Today, we’re tackling a question that’s been on the minds of many: Can I use tile adhesive for FRP? You see, Fiberglass Reinforced Plastic (FRP) panels have been making waves in various industries, thanks to their incredible durability and versatility.

But when it comes to installing these bad boys, there’s always a heated debate about which adhesive is best. Some folks swear by using tile adhesive, thinking it’s the ultimate convenience.

Together, we’ll uncover the truth about using tile adhesive for FRP, so you can make an informed choice for your next project.

Benefits of Using Tile Adhesive for FRP

Contents

- 1 Benefits of Using Tile Adhesive for FRP

- 2 Considerations When Choosing to Use Tile Adhesive for FRP

- 3 Comparing Different Types of Adhesives for FRP

- 4 Step-by-Step Guide on How to Apply Tile Adhesive to FRP

- 5 Pros and Cons of Using Tile Adhesive for FRP

- 6 Tips on Applying and Curing the Adhesive Properly

- 7 Common Mistakes to Avoid When Using Tile Adhesive for FRP

- 8 Alternatives to Using Tile Adhesive for FRP

- 9 Conclusion

When it comes to the installation of FRP (Fiber Reinforced Polymer) panels, achieving a robust bond, flawless finish, and resistance to moisture and heat are paramount. Amidst the plethora of available adhesives, tile adhesive stands out as a versatile and effective choice for FRP applications. In this comprehensive article, we will delve into the advantages of using tile adhesive for FRP, highlighting its exceptional bonding properties, gap-filling capability, resilience against moisture and heat, user-friendly nature, and diverse range of formulations.

Unyielding Bonding Properties:

Renowned for its ability to forge durable and long-lasting bonds between tiles and substrates, tile adhesive can be harnessed to securely fasten FRP panels. With its unparalleled grip, concerns surrounding panel detachment or shifting are eradicated.

Seamless Finish:

Given that FRP panels are often installed on uneven surfaces, tile adhesive serves as a leveling agent by filling gaps and offering a seamless finish. This not only enhances the aesthetics but also provides a smooth surface for subsequent treatments or coatings.

Moisture and Heat Resistance:

Areas prone to water exposure, such as bathrooms and kitchens, necessitate an adhesive that can withstand moisture. Tile adhesive boasts excellent resistance, acting as a watertight barrier that prevents water from seeping behind FRP panels and causing damage. Moreover, its ability to endure high temperatures renders it suitable for installations near heat sources.

Ease of Use:

A standout feature of tile adhesive lies in its user-friendly characteristics. It comes in a ready-to-use form, eliminating the need for time-consuming mixing or measuring. Simply apply the adhesive directly onto the substrate and affix the FRP panel in place. This hassle-free installation process saves both time and effort.

Availability and Flexibility:

Widely accessible in most hardware stores, tile adhesive is available in various formulations to cater to different types of FRP panels and substrates. Its flexibility allows for slight movement of the FRP panels without compromising the bond, effortlessly accommodating temperature fluctuations or structural shifts.

Considerations When Choosing to Use Tile Adhesive for FRP

When it comes to choosing the right tile adhesive for your FRP (Fiber Reinforced Plastic) installation, there are several key considerations to keep in mind. After all, you want a strong and durable bond that can withstand the challenges of your specific application.

First and foremost, compatibility is crucial. Not all tile adhesives are designed to effectively bond with FRP panels. To ensure a secure bond, choose an adhesive specifically formulated for FRP.

Bond strength is another important factor to consider. FRP panels are often used in high-moisture or high-heat environments, such as bathrooms or industrial settings. Selecting an adhesive with excellent bond strength is vital to withstand these harsh conditions.

Moisture resistance is essential when choosing a tile adhesive for FRP. Since FRP panels are commonly installed in wet or damp areas, opt for an adhesive that is water-resistant or specifically formulated for wet environments.

Temperature resistance is another consideration. If your FRP panels will be exposed to extreme temperatures, choose an adhesive that can handle these variations without compromising the bond strength.

Flexibility is critical for the longevity of your installation. FRP panels can expand and contract due to temperature changes or structural movement. To prevent cracking or delamination, select a flexible adhesive that can accommodate these movements.

Chemical resistance should also be taken into account, especially in industrial settings or areas with exposure to harsh chemicals. Ensure your adhesive has excellent chemical resistance properties to maintain the bond integrity.

Additionally, consider the application method of the tile adhesive. Since FRP panels are often large and heavy, you’ll want an adhesive that can be applied evenly and smoothly. Make sure the adhesive aligns with the installation requirements and may require special tools or techniques.

Lastly, always follow the manufacturer’s recommendations for selecting an adhesive for FRP panels. They have tested and approved specific adhesives for use with their products, ensuring optimal performance and longevity.

