Imagine this: you’re knee-deep in a DIY project that demands an adhesive tough enough to withstand anything. But here’s the burning question – can Gorilla Glue really handle high heat? Whether you’re a seasoned DIY pro or just starting out, knowing if your glue can take the heat is crucial to your project’s success.

Well, fret no more. In this blog post, we’ll dig deep into the world of Gorilla Glue’s heat resistance and equip you with all the knowledge you need to tackle those scorching-hot projects.

So, how does Gorilla Glue fare when things get hot?

Contents

- 1 What is Gorilla Glue?

- 2 Heat Resistance of Gorilla Glue

- 3 Factors Affecting the Heat Resistance of Gorilla Glue

- 4 Applications Suitable for Gorilla Glue in High Temperature Environments

- 5 Precautions to Take When Using Gorilla Glue in High Temperature Environments

- 6 Alternatives to Consider for High Temperature Applications

- 7 Manufacturer’s Instructions and Guidelines for Using Gorilla Glue

- 8 Conclusion

Gorilla Glue has earned its reputation for being a beast when it comes to handling extreme temperatures. That’s why it’s a popular choice for all sorts of projects, from crafts to home repairs. The secret behind its heat resistance lies in its unique formula and rock-solid composition.

Unlike regular adhesives, Gorilla Glue is made from a special moisture-activated polyurethane formula. This means that when moisture hits the glue, it expands and forms an insanely strong bond. But what does this have to do with high heat?

Gorilla Glue doesn’t stop at just bonding with moisture. Thanks to its incredible chemical makeup, it can brave temperatures ranging from -40°F to 200°F (-40°C to 93°C). Impressive stuff, right?

What sets Gorilla Glue apart is its ability to stay strong even under intense heat. Its molecular structure allows it to hold its bond together even when faced with scorching temperatures. So whether you’re fixing a handle on a sizzling skillet or crafting something fire-resistant, rest assured that Gorilla Glue has got your back.

But wait, there’s more. Not only does Gorilla Glue stand up against high heat, but it also boasts outstanding durability and impact resistance. This means that no matter how tough the situation gets, the bond formed by Gorilla Glue will remain unyielding and secure.

In conclusion, if you’re on the hunt for an adhesive that can truly handle the heat, Gorilla Glue is your superhero of choice. With its moisture-activated polyurethane formula and unbeatable heat resistance, this glue is the real deal for all your high-temperature projects.

Stay tuned for more insider tips and tricks on everything adhesive-related.

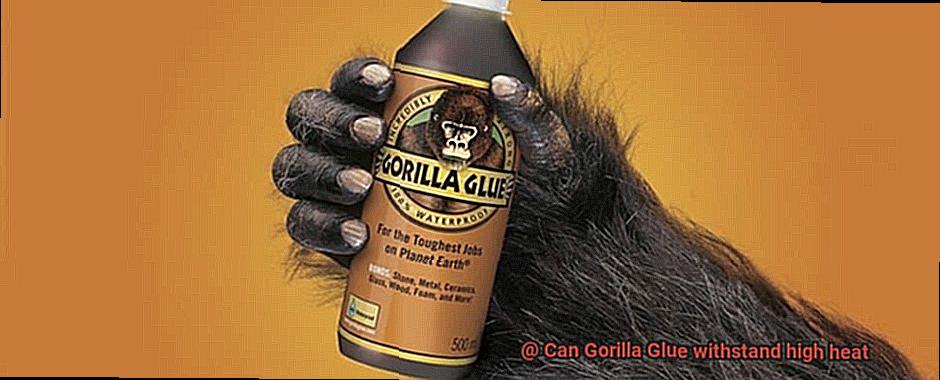

What is Gorilla Glue?

For those seeking an adhesive that boasts unparalleled strength and versatility, look no further than Gorilla Glue. This extraordinary adhesive has captured the hearts of DIY enthusiasts and professionals alike, owing to its remarkable bonding capabilities, water resistance, and ability to firmly adhere to a multitude of materials.

In this comprehensive exploration of Gorilla Glue, we will delve into its key features and examine the myriad of applications it can be used for.

Key Features of Gorilla Glue:

- Unrivaled Adhesive Strength: Gorilla Glue is meticulously designed to fuse together an extensive array of materials, including wood, metal, plastic, stone, and ceramic. It forms an indomitable bond capable of withstanding substantial stress and strain.

- Expansive Properties: Upon application, Gorilla Glue expands as it cures, ingeniously filling gaps or voids in the material at hand. This ingenious characteristic augments the bond’s strength by increasing the surface area of adhesion.

