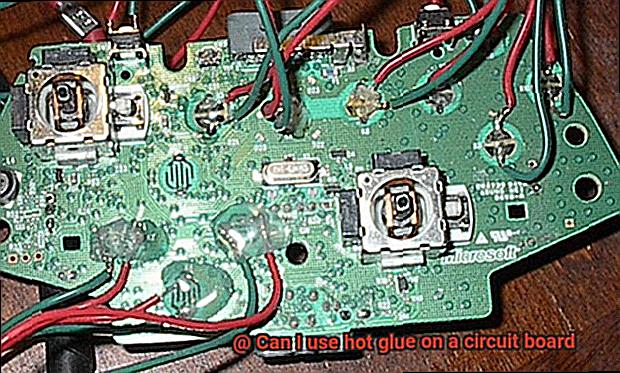

Ready to embark on a thrilling journey into the mesmerizing world of circuit board tinkering? Brace yourself, because as you dive deeper, you’re bound to encounter a multitude of questions and concerns. And one burning inquiry that might cross your mind is this: “Can I use hot glue on a circuit board?”

Ah, hot glue – that trusty companion in countless crafting and DIY projects. Its effortless application, lightning-fast drying time, and adaptability make it an irresistible choice for securing components and insulating connections. But when it comes to electronics and delicate circuitry, tread carefully my friend.

In this blog post, we’ll plunge headfirst into the potential wonders and pitfalls of using hot glue on a circuit board. Our mission? To arm you with all the knowledge you need to make an informed decision. Plus, we’ll dish out some invaluable safety tips so your DIY escapades can unfold smoothly and without any nasty surprises.

So, join us as we unravel the enigmatic realm of hot glue and its potential role in conquering those circuit board challenges.

Understanding the Nature of Hot Glue

Contents

- 1 Understanding the Nature of Hot Glue

- 2 Potential Risks of Using Hot Glue on a Circuit Board

- 3 Hot Glue and Heat Generation in Electronic Devices

- 4 Removing Hot Glue from a Circuit Board

- 5 Advantages of Specialized Adhesives for Electronics and Circuit Boards

- 5.1 Advantage 1: Unmatched Electrical Insulation

- 5.2 Advantage 2: Turbocharged Thermal Conductivity

- 5.3 Advantage 3: Herculean Mechanical Bonding

- 5.4 Advantage 4: Material Compatibility Mastery

- 5.5 Advantage 5: Chemical Resistance Wizardry

- 5.6 Advantage 6: Low Outgassing Sorcery

- 5.7 Advantage 7: Effortless Application and Curing Mastery

- 6 Types of Specialized Adhesives for Electronics and Circuit Boards

- 6.1 Epoxy Adhesives: Strong Bonds and Excellent Insulation

- 6.2 Silicone Adhesives: Flexibility and High Temperature Resistance

- 6.3 Acrylic Adhesives: Fast Curing Time and Good Conductivity

- 6.4 Polyurethane Adhesives: Resistance to Chemicals and Moisture

- 6.5 Considerations for Selecting the Right Adhesive

- 7 How to Properly Use Specialized Adhesives on a Circuit Board

- 8 Conclusion

Hot glue, a versatile adhesive used in DIY projects and crafts, must be approached with caution when considering its use on circuit boards. Delicate electronic components require specific adhesives to ensure their integrity and functionality. In this article, we will explore the potential risks of using hot glue on circuit boards and discuss alternative options better suited for electronic applications.

The Risks of Using Hot Glue on Circuit Boards:

- Thermal Stress: Hot glue’s high melting point can expose circuit boards to temperatures that damage or stress delicate electronic components. The heat generated during operation, combined with the heat resistance limitations of circuit board materials, can lead to malfunction or component failure.

- Lack of Electrical Conductivity: Hot glue is not electrically conductive, disrupting the flow of electricity and interfering with circuit performance. This is especially problematic when applied over electrical connections or traces on the circuit board.

- Incompatibility with Circuit Board Materials: Circuit boards, typically made of non-conductive materials like fiberglass or epoxy resin, have low heat resistance. Applying hot glue directly onto these materials can cause damage and compromise the board’s functionality.

Alternatives to Consider:

- Epoxy-Based Adhesives: Designed for electronics, these adhesives have low melting points that prevent excessive heat exposure to delicate components. They offer excellent electrical insulation and thermal stress resistance.

