Picture this: you’re knee-deep in a plumbing project, ready to tackle the world like a DIY champion. You realize that all you have is regular clear PVC cement, and the job requires CPVC. Uh-oh. It’s a common predicament that leaves many scratching their heads.

Can you really use regular clear PVC cement on CPVC without any consequences? Well, fear not because we’re here to shed some light on this puzzling question. In this blog post, we’ll take a deep dive into the realms of PVC and CPVC materials and uncover whether swapping one cement for another is a genius shortcut or a plumbing nightmare waiting to happen.

So, grab your toolkit and get ready as we unravel the truth behind this piping puzzle.

What is PVC and CPVC?

Contents

- 1 What is PVC and CPVC?

- 2 What is Solvent Cement?

- 3 Can I Use Regular Clear PVC Cement on CPVC?

- 4 Advantages of Using the Appropriate Solvent Cement for Each Type of Pipe

- 5 Disadvantages of Using Regular Clear PVC Cement on CPVC

- 6 How to Select the Right Solvent Cement for Your Plumbing Application

- 7 Compatible Solvent Cements for Both PVC and CPVC

- 8 Tips for Properly Applying Solvent Cement to Create a Reliable Bond

- 9 Conclusion

Plumbing and home renovation projects often introduce us to the terms PVC and CPVC. But what exactly are they, and how do they differ? Let’s plunge into the realm of plastic pipes and uncover their distinct characteristics, with a focus on glue.

PVC, short for polyvinyl chloride, reigns as a versatile and widely used material in the plumbing industry. Its reputation for durability, affordability, and easy installation attracts both residential and commercial plumbing systems, along with various industrial applications. PVC pipes typically display hues of white or gray and boast a sleek surface.

In contrast, CPVC stands as a chlorinated polyvinyl chloride—a modified version of PVC that undergoes chlorination. This process enhances its heat resistance, rendering it suitable for hot water supply lines and sprinkler systems. CPVC pipes weather high temperatures without deformation or melting, making them the go-to choice for applications involving hot water or high-temperature fluids.

One pivotal distinction between PVC and CPVC lies in their maximum service temperature. PVC stands strong at temperatures up to 140°F (60°C), while CPVC confidently handles temperatures up to 200°F (93°C) or even higher depending on the specific product. As a result, CPVC emerges as the material of choice for hot water applications.

Chemical resistance also sets these two materials apart. While both PVC and CPVC exhibit resilience against many common chemicals, CPVC surpasses regular PVC in its ability to withstand substances like chlorine. Regular PVC may gradually degrade when exposed to chlorine, making CPVC the superior option for applications where chemical exposure is a concern.

Now let’s move on to glue. When joining PVC and CPVC pipes, solvent cement takes center stage. However, it is crucial to select the appropriate cement for each type of pipe. Regular clear PVC cement specifically caters to PVC pipes and fittings, not CPVC. Employing regular PVC cement on CPVC weakens joints over time, potentially leading to leaks.

To guarantee robust and reliable connections, it becomes paramount to use solvent cement explicitly designed for CPVC when working with CPVC pipes and fittings. This ensures a secure and long-lasting bond, granting you peace of mind.

In summary, PVC and CPVC represent two types of plastic pipes commonly utilized in plumbing systems. While they share similarities such as durability and affordability, key differences set them apart. CPVC’s chlorination enhances its heat resistance and chemical resilience, making it the superior choice for hot water applications and situations involving chemical exposure. When joining CPVC pipes, selecting the correct solvent cement formulated for CPVC ensures sturdy and leak-proof connections.

What is Solvent Cement?

In the vast world of plumbing, one tool stands out as the secret weapon for leak-proof connections and lasting durability: solvent cement. This specialized adhesive, also known as PVC glue or pipe glue, is designed specifically for joining plastic pipes and fittings.

In this article, we will explore the power of solvent cement, its properties, applications, and the importance of choosing the right type for your specific needs.

The Power of Solvent Cement:

Solvent cement is no ordinary adhesive. Its liquid form consists of solvents and resins that work together to create a chemical bond between plastic pipes and fittings. The solvents act as dissolvers, breaking down the outer layer of the pipes and fittings.

