Are you curious about using Permatex on intake manifold gaskets?

Contents

- 1 What Is Permatex?

- 2 What Are Intake Manifold Gaskets?

- 3 What Types of Sealants Does Permatex Offer?

- 4 Preparing the Surfaces for Sealing

- 5 Applying the Sealant to Intake Manifold Gaskets

- 6 Benefits of Using Permatex on Intake Manifold Gaskets

- 7 Limitations of Using Permatex on Intake Manifold Gaskets

- 8 Regular Inspection and Maintenance of Intake Manifold Gaskets

- 9 Conclusion

Well, look no further. It’s a question that often pops up when tackling automotive repairs or maintenance, and it deserves a thorough answer.

Permatex, a trusted name in automotive adhesives and sealants, boasts a range of products that claim to work wonders on intake manifold gaskets. But before you dive headfirst into the world of Permatex, it’s crucial to understand the pros and cons of using their products for this specific task.

In this blog post, we’ll delve into the benefits of employing Permatex on intake manifold gaskets while also exploring any potential drawbacks. By the end, you’ll be armed with all the knowledge necessary to make an informed decision for your next project.

So let’s jump right in and see if Permatex is truly the perfect fit for you.

What Is Permatex?

Permatex, the go-to brand for adhesive and sealant products in the automotive industry, has been a trusted name since its founding in 190With a commitment to quality and innovation, Permatex offers a wide range of high-quality products designed to provide strong bonds and reliable seals. In this article, we will explore what Permatex is, how it works, and its applications in the automotive world.

Types of Permatex:

Permatex boasts an impressive lineup of adhesive and sealant products that cater to various needs and requirements. Their silicone-based sealants are renowned for their ability to withstand high temperatures and resist oil and coolant leaks. For metal-to-metal sealing applications, their anaerobic sealants provide exceptional bonding strength. Furthermore, their gasket makers are specifically formulated to ensure excellent sealing properties.

Applications:

Permatex products find extensive use in the automotive industry. From sealing engine components like intake manifold gaskets to preventing vacuum leaks, coolant leaks, and air intake issues, these sealants are essential for maintaining peak performance. In addition, Permatex products come in handy for bonding metal surfaces together and repairing cracks or leaks. Whether you need to seal an oil pan or bond plastic parts, Permatex has a solution for you.

Advantages:

Permatex products offer numerous advantages that set them apart from the competition. Their high quality ensures durability and longevity, making them ideal for demanding automotive applications. These sealants are engineered to withstand extreme temperatures and resist common automotive fluids like oil and coolant. With excellent bonding strength, Permatex adhesives provide reliable solutions for critical applications. Moreover, their availability in different forms – liquid, paste, and tape – makes them versatile and easy to use.

Disadvantages:

While Permatex offers many advantages, it’s important to note that sealants should not be considered a permanent fix for severely damaged or worn-out gaskets. In such cases, it is recommended to replace the gaskets rather than relying solely on sealants. Additionally, proper surface preparation and following manufacturer instructions are crucial for achieving optimal results.

What Are Intake Manifold Gaskets?

