Are you ready to give your kitchen a jaw-dropping makeover? Well, look no further than the world of countertop lamination. It’s the budget-friendly way to transform your space into a culinary paradise. But hold on a second, can you really use liquid nails, that sticky savior of DIY projects, to laminate countertops? Buckle up and get ready for an adventure through the wild world of countertop lamination as we explore whether liquid nails could be the answer to your dreams.

Countertop lamination is all about adding a layer of laminate material onto your existing countertop. Not only does this protect your precious surface from stains and scratches, but it also gives your kitchen a fresh new vibe. While traditional laminate adhesive is usually recommended for this job, some brave souls have dared to venture into uncharted territory by trying out liquid nails.

So here’s what we’re going to do: we’ll take you on a journey through the pros and cons of using liquid nails for countertop lamination. We’ll spill the beans on how easy it is to apply, how long it lasts, and any sneaky drawbacks you should watch out for. By the end of this blog post, you’ll have all the info you need to decide if liquid nails are your secret weapon for revamping those countertops.

So grab yourself a cup of coffee (or maybe something stronger) because we’re about to dive headfirst into the fascinating world of liquid nails and countertop lamination. Let’s find out if this sticky stuff is truly worthy of being crowned king in your kitchen.

Advantages of Using Liquid Nails

Contents

- 1 Advantages of Using Liquid Nails

- 2 Disadvantages of Using Liquid Nails

- 3 Why Contact Cement Is Recommended for Laminate Countertops

- 4 How to Use Contact Cement for Laminate Countertops

- 5 Benefits of Using Contact Cement for Laminate Countertops

- 6 Common Mistakes When Applying Contact Cement

- 7 Alternatives to Contact Cement and Liquid Nails

- 8 Conclusion

When it comes to tackling DIY projects, having the right adhesive can make all the difference. One adhesive that stands out among the rest is Liquid Nails. In this article, we will explore the advantages of using Liquid Nails for laminating countertops and other projects, highlighting its strong bond, versatility, easy application, quick drying time, moisture resistance, and cost-effectiveness.

Strong Bond:

Liquid Nails is engineered to create a strong and durable bond between different materials. When used for laminating countertops, it ensures that the laminate stays securely in place, even with regular use and exposure to moisture. Say goodbye to concerns about your countertop peeling or coming loose.

Versatility:

One of the greatest advantages of Liquid Nails is its versatility. It can be used on various surfaces, making it suitable for laminating countertops made from different materials such as wood, particleboard, or plywood. With Liquid Nails, you won’t need multiple adhesives for different surfaces – one product does it all.

Easy Application:

Liquid Nails is designed with ease of use in mind. Its convenient tube packaging and nozzle allow for precise and controlled dispensing of the adhesive. This means no messy application or uneven coverage. Even if you are new to DIY projects, you can confidently apply Liquid Nails and achieve professional-looking results.

Quick Drying Time:

Time is of the essence when it comes to DIY projects, especially ones that involve laminating countertops. Luckily, Liquid Nails has a relatively quick drying time. Once applied, it starts setting within minutes, allowing you to complete your project faster and minimizing downtime.

Moisture Resistance:

Countertops in areas like kitchens and bathrooms are constantly exposed to moisture. Liquid Nails is specially formulated to be moisture-resistant, ensuring that your laminated countertop remains securely bonded, even in high-moisture environments. No need to worry about water damage compromising the integrity of your project.

Cost-Effectiveness:

DIY projects often come with a budget, and Liquid Nails is a cost-effective adhesive solution. Compared to specialized countertop adhesives, Liquid Nails is more affordable and doesn’t require additional tools or equipment for application. With Liquid Nails, you can achieve professional results without breaking the bank.

Disadvantages of Using Liquid Nails

In this article, we will explore the disadvantages of using Liquid Nails, including its lack of flexibility, lengthy drying time, general-purpose composition, potential health hazards, and difficulty in removal.

Lack of Flexibility:

Countertops are constantly exposed to temperature changes, moisture, and pressure. Unfortunately, Liquid Nails is a rigid adhesive that may not withstand these movements over time. This lack of flexibility can lead to delamination, compromising the strength and stability of your countertop.

Lengthy Drying Time:

While Liquid Nails dries relatively fast initially, it takes much longer to fully cure. As a result, you may need to clamp or weigh down your countertop for an extended period during the curing process. This inconvenience can delay your project and disrupt your routine.

