Crafting and woodworking projects are all about finding the perfect adhesive to bring your creations to life. While traditional options like wood glue and fasteners have always been reliable, there’s a new contender in town – the hot glue gun. But can this fiery tool really be used on wood? Join us as we dive into the exciting world of hot glue guns and discover their unexpected potential in woodworking.

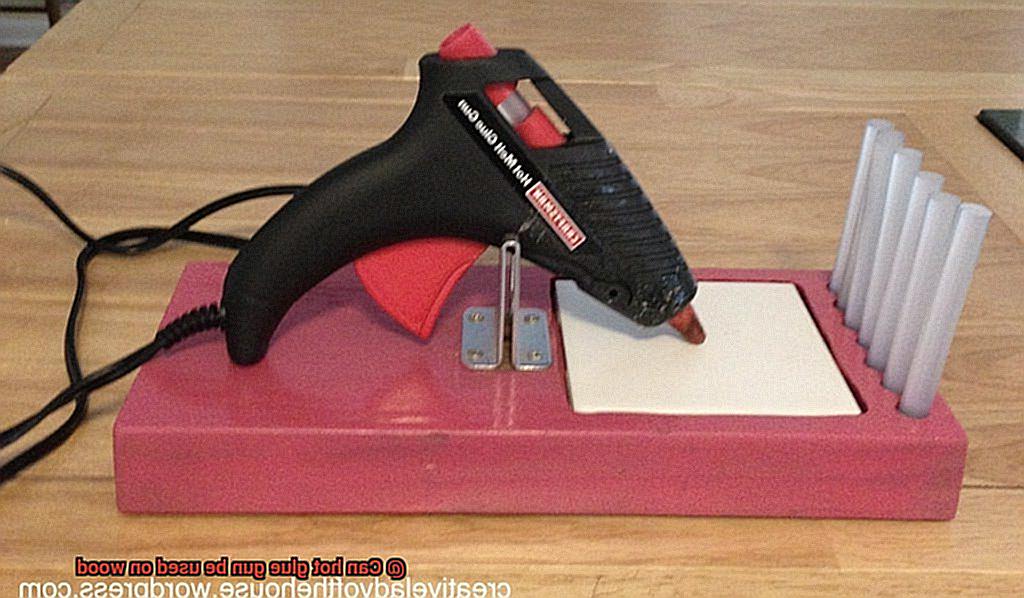

Hot glue guns have become the ultimate sidekick for DIY enthusiasts and seasoned pros alike. These handheld marvels dispense a heated, molten adhesive that bonds with almost anything, including wood. With their versatility and user-friendly design, they’ve quickly become a go-to choice for countless woodworking projects.

One of the biggest perks of using a hot glue gun on wood is its lightning-fast drying time. Say goodbye to waiting hours for traditional glues to set – hot glue hardens within minutes, getting you back to creating in no time. This rapid bonding ability is especially handy when you need quick repairs, delicate touches, or simply want to finish your project in record time.

But it’s not just speed that makes hot glue guns shine; they also provide an unbeatable grip on various types of wood surfaces. Whether your piece is porous or non-porous, smooth or rough, these trusty tools will hold everything together securely. From MDF board to plywood and even those quirky, irregular wooden pieces – hot glue guns conquer them all.

What’s more, hot glue guns offer flexibility when it comes to adhesive choices. While regular sticks work just fine for most projects, specialty glue sticks tailored specifically for woodworking take things up a notch. With their enhanced strength and durability, these formulations ensure that your bond can withstand the test of time and the natural stresses that wood experiences.

Of course, it’s important to recognize that hot glue does have its limitations when it comes to wood. Unlike traditional wood glue, hot glue doesn’t penetrate the fibers, resulting in a bond that may not be as permanent. So, while it’s perfect for most areas, heavy-load-bearing joints or high-stress spots might require a different approach. Additionally, extreme temperatures can weaken the bond, making hot glue less suitable for projects exposed to constant temperature fluctuations.

So, hot glue guns can definitely be used on wood – they just need to be used wisely.

What is Hot Glue?

Contents

- 1 What is Hot Glue?