As they evaporate, the resins fuse together, forming a solid and permanent connection that can withstand the test of time.

Watertight Seals and Chemical Resistance:

One of the greatest advantages of solvent cement lies in its ability to create watertight seals. When applied correctly, it forms a strong bond that eliminates any possibility of leakage. This makes it an ideal choice for plumbing systems where maintaining a reliable seal is crucial.

Additionally, solvent cement exhibits resistance to a wide range of chemicals, ensuring its suitability for various applications.

Different Types for Different Pipes:

Not all solvent cements are created equal. There are different types available, each formulated for specific types of plastic pipes. The most common ones are PVC solvent cement and CPVC solvent cement. While they may appear similar, they should never be used interchangeably.

PVC Solvent Cement vs. CPVC Solvent Cement:

PVC solvent cement is tailor-made for PVC pipes and fittings. It should never be used with CPVC pipes due to their different chemical compositions. Using PVC solvent cement on CPVC can result in weak joints, leaks, and potential pipe failure over time. On the other hand, CPVC solvent cement is specifically formulated for use with CPVC pipes, providing a stronger bond and ensuring a reliable connection.

Proper Application for Optimal Results:

To harness the full power of solvent cement, proper application is key. Following the manufacturer’s instructions and guidelines is essential. This includes using the correct type of solvent cement for the specific type of plastic pipe being used and ensuring proper surface preparation. Clean, dry, and debris-free pipes and fittings are paramount for a successful application.

Can I Use Regular Clear PVC Cement on CPVC?

When it comes to DIY plumbing projects, it’s important to use the right materials for the job. One common question that arises is whether regular clear PVC cement can be used on CPVC pipes and fittings. The short answer is no, and here’s why.

Regular clear PVC cement is specifically designed for bonding PVC pipes and fittings together. It’s like a perfect match, just like peanut butter and jelly. However, CPVC is a whole different ballgame. It is made to handle hot water applications and has different chemical properties compared to PVC.

The solvents in regular clear PVC cement may not be compatible with CPVC, which can lead to weak joints, leaks, cracks, and other issues. Additionally, CPVC and PVC have different rates of expansion and contraction. Using the wrong glue can result in serious structural problems down the line.

So what’s the solution? Enter CPVC-specific cement. These glues are specially formulated for CPVC and ensure a strong bond that can withstand the heat. They contain solvents that are compatible with CPVC, providing peace of mind that your pipes won’t spring a leak unexpectedly.

To summarize:

- Regular clear PVC cement is not recommended for use on CPVC pipes and fittings.

- CPVC-specific cement is designed for bonding CPVC pipes and fittings together.

- Using the wrong glue can result in weak joints, leaks, cracks, and structural issues.

- Follow the manufacturer’s instructions when working with CPVC pipes and fittings.

- Consult with a professional plumber or contact the manufacturer for guidance if you are unsure about which type of cement to use.

Advantages of Using the Appropriate Solvent Cement for Each Type of Pipe

Well, before you dive into connecting those pipes, it’s crucial to understand the immense benefits of using the appropriate solvent cement for each type of pipe. Trust me; it can make all the difference in the world. Let’s take a deep dive into the advantages of using the correct solvent cement for your plumbing needs.

Secure and Long-Lasting Bond:

Using the appropriate solvent cement ensures a secure and long-lasting bond between the pipes. Different types of pipes have distinct chemical compositions and properties. Therefore, using the right solvent cement designed specifically for your type of pipe guarantees a strong and durable connection. Say goodbye to leaks and failures.

Compatibility:

Solvent cements are formulated to work harmoniously with specific types of pipes, considering their unique characteristics and materials. Using the wrong solvent cement can result in an improper bond, leading to future problems. By choosing the appropriate solvent cement, you can rest easy knowing that your bond will be reliable and resistant to pressure, temperature changes, and other environmental factors.

Tight Seal:

Solvent cements soften the surface of the pipe and fitting, allowing them to fuse together seamlessly. This fusion creates a strong bond that prevents leaks and ensures a smooth flow of fluids through your pipes. Using the wrong solvent cement may result in an incomplete or weak seal, compromising the integrity of your system. Yikes. Nobody wants that.