General-Purpose Composition:

Liquid Nails is not specifically designed for laminate bonding. Unlike specialized laminating adhesives, it may not provide the same level of strength and durability required for countertops. Choosing the wrong adhesive can compromise the longevity and resistance of your laminate countertop against moisture and heat.

Potential Health Hazards:

It is important to note that Liquid Nails contains volatile organic compounds (VOCs), which can be harmful if inhaled or exposed to skin. To ensure safety while using this adhesive, proper precautions such as wearing gloves and working in a well-ventilated area should be taken.

Difficulty in Removal:

Repairing or replacing a laminate countertop bonded with Liquid Nails can be a challenging task. The strong adhesive properties make it difficult to separate the laminate from the substrate without causing damage. This can be problematic if you ever need to make changes or repairs in the future.

Why Contact Cement Is Recommended for Laminate Countertops

When it comes to the installation of laminate countertops, selecting the right adhesive is paramount to ensure a robust and enduring bond. Among the array of options available, contact cement reigns supreme as the adhesive of choice for professionals and DIY enthusiasts alike. In this article, we will delve into the reasons why contact cement is highly recommended for laminate countertops, highlighting its unparalleled strength, durability, and an array of other benefits.

Instant Bonding Power:

The standout feature of contact cement lies in its ability to instantly forge an unyielding bond when the two surfaces are firmly pressed together. This makes it exceptionally well-suited for laminating countertops, where an unbreakable and secure bond is of utmost importance. Unlike other adhesives that necessitate drying time, contact cement allows you to forge ahead with your project without any inconvenient delays.

Resistance to Heat and Moisture:

In kitchens and bathrooms, laminate countertops face the relentless onslaught of heat and moisture on a daily basis. It is precisely in these conditions that contact cement truly excels, as it is specifically engineered to repel these elements with unwavering tenacity. Its watertight seal acts as an impenetrable fortress against potential water damage or warping that could ravage a less resilient adhesive.

Chemical Resistance:

In areas prone to spills and inescapable encounters with cleaning agents, contact cement proves its mettle by displaying exceptional resistance to chemicals and solvents commonly employed in these spaces. This ensures that your laminate countertops remain unscathed and impervious to any cleaning mishaps that may befall them.

Flexibility for Longevity:

Laminate materials possess a propensity to expand and contract due to fluctuations in temperature or humidity. Contact cement’s inherent flexibility deftly accommodates these movements without compromising the bond between the laminate and the countertop. This guarantees that your countertops remain steadfastly in place, undeterred by the passage of time.

Easy Application:

Beyond its dependability, contact cement also earns high marks for its effortless application. Its straightforward process demands minimal tools, making it a conveniently accessible choice for DIY projects. With contact cement, achieving a smooth and seamless finish becomes an achievable reality, ensuring that no unsightly gaps or seams mar the flawless facade of your laminate sheets.

How to Use Contact Cement for Laminate Countertops

Get ready to unleash your creativity and achieve stunning results with this magical adhesive.

Step 1: Prepare for Success

Before you embark on your countertop transformation, ensure that the surface is impeccably clean. Bid farewell to dust bunnies and greasy fingerprints by giving it a thorough scrub with a mild detergent. Let it dry, embracing the anticipation of a superhero cape fluttering in the wind.

Step 2: Slice and Dice

Now it’s time to cut your laminate sheet to fit your countertop’s dimensions. Leave a bit of wiggle room on all sides, like a stylish belt hugging your favorite pair of jeans.