- Impervious Water Resistance: Once cured, Gorilla Glue becomes impervious to water and can endure exposure to moisture or even submersion without compromising its adhesive prowess. Consequently, it thrives in both indoor and outdoor settings.

Utilizing Gorilla Glue:

- Surface Preparation: Before applying Gorilla Glue, meticulous preparation is crucial. Ensure that the surfaces are clean, dry, and devoid of any contaminants. For non-absorbent surfaces such as glass or metal, enhance adhesion by roughening them with sandpaper or using a primer.

- Activation and Curing: To activate and facilitate proper curing of Gorilla Glue, moisture is essential. Prior to applying the glue, dampen one of the surfaces with water or lightly spray it with a misting bottle. This moisture triggers a chemical reaction within the glue, resulting in expansion and the formation of a secure bond.

Gorilla Glue Varieties:

- Original Polyurethane Glue: This variant excels at bonding porous materials and filling gaps.

- Super Glue (Cyanoacrylate): Swift and robust, this type of Gorilla Glue is ideal for smaller repairs.

- Epoxy: Offering unrivaled strength, epoxy is a two-part adhesive perfect for bonding diverse materials.

Heat Resistance:

Although Gorilla Glue exhibits commendable resistance to heat and can tolerate temperatures up to 200°F (93°C), extended exposure to high temperatures may compromise its performance. For constant exposure to elevated heat, it is advisable to utilize specialized adhesives specifically formulated for such environments.

Heat Resistance of Gorilla Glue

Gorilla Glue, the polyurethane wonder adhesive that activates upon contact with moisture, has earned its reputation for strength and versatility. But what about its heat resistance? Can it withstand the scorching temperatures of your DIY projects? Let’s dive deep into the fiery realm of Gorilla Glue and explore its ability to endure high heat.

Once fully cured, Gorilla Glue can handle temperatures up to a sizzling 200°F (93°C). This means you can confidently use it for outdoor projects or repairs in hot environments without worrying about it losing its grip. It’s like having a heat-resistant superhero by your side, ready to save the day.

However, before you go sticking everything under the sun, there are a few things to keep in mind. While Gorilla Glue is designed to be heat-resistant, extended exposure to extreme heat can weaken its bond. So, if possible, try to avoid subjecting your glued surfaces to excessive heat. After all, even superheroes have their limits.

Now let’s talk about the different types of Gorilla Glue available. There’s the Original Gorilla Glue, Super Glue Gel, and Epoxy Gorilla Glue. Each variant may have slightly different temperature tolerances, so make sure to check the product’s specifications for accurate information. It’s like assembling your own team of adhesive Avengers, each with their own unique powers.

But here’s an important reminder: while Gorilla Glue itself may handle high temperatures, the surfaces it bonds might not. Different materials have different melting points and reactions to heat. So while your Gorilla Glue bond might remain intact under intense heat, the materials it’s sticking together may not fare as well. Keep that in mind to ensure a successful and long-lasting bond.

If you find yourself in need of extreme heat resistance, such as for industrial applications or automotive repairs, specialized adhesives designed for high-temperature environments might be your best bet. These adhesive superheroes have higher heat tolerances and can withstand even the toughest conditions. They’re like the invincible Iron Man suits of the adhesive world.

In conclusion, Gorilla Glue is a reliable adhesive that can handle temperatures up to 200°F (93°C) once it’s fully cured. It’s an adhesive superhero that’s ready to take on the heat and keep your projects intact. Just remember to consider your specific application, surface materials, and potential exposure to extreme heat. By following the manufacturer’s instructions and using a little common sense, you’ll achieve optimal results and a bond that won’t let you down.

Factors Affecting the Heat Resistance of Gorilla Glue

When it comes to selecting an adhesive that can withstand high temperatures, Gorilla Glue stands out as a reliable choice. However, what factors contribute to its exceptional heat resistance? In this article, we will delve into the various aspects that influence the heat resistance of Gorilla Glue, providing you with a comprehensive understanding of its capabilities.

Chemical Composition:

The chemical composition of Gorilla Glue is an essential factor in determining its heat resistance. Comprised of a polyurethane formula, this adhesive possesses inherent qualities that make it resistant to heat. However, slight variations in the specific composition of Gorilla Glue may impact its overall heat resistance compared to other polyurethane glues.

Curing Process:

Gorilla Glue undergoes a curing process after application, transforming from a liquid state to a solid form. The temperature at which this curing process occurs significantly impacts the glue’s ability to withstand high heat. Higher curing temperatures result in stronger and more heat-resistant bonds. Thus, following the manufacturer’s instructions regarding curing temperature is crucial for optimal heat resistance.

