Have you ever found yourself in a sticky situation where you needed to seal a gap or crack, but didn’t have the right material at hand? Maybe you’ve considered using super glue as a quick fix, but wondered if it’s up for the task. Well, the answer isn’t straightforward as there are many factors to consider.

Super glue, also known as cyanoacrylate adhesive, is renowned for its fast-drying and robust bonding properties. However, its effectiveness as a sealant is questionable. A sealant’s primary function is to close gaps and prevent air or fluid passage. While super glue can fill tiny gaps, it may not withstand the pressure or temperature changes that sealants must endure.

Moreover, some super glue formulas may break down under exposure to water or UV light, making them unsuitable for most sealing applications. But don’t give up hope just yet. Some specialized super glue products are designed explicitly for sealing purposes and can be effective in specific scenarios.

In this blog post, we will dive deeper into the properties and limitations of super glue as a sealant and provide guidance on when and how it can be used effectively. Whether you’re an avid DIY enthusiast or professional tradesperson, this information will help you make informed decisions about your sealing needs. So buckle up and discover the truth about using super glue as a sealant.

How Does Super Glue Work?

Contents

- 1 How Does Super Glue Work?

- 2 Advantages of Using Super Glue as a Sealant

- 3 Disadvantages of Using Super Glue as a Sealant

- 4 Alternatives to Super Glue for Sealing Purposes

- 5 Tips for Using Super Glue as a Sealant

- 6 Common Mistakes When Using Super Glue as a Sealant

- 7 How to Remove Excess or Dried-up Super Glue from Surfaces

- 8 Safety Precautions When Using Super Glue as a Sealant

- 9 Conclusion

Super glue is a remarkable adhesive famed for its strong bonding capability. Its secret lies in its main ingredient, cyanoacrylate, a fast-acting adhesive that can bond almost any material together. But how does it work?

When exposed to air, super glue starts to polymerize, meaning that the cyanoacrylate molecules rapidly link to form a tight seal between two surfaces. This chemical reaction is triggered by the moisture in the air, which causes the cyanoacrylate molecules to bond together, creating a strong and durable bond.

One of the most significant advantages of using super glue is its ability to penetrate small gaps and crevices, providing an incredibly strong bond that can resist shear forces and other types of stress. This versatility makes it an attractive choice for bonding metal, plastic, wood, and other materials together.

However, while super glue is an excellent adhesive for bonding materials together, it may not be the best option for sealing purposes. The lack of moisture can prevent the cyanoacrylate from fully curing and bonding to the surface, which means it may not provide a complete seal.

Additionally, super glue may not be flexible enough to work as a sealant in certain situations. Any movement or expansion in the joint or surface being sealed could cause the rigid nature of the super glue to crack or break. This can lead to leaks or other issues that defeat the purpose of using a sealant.

Although super glue can be used as a temporary solution for sealing small cracks or gaps, it is better to use a sealant specifically designed for that purpose, such as silicone or polyurethane sealants, for more significant sealing projects.

Advantages of Using Super Glue as a Sealant

As an expert in the field, I can attest to the numerous advantages that using super glue as a sealant provides.

First and foremost, one of the main advantages of using super glue as a sealant is its ability to create a water-resistant barrier. This is especially useful in situations where moisture can compromise the integrity of the sealant. Super glue can easily seal small leaks in plumbing or protect electronic components from water damage, providing a long-lasting and secure seal.

Another advantage of using super glue as a sealant is its impressive ability to withstand extreme temperatures. Unlike traditional sealants that may break down over time, super glue remains flexible and durable even in high-heat or freezing conditions. This makes it an ideal choice for sealing outdoor equipment, such as camping gear or automotive parts.

But that’s not all. Super glue also offers the advantage of being easy to apply. Its applicator tip allows for precise and controlled application, making it perfect for use in small or hard-to-reach areas. Plus, since super glue dries quickly, it saves time and reduces the need for additional equipment or tools.

In summary, using super glue as a sealant offers several key advantages over traditional sealants. These include its water-resistance, temperature resilience, and ease of application.

