Are you gearing up to construct a wooden masterpiece, but wondering how to safeguard it against moisture and water damage? It’s a common dilemma – can glue be used as a sealant for wood? The answer isn’t black and white, since the market is flooded with various types of glue, each with its own purpose and application.

While some glues can effectively seal wood, others may not be ideal for the job. Although using glue as a sealer might seem like an easy and budget-friendly solution, it’s crucial to understand the limitations and potential drawbacks of this method.

In this blog post, we’ll explore the ins and outs of using glue to seal wood. We’ll delve into the different types of glue available and their suitability for sealing wood. Additionally, we’ll discuss the pros and cons of using glue as a sealer, while providing useful tips and guidelines for those considering this option.

Stay tuned to discover if using glue to seal wood is a viable choice for your next woodworking project. With our guidance, you can ensure that your wooden structures and furniture remain protected against any weather-related wear-and-tear for years to come.

Types of Glue for Sealing Wood

Contents

- 1 Types of Glue for Sealing Wood

- 2 Advantages and Disadvantages of Using Glue to Seal Wood

- 3 How to Choose the Right Glue for Your Project

- 4 Preparing the Wood Before Applying Glue

- 5 Applying Glue as a Sealant

- 6 Curing Time for Glued Surfaces

- 7 Tips and Tricks for Working with Glue

- 8 Special Considerations When Using Glue to Seal Wood

- 9 Conclusion

When it comes to sealing wood with glue, there are several types of glue available that offer unique properties and benefits. Here are five sub-sections that explore the different types of glue you can use for sealing wood:

Polyurethane Glue

This type of glue is a fan-favorite for sealing wood due to its strong and durable bonding capabilities. It is perfect for both indoor and outdoor projects as it can expand and contract with changes in temperature and humidity without losing its grip. The polyurethane glue creates a waterproof seal, making it ideal for areas that are exposed to moisture such as bathrooms or kitchens.

Epoxy Resin

Epoxy resin is a two-part adhesive that forms a hard, durable surface when it cures. It is often used to seal wooden boats or other items that will be exposed to water. Epoxy is resistant to water and temperature changes, making it an excellent choice for outdoor projects or areas with high humidity.

White or Yellow Glue

Water-based white or yellow glue is a great option for indoor projects or areas with low humidity. It creates a strong bond that dries clear and is easy to clean up with water. White glue is affordable, readily available, and can be used on a wide range of surfaces.

Cyanoacrylate Glue

Also known as superglue, cyanoacrylate glue is perfect for small repairs or bonding delicate pieces of wood together. It bonds quickly and strongly, making it ideal for sealing small gaps and cracks in wood surfaces.

Specialty Glues

There are also specialty glues available for specific types of wood or applications. For example, if you are working with porous wood, you may want to consider using a specialized wood glue that will penetrate the wood fibers more deeply.

No matter which type of glue you choose, always read the manufacturer’s instructions carefully before use and ensure that it is compatible with the type of wood you are using. Allow sufficient drying time before using the sealed wood to ensure a proper seal.

Advantages and Disadvantages of Using Glue to Seal Wood

Glue can be an excellent choice, but it’s essential to consider both its advantages and disadvantages before making a decision.

Advantages:

- Strong and Durable: One of the main benefits of using glue is that it can provide a strong and durable seal. This makes it an ideal choice for protecting wood from moisture damage, which can cause warping or rotting over time.

- Inexpensive and Easy-to-Use: Compared to other sealing options, glue is often relatively inexpensive and easy to use. This makes it a popular choice for DIY enthusiasts looking for an affordable solution.

- Versatile: There are various types of glue available in the market, each designed for specific purposes. This versatility allows you to choose the right type of glue for your specific project, ensuring optimal results.

Disadvantages:

- Challenging to Work With: Working with glue can be challenging, especially if you lack experience. If not applied correctly, it can leave a messy and uneven finish that can ruin your project.

- Not Suitable for All Types of Wood: Not all types of glue are suitable for all types of wood. It’s crucial to choose the right type of glue that matches your wood type to avoid any potential damage or issues.