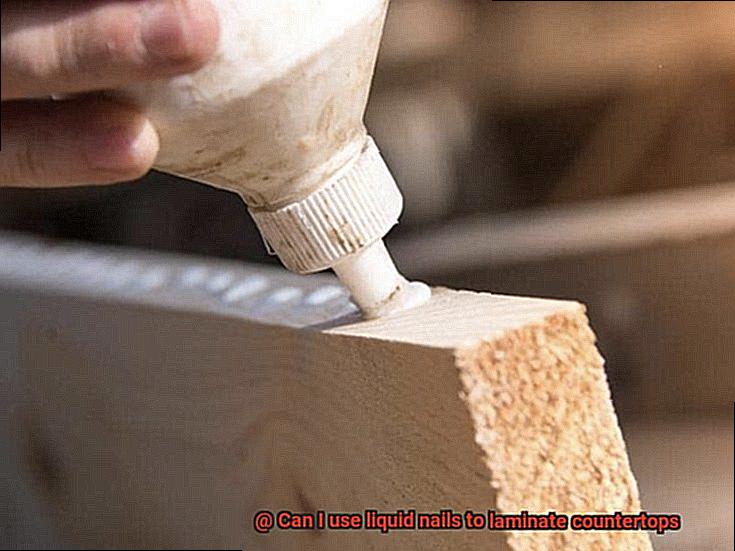

Step 3: The Sticky Situation

Equip yourself with a brush or roller, ready to spread the contact cement. Apply it generously on both the backside of the laminate sheet and the countertop surface. Leave no nooks or crannies untouched.

Step 4: Patience is Key

Exercise restraint and allow the contact cement to dry until it becomes delightfully tacky to the touch. Picture a sticky spiderweb patiently awaiting its prey. This usually takes around 15-20 minutes, but keep an eye on it – different brands have their own time limits.

Step 5: The Perfect Union

It’s showtime. Begin by carefully aligning the laminate sheet with one edge of the countertop. Slowly press it down, savoring the satisfaction as it adheres in all the right places. Use a laminate roller to smooth out any air bubbles, like ironing out wrinkles from your favorite shirt.

Step 6: Trim, Trim, Hooray.

Now it’s time to trim off any excess laminate with finesse. Equip yourself with a router or laminate trimmer, but proceed with caution, my friends. A steady hand and deliberate movements are your allies. Ensure a precise and clean finish, avoiding any accidental chips or damage.

Step 7: Embrace Smoothness

Grab a file or sandpaper and indulge in the art of refinement. Smooth out any rough edges or uneven surfaces, transforming your countertop into a canvas as smooth as a baby’s bottom.

Step 8: Bid Farewell to Stickiness

In this final act, bid adieu to any lingering adhesive residue. Utilize a solvent recommended by the contact cement manufacturer, eradicating every last trace of stickiness.

Benefits of Using Contact Cement for Laminate Countertops

Are you ready to embark on a kitchen or bathroom remodel? If so, laminate countertops are undoubtedly one of the most popular choices for homeowners.

With their durability, affordability, and endless design options, it’s no wonder why they’ve become a staple in modern homes. However, when it comes to installing laminate countertops, there is one essential tool that should not be overlooked: contact cement.

This magical adhesive is specifically designed to bond laminate materials, making it the perfect choice for your countertop project.

So, what exactly makes contact cement the superhero of adhesives? Let’s dive into the benefits:

- Strong and Durable Bond: Contact cement creates a bond that can withstand the test of time. It forms a permanent connection between the laminate and the substrate, ensuring your countertop stays intact for years to come. Say goodbye to worries about your countertop coming apart at the seams.

- Easy Application: Applying contact cement is as easy as spreading butter on toast. It comes in a can or tube and can be easily spread using a brush or roller. Once applied, you just need to let it dry before pressing the laminate into place. Easy peasy.

- Seamless and Smooth Surface: Contact cement ensures a seamless and smooth surface for your countertop. Unlike other adhesives that may leave behind unsightly gaps or ridges, contact cement creates a uniform bond that is virtually invisible. This not only enhances the aesthetic appeal of your countertop but also prevents dirt and bacteria from collecting in hard-to-reach crevices.

- Flexibility: Laminate materials expand and contract with changes in temperature and humidity. Fortunately, contact cement is flexible enough to accommodate these movements without compromising the bond. So go ahead and enjoy your hot cup of coffee without worrying about damaging your countertop.

- Cost-Effective: Saving money is always a plus. Contact cement is an affordable option compared to other adhesives used for laminate countertops. You get a strong and durable bond without breaking the bank – a win-win situation.

- Quick Installation: Time is of the essence, especially during a remodel. The beauty of contact cement is that once it’s dried, your countertop is ready to be used immediately. No more waiting around for hours or days. This speedy installation process allows you to enjoy your new countertop without unnecessary delays.

- Versatile Design Options: Contact cement can be used with various types of laminate materials, allowing you to unleash your creativity. Whether you prefer a classic solid color or a bold pattern, contact cement can bring your vision to life. With endless colors, patterns, and textures to choose from, you can create a countertop that truly reflects your personal style.