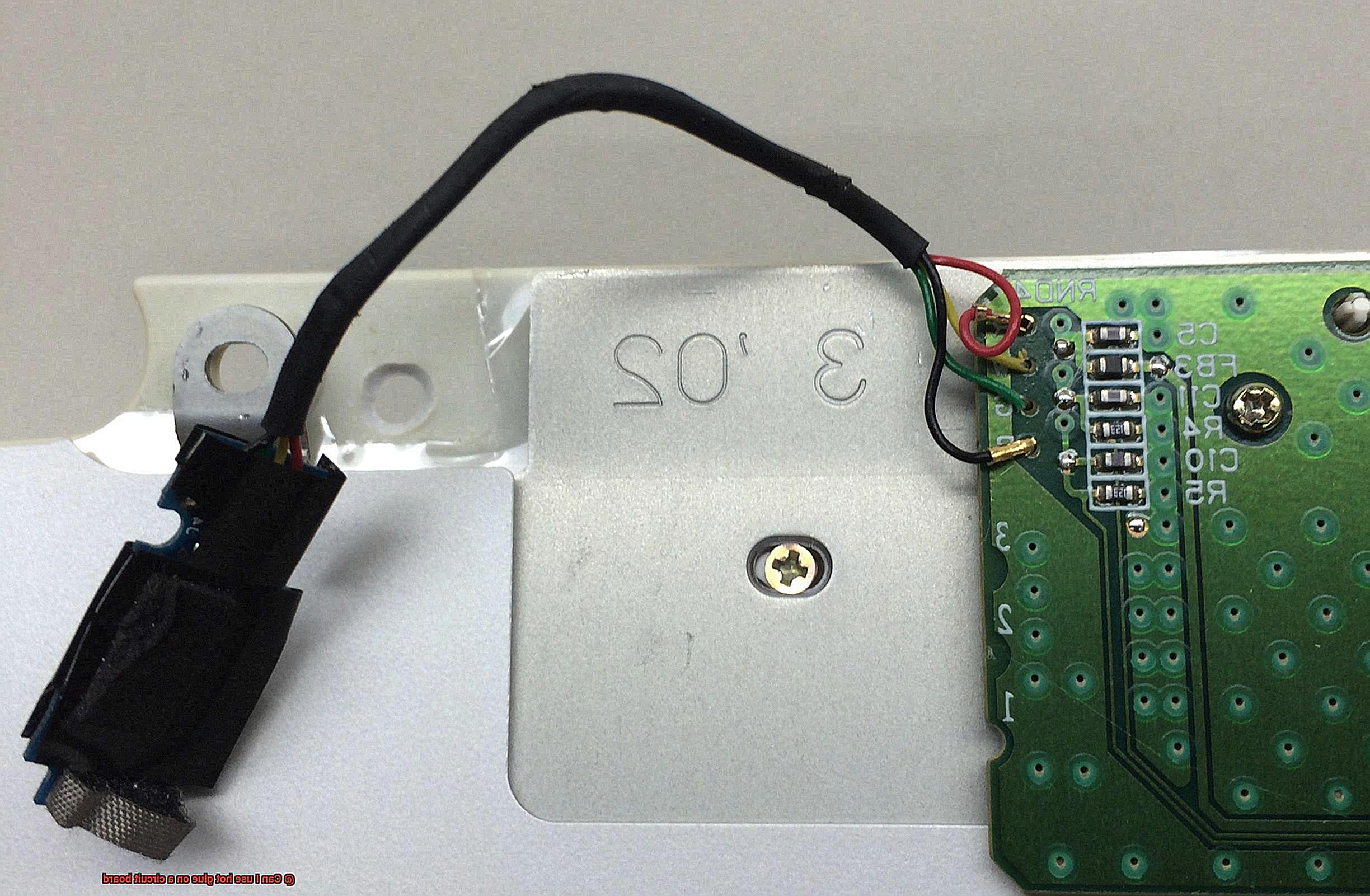

- Conductive Adhesives: For applications requiring electrical conductivity, conductive adhesives with conductive particles are suitable alternatives. They allow electricity flow while maintaining a secure bond.

- Double-Sided Tape: In some cases, double-sided tape can replace hot glue, providing a secure bond without exposing the circuit board to high temperatures or interfering with electrical performance.

Potential Risks of Using Hot Glue on a Circuit Board

Think again. While it may seem like a quick fix, there are potential risks that could melt your circuit board dreams. In this blog post, we will delve into the dangers of using hot glue on a circuit board and uncover why alternative methods are a must. Get ready to stick around and discover the truth.

Damage to the Circuit Board:

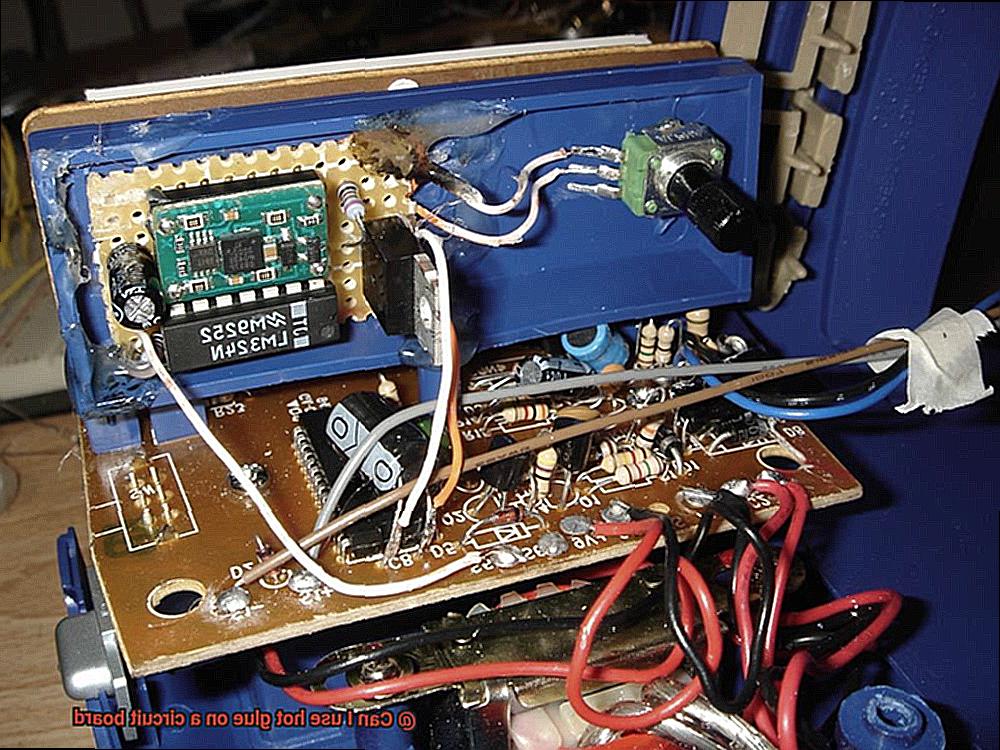

The scorching heat of hot glue can wreak havoc on sensitive components, melting them or causing short circuits. One wrong move during application can spell disaster.

Difficulty in Repairs or Modifications:

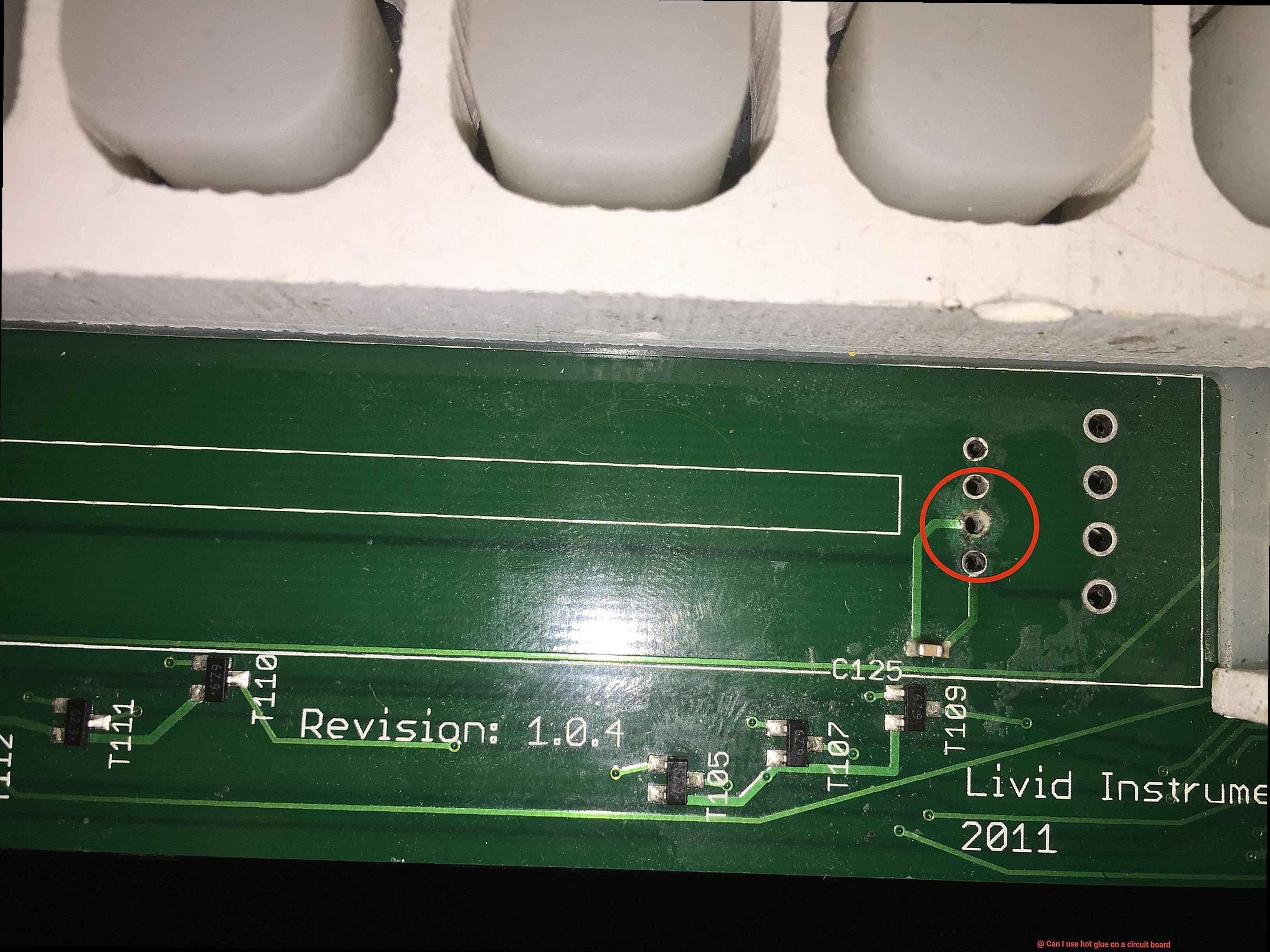

Once hot glue infiltrates tiny crevices, it becomes a stubborn nemesis. Removing or repairing components in the future becomes an uphill battle, leaving you stuck in a sticky situation.