- 2 Advantages of Using Hot Glue on Wood

- 3 Disadvantages of Using Hot Glue on Wood

- 4 Factors to Consider Before Applying Hot Glue on Wood

- 5 Cleaning and Preparing the Wood Surface

- 6 Applying the Hot Glue to the Wood Surface

- 7 Heat Resistance of Different Types of Wood

- 8 Testing the Hot Glue Before Use

- 9 Conclusion

Indispensable in the world of crafting and DIY projects, hot glue, also known as hot melt adhesive, is a versatile tool that offers ease of use, quick drying time, and reliability. In this comprehensive guide, we will delve into the intricacies of hot glue, exploring its composition, applications, and important considerations when working with it.

Hot glue is a thermoplastic adhesive that transforms into a soft, pliable state upon heating. Composed primarily of ethylene-vinyl acetate (EVA) or polyamides, hot glue sticks are solid at room temperature but melt to a liquid form when exposed to heat. This melt is then dispensed through a specialized glue gun.

Applications of Hot Glue:

- Crafts: A true companion for crafters, hot glue bonds various materials like fabric, wood, and plastic with remarkable efficiency. From handmade cards to jewelry assembly and picture frame decoration, the quick-drying nature of hot glue ensures reliable adhesion in a multitude of creative projects.

- DIY Projects: The go-to adhesive for DIY enthusiasts, hot glue aids in small repairs around the house such as securing loose knobs or fixing trim pieces. It is also ideal for crafting custom home decor items like wreaths and centerpieces due to its versatility and ability to bond different materials together.

Considerations When Using Hot Glue on Wood:

- Strength: While hot glue can be used on wood, it may not provide the same level of strength as specialized wood glues. For lightweight or temporary projects, hot glue is suitable. However, for projects requiring long-term durability or heavier loads, consider using stronger adhesives.

- Surface Preparation: Prior to applying hot glue on wood, ensure the surface is clean and free from dust or moisture. This preparation enhances the bond between the adhesive and the wood, ensuring a more effective result.

- Temperature and Application: When working with delicate or heat-sensitive woods, it is advisable to use a lower temperature setting on the glue gun. Additionally, applying hot glue in thin lines or dots allows for better control and distribution, enhancing the overall adhesion.

- Testing: To ensure compatibility and desired results, it is essential to test the hot glue on a small, inconspicuous area of the wood before applying it to the entire project. This step allows for adjustments and guarantees optimal outcomes.

Advantages of Using Hot Glue on Wood

When it comes to finding the ideal adhesive for your woodworking projects, look no further than hot glue. This versatile and dependable adhesive has become a staple in the crafting world, offering a range of benefits for bonding wood. Let’s explore the advantages of using hot glue on wood and discover why it’s the superhero of adhesives.

Unparalleled Strength:

Hot glue means business when it comes to bonding wood. It creates a robust and long-lasting connection between wood pieces, ensuring your projects withstand the test of time. Whether you’re crafting small trinkets or building furniture, hot glue provides a reliable hold that won’t disappoint.

Lightning-Fast Drying:

Time is precious, especially when you’re immersed in an exciting woodworking project. Hot glue saves the day with its rapid drying time. Unlike other adhesives that take hours or days to set, hot glue solidifies within minutes. This allows you to maintain momentum and finish your project in record time.

Versatility at Its Finest:

Hot glue is a chameleon when it comes to compatibility with different types of wood. It effortlessly adheres to hardwoods, softwoods, plywood, and even MDF (medium-density fiberboard). No matter what type of wood you’re working with, hot glue forms a strong bond that gets the job done effectively.