Comparing Different Types of Adhesives for FRP

Choosing the correct adhesive is crucial when it comes to bonding FRP (Fiber Reinforced Plastic) materials. The wrong adhesive can result in weak bonds that compromise the structural integrity of the FRP. In this article, we will compare and contrast five commonly used adhesives for FRP bonding: epoxy, polyurethane, acrylic, cyanoacrylate, and tile adhesives. By understanding their characteristics and suitability for different applications, you can make an informed decision.

Epoxy Adhesives:

Epoxy adhesives are a popular choice due to their exceptional bonding strength, durability, and resistance to moisture and chemicals. They boast high tensile strength and effectively bond various types of FRP materials together. The long curing time of epoxy allows for proper alignment and adjustment before the adhesive sets, ensuring precise bonding.

Polyurethane Adhesives:

Polyurethane adhesives are another excellent option for FRP bonding. They offer good bonding strength and flexibility, making them suitable for applications that involve movement or vibration. Additionally, polyurethane adhesives exhibit resistance to moisture and temperature fluctuations, further enhancing their versatility.

Acrylic Adhesives:

Acrylic adhesives are known for their fast curing time and high initial bond strength. They are perfect for applications that require quick assembly or limited curing time. However, it is important to note that acrylic adhesives may not provide the same level of long-term durability as epoxy or polyurethane adhesives.

Cyanoacrylate Adhesives:

Cyanoacrylate adhesives, commonly referred to as super glue, offer instant bonding due to their rapid-curing nature. While they can be used for small-scale FRP bonding, they may not offer sufficient strength for larger or load-bearing applications. Therefore, cyanoacrylate adhesives are better suited for minor repairs or temporary bonding needs in FRP projects.

Tile Adhesives:

Tile adhesives, specifically formulated for bonding ceramic or stone tiles, are not typically suitable for FRP bonding. They lack the necessary properties to effectively bond FRP materials, such as fiberglass reinforced plastic or carbon fiber reinforced plastic. Using tile adhesive may result in weak bonds and compromised structural integrity.

Step-by-Step Guide on How to Apply Tile Adhesive to FRP

Step-by-Step Guide on How to Apply Tile Adhesive to FRP

Are you ready to transform your FRP (Fiberglass Reinforced Plastic) surface with stunning tiles? Before you embark on this exciting project, it’s important to know how to properly apply tile adhesive to ensure a successful installation. Fear not, for I have prepared a step-by-step guide that will turn you into a tiling pro in no time.

Step 1: Prepare the Surface

Start by giving your FRP surface a thorough cleaning. Use a mild detergent and water solution or a specialized FRP cleaner to remove any dirt, grease, or debris that might hinder the adhesive’s ability to stick. Rinse the surface well and let it dry completely before moving on.

Step 2: Prime Time

To achieve maximum adhesion, prime your FRP surface before applying the tile adhesive. Choose a primer specifically designed for FRP and tile adhesive and follow the manufacturer’s instructions for application. Use a brush or roller to apply the primer evenly and allow it to dry according to the recommended drying time.

Step 3: Mix It Up

Now it’s time to mix the tile adhesive. Refer to the manufacturer’s instructions for the correct water-to-adhesive ratio. Grab a clean bucket or container and thoroughly mix the adhesive until it reaches a smooth consistency. Take care to follow the instructions closely, as you don’t want the adhesive to be too thick or too runny.

Step 4: Plan Your Layout

Before diving into the adhesive application, take a moment to plan out your tile layout. Measure and mark the desired position of each tile on the FRP surface. This will ensure proper alignment and serve as your guide during adhesive application.

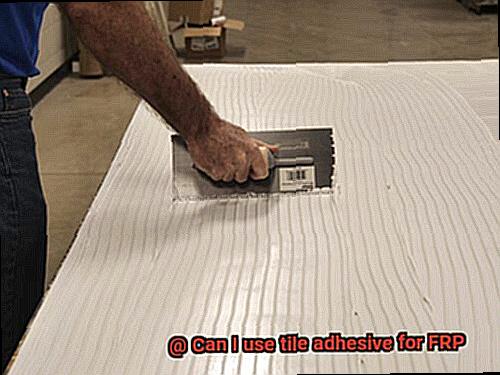

Step 5: Spread the Love… I Mean, Adhesive

Grab your notched trowel and start spreading the adhesive onto the FRP surface. Begin at one corner and work your way outwards, applying enough adhesive to cover an area that you can comfortably tile within 15-20 minutes. Hold the trowel at a 45-degree angle to create grooves in the adhesive, promoting better adhesion.

Step 6: Tile Time

With the adhesive evenly spread, it’s time to lay the tiles. Firmly press each tile into the adhesive, using a slight twisting motion to ensure good contact. Remember to use spacers to maintain consistent spacing between the tiles. Work in small sections until all the tiles are beautifully laid.