Interference with Electrical Flow:

Hot glue’s non-conductive nature poses a threat to the smooth flow of electricity on your circuit board. Performances suffer, and functionality takes a nosedive.

Deterioration over Time:

The adhesive properties of hot glue can crumble under pressure, especially when exposed to heat or moisture. Loose components, faulty connections, and potential malfunctions become your worst nightmares.

Insufficient Insulation:

Certain circuit board components require insulation to shield against electrical interference and short circuits. Hot glue falls short in providing the protection they need, leaving them vulnerable.

Difficult Removal:

Peeling off hot glue without damaging the delicate circuit board is like trying to untangle a spider’s web with bare hands. Future repairs or modifications turn into time-consuming frustrations.

Warranty Voidance:

Using hot glue on your circuit board may send your device’s warranty up in smoke. Manufacturers have strict repair guidelines, and deviating from them risks invalidating your warranty.

Hot Glue and Heat Generation in Electronic Devices

Let’s dive deep into the sizzling world of hot glue and its impact on heat generation in our beloved gadgets.

Electronic devices are no strangers to the heat. They generate it like a fiery dragon, but if that heat can’t escape, trouble brews. And here comes hot glue, our knight in shining adhesive armor. But beware, for this knight can turn into a villain if applied incorrectly or excessively.

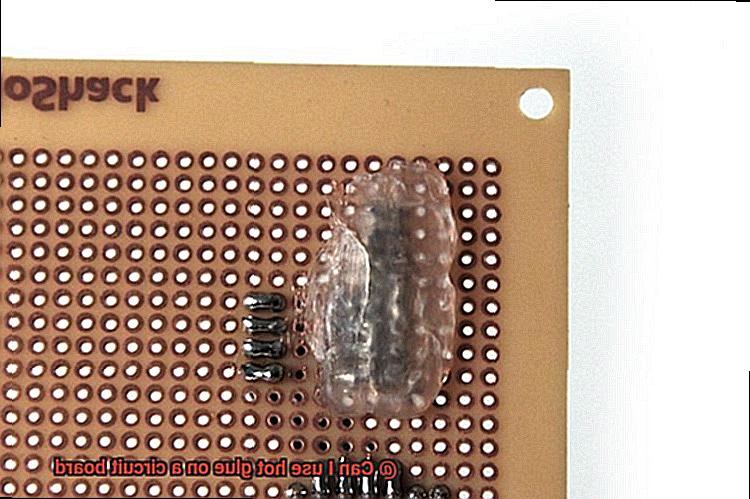

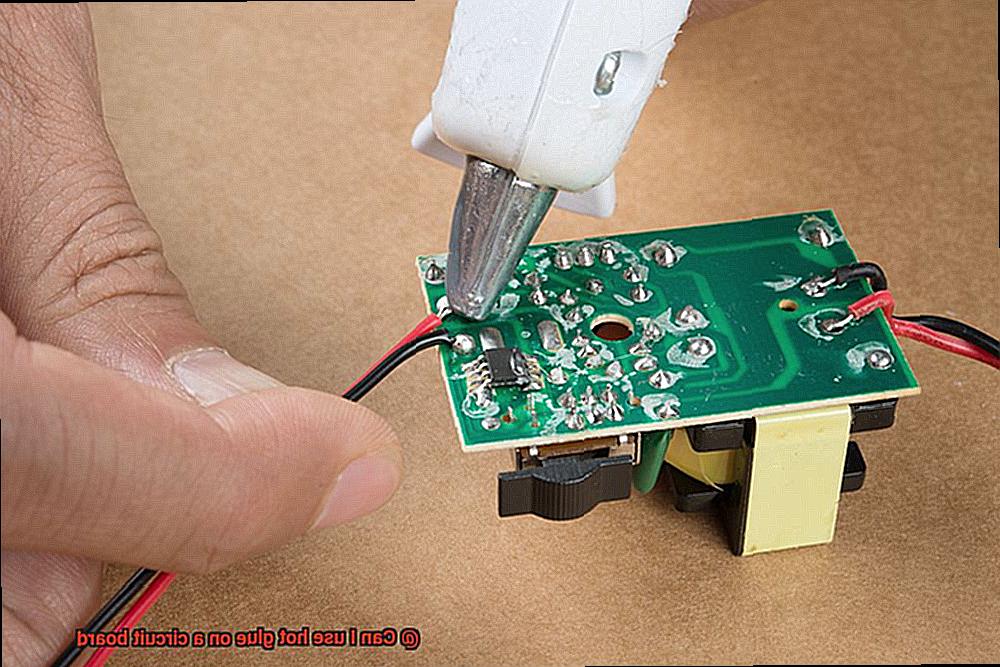

So, what does this mean for our precious circuit boards? Well, picture this: excessive hot glue acts like a blanket, suffocating the components and causing them to overheat. And trust me, overheating is not a game we want to play. It leads to malfunctions and can even permanently damage our treasured electronics. Talk about a disaster waiting to happen.