Effortless Application:

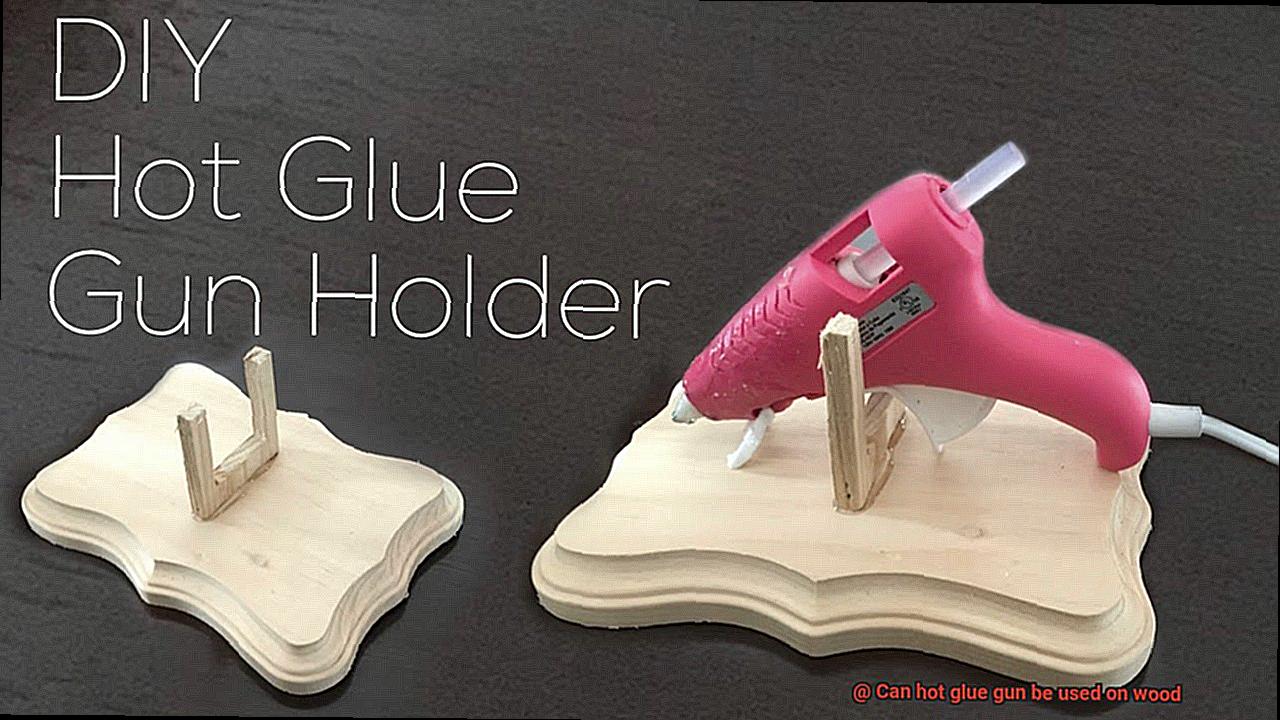

Using a hot glue gun is as easy as 1-2-Insert the glue stick, wait for it to melt into liquid form, and apply it directly onto the wood surface. The beauty lies in its precision and control. Whether you’re a seasoned pro or a beginner, hot glue is a breeze to work with, ensuring smooth application every time.

Reversible Bonding Power:

Mistakes happen, and adjustments are sometimes necessary. Hot glue offers a solution with its reversible bond on wood. Unlike permanent adhesives, hot glue can be softened with heat, allowing for easy disassembly or modifications without damaging the wood surface. Flexibility at its finest.

Mess-Free Magic:

Say goodbye to messy adhesives that drip and spread everywhere. Hot glue is relatively clean to work with, drying clear and leaving no unsightly residue or marks on your wood surface. Keep your workspace neat and tidy with hot glue’s magic touch.

Budget-Friendly Brilliance:

Crafting and woodworking can be costly endeavors. But fear not, because hot glue is here to save your wallet. Glue sticks are readily available and cost-effective compared to specialized adhesives. You can enjoy the benefits of a strong bond without breaking the bank.

Disadvantages of Using Hot Glue on Wood

Hot glue may seem like the superhero of adhesives when it comes to bonding wood, but even superheroes have their weaknesses. In this blog post, we will explore the drawbacks of using hot glue on wood, equipping you with the knowledge needed to make informed decisions for your woodworking projects.

Weaker Bond Strength:

Hot glue falls short in terms of bond strength compared to other wood glues like carpenter’s glue or wood glue. It lacks the ability to hold up under heavy weight or stress, making it unsuitable for projects that demand a strong and durable bond.