Step 7: Patience is a Virtue

Now, exercise patience and allow your tiles and adhesive to bond. Resist the temptation to walk on or disturb them during this crucial period. The curing time will vary depending on the tile adhesive, so refer to the manufacturer’s instructions for guidance.

Pros and Cons of Using Tile Adhesive for FRP

Tile adhesive can be a great option for bonding FRP (Fiber-Reinforced Polymer) panels, but it’s important to consider both the pros and cons before making a decision.

One of the major advantages of using tile adhesive for FRP is its strong bonding properties. Tile adhesive is known for its excellent adhesion, providing a secure and long-lasting bond between FRP panels and the substrate. This is particularly beneficial in high-traffic areas or places prone to moisture or humidity. The strong bond ensures that the FRP panels stay securely in place.

Versatility is another advantage of using tile adhesive for FRP. There are different formulations of tile adhesive available, allowing you to choose the right one for your specific needs. Whether you’re working with porous or non-porous surfaces, there’s an adhesive out there that can effectively bond FRP panels to various substrates. This versatility makes it easier to find the right adhesive for your specific installation requirements.

Ease of application is also worth mentioning. Most tile adhesives come ready-to-use, eliminating the hassle of mixing or adding additional components. Plus, they are easy to spread and work with, making your installation process a breeze. This can save time and effort during installation, whether you’re a DIY enthusiast or a professional installer.

However, there are some potential drawbacks to using tile adhesive for FRP. One concern is the weight of the panels. If you’re dealing with heavier or larger FRP panels, tile adhesive may not provide enough support. In such cases, you might need a stronger adhesive or mechanical fasteners to ensure that the panels stay securely in place.

Flexibility is another consideration. Tile adhesives tend to be rigid once they cure, which may not be ideal if your FRP panels need to flex or move due to temperature changes. A rigid adhesive could lead to cracks or delamination over time.

Furthermore, not all FRP panels are suitable for tile adhesive. Some panels have specialized coatings or finishes that require specific adhesives for proper bonding. Using tile adhesive may not give you the desired aesthetics or durability.

Lastly, let’s not forget about compatibility and cost. Make sure the tile adhesive is compatible with both the substrate and FRP panels to avoid adhesion issues. Additionally, using tile adhesive for large-scale FRP installations can significantly increase costs, so it’s important to weigh the benefits against your budget.

Tips on Applying and Curing the Adhesive Properly

When it comes to bonding FRP (Fiber Reinforced Plastic) materials, knowing how to properly apply and cure adhesive is essential. By following these expert tips, you can achieve a strong and durable bond that will withstand the test of time. Let’s delve into the details and ensure successful adhesive application and curing.

Surface Preparation: The Foundation of a Strong Bond

Before applying adhesive, thoroughly clean the surface of the FRP. Ensure it is free from dirt, dust, or grease that may hinder the adhesive’s effectiveness. A meticulous cleaning with a mild detergent and water solution will do the trick. Rinse off any residue and allow the surface to dry completely before proceeding.

Choose the Right Adhesive: The Key to Optimal Bonding

Not all adhesives are created equal. It is crucial to select an adhesive specifically designed for bonding plastics or composite materials like FRP. These specialized adhesives offer superior bonding strength and adhesion to FRP surfaces compared to general-purpose adhesives.

Follow Manufacturer’s Instructions: A Roadmap to Success

Each adhesive has its unique set of instructions for application and curing. Carefully read and follow these instructions to the letter. They will guide you on proper application techniques, curing time, and any specific considerations for the adhesive you are using.

Apply Evenly: The Secret to Uniform Strength

When applying the adhesive, ensure it is spread evenly over the entire surface of the FRP. You can use a notched trowel or applicator recommended by the adhesive manufacturer for optimal results. Applying too much or too little adhesive can lead to weak bonds or uneven curing, compromising the overall strength of the bond.

Allow Sufficient Curing Time: Patience Pays Off

Curing time is crucial for the adhesive to fully bond and reach its maximum strength. The required curing time may vary depending on factors such as temperature, humidity, and the type of adhesive used. Adhere strictly to the manufacturer’s recommended curing time to ensure a strong and durable bond.

Common Mistakes to Avoid When Using Tile Adhesive for FRP

The successful installation of FRP panels relies on using the right tile adhesive. However, there are common mistakes that can compromise the adhesion and durability of the installation. This article will outline key factors to consider and provide a comprehensive list of mistakes to avoid when using tile adhesive for FRP. By following these expert tips, you can ensure a long-lasting and secure bond.

Lack of Surface Preparation:

Proper surface preparation is crucial for a successful installation. Neglecting to clean and smooth the surface before applying adhesive can result in weak adhesion. Ensure the surface is free from dirt, grease, and loose material, and completely dry. This provides a clean canvas for the adhesive to effectively bond with the FRP.