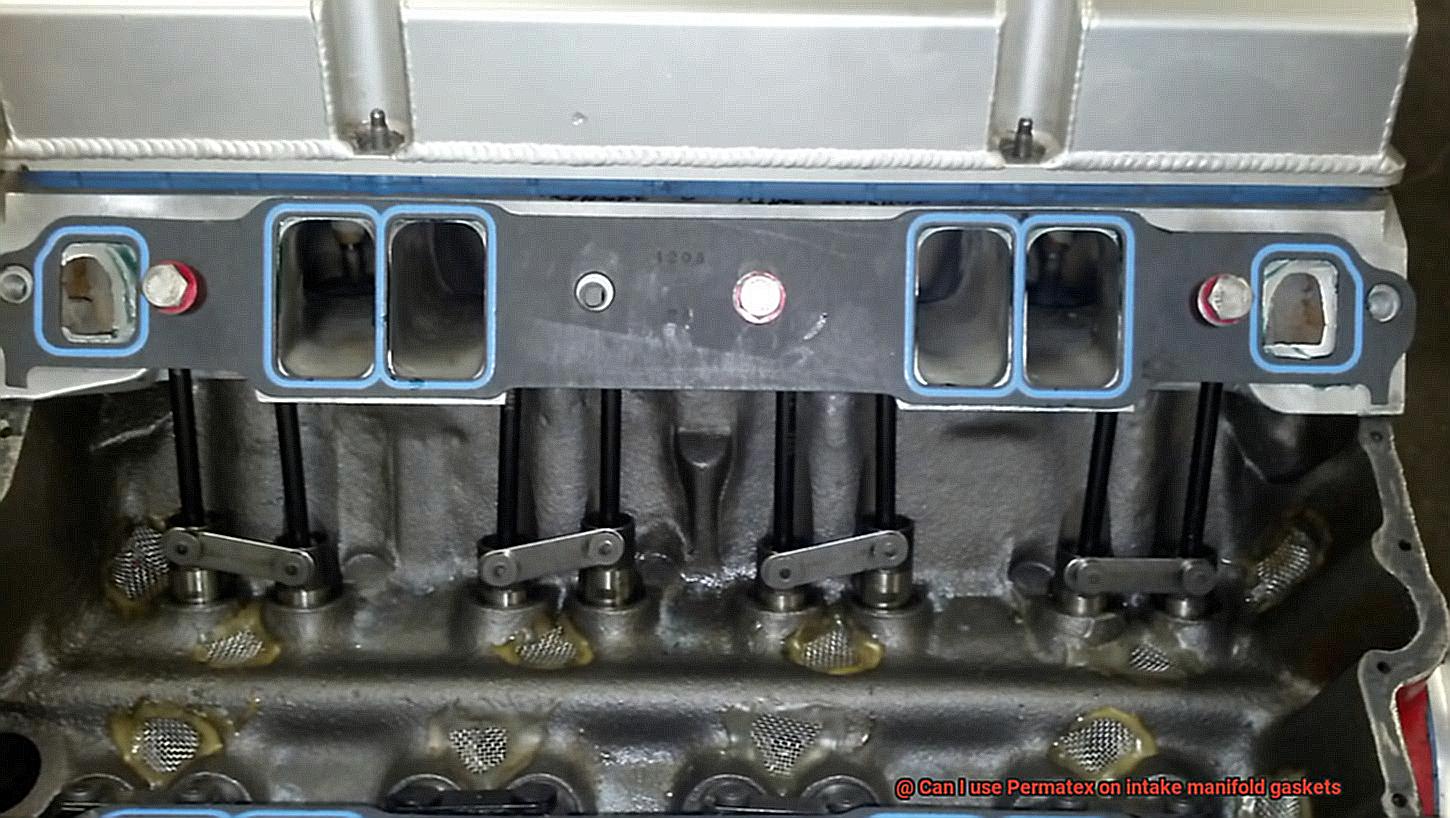

Intake manifold gaskets, though not the flashiest or most exhilarating part of an engine, are an essential component that significantly contributes to its performance. These small yet powerful gaskets serve the crucial role of sealing the connection between the intake manifold and the cylinder head, ensuring that the engine receives the perfect blend of air and fuel for optimal combustion.

Picture your engine as a happening party, with air and fuel as the esteemed guests. The intake manifold gaskets act as the vigilant bouncers, allowing only the right guests to enter while preventing any gatecrashers from sneaking through. Without these gaskets, air and fuel could leak out, leading to a multitude of problems that can hamper your engine’s performance.

One of the primary ways in which intake manifold gaskets impact engine performance is by preserving the integrity of the intake system. Any leaks in this system can result in a loss of pressure or vacuum, ultimately reducing power and fuel efficiency. In severe cases, these leaks can even cause significant damage to the engine.

Moreover, intake manifold gaskets play an instrumental role in directing the flow of air and fuel within the intake system. Equipped with specific channels and ports, they steer this mixture towards the combustion chamber, ensuring a swift and efficient journey. This optimization of performance and enhancement of overall efficiency are made possible by these unsung heroes.