Vulnerability to Temperature Changes:

Hot glue has a tendency to shrink and expand with temperature fluctuations. This can weaken the bond between the wood and the glue over time, especially in areas with extreme temperature changes. If your project will be exposed to outdoor elements or placed near heat sources, hot glue may not be the most reliable choice.

Messy Application:

Working with hot glue can be a messy affair, particularly if you lack experience with a hot glue gun. Drips and stringy strands can make it challenging to achieve clean and precise bonds. This drawback becomes especially apparent when your project demands pristine and professional-looking results.

Lack of Waterproofing:

Hot glue is not waterproof, meaning it can soften or melt when exposed to moisture. This weakness makes it unsuitable for outdoor projects or items that may come into contact with water.

Irreversible Bonding:

Once hot glue dries and hardens, removing it without causing damage to the wood surface becomes difficult. This lack of reversibility can pose problems if you need to make adjustments or repairs in the future.

Compatibility Issues:

Not all types of wood or finishes are compatible with hot glue. Some woods contain natural oils or coatings that hinder effective bonding. Conducting a small, inconspicuous area test before committing to the entire project is crucial.

Limited Repositioning Time:

Compared to other wood glues, hot glue has a short drying time. This makes it challenging to reposition pieces once they are glued together. If precise alignment or adjustments are necessary, hot glue may not be the most suitable option.

Residue and Stringy Strands:

Hot glue can leave behind visible residue and stringy strands on the wood surface. Removing these imperfections may require sanding or scraping, adding extra effort to achieve a smooth finish.

Factors to Consider Before Applying Hot Glue on Wood

In the world of woodworking, selecting the right adhesive is paramount to achieving sturdy and durable bonds. Hot glue is a popular choice due to its convenience and quick drying time. However, before diving into your project armed with a hot glue gun, there are several factors you need to carefully consider.

These factors will help you make informed decisions that will lead to professional and successful results in your woodworking endeavors.

Firstly, it is crucial to assess the temperature sensitivity of the wood. Different types of wood have varying tolerance levels when it comes to high temperatures. Softwoods like pine or cedar are particularly susceptible to damage from hot glue. To avoid unsightly discoloration, warping, or scorching, always check the recommended temperature range for the specific type of wood you are working with before applying hot glue.

Secondly, take into account the porosity of the wood. The porosity determines how well the glue will bond with the surface. Woods with higher porosity, such as oak or mahogany, generally provide better adhesion for hot glue. Conversely, woods with lower porosity, like maple or cherry, may require additional preparation or priming to ensure a strong bond.

Proper surface preparation is another crucial factor to consider. Ensure that the wood surface is clean, dry, and free from any dust, dirt, or previous finishes. Lightly sanding the surface can also enhance adhesion by creating a slightly rougher texture for the glue to grip onto.

Additionally, evaluate the strength requirements of your project. While hot glue can provide decent strength for lightweight applications or temporary bonds, it may not be suitable for heavy-duty or load-bearing projects. If your project demands higher strength and durability, it is worth exploring other adhesive options specifically designed for bonding wood.

Wood naturally expands and contracts with changes in humidity and temperature. This movement can put stress on adhesive bonds over time. While hot glue is relatively flexible and can accommodate some wood movement, it may not be the best choice for projects with significant wood movement. In such cases, consider using adhesives formulated to withstand these conditions, like wood glues or epoxy.

Lastly, pay attention to the application technique. The way hot glue is applied can significantly impact the bond strength and overall result. Apply an even layer of glue without excessive squeezing or over-application. Uneven application or excess glue can create weak spots or unsightly bulges. Furthermore, using clamps or weights to hold the glued parts together until the glue sets will ensure a secure bond.

Cleaning and Preparing the Wood Surface

Proper cleaning and preparation are essential for achieving a strong bond. Let’s explore the crucial steps for cleaning and preparing the wood surface with vivid language.

Step 1: Dust off the Surface

First, we must banish any dust, dirt, or debris that may have settled on the wood surface. Gently wield a soft brush or cloth to whisk away these unwanted particles. This meticulous process guarantees a clean and uncontaminated surface, primed for optimal glue adhesion.