- Health Risks: Some types of glue contain harmful chemicals that can pose a health risk if not used correctly. It’s essential to follow proper safety precautions when working with glue, such as wearing protective gear and working in well-ventilated areas.

How to Choose the Right Glue for Your Project

Choosing the right glue for your woodworking project can mean the difference between a strong, durable finished product and a frustrating failure. To make sure you choose the right glue, consider these five factors.

Consider the Type of Wood

Different types of wood require different types of glue. Pine or cedar, for example, work well with PVA (polyvinyl acetate) glue, while teak or oak requires a stronger adhesive like epoxy glue. Take a moment to research which type of glue works best for the type of wood you’re working with.

Think About Application Method

Choose an application method that suits your project’s needs. If you need to apply glue to a large surface area, a spray adhesive may be more suitable than a liquid adhesive. However, if you need to bond materials with a tight fit, cyanoacrylate glue (super glue) would be the best option.

Consider Drying Time

The drying time of the glue is also an important consideration. Some adhesives dry quickly, while others take longer to set. If you need to reposition items or make adjustments during the gluing process, you may want to choose a slower-drying adhesive. This will give you more time to work with the materials before the glue sets.

Think About Desired Outcome

When choosing the right glue for your project, think about what kind of outcome you want. If you need a waterproof bond, then polyurethane glue may be the best option. On the other hand, if you want a bond that can withstand high temperatures, then epoxy glue may be ideal. Be sure to research which types of adhesives will achieve your desired outcome.

Read Manufacturer’s Instructions

Always read the manufacturer’s instructions carefully before using any glue to ensure that you are using it correctly and safely. Some adhesives contain harmful chemicals or require special ventilation during use. By following the manufacturer’s instructions, you can ensure that your project is not only strong and long-lasting but also safe to work with.

Preparing the Wood Before Applying Glue

This simple yet essential step can make a tremendous difference in the overall quality of your project. So, what does preparing the wood for glue actually entail? Let’s take a closer look.

First and foremost, it’s vital to ensure that the surface of the wood is clean, dry, and free of any dust or debris. Even the tiniest amount of dirt or debris can prevent the glue from adhering properly, leading to a weak bond.

To achieve a pristine surface, start by sanding down the wood to remove any rough spots or bumps. Sanding creates a smooth surface that allows the glue to spread evenly and creates a strong bond. Be sure to sand with the grain of the wood to avoid damaging the fibers.

Once you’ve sanded down the surface, it’s time to clean it thoroughly with a damp cloth. This step removes any lingering dust or debris that could compromise the bond. After cleaning, let the surface dry completely before applying any glue.

Now comes an often-overlooked but crucial step: proper alignment and clamping during bonding. Make sure all pieces fit together snugly and are held in place securely with clamps or other tools. Any movement during the bonding process can cause gaps or weak spots in the bond, so take your time to ensure everything is aligned correctly.