Incorrect Adhesive Selection:

Using the wrong type of tile adhesive is a common mistake. Regular tile adhesives may lack the necessary properties to adhere effectively to FRP panels. Opt for an adhesive specifically formulated for bonding FRP to various substrates. These adhesives have higher bond strength and flexibility to accommodate expansion and contraction.

Insufficient Adhesive Coverage:

Proper adhesive coverage is vital for a strong bond between FRP and the substrate. Apply an even and adequate amount of adhesive to both surfaces. Use a notched trowel or similar tool to spread the adhesive evenly. Insufficient coverage can lead to weak spots and compromised adhesion.

Improper Mixing of Adhesive:

Some tile adhesives require mixing with water or additives before use. Failing to follow the manufacturer’s instructions for mixing can result in inconsistent adhesive properties and compromised bond strength. Carefully read and follow the instructions provided by the adhesive manufacturer to ensure proper mixing.

Inadequate Curing Time:

Patience is crucial when it comes to curing time. Rushing the process can result in a weak bond that may fail over time. After applying the adhesive and installing the FRP panels, allow sufficient curing time before subjecting the installation to stress or load. Follow the manufacturer’s recommended curing time to ensure maximum bond strength.

Alternatives to Using Tile Adhesive for FRP

Look no further. In this article, we’ll explore some adhesive-free options that can provide a strong and durable bond for your FRP installation. Whether you’re a DIY enthusiast or a professional contractor, understanding these alternatives will help you make an informed decision for your project.

Construction Adhesive:

One popular alternative is using construction adhesive specifically designed for bonding FRP panels. These adhesives are formulated to withstand the unique demands of FRP, offering excellent adhesion properties and moisture resistance. They ensure a secure bond between the panels and the substrate, providing durability and longevity. With construction adhesive, you can confidently install your FRP panels without worrying about them coming loose or deteriorating over time.

Epoxy Adhesive:

Another option to consider is epoxy adhesive. Known for its high strength and durability, epoxy adhesives can bond various materials, including FRP. They can withstand extreme temperatures, moisture, and chemicals, making them suitable for demanding applications. Epoxy adhesives provide a reliable and long-lasting bond, ensuring that your FRP panels stay firmly in place even in challenging environments.

Specialized FRP Adhesives:

Some manufacturers offer specialized adhesives exclusively designed for installing FRP panels. These water-based and low VOC adhesives are environmentally friendly and easy to apply. They provide a secure bond and are often recommended by professionals in the field. Specialized FRP adhesives offer peace of mind, knowing that you’re using a product specifically tailored to the unique properties of FRP panels.

Mechanical Fastening:

If you prefer an alternative that doesn’t involve adhesives, mechanical fastening is worth considering. This method involves using screws or nails to secure the panels to the substrate. Mechanical fastening provides a reliable and sturdy installation, especially in high-impact areas or where extra strength is required. This option allows for easy removal and replacement of FRP panels if necessary, making it a flexible choice for your installation needs.

Remember:

When choosing an alternative adhesive or fastening method for your FRP installation, it’s crucial to follow the manufacturer’s recommendations and instructions. Each product may have specific application requirements, such as surface preparation, curing time, or temperature conditions. Consulting with professionals or experts in FRP installation can provide valuable insights and recommendations based on their experience and knowledge.

GqrD_G1W4-4″ >

Conclusion

In conclusion, it is not recommended to use tile adhesive for FRP. While tile adhesive may seem like a convenient option, it is not designed to bond with FRP materials effectively. FRP requires a specialized adhesive that can provide strong and durable adhesion.

Using tile adhesive for FRP can lead to several issues. Firstly, the bond between the adhesive and the FRP may not be strong enough, resulting in a weak and unreliable connection. This can compromise the structural integrity of the FRP and potentially lead to failure or damage.

Additionally, tile adhesive may not be able to withstand the unique conditions that FRP often encounters. FRP is commonly used in high-moisture environments such as bathrooms or swimming pools, where it is exposed to water, humidity, and temperature changes. Tile adhesive may not have the necessary waterproofing properties or resistance to these environmental factors.

Furthermore, using tile adhesive for FRP may void any warranties or guarantees provided by manufacturers. Most manufacturers of FRP materials specify the type of adhesive that should be used for proper installation and performance. Deviating from these recommendations could result in the loss of warranty coverage.

To ensure a successful installation and long-lasting performance of your FRP materials, it is crucial to use an adhesive specifically formulated for bonding with FRP. These adhesives are designed to provide excellent adhesion strength, durability, resistance to moisture and temperature fluctuations, and compatibility with FRP materials.

In conclusion, while it may be tempting to use tile adhesive for FRP due to its availability and ease of use, it is best to follow manufacturer recommendations and opt for an adhesive specifically designed for bonding with FRP.