When it comes to selecting intake manifold gaskets, various types are available on the market. The common options include rubber gaskets, composite gaskets, and metal gaskets. Each type offers its own set of advantages and disadvantages.

Rubber gaskets often serve as the most affordable option while providing reliable sealing capabilities. However, their durability may not match that of other materials, potentially necessitating more frequent replacements.

Composite gaskets strike a balance between cost-effectiveness and durability. Constructed using a combination of materials such as rubber and metal, they offer a robust seal without breaking the bank.

Metal gaskets, on the other hand, provide the highest level of durability, capable of withstanding extreme temperatures and pressures. However, they tend to be more expensive and often require professional installation.

To ensure optimal performance and suit your specific engine and driving needs, it is crucial to select the appropriate type of gasket. Seeking advice from a trusted mechanic or conducting thorough research can help you make an informed decision.

What Types of Sealants Does Permatex Offer?

Permatex is a renowned manufacturer known for its wide range of sealants and adhesives designed for automotive applications. When it comes to intake manifold gaskets, Permatex offers several sealants that provide reliable and long-lasting seals, ensuring optimal engine performance. In this article, we will explore the different types of sealants Permatex offers for intake manifold gaskets, their features, benefits, and best practices for application.

Ultra Black Maximum Oil Resistance RTV Silicone Gasket Maker:

Permatex’s Ultra Black Maximum Oil Resistance RTV Silicone Gasket Maker is a popular choice for intake manifold gaskets. This sealant creates reliable seals on a variety of surfaces and is specifically formulated to withstand high torque and resist oil and other automotive fluids. With its exceptional resistance to high temperatures and pressures, it ensures a tight and leak-free seal, preventing vacuum leaks and air intake issues.

High-Temp Red RTV Silicone Gasket Maker:

The High-Temp Red RTV Silicone Gasket Maker is another excellent option from Permatex. Engineered to withstand extreme temperatures, this sealant is ideal for intake manifold gaskets exposed to high heat. Its exceptional adhesion and flexibility ensure a secure and durable seal that can handle the rigorous demands of the engine.

Copper Spray-A-Gasket Hi-Temp Adhesive Sealant:

Permatex’s Copper Spray-A-Gasket Hi-Temp Adhesive Sealant is a versatile option suitable for various surfaces, including metal, rubber, and paper gaskets. Designed to create a flexible and heat-resistant seal, it excels in preventing leaks and ensuring proper sealing even in demanding conditions. This sealant is an excellent choice for intake manifold gaskets as it effectively prevents coolant leaks and maintains optimal engine performance.

Aviation Form-A-Gasket No. 3 Sealant:

Permatex also offers the Aviation Form-A-Gasket No. 3 Sealant, which remains flexible and pliable even after prolonged exposure to high temperatures and chemicals. This non-hardening sealant is perfect for intake manifold gaskets, providing a reliable seal that resists leaks caused by vibration or thermal expansion. Its durability and versatility make it an ideal choice for sealing critical engine components.

Choosing the Right Sealant and Application Tips:

When using Permatex sealants on intake manifold gaskets, it’s crucial to select the most suitable product for your specific needs. Carefully read and follow the instructions provided by Permatex for proper application. Thoroughly clean the surfaces before applying the sealant to ensure optimal adhesion. Adhere to the recommended curing time and temperature for best results. Keep in mind that while Permatex offers high-quality sealants, it’s always wise to consult your vehicle’s manufacturer or a professional mechanic for compatibility and proper application.

Preparing the Surfaces for Sealing

Before applying any sealant, it is crucial to prepare the surfaces properly. This ensures that the sealant adheres well and provides a reliable seal. The process of preparing surfaces for sealing involves several key steps.

First, the surfaces must be thoroughly cleaned. Use a suitable solvent or cleaner to remove dirt, grease, or old sealant residue. Different surfaces may require different cleaning methods. For rubber or silicone surfaces, a mild detergent and water solution should suffice. For metal surfaces, a stronger solvent may be necessary to remove oil or grease.

