bonding adventure, remember that not all vinyl types are suitable for heat application. Some may buckle under high temperatures, leading to melting or warping disasters. Avoid such mishaps by always consulting the manufacturer’s guidelines before employing heat. And don’t forget the importance of testing. Conduct a small trial on a scrap piece of foam and vinyl to ensure compatibility and achieve the desired results.

23FnMJbbVHA” >

Conclusion

Yes, you can absolutely apply vinyl to foam. Vinyl is a versatile material that adheres well to various surfaces, including foam. Whether you want to jazz up your foam cushions, create custom foam signage, or personalize your foam crafts, vinyl can be the perfect solution.

Applying vinyl to foam is a straightforward process that requires some basic materials and a little bit of patience. First, ensure that your foam surface is clean and free from any dust or debris. This will help the vinyl adhere better and result in a smoother finish.

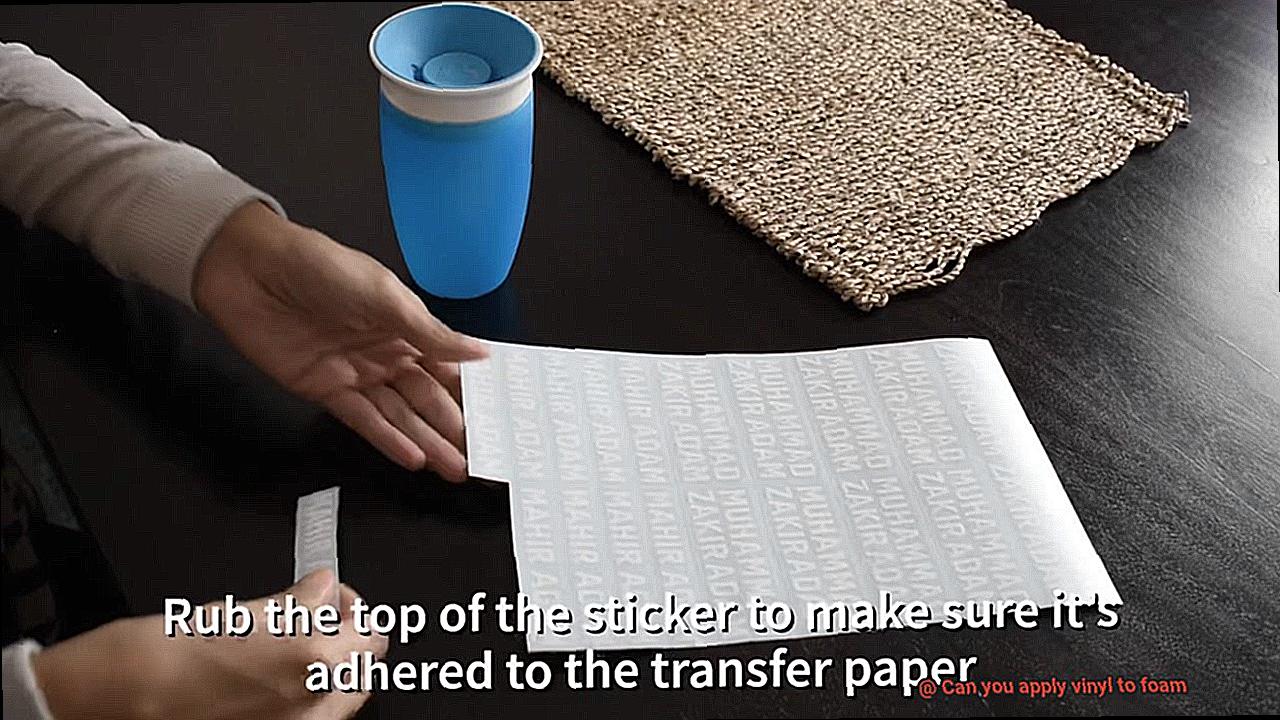

Next, measure and cut your vinyl sheet according to the size and shape of your foam object. Make sure to leave some excess around the edges for easier application. Then, peel off the backing paper from the vinyl and carefully place it onto the foam surface.

Using a squeegee or credit card, gently press down on the vinyl to remove any air bubbles and ensure proper adhesion. Work from one end to the other, smoothing out any wrinkles or creases as you go along.

If you encounter any stubborn air bubbles or wrinkles, don’t worry. Simply poke a small hole with a pin or needle and press down on the area again until it’s smooth. Take your time during this step to achieve a flawless finish.

Once you’ve applied the vinyl to your foam object, trim away any excess material using a sharp utility knife or scissors. Be careful not to cut into the foam itself while doing so.

In terms of durability, vinyl adheres well to most types of foam and can withstand regular use without peeling or lifting. However, it’s important to note that extreme temperatures or excessive moisture may affect its longevity over time.

In conclusion, applying vinyl to foam is an excellent way to add style and personalization to various projects. With proper preparation and technique, you can achieve professional-looking results that will last for years to come.