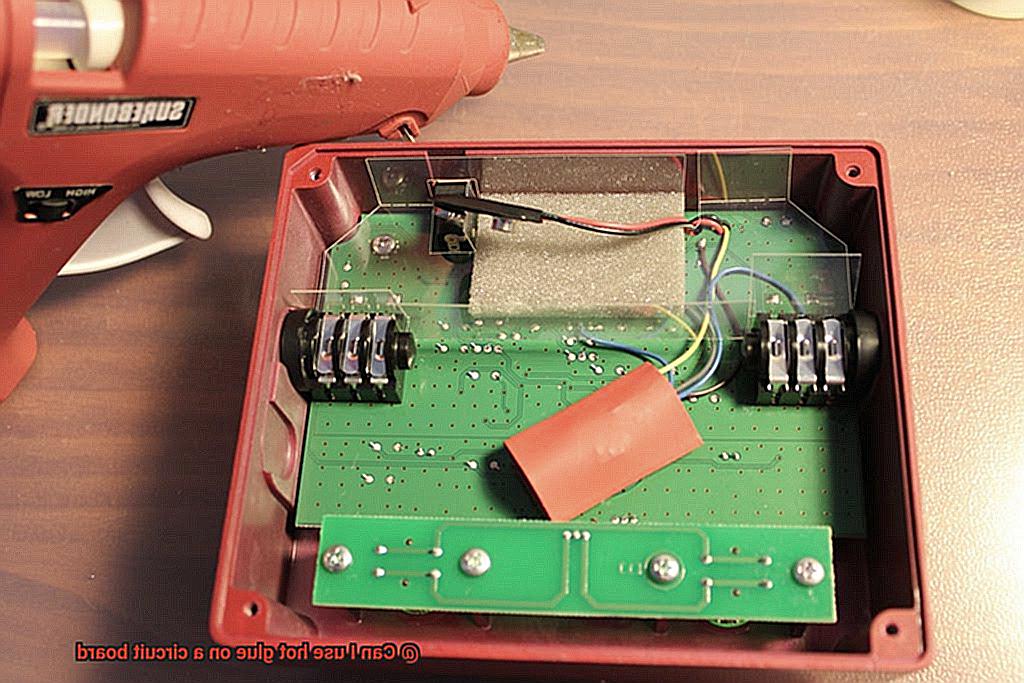

But fret not, my friends. There are ways to wield hot glue responsibly. First off, use it sparingly and with finesse. Don’t slap it on top of those heat-generating components or areas that require ventilation. Instead, consider alternative options like cable ties, adhesive-backed clips, or specialized adhesive tapes made for the electronic world.

If you absolutely must use hot glue, go for the low-temperature variant. This beauty has a lower melting point and won’t interfere with the vital process of heat dissipation. And while you’re at it, take a good look at your circuit board’s layout. Proper spacing between components, adequate ventilation, and efficient heat sinks are all part of the grand plan for superior heat management. Less need for excessive hot glue? Yes, please.

But hold on tight because there’s more to this tale. Hot glue might not be the right match for every circuit board or applications with temperature fluctuations. In these cases, we must explore other adhesives or securing methods specifically designed for the scorching environments our electronics may encounter.

So remember, hot glue is a handy tool, but it must be handled with care when it comes to electronics. Prioritize heat management and ensure our adhesive ally doesn’t become a heat-trapping enemy. Your circuit board will thank you, and you’ll avoid any potential heat-related nightmares.