Maintaining Structural Integrity:

Different types of pipes have varying levels of chemical resistance and mechanical strength. Solvent cements specifically formulated for each type of pipe take these factors into consideration, ensuring that the bond formed is compatible with the pipe’s properties. This compatibility helps prevent degradation or weakening of the pipe material over time, extending its lifespan.

Simplifying Future Repairs or Modifications:

If you ever need to make changes or upgrades to your plumbing system, using the correct solvent cement makes it a breeze. The bond created by the appropriate solvent cement can be easily dissolved or reactivated using the same solvent, allowing for easy disassembly and reassembly of your pipes. Talk about flexibility.

Disadvantages of Using Regular Clear PVC Cement on CPVC

Hold on just a minute. While it may seem like a cost-effective solution, using the wrong type of cement can lead to disastrous consequences. In this article, we’ll explore the disadvantages of using regular clear PVC cement on CPVC and explain why it’s crucial to stick with the right adhesive for the job.

Weak Bonds and Potential Leaks:

Regular clear PVC cement is not designed to bond CPVC due to their different chemical properties and higher melting point. As a result, the bond created between the two materials may be weak and prone to leaks. Imagine discovering drips and leaks after all your hard work.

Damage to CPVC Pipes:

Mixing incompatible chemicals is like playing with fire, or in this case, water. The chemicals in regular PVC cement can react with CPVC, causing degradation or weakening of the pipes over time. This could lead to costly repairs or even pipe failures down the line.

Voided Warranties:

Manufacturers specify compatible adhesives and solvents for CPVC products for a reason. By using an incompatible cement, you risk voiding any warranties or guarantees provided by the manufacturer. Don’t let your DIY project turn into a financial nightmare.

Violation of Building Codes:

Building codes exist to ensure safety and compliance. Using regular PVC cement on CPVC may fail to meet these code requirements and result in violations. Additionally, non-compliance can have serious consequences when selling your property or obtaining insurance.

How to Select the Right Solvent Cement for Your Plumbing Application

If you’re tackling a plumbing project and need to join pipes and fittings together, you’ll need to use solvent cement. Solvent cement is like glue for plumbing, creating a strong and durable bond that ensures your pipes won’t leak. But how do you know which solvent cement to choose? Here are some tips to help you select the right one for your plumbing application.

Determine the Type of Pipe Material

The first step in selecting the right solvent cement is to identify the type of pipe material you’re working with. PVC and CPVC are two common materials used in plumbing, but they have different properties and require different types of solvent cement.

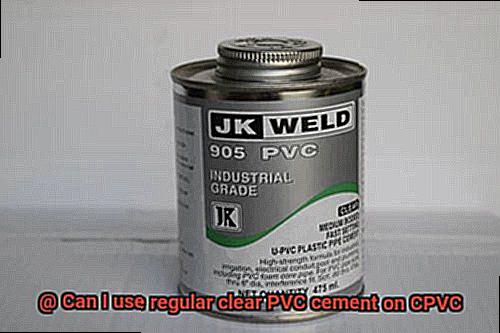

PVC (Polyvinyl chloride) is a rigid plastic material often used for drain, waste, and vent systems. For joining PVC pipes and fittings, you’ll want to use regular clear PVC cement. This special adhesive chemically fuses the surfaces of the pipes together, creating a strong and leak-proof connection.

CPVC (Chlorinated polyvinyl chloride) is a more heat-resistant version of PVC and is commonly used for hot water distribution systems. Regular clear PVC cement should not be used on CPVC pipes as it may not provide a reliable bond and can lead to leaks or failures over time. Instead, look for solvent cement specifically formulated for CPVC materials, which usually have a yellow or orange color to differentiate them from regular PVC solvent cements.

Consider the Size of Pipes and Fittings

In addition to the type of pipe material, it’s important to consider the size of the pipes and fittings you’re working with when selecting solvent cement. Solvent cements come in different viscosities, ranging from thin to medium to heavy-bodied. The viscosity should match the size of the pipes being joined.