Once the surfaces are clean, they must be dried completely. Moisture can interfere with the bonding process and compromise the effectiveness of the sealant.

Next, roughen the surfaces slightly using sandpaper or a wire brush. This creates a better bond between the gasket and the sealing surface, ensuring a tighter seal. Be careful not to damage anything—just a few strokes to remove imperfections and smooth out uneven areas.

After roughening, clean the surfaces again to remove any debris or particles generated during the process. This ensures that no foreign substances interfere with the sealing process.

Some surfaces may require additional treatment before applying the sealant. If there are cracks or imperfections on the sealing surface, use an appropriate filler or epoxy to repair them.

Finally, follow the manufacturer’s instructions when applying the sealant. Apply it in the recommended thickness and allow it to cure for the specified time before assembling the components.

Applying the Sealant to Intake Manifold Gaskets

Today, we’re going to explore the art of applying Permatex sealant to intake manifold gaskets. Just like a skilled artist carefully prepares their canvas before creating a masterpiece, we’ll walk you through the steps to ensure a tight and reliable seal for your engine.

Step 1: Cleanse the Surfaces:

Imagine you’re an artist preparing your canvas. You start by cleaning it thoroughly, removing any dirt or imperfections that could hinder your artwork. Similarly, before applying sealant, it’s crucial to cleanse the surfaces of both the intake manifold and the gasket. Any dirt, oil, or residue can compromise the effectiveness of the sealant. Use a gasket scraper or a wire brush to remove old gasket material or debris from the mating surfaces.

Step 2: Brushing for Texture:

Just as an artist gently strokes sandpaper on a canvas to create texture and depth, lightly roughen the surfaces with sandpaper or a wire brush. This step enhances the bond between the gasket and sealing surface, ensuring a secure connection. Be cautious not to damage anything – just a few strokes to remove imperfections and smooth out uneven areas will do.