Application Method:

The manner in which Gorilla Glue is applied also influences its heat resistance. Properly adhering to the manufacturer’s instructions regarding application techniques and surface preparation enhances the glue’s ability to withstand heat. This includes applying the glue evenly and ensuring proper contact between the bonded surfaces.

Surface Preparation:

In preparing surfaces before applying Gorilla Glue, cleanliness is key. Removing any contaminants or oils that may hinder adhesion is vital for maximizing the adhesive’s bonding strength. By properly preparing surfaces, one can achieve better adhesion and enhance the glue’s ability to withstand high temperatures.

Bond Thickness:

The thickness of the bond created by Gorilla Glue plays a significant role in its heat resistance. Thicker bonds tend to have better resistance to heat compared to thinner ones. Ensuring an adequate amount of glue is applied to create a sufficiently thick bond is essential for withstanding high temperatures.

Environmental Factors:

Apart from the chemical composition and application process, environmental factors also affect Gorilla Glue’s heat resistance. Humidity, sunlight exposure, and the presence of chemicals or solvents in the surroundings can impact the glue’s performance under high heat conditions. Considering these factors when using Gorilla Glue in different environments is important.

Testing and Certification:

Gorilla Glue undergoes rigorous testing procedures to determine its heat resistance capabilities. The manufacturer conducts tests to assess the glue’s ability to withstand various temperature ranges. Look for certifications or labels on the product packaging that indicate its suitability for high-temperature applications, providing peace of mind and ensuring optimal performance.

Applications Suitable for Gorilla Glue in High Temperature Environments

We’re about to reveal the incredible applications where this adhesive shines.

- Attaching Heat-Resistant Materials: In the automotive and industrial sectors, Gorilla Glue proves its worth by bonding metal or ceramic components that face scorching temperatures. It’s a trusty sidekick that ensures your materials stay firmly together.

- Sealing and Repairing Heat-Resistant Materials: Say goodbye to annoying gaps and cracks in exhaust systems or heating elements. Gorilla Glue comes to the rescue, providing a strong seal for heat-resistant materials. Just remember to keep it away from flames or extreme temperatures.

- Bonding Insulation: Gorilla Glue excels at securely bonding insulation panels or blocks, even in the face of a fiery furnace. Whether it’s HVAC systems or industrial applications, you can rely on this adhesive to maintain insulation integrity.

- High-Temperature Electrical Connections: Need a strong and durable bond for your high temperature electrical components? Gorilla Glue is here to save the day. Just ensure that it doesn’t interfere with electrical conductivity and check for any safety hazards.

While Gorilla Glue is a superhero in high temperature environments, it’s important to recognize its limits. Always refer to the manufacturer’s guidelines and perform thorough testing before fully relying on it.

In conclusion, Gorilla Glue is your go-to adhesive for a range of high temperature applications. Whether you’re attaching heat-resistant materials, sealing and repairing, bonding insulation, or securing electrical components, this adhesive has got you covered. Just remember to exercise caution and test it out beforehand.

Precautions to Take When Using Gorilla Glue in High Temperature Environments

When it comes to gluing in high temperature environments, you need an adhesive that can withstand the heat and provide a strong and durable bond. This is where Gorilla Glue steps in as a superhero, ready to conquer any fiery challenge. However, it’s important to take precautions to ensure the best results and avoid any potential issues. In this article, we will explore the necessary precautions you need to take when using Gorilla Glue in high temperature environments.

Choose the Right Type of Gorilla Glue:

In the realm of Gorilla Glue, not all variations are created equal. To ensure success in high temperature applications, select the appropriate variation such as Gorilla Super Glue Gel, specifically designed to withstand extreme heat. Always read the product labels and choose accordingly.

Surface Preparation is Key:

Before embarking on your bonding journey, properly preparing the surfaces is crucial for a strong and enduring bond. Clean the surfaces thoroughly to remove any dirt or grease that may hinder adhesion. Use a mild detergent or rubbing alcohol for cleaning. Additionally, roughen the surfaces with sandpaper or a file to enhance adhesion.

Apply Thin Layers:

In high temperature environments, applying Gorilla Glue in thin layers ensures proper curing and minimizes heat-related issues. Thick layers may not cure properly and result in weaker bonds. So remember, thin is in.

Temperature Control:

Maintaining a stable temperature is essential for successful bonding. Extreme heat can accelerate curing, potentially leading to weaker bonds or improper adhesion