Removing Hot Glue from a Circuit Board

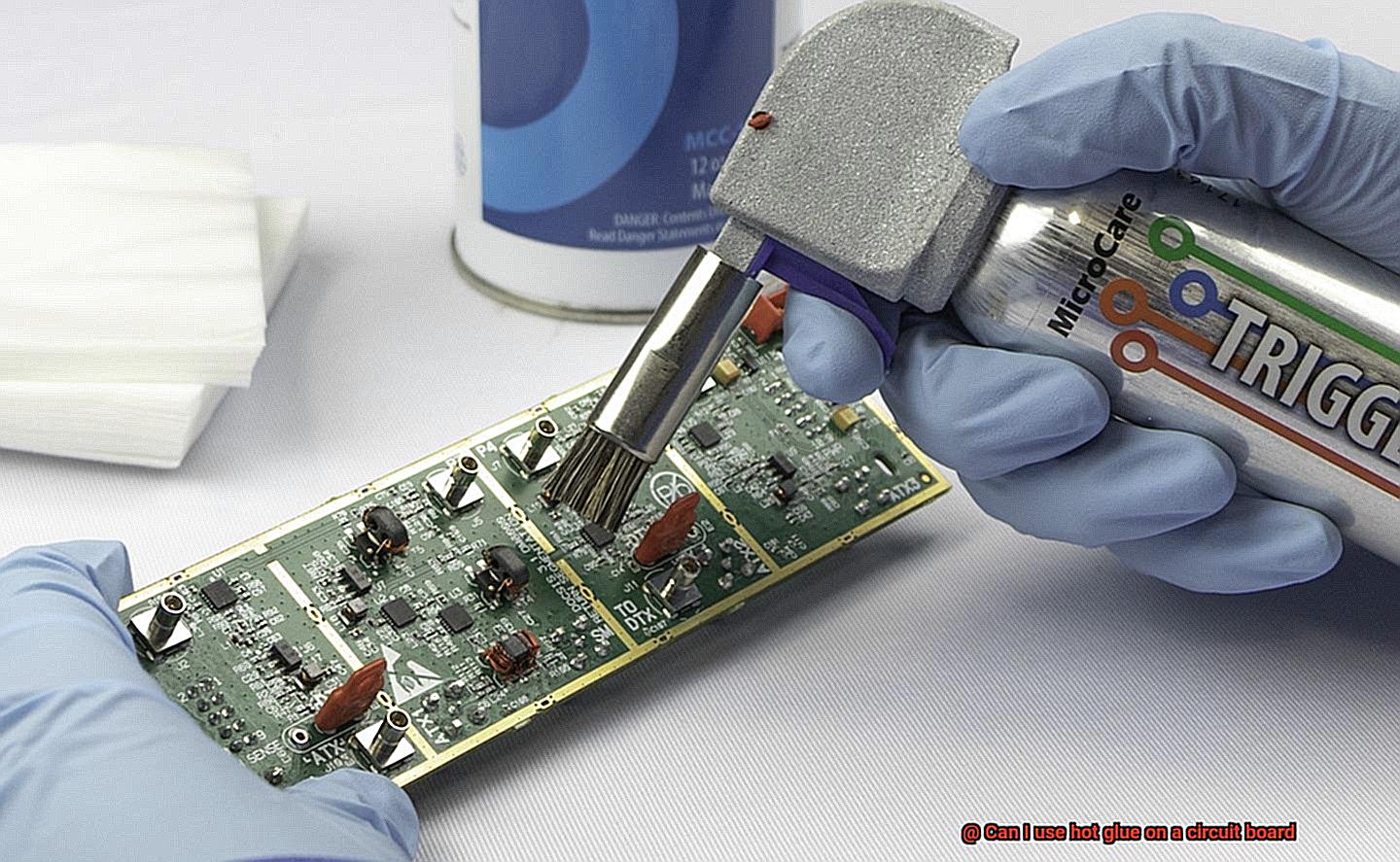

Today, I’ll guide you through the process of safely removing hot glue from a circuit board without damaging those precious components.

- There are two primary methods for removing hot glue: heat and isopropyl alcohol. Let’s dive into the step-by-step process for each method:

- Heat it up: Use a hairdryer or heat gun set to a low temperature. Gently apply heat to the hot glue area, watching it soften. Now comes the fun part – peel or scrape away the glue using a plastic tool. Remember, patience is key here. Take breaks to let the board cool down, and gradually increase the heat if necessary.

- Alcohol to the rescue: Isopropyl alcohol is a handy solvent that dissolves hot glue. Soak a cotton swab or cloth with isopropyl alcohol and gently rub it over the glue-covered areas. The alcohol will work its magic, making the glue easier to wipe away.

Before diving in, keep these crucial tips in mind:

- Power off and disconnect: Always ensure your circuit board is powered off and disconnected from any power source before removing hot glue. Safety first.

- Test, test, test: Try the isopropyl alcohol on a small area of the board first to avoid damaging sensitive components or markings.

- Combo time: Sometimes, you might need to combine both heat and solvent methods. Start with heat to soften the glue, then use isopropyl alcohol to dissolve and remove any residue.

Remember, removing hot glue from a circuit board can be time-consuming, especially if it has seeped into tiny crevices or around delicate components. Don’t lose your cool – be patient. It might take a few attempts to achieve desired results.

If you’re not confident about tackling this task yourself, reach out to professionals like electronics technicians or repair specialists. They have the skills and tools necessary to safely remove hot glue without damage.

Advantages of Specialized Adhesives for Electronics and Circuit Boards

Crafting a masterpiece in the realm of electronics requires the magic touch of specialized adhesives. While hot glue may have its place in arts and crafts, it pales in comparison to the superhero-like qualities of adhesives tailor-made for electronics. In this article, we will explore the mesmerizing advantages of utilizing these specialized adhesives, as they bring electronic devices and circuit boards to life.

Advantage 1: Unmatched Electrical Insulation

Unlike hot glue, specialized adhesives deliver unrivaled electrical insulation. With their exceptional dielectric strength, they form an impenetrable shield around electronic components, safeguarding them from the perils of moisture, dust, and even electromagnetic interference. This insulation preserves the integrity and longevity of circuit boards, ensuring smooth performance even in demanding environments.

Advantage 2: Turbocharged Thermal Conductivity

Electronic devices generate a fiery heat that, if not tamed, can lead to performance degradation or component damage. Specialized adhesives excel in thermal conductivity, deftly whisking away heat from sensitive components. This superpower is vital for maintaining optimal performance levels while preventing the dreaded specter of overheating.