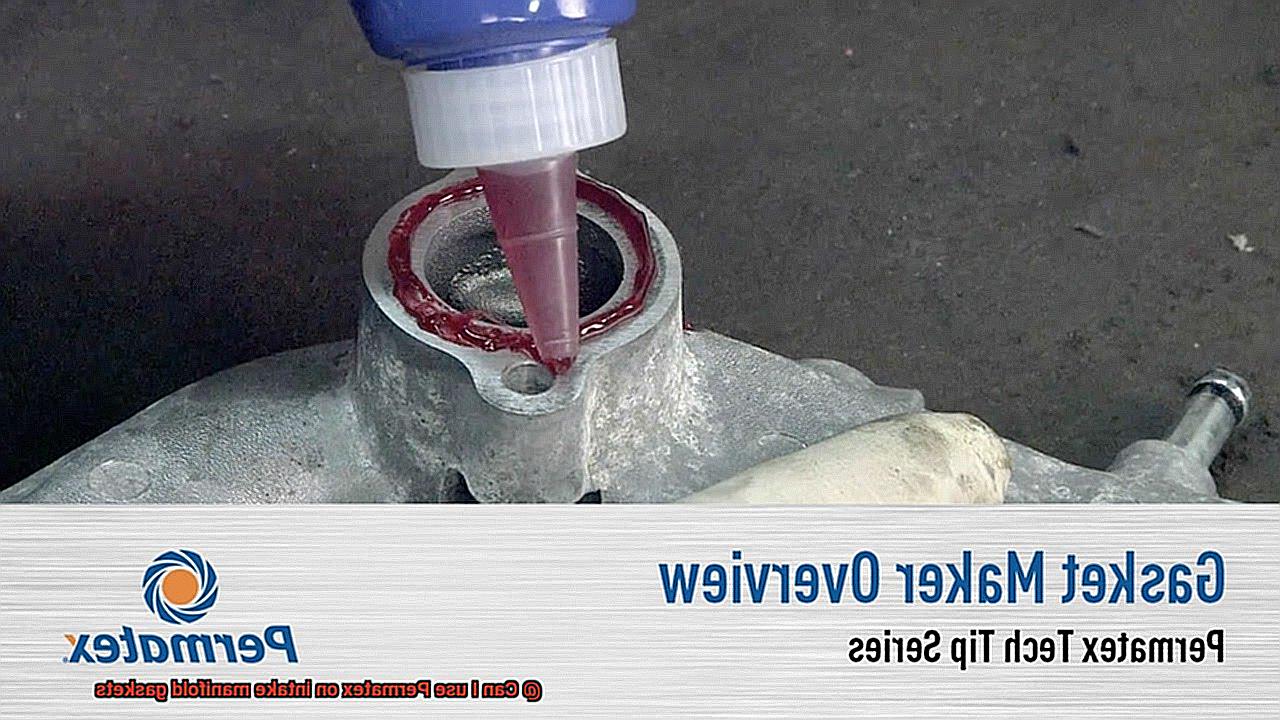

Step 3: Apply Sealant with Precision:

Now it’s time to apply the Permatex sealant. Think of it as following a recipe for your masterpiece. Apply a thin and even layer of sealant to both sides of the intake manifold gasket. Imagine your brush gliding effortlessly across the canvas, creating beautiful strokes. In this case, carefully apply the sealant in a continuous line along the entire perimeter of the gasket. Take care not to apply too much sealant, as excess can squeeze out and potentially cause issues.

Step 4: Proper Placement:

After applying the sealant, it’s time to carefully place the intake manifold onto the engine block. Imagine fitting together puzzle pieces to create a coherent image. Align the manifold with the mounting holes and ensure that the gasket is properly seated. This step is crucial for achieving a tight seal and preventing leaks.

Step 5: Tighten to Specifications:

Just as an artist knows the perfect amount of pressure to apply to their brush, it’s important to follow the torque specifications provided by the vehicle manufacturer when tightening the intake manifold bolts. This ensures a proper seal and prevents any leaks.

Step 6: Allow Time to Cure:

Now that you’ve completed your masterpiece, it’s time to let it dry and cure. Allow the sealant to cure as per the manufacturer’s instructions. This may involve letting it sit for a specific period or allowing it to set overnight before starting the engine. Patience is key here, just as it is with waiting for paint to dry on a canvas.

Benefits of Using Permatex on Intake Manifold Gaskets

When it comes to taking care of your engine, every detail matters. That’s why using Permatex on your intake manifold gaskets is a smart move. This adhesive sealant, specifically designed for automotive applications, offers a wide range of benefits that can protect and enhance your engine’s performance.

First and foremost, Permatex provides a reliable and long-lasting seal between the intake manifold and the engine block. This is crucial because any leaks in this area can lead to serious engine damage. By creating a tight seal, Permatex helps prevent coolant or oil from leaking out and causing harm to your engine components.

One of the standout features of Permatex is its ability to withstand high temperatures and pressure. Engines generate a lot of heat, especially during intense driving conditions. Permatex is specially formulated to handle these extreme temperatures without breaking down or losing its adhesive properties. It can also withstand the pressure created by the combustion process, ensuring that it stays in place even under the most demanding circumstances.

In addition to its heat and pressure resistance, Permatex is highly resistant to chemicals such as gasoline, oil, and coolant. This means that even when exposed to these substances, the sealant remains intact and effective. This durability ensures that your intake manifold gaskets stay securely in place for a longer period of time, reducing the need for frequent replacements.

Not only does Permatex provide excellent adhesion properties, but it is also incredibly easy to apply. You don’t need any special tools or equipment – just a tube or bottle of Permatex sealant and a steady hand. Simply apply the sealant directly onto the gasket surface, and you’re good to go. This ease of use saves both time and money compared to replacing the entire gasket.

Using Permatex on your intake manifold gaskets can also contribute to improved engine performance. By maintaining a proper seal, it ensures that the air and fuel mixture is optimal, leading to better combustion and increased engine efficiency. This can result in improved power, fuel economy, and overall performance.