Thicker solvent cements are generally recommended for larger diameter pipes to ensure adequate coverage and bonding. Using a thin solvent cement on a large pipe may not provide enough adhesive, leading to weak joints and potential leaks.

Follow Manufacturer’s Instructions

Once you’ve selected the appropriate solvent cement for your plumbing application, it’s crucial to follow the manufacturer’s instructions. This includes proper surface preparation, application techniques, and curing times. Failure to follow these instructions can result in weak or failed joints.

Take the time to clean and dry the surfaces to be bonded before applying the solvent cement. Apply the cement evenly and avoid excess or insufficient amounts. Allow sufficient curing time before pressurizing the plumbing system to ensure a proper bond.

Avoid Using Solvent Cement for Repairs

It’s important to note that solvent cement should not be used as a substitute for proper pipe sizing or as a means of repairing damaged pipes. Solvent cement is designed for joining new pipes and fittings together and should not be used to fix existing plumbing issues. If you have damaged pipes, it’s best to consult with a professional plumber for appropriate repairs.

Compatible Solvent Cements for Both PVC and CPVC

When it comes to joining PVC and CPVC pipes and fittings, using the right solvent cement is crucial. While PVC and CPVC may seem similar, they have different chemical compositions and properties that require specific glues for a strong and durable connection. In this article, we’ll explore how to identify compatible solvent cements for both PVC and CPVC, as well as recommend some top choices.

Understanding the Differences:

PVC (polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) are commonly used thermoplastic materials in plumbing and construction. PVC is a versatile material known for its durability, affordability, and resistance to chemicals. On the other hand, CPVC is a more advanced version of PVC, featuring increased chlorine content that enhances its ability to handle higher temperatures.

Choosing the Right Solvent Cement:

Using the correct solvent cement is vital for ensuring a secure joint between PVC or CPVC pipes and fittings. Regular clear PVC cement should never be used on CPVC as it may not effectively bond the materials together, potentially leading to leaks or failures over time. Instead, opt for solvent cements specifically formulated for each material.

Recommended Solvent Cements:

- Oatey All-Purpose Cement: This dual-purpose solvent cement is compatible with both PVC and CPVC. Its unique formulation ensures strong bonds for both materials, making it a reliable choice for various applications.

- Weld-On 724 CPVC Solvent Cement: Specifically designed for CPVC, this solvent cement offers excellent adhesion and can withstand higher temperatures. It provides a secure bond that can handle the demands of hot water systems.

- Hercules Clear PVC Cement: Ideal for joining PVC pipes and fittings, this solvent cement provides reliable bonding strength. It is easy to apply and creates a durable connection that resists pressure and stress.

Consult the Manufacturer:

To identify compatible solvent cements, always consult the manufacturer’s instructions or seek advice from a plumbing professional. Some manufacturers offer dual-purpose solvent cements that are suitable for both PVC and CPVC, providing a convenient solution for those working with both materials. These dual-purpose solvent cements have specific formulations or additives that ensure compatibility and optimal bonding strength.

Proper Application:

To achieve optimal results, follow the manufacturer’s instructions carefully. This includes preparing the surface by cleaning and roughening it, applying the solvent cement correctly using a brush or applicator, and allowing sufficient curing time for the bond to strengthen. Proper storage of solvent cements is also essential to maintain their effectiveness. Store them in a cool, dry place away from direct sunlight and heat sources.

Tips for Properly Applying Solvent Cement to Create a Reliable Bond

Creating a strong and reliable bond between PVC and CPVC pipes and fittings is essential for a leak-proof plumbing system. One of the key components in achieving this bond is solvent cement. Solvent cement works by chemically bonding the PVC surfaces together, ensuring a secure connection. In this article, we will discuss some important tips for properly applying solvent cement to create a reliable bond.