It’s a versatile solution for a variety of sealing needs and can be used on almost any surface, including plastic, metal, wood, and even skin. However, it is important to note that super glue may not be suitable for all types of surfaces or applications, so always remember to read the manufacturer’s instructions carefully before use.

Disadvantages of Using Super Glue as a Sealant

It might seem like a convenient solution for sealing gaps or cracks, but the disadvantages of using it far outweigh the benefits.

To start with, super glue is not designed to withstand the pressure and movement that traditional sealants can handle. It lacks flexibility and can become brittle and break apart over time. This means that it may not hold up against the elements or stresses of day-to-day use, leading to leaks or other issues.

Secondly, super glue is not waterproof and is not suitable for sealing areas that are exposed to moisture or water. It may also react poorly to certain chemicals or solvents, leading to further deterioration or damage. In short, your sealed area may not stay sealed for long.

Thirdly, using super glue as a sealant may create difficulties when it comes to future repairs or modifications. It is challenging to remove once applied, making it harder to address any underlying issues or make changes to the sealed area. This could lead to more significant problems down the line.

Lastly, super glue may not be safe for use on certain materials or surfaces. It can cause discoloration, staining, or even damage to some materials. Additionally, it releases fumes that can be harmful if inhaled in large quantities. You don’t want to risk damaging your property or your health.

Alternatives to Super Glue for Sealing Purposes

While it may seem like a quick fix, super glue can be inflexible, damage surfaces, and is difficult to remove. Fortunately, there are several alternatives available that may be better suited to your needs.

Firstly, there’s epoxy – a two-part adhesive that forms a strong and durable bond when mixed together. It’s an exceptional option for sealing purposes and can be used on a range of materials including metal, wood, glass, and plastic. Epoxy is versatile and dependable and offers superior bonding capabilities.

Another excellent alternative to super glue is silicone sealant. This flexible and waterproof sealant can withstand extreme temperatures and weather conditions, making it perfect for outdoor use. It’s commonly used in plumbing and automotive applications but can be used on various surfaces such as glass, metal, and plastic. Silicone sealant is also mold-resistant and easy to apply.

For specialized sealing needs, plumber’s putty may be the solution you’re looking for. It’s a soft and pliable material designed specifically for sealing plumbing fixtures and joints. Plumber’s putty is easy to mold into the desired shape and provides a reliable, long-lasting seal.

And let’s not forget about duct tape. While it may not provide the same level of strength and durability as other options, it’s still a quick and easy fix for temporary sealing needs.

Tips for Using Super Glue as a Sealant

Super glue is a versatile adhesive that can be used for bonding materials together as well as sealing gaps and joints. However, using super glue as a sealant requires some important tips to ensure its effectiveness.