Limitations of Using Permatex on Intake Manifold Gaskets

Your car is your pride and joy, and you want to keep it running smoothly for years to come. But when it comes to using Permatex on your intake manifold gaskets, there are some limitations you need to be aware of. In this article, we’ll dive into the potential drawbacks of using Permatex in this specific application, and why it may not provide the reliable seal and performance you’re looking for.

Temperature Resistance:

- Permatex is not designed to withstand the high temperatures that intake manifold gaskets are exposed to.

- The intense heat from the engine and exhaust gases can reach temperatures well over 200 degrees Celsius, beyond the operating range of most Permatex products.

- This can cause the adhesive to break down, leading to leaks and potential engine damage.

Sealing Capability:

- Intake manifold gaskets play a crucial role in sealing off the intake manifold from the engine block.

- Permatex may not have the strength or flexibility to create a reliable seal between these two components.

- Constant vibrations and movements experienced by the engine can further compromise the sealing capability of the gasket.

- This can result in vacuum leaks, loss of power, poor fuel efficiency, and even engine misfires.

Compatibility with Mating Surfaces:

- Permatex may not be able to compensate for any irregularities or imperfections in the mating surfaces of the intake manifold and engine block.

- These imperfections can prevent a proper seal from being formed, leading to leaks and decreased performance.

- Manufacturers often recommend specific types of gasket materials designed for intake manifold applications that can withstand high temperatures and provide a reliable seal.

Temporary Solution:

- While using Permatex on intake manifold gaskets may be seen as a temporary or emergency fix, it is not a recommended long-term solution.

- It’s best to replace the gasket with a suitable replacement designed specifically for this application.

- This ensures that the gasket can provide the necessary sealing function and maintain the integrity of the engine’s performance and reliability.

Regular Inspection and Maintenance of Intake Manifold Gaskets

Today, we’re diving into a topic that often goes unnoticed but is vital for optimal engine performance – the regular inspection and maintenance of intake manifold gaskets. While using adhesives like Permatex may seem like a quick fix, let’s explore why it may not be the reliable solution you’re hoping for.

Temperature Resistance:

Intake manifold gaskets face extreme temperatures from the engine and cooling system, causing them to expand and contract. Unfortunately, common adhesives like Permatex may not have the necessary temperature resistance to maintain a strong seal over time. This can lead to leaks and potential engine damage.

Sealing Capability:

Intake manifold gaskets are designed specifically to create an airtight seal between the intake manifold and engine block. This seal is critical for maintaining proper air and coolant flow within the engine. While adhesives may provide a temporary fix, they may not offer the same level of sealing capability as dedicated intake manifold gaskets. This can result in reduced engine performance and efficiency.

Compatibility with Mating Surfaces:

Intake manifold gaskets are made from materials carefully selected for compatibility with mating surfaces. These materials withstand the chemicals and fluids present in the engine environment. Using adhesives may not provide the same level of compatibility, potentially leading to chemical reactions or corrosion that compromise the gasket’s integrity.

Suitable Replacement Gasket:

Instead of relying on adhesives, it’s best to opt for a suitable replacement gasket. OEM or reputable aftermarket gaskets are specifically designed for your vehicle make and model, ensuring proper fitment and sealing. These gaskets are engineered to withstand demanding engine conditions, offering superior performance and longevity compared to adhesives.

BMIgJcviWBA” >

Conclusion

In conclusion, it is not recommended to use Permatex on intake manifold gaskets. While Permatex is a reliable adhesive for various automotive applications, it is not designed specifically for sealing intake manifold gaskets. These gaskets require a specialized sealant that can withstand high temperatures and pressures. Using Permatex may lead to leaks and potential engine damage.

Instead, it is best to use a dedicated intake manifold gasket sealant that is formulated to withstand the unique conditions of the intake manifold. These sealants are designed to provide a reliable and long-lasting seal, ensuring optimal performance and preventing any air or coolant leaks.

By using the appropriate sealant for your intake manifold gaskets, you can ensure that your engine operates smoothly and efficiently without any complications. It’s always important to follow manufacturer recommendations and consult with professionals if you have any doubts or concerns.

Remember, taking proper care of your vehicle’s components will ultimately contribute to its longevity and overall performance.