Step 2: Remove Existing Finishes

If our wood surface is adorned with any existing finishes like paint or varnish, we must strip them away before applying hot glue. We can accomplish this by diligently sanding the surface with sandpaper or employing a chemical stripper. Remember to follow the manufacturer’s instructions when using chemical products and don’t forget your protective gear.

Step 3: Smooth it Out

Once we’ve completed the cleaning and removal of finishes, it’s time to refine the wood surface. With finesse, take hold of fine-grit sandpaper and tenderly caress the surface. This gentle sanding creates a rougher texture, enhancing the grip of the glue.

Step 4: Dry it Up

Moisture can be an adversary to effective glue adhesion. Therefore, it is crucial to ensure that our wood surface is dry before applying hot glue. If any hint of dampness lingers, exercise patience and allow it to evaporate entirely before proceeding.

Step 5: Consider Primer or Sealer

To bolster adhesion and safeguard against potential damage, we may opt to apply a primer or sealer to the wood surface. However, we must choose one that harmonizes effortlessly with both the wood and the hot glue we plan to use.

Step 6: Temperature Matters

Each type of wood possesses its own heat resistance level. Consequently, we must wield our hot glue gun with caution and select a temperature setting that aligns harmoniously with the specific wood species. Excessive heat risks damaging the wood, while inadequate heat may yield a feeble bond.

Applying the Hot Glue to the Wood Surface

Applying hot glue to a wood surface is a delicate art, requiring precision and attention to detail. Before you embark on this adhesive adventure, it’s crucial to prepare your wooden canvas. Like a true artist, you must clean the surface, banishing any dust or debris that might hinder the bond. A gentle wipe-down with a damp cloth or a mild cleaning solution will do the trick, setting the stage for a successful union.

- But let’s not forget the star of our show – the hot glue gun. This trusty companion needs a preheating period to reach its optimal bonding temperature. Give it a few minutes to warm up, ensuring that the glue will flow smoothly onto the wood, creating a stronghold.

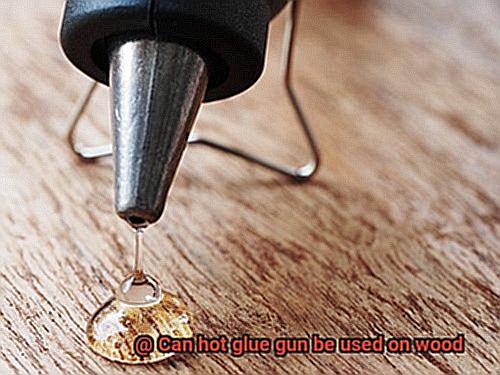

- Now comes the moment of truth – applying the glue. Consistency is key here, my friend. As you gently squeeze the trigger of your glue gun, move it steadily along the wood’s surface. A graceful dance that results in an even layer of glue, ready to embrace your project.

But beware of excess. Too much glue can overflow and create unwanted messiness. Practice caution and moderation as you apply just enough to create a robust bond. If unsure, experiment on a scrap piece of wood to find your perfect balance.

Once the glue is applied, it’s time for the grand finale – bringing your wood pieces together. Press them firmly, using either the strength of your hands or clamps if necessary. This act of unity ensures a strong bond that will withstand the test of time.

Patience becomes your virtue as you enter the waiting game. Allow the glue to dry and cure fully before handling or moving your wooden creation. The duration depends on various factors such as glue type and environmental conditions, but be patient, my friend. Good things come to those who wait.

Heat Resistance of Different Types of Wood

In this article, we will delve into the factors that influence the heat resistance of wood and provide insights on how to choose the right type of wood for your projects. From the density and moisture content of wood to the impact of finishes and adhesive compatibility, understanding these factors will help ensure successful and safe crafting experiences.

Hardwoods vs. Softwoods

When it comes to heat resistance, hardwoods like oak and maple are like superheroes. With their dense structure, they are less likely to warp or burn when subjected to high temperatures. On the other hand, softwoods like pine and cedar have a lower density and looser grain structure, making them more sensitive to heat. It is important to consider the type of wood you are using and its heat resistance properties before using a hot glue gun.