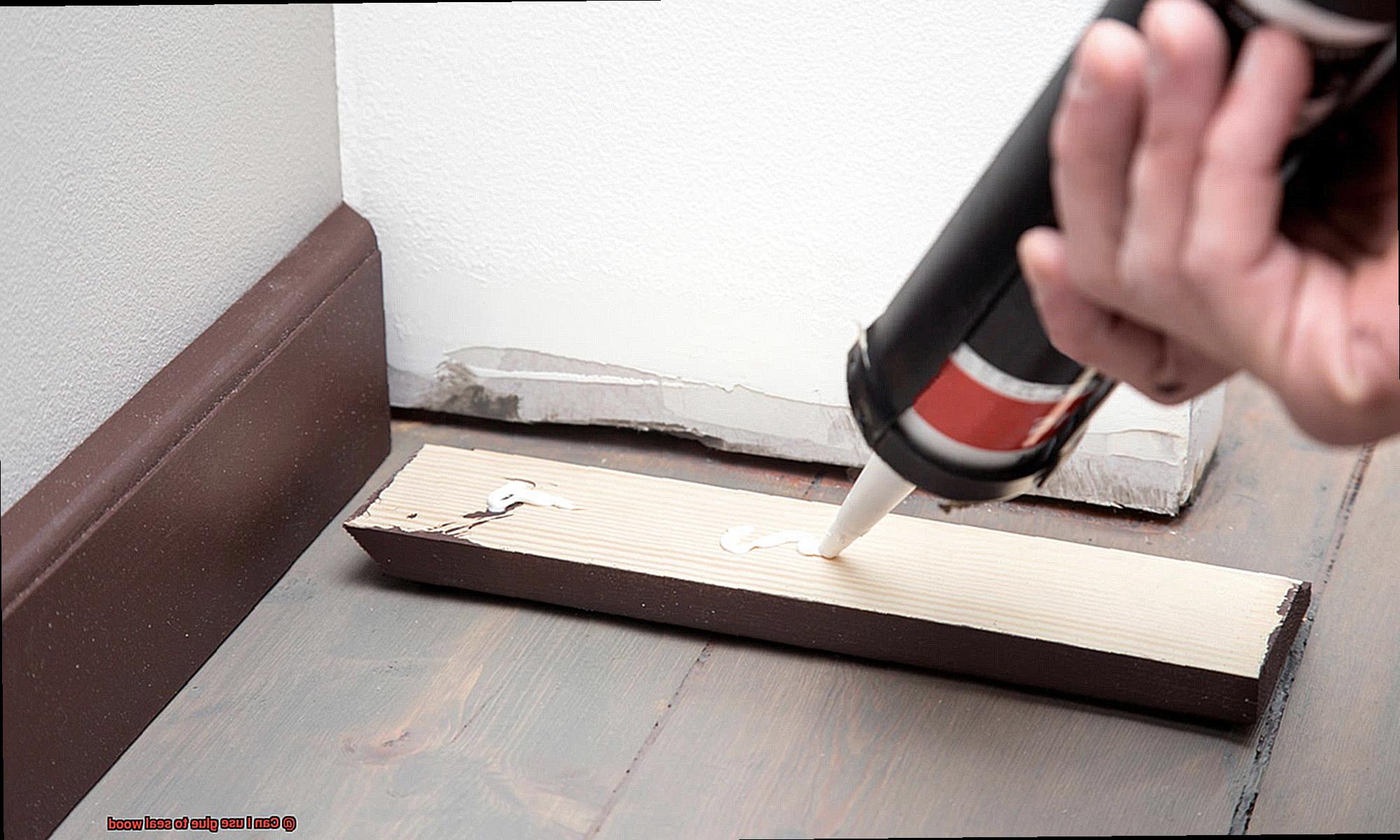

Applying Glue as a Sealant

Before you get started, it’s important to choose the right type of glue for the job.

First up, we have polyurethane glue. This waterproof glue dries to a hard finish, making it perfect for sealing wood against moisture and other environmental factors. However, it can be tricky to work with and may require some skill and experience to apply properly.

If you’re not dealing with moisture issues, carpenter’s glue is a strong and durable option for indoor projects or those that won’t be exposed to the elements. But if you want a specialized wood sealant that’s easy to apply and provides a long-lasting seal, look into those specifically designed for wood.

No matter which glue you choose, following the manufacturer’s instructions and using proper application techniques is key. Use a brush or roller to apply the glue evenly or opt for a spray gun for larger projects.

Curing Time for Glued Surfaces

As a seasoned researcher on this topic, I’ll guide you through the intricacies of curing time, and provide tips on how to optimize your glue usage.

Firstly, it’s important to understand that different types of glue have varying curing times. The chemical composition and intended use of the glue impact the drying time. While some glues dry almost instantly, others may take several hours or even days to fully cure. Therefore, make sure to read the manufacturer’s instructions carefully before selecting a glue that suits your needs.

Secondly, environmental factors such as temperature, humidity, and ventilation can also affect curing time. High temperatures can accelerate drying while low temperatures may slow down the process. Similarly, high humidity can extend the curing time, while low humidity can speed it up. Make sure you are aware of these factors and adjust your work environment accordingly.

Thirdly, applying an appropriate amount of glue is crucial when sealing wood surfaces. Too little glue may result in a weak bond that could easily break apart. On the other hand, too much glue can cause the glue to take longer to dry and cure properly.