Advantage 3: Herculean Mechanical Bonding

In a world rife with vibrations and temperature fluctuations, sturdy mechanical bonding is an absolute necessity. Unlike feeble hot glue, specialized adhesives possess a mighty adhesive strength that stands tall against the harshest conditions. With each component securely held in place, reliability and durability reign supreme within the circuit board’s domain.

Advantage 4: Material Compatibility Mastery

Electronics and circuit boards boast an eclectic mix of materials, ranging from metals to plastics and ceramics. Specialized adhesives are masterful in their ability to form robust connections with these materials, creating an unbreakable bond impervious to the onslaught of harsh environmental factors.

Advantage 5: Chemical Resistance Wizardry

Specialized adhesives possess an enchanting resistance to common chemicals found in electronic devices, such as solvents and cleaning agents. This spellbinding resilience ensures long-term stability and performance by preventing the degradation or loss of adhesive properties over time, leaving behind a trail of unyielding strength.

Advantage 6: Low Outgassing Sorcery

The malevolent outgassing emanating from inferior adhesives can contaminate or disrupt the delicate workings of electronic devices. Specialized adhesives, however, possess mystical powers that minimize outgassing, ensuring a pristine and reliable environment for the intricate circuitry to flourish.

Advantage 7: Effortless Application and Curing Mastery

Specialized adhesives don their versatile capes, offering various forms including liquids, pastes, and films, making them adaptable to different surface types. Their rapid curing times add an extra touch of swiftness to production or repair processes, leaving no room for delays.

Types of Specialized Adhesives for Electronics and Circuit Boards

Selecting the right adhesive for electronics and circuit boards is a crucial decision that can greatly impact the performance and reliability of these devices. With a wide range of specialized adhesives available, it is important to understand their properties, applications, and considerations for choosing the most suitable adhesive for your specific needs.

In this blog post, we will explore five types of specialized adhesives used in the electronics industry, taking into account factors such as application requirements, cost, environmental conditions, and curing time.

Epoxy Adhesives: Strong Bonds and Excellent Insulation

Epoxy adhesives are widely used in electronics due to their exceptional bonding strength and excellent electrical insulation properties. They provide a strong bond between components, ensuring long-term durability. However, epoxy adhesives have a longer curing time, which may affect production timelines. Despite this limitation, their high performance makes them ideal for applications where reliability is paramount.

Silicone Adhesives: Flexibility and High Temperature Resistance

Silicone adhesives offer flexibility, making them suitable for applications where thermal expansion and contraction occur. They exhibit high temperature resistance and excellent water resistance, protecting electronic components from moisture damage. However, silicone adhesives may not provide the same level of bonding strength as epoxy adhesives. It is essential to consider the specific application requirements when choosing between epoxy and silicone adhesives.

Acrylic Adhesives: Fast Curing Time and Good Conductivity

Acrylic adhesives are known for their fast curing time, which helps improve production efficiency. They also have good electrical conductivity properties, making them suitable for applications requiring electrical connections. However, acrylic adhesives are more prone to degradation when exposed to harsh chemicals. Therefore, it is important to consider the chemical environment in which the circuit board will be used.

Polyurethane Adhesives: Resistance to Chemicals and Moisture

Polyurethane adhesives offer excellent resistance to chemicals and moisture, making them suitable for applications in harsh environments. They provide a strong bond and maintain flexibility even in extreme conditions. However, polyurethane adhesives may have lower electrical insulation properties compared to epoxy or silicone adhesives. It is important to balance the need for chemical and moisture resistance with the electrical requirements of the application.

Considerations for Selecting the Right Adhesive

When choosing an adhesive for circuit boards, several factors need to be considered. These include thermal conductivity, electrical insulation properties, chemical resistance, moisture resistance, flexibility, and durability. It is crucial to consult the manufacturer’s guidelines and seek professional advice to ensure optimal performance. Additionally, cost considerations should be taken into account, as some specialized adhesives may be more expensive than others.

How to Properly Use Specialized Adhesives on a Circuit Board

When it comes to working with circuit boards, using specialized adhesives is crucial for optimal protection and durability. Regular glue or hot glue won’t cut it. In this guide, we will explore the dos and don’ts of properly using specialized adhesives on a circuit board.

Clean the Surface:

Before applying any adhesive, ensure that the surface of the circuit board is clean and free from dirt, dust, or residue. Use a soft cloth or brush to gently remove any unwanted particles from the board. This step is vital as it allows for proper adhesion and prevents any hindrance in the bonding process.

Use Sparingly and Precisely:

When applying specialized adhesive, remember to use it sparingly and with precision. Excessive amounts can lead to unwanted contact between components or create short circuits. To achieve precise application, opt for a fine-tipped applicator or a syringe. These tools allow for better control and ensure that the adhesive is applied only where it is needed.

Choose the Right Type of Adhesive:

Not all specialized adhesives are created equal. Different types serve different purposes on a circuit board. For bonding electrical components, conductive adhesives are ideal. Thermal adhesives help dissipate heat, while epoxy-based adhesives work well for general purposes. It’s essential to choose the right adhesive based on your specific requirements and the components being used.