Common Mistakes When Applying Contact Cement

With contact cement, you’re on your way to achieving a professional-looking finish. However, it’s important to avoid common mistakes that can lead to a less-than-desirable outcome. Let’s explore these pitfalls and learn how to steer clear of them.

Thorough Surface Preparation:

One of the biggest mistakes is neglecting proper surface preparation. Dust, dirt, and grease can hinder the adhesive’s ability to create a strong bond. Take the time to thoroughly clean both the countertop and laminate. This ensures a solid foundation for a flawless finish.

The Goldilocks Approach:

Finding the perfect balance is essential when applying contact cement. Using too much adhesive creates a sticky mess, increases drying time, and can lead to a weak bond. Conversely, using too little adhesive results in an inadequate bond that won’t withstand the test of time. Follow the manufacturer’s guidelines for the right amount.

Timing is Everything:

Patience is key when working with contact cement. Rushing the drying process by not allowing sufficient time for it to become tacky can result in a weak bond or even complete failure. Take a breather and let the adhesive work its magic before joining the surfaces together.

Apply Even Pressure:

To ensure a strong and uniform bond, apply even pressure across the entire surface. Use a roller or a block of wood to distribute pressure evenly, eliminating air bubbles and uneven areas. Remember, no lumps or bumps allowed.

No Cutting Corners:

Don’t be tempted to cut corners or rush through the application process. Following the manufacturer’s instructions regarding drying time and application process is crucial for optimal results. Taking shortcuts may lead to subpar outcomes and require redoing the entire lamination process.

Prioritize Ventilation:

Proper ventilation is crucial when working with contact cement. The adhesive contains volatile chemicals that release strong fumes. Work in a well-ventilated area or use proper respiratory protection to avoid any adverse health effects.

Alternatives to Contact Cement and Liquid Nails

Luckily, there are alternative options available that can provide the same professional finish without the hassle. In this article, we’ll explore some exciting alternatives to contact cement and Liquid Nails that will have your countertops looking fabulous in no time.

Epoxy Adhesive: The Powerhouse Bonding Solution

When it comes to strength and durability, epoxy adhesive is the go-to option. Not only does it create a rock-solid bond, but it also boasts resistance against moisture, heat, and chemicals. Perfect for kitchens and bathrooms, epoxy adhesive requires mixing the resin and hardener together before application. Applying pressure or using clamps ensures a solid bond that will last for years to come.

Construction Adhesive: Versatility with Dependability

If you need an adhesive that can bond various materials, including laminate countertops, construction adhesive is your answer. This versatile alternative offers resistance against moisture and heat, making it an excellent choice for kitchen and bathroom projects. With its convenient tube packaging, applying construction adhesive is a breeze. Simply clamp or apply pressure during the curing process to achieve maximum strength.

Wood Glue: Embracing Tradition with a Modern Twist

For those who prefer a more traditional approach, waterproof or moisture-resistant wood glue is an excellent alternative. While it requires clamping or pressure during drying to create a strong bond, wood glue is perfect for wet environments like kitchens and bathrooms. Embrace the time-tested method of using wood glue and enjoy a beautiful laminate countertop with confidence.

Polyurethane Adhesive: Flexibility Meets Durability

When flexibility and durability are top priorities, look no further than polyurethane adhesive. This remarkable alternative can withstand temperature changes and moisture, making it ideal for laminating countertops. Applying polyurethane adhesive directly from the tube is a breeze, and clamping or applying pressure during curing ensures a strong and long-lasting bond. Say goodbye to worries about your countertop’s durability and hello to a stunning surface that can withstand the test of time.

Double-Sided Tape: Quick and Convenient Temporary Solution

If you’re in need of a temporary solution or prefer a more temporary bond, double-sided tape can save the day. While it may not offer the same level of durability as other adhesives, it provides a convenient way to adhere laminate materials. Keep in mind that double-sided tape may not be suitable for high-moisture or heat-exposed areas, but it can serve as a handy solution for quick fixes or temporary projects.

WSoaX4kgMeg” >

Conclusion

Yes, you can use liquid nails to laminate countertops.

Liquid nails is a strong adhesive that can bond materials together, including laminate and countertop surfaces. It provides a secure and durable bond that can withstand daily use and moisture exposure.

Additionally, ensure that the surfaces are clean, dry, and free of any debris or grease before applying the liquid nails.