Lastly, patience is key when it comes to curing time. In general, it’s recommended to wait at least 24 hours before applying any stress or pressure to glued surfaces. This allows enough time for the glue to fully cure and bond the wood together. However, some types of glue may continue to strengthen over time, even after they have initially cured.

Tips and Tricks for Working with Glue

Working with glue can be a messy and frustrating process, but with the right tips and tricks, you can achieve professional-quality results every time. Here are five important sub-sections to keep in mind when working with glue.

Choosing the Right Type of Glue

Choosing the right type of glue for your project is crucial for achieving the best results. For sealing wood, a waterproof or weatherproof glue is typically recommended to ensure it holds up in damp or humid conditions. Make sure to read the label carefully and select the appropriate glue for your specific project.

Applying Glue Evenly and Thinly

When applying glue, it’s important to use the right amount. Too much glue can lead to messy results and may take longer to dry or cure. A thin, even layer is usually sufficient for most projects. Use a small brush or applicator to apply the glue precisely where you need it, without making a mess.

Clamping Pieces Together While Drying

Clamping or holding the pieces together while the glue dries is crucial for ensuring a strong bond between the wood pieces. Depending on the type of glue you are using, you may need to hold the pieces together for several hours or overnight. This helps prevent the pieces from shifting or moving while the glue sets.

Cleaning Up Excess Glue

Cleaning up any excess glue is important for achieving a professional-looking finish. Use a damp cloth or sandpaper once the glue has dried completely to remove any excess glue and create a smooth surface.

Following Safety Precautions

When working with glue, it’s important to follow all safety precautions. This may include wearing gloves or protective eyewear, ensuring adequate ventilation in your workspace, and keeping the glue away from children and pets. Taking these precautions can help ensure that your project is not only successful but also safe.

Special Considerations When Using Glue to Seal Wood

Sealing wood with glue may seem like a simple task, but there are some crucial considerations to keep in mind to achieve a professional and long-lasting finish. Here are some tips to help you get started.

Choose the Right Glue:

Not all adhesives are created equal. It’s essential to select a high-quality adhesive that is specifically designed for sealing wood and is resistant to moisture, heat, and other environmental factors. This will ensure a strong bond and protect your wood surface from damage.

Prepare the Surface:

Before applying the glue, make sure your wood surface is clean and free of any dirt, debris, or previous coatings. You can achieve this by sanding the surface with fine-grit sandpaper or using a cleaning solution specifically designed for wood surfaces.

Consider the Application Method:

Depending on the size and shape of the surface, different application methods may be more appropriate. For larger areas, using a roller or brush may be more efficient than applying glue by hand. Ensure that you apply the glue evenly and thinly, so as not to create any bumps or bubbles in your finished product.

Allow Sufficient Drying Time:

It’s important to allow sufficient drying time for the glue to set and cure properly. Rushing the drying process can result in a weak bond or other issues with the finished product. The drying time can vary depending on the type of glue used and environmental factors such as temperature and humidity.

_PAi5S-929o” >

Also Read: Can you use Elmer’s glue as a sealant?

Conclusion

To sum up, sealing wood with glue can be a practical option to safeguard your wooden furniture and structures from moisture and weather damage. However, it’s crucial to understand the different types of glue available and their suitability for sealing wood. Polyurethane glue, epoxy resin, white or yellow glue, cyanoacrylate glue, and specialty glues are all viable options for sealing wood with unique properties and benefits.

While using glue as a sealer offers several advantages such as its strength and affordability, there are also potential drawbacks to consider. Incorrect application of glue can make it challenging to work with, and not all types of wood may be suitable for use with certain glues. Additionally, safety precautions must be followed when working with some types of glue that contain harmful chemicals.

Choosing the appropriate type of glue is critical in achieving optimal results. Factors like the type of wood you’re working with, application method, desired outcome, and curing time should all be considered when selecting a glue.

Proper preparation of the wood surface is also essential in creating a strong bond between the wood and the glue. Sanding down rough spots or bumps and cleaning the surface thoroughly will ensure that the glue spreads evenly and creates a durable seal.

By following these tips and guidelines meticulously, you can effectively use glue as a sealant for your next woodworking project.