Moisture Content Matters

The moisture content of wood plays a crucial role in its heat resistance. Wood with higher moisture content is more prone to warping or cracking when exposed to heat. To avoid this issue, it is recommended to use wood with low moisture content or opt for kiln-dried lumber. By using adequately dried wood, you can enhance its heat resistance and reduce the risk of damage.

The Power of Finishes

Applying the right finish can significantly impact the heat resistance of wood when using a hot glue gun. Finishes like lacquer or polyurethane create a protective barrier between the hot glue and the wood surface, allowing the wood to withstand higher temperatures without damage. However, not all finishes are heat resistant, so be sure to choose one that is suitable for your specific project.

Adhesive Compatibility

Choosing the right adhesive is essential for a strong bond between wood and hot glue. It is crucial to ensure that the adhesive you use is compatible with wood surfaces. Using an incompatible adhesive can lead to weak bonds, damaged wood, or even a fire hazard. Always refer to the manufacturer’s instructions or consult an expert to ensure the adhesive’s suitability for wood applications.

Precautions and Best Practices

To prevent any mishaps or damage, it is important to take precautions when using a hot glue gun on wood. Before applying glue to your project, test it on a scrap piece of wood to observe how it reacts. Avoid excessive heat or pressure, as this can deform or burn the wood. Additionally, allow the glue to cool and harden completely before handling or moving the glued pieces.

Testing the Hot Glue Before Use

Hot glue has gained popularity for its versatility and quick-drying properties. However, not all glues are created equal, especially when it comes to bonding with wood. To avoid mishaps or disappointments, it is crucial to test the compatibility of hot glue with the specific type of wood being used. In this article, we will guide you through the steps involved in testing hot glue on wood, ensuring that your crafting adventures are a resounding success.

Step 1: Selecting the Right Wood:

Different types of wood have varying densities and surface qualities that can affect adhesion. To achieve accurate results, use the same type of wood for testing as the one used in your project. This step helps you understand how the hot glue will bond with your chosen wood.

Step 2: Preparing the Surface:

Clean the surface of the scrap wood by removing any dust or debris. This ensures that the hot glue bonds directly to the wood and not any foreign particles that may interfere with adhesion.

Step 3: Temperature Selection:

Follow the instructions provided with your hot glue gun to heat it up to the appropriate temperature for your specific type of wood. Adjustable temperature settings offer better control and customization.

Step 4: Applying the Hot Glue:

Apply a small amount of hot glue onto the cleaned surface of the scrap wood. For better distribution and adhesion, consider applying the glue in a straight line or small dots.

Step 5: Bonding Test:

Immediately after applying the hot glue, press another scrap piece of wood onto it. Apply firm pressure for a few seconds to allow the adhesive to bond properly.

Step 6: Inspecting the Bond:

After a short period, carefully inspect the bond between the two pieces of wood. Look for a strong bond with no visible gaps or signs of weak adhesion. Test the bond’s strength by gently bending or twisting the pieces of wood.

Step 7: Experimentation:

If working with different types of wood or unsure about the optimal temperature, repeat the testing process to find the best settings for each specific wood. Keep in mind that some woods may not bond well with hot glue due to their natural oils or surface properties. In such cases, explore alternative adhesive options.

ztUt9yn8nHM” >

Also Read: How Much Weight Can Hot Glue Hold?

Conclusion

Yes, a hot glue gun can indeed be used on wood.

It is a versatile tool that can bond various materials together, including wood. The hot glue melts upon application and quickly solidifies as it cools down, creating a strong and durable bond.

This makes it perfect for woodworking projects, such as joining pieces of wood or attaching embellishments to wooden surfaces. Whether you are a professional carpenter or a DIY enthusiast, using a hot glue gun on wood can save you time and effort compared to other traditional methods like screws or nails.

Additionally, the adhesive properties of hot glue make it ideal for filling gaps or cracks in wood surfaces. However, it is important to note that the strength of the bond may vary depending on factors such as the type of wood and the temperature at which the glue gun is operated.

Therefore, it is recommended to test the strength and durability of the bond before relying solely on hot glue for load-bearing applications.