Tip 1: Choose the right type of super glue

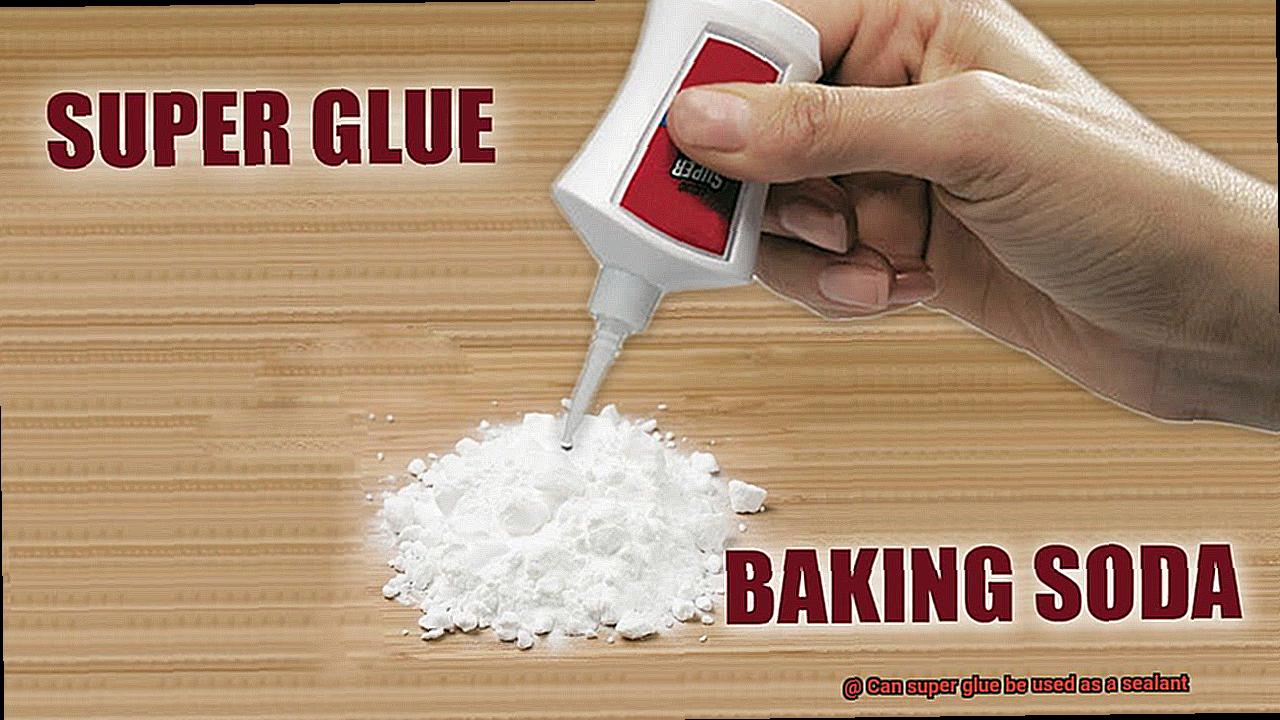

When using super glue as a sealant, it’s crucial to select the appropriate type of glue. For sealing purposes, cyanoacrylate-based super glue is the best option due to its strong bonding capabilities and ability to seal small gaps. Using a different type of super glue may result in a weak seal that doesn’t last long.

Tip 2: Prepare the surfaces properly

To achieve a strong and long-lasting seal, it’s essential to prepare the surfaces you plan to seal carefully. Clean and dry surfaces will allow the super glue to bond effectively without any interference from dirt, dust, or moisture.

Tip 3: Apply thin layers of glue

While it may be tempting to apply a thick layer of super glue for a stronger seal, this approach can backfire. Thick layers take longer to dry and may not provide an adequate seal. Instead, apply several thin layers of glue, allowing each layer to dry before applying the next. This approach builds up a stronger bond and ensures that the seal is tight.

Tip 4: Allow enough time for the glue to cure

While super glue dries quickly, it takes time to reach its full strength. It’s best to leave the sealed surface undisturbed for at least 24 hours after applying the final layer of glue. This allows enough time for the glue to cure completely and provide a strong, long-lasting seal.

Tip 5: Be cautious when using super glue

Super glue is notoriously sticky and challenging to remove from surfaces or skin. It’s important to work in a well-ventilated area and wear gloves when handling super glue. Additionally, if you accidentally get super glue on your skin, soak the affected area in warm soapy water to loosen the glue before attempting to remove it.

Common Mistakes When Using Super Glue as a Sealant

If you’re looking for a quick and easy way to seal something, super glue may seem like the perfect solution. However, using it as a sealant requires some careful considerations to avoid common mistakes that can lead to weak and ineffective seals.

First and foremost, one of the most common mistakes people make when using super glue as a sealant is not applying enough glue. Super glue’s strength comes from its ability to bond with the surface it’s applied to, so if you don’t use enough, you’re not going to get a strong bond. Therefore, it’s critical to apply enough glue to create a solid seal that can withstand various environmental factors.

Another mistake that can ruin your seal is not properly preparing the surface before applying the glue. Dirty or oily surfaces won’t bond well with the glue, leading to weak seals that may fail over time. So, be sure to clean and dry the surface thoroughly beforehand. This will ensure that the glue adheres properly and creates a strong seal that can stand the test of time.