Consider Curing Time:

Adhesive curing time varies depending on the type used. Some require specific conditions like heat or UV light for curing, while others cure at room temperature. To ensure proper bonding, follow the manufacturer’s instructions for curing time and conditions. Allow sufficient time for the adhesive to cure completely before handling or applying any stress to the circuit board.

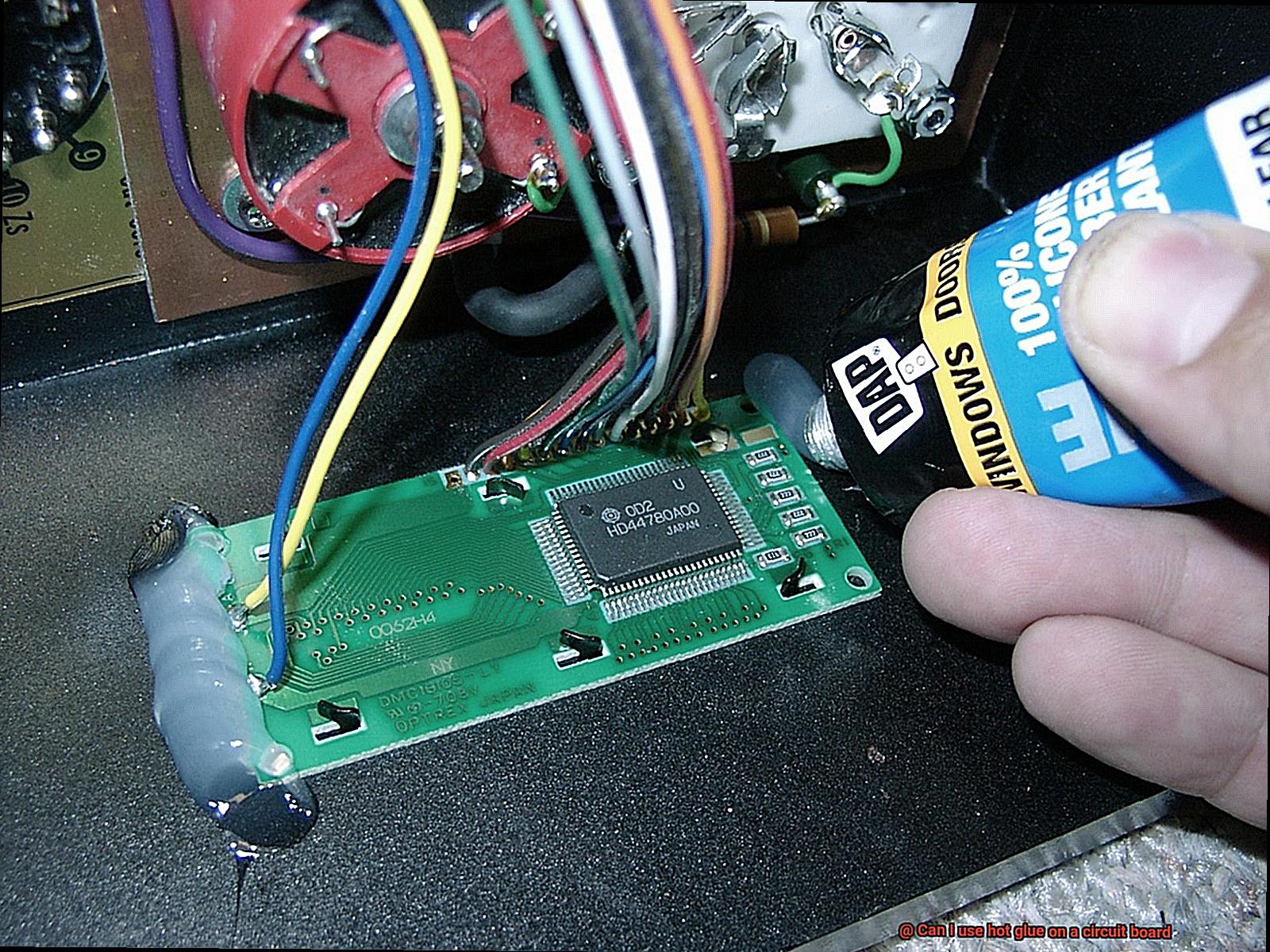

Removal and Rework:

Mistakes happen, and sometimes rework is necessary. If you need to remove the adhesive, use solvents specifically designed for that purpose. Follow safety guidelines and the manufacturer’s recommendations when using solvents to avoid any damage to the circuit board or its components.

4Mjdu0B20YQ” >

Conclusion

Using hot glue on a circuit board is not recommended.

While it may seem like a quick and easy solution, it can actually cause more harm than good. Hot glue is not designed to withstand the high temperatures and electrical currents that circuit boards generate.

It can melt under these conditions, potentially damaging the components and creating short circuits. Additionally, hot glue is not conductive, so it can interfere with the proper flow of electricity through the board.

Instead of resorting to hot glue, it’s best to use proper techniques and materials specifically designed for circuit board assembly and repair.