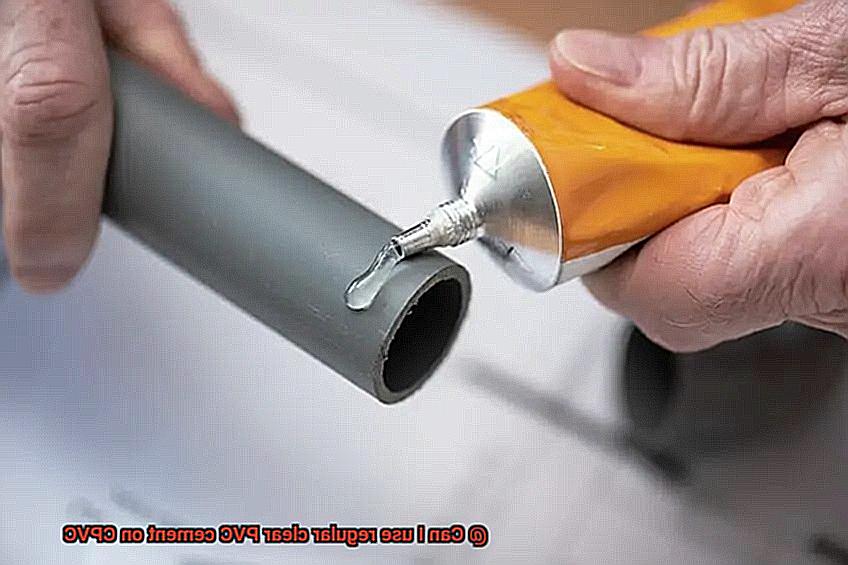

Clean and Dry Surfaces

Before applying solvent cement, it is crucial to clean the surfaces of the PVC and CPVC pipes and fittings. Use a clean cloth or brush to remove any dirt, grease, or debris. Any contaminants on the surfaces can interfere with the bonding process and weaken the connection. Additionally, ensure that the surfaces are dry before applying the cement.

To create a reliable bond, it is important to use a PVC cleaner or primer before applying solvent cement. This cleaner helps remove any dirt or debris that may still be present on the surfaces, ensuring a clean bonding surface. Apply the cleaner according to the manufacturer’s instructions and allow it to dry completely before proceeding with the next step.

Apply a Thin Layer of Cement

When applying solvent cement, it is important not to use too much. Apply a thin layer of cement to both the PVC pipe and the CPVC fitting. Using too much cement can lead to excess buildup, which can weaken the bond. Use a brush or applicator to evenly spread the cement on the surfaces, ensuring full coverage.

Remember to work quickly when applying solvent cement as it tends to dry fast. Apply an even layer of cement on both surfaces, making sure not to miss any areas. The thickness of the cement layer should be enough to cover the entire surface without excess buildup.

Align and Insert

After applying the solvent cement, quickly insert the PVC pipe into the CPVC fitting, ensuring a tight fit. Make sure that the parts are properly aligned before pushing them together firmly. This ensures that the cement spreads evenly and creates a strong bond. Rotate the pipe slightly to ensure that the cement covers the entire surface and removes any trapped air.

When inserting the pipe into the fitting, be mindful of any twist or misalignment. A secure and tight fit is crucial for a reliable bond. Make sure to insert the pipe fully into the fitting until it reaches the stop. Apply even pressure to ensure that the cement is distributed evenly between the surfaces.

Allow Sufficient Curing Time

Once the parts are joined together, hold them in place for a few seconds to allow the cement to set. The curing time may vary depending on the specific type of solvent cement being used, so it is important to refer to the manufacturer’s instructions for guidance. Avoid disturbing or putting stress on the joint while it is curing to prevent any potential weakening of the bond.

p4gDV6Pe7iI” >

Conclusion

Yes, you can use regular clear PVC cement on CPVC.

It is important to note that while the two types of pipes may appear similar, they are made from different materials and have different temperature and pressure ratings. Regular PVC cement may not provide the same level of bond strength and durability when used on CPVC.

It is recommended to use a solvent specifically formulated for CPVC to ensure a secure and long-lasting connection between CPVC pipes and fittings. This will help prevent leaks and potential damage to your plumbing system.

So, while it may be tempting to use regular PVC cement on CPVC due to its availability or cost-effectiveness, it’s best to invest in the appropriate solvent for CPVC applications.