However, using too much glue can also be problematic when using super glue as a sealant. Overly applying glue can cause it to overflow and create a messy and uneven seal- which is unsightly and ineffective. It’s important to apply just enough glue to create a strong bond without overdoing it. A little goes a long way in this case.

Finally, giving the glue enough time to dry and cure is crucial for creating an effective seal. Super glue needs time to fully dry and cure before it can create a strong bond, so be sure to give it ample time to set before handling or using the sealed object. Rushing this process could mean compromising the effectiveness of your seal.

How to Remove Excess or Dried-up Super Glue from Surfaces

Removing excess or dried-up super glue from surfaces can be a frustrating and challenging task, but there are several methods you can try to make it easier. Here are 5 effective ways to remove super glue from surfaces:

Acetone

This powerful solvent is one of the most effective ways to remove super glue from surfaces. To use it, dip a cotton swab or cloth into acetone and gently rub it onto the affected area. However, be sure to work in a well-ventilated area and wear gloves to protect your skin as acetone can be harsh.

Warm soapy water

This method works well for removing small amounts of super glue from non-porous surfaces like glass or metal. Soak the affected area in warm soapy water for a few minutes and then gently rub the area with your fingers or a soft-bristled brush. The warm water and soap will help break down the glue, making it easier to remove.

Vinegar and baking soda

This method is best for delicate surfaces like wood or fabric that could be damaged by harsh chemicals. Mix equal parts vinegar and baking soda until it forms a paste, apply it to the affected area, and let it sit for a few minutes before gently scrubbing away the glue using a soft-bristled brush.

Sandpaper

While this method should only be used as a last resort, it can be effective for removing excess super glue from non-delicate surfaces like plastic or metal. Use sandpaper to gently sand away the excess glue, being careful not to damage the surface.

Patience

Removing super glue takes time and patience, so don’t rush the process. Take breaks if needed and work slowly to avoid damaging the surface.

Safety Precautions When Using Super Glue as a Sealant

While it’s a reliable and powerful adhesive, it’s crucial to take safety precautions to prevent any accidents or injuries. Here are some top safety tips to keep in mind when working with super glue:

- Protect Yourself: Super glue can quickly bond to skin and eyes, causing irritation and potentially more severe damage. It’s essential to wear protective gear such as gloves and eye protection before beginning your project.

- Ventilation is Key: The fumes emitted from super glue can be harmful if inhaled in large amounts. It’s crucial to work in a well-ventilated area, whether it’s opening windows or using a fan to ensure proper airflow.

- Select Appropriate Materials: While super glue is a versatile adhesive, certain materials should be avoided, such as porous surfaces like fabrics. It’s also important to avoid using it on surfaces exposed to heat or moisture, as it may break down and lose its bond.

- Store Properly: After use, store super glue in a cool, dry place out of reach of children and pets. Never store it near heat sources or open flames as it is flammable.

Also Read: Can you use Elmer’s glue as a sealant?

Conclusion

In conclusion, while super glue may seem like a convenient solution for sealing gaps or cracks, its effectiveness as a sealant is uncertain. Super glue’s primary function is to bond materials together, and it may not withstand the pressure or temperature changes that sealants must endure. Moreover, some super glue formulas may disintegrate under exposure to water or UV light, making them unsuitable for most sealing applications.

However, specialized super glue products are explicitly designed for sealing purposes and can be effective in specific scenarios. While using super glue as a temporary solution for sealing small cracks or gaps is possible, it’s better to use a sealant specifically formulated for that purpose, such as silicone or polyurethane sealants, for more significant sealing projects.

While using super glue as a sealant offers several advantages over traditional sealants such as water-resistance, temperature resilience and ease of application. It’s worth noting that super glue may not be suitable for all types of surfaces or applications. Therefore, always remember to read the manufacturer’s instructions carefully before use.

Finally, safety precautions should always be taken when working with super glue. Protect yourself with gloves and eye protection and work in a well-ventilated area. Select appropriate materials and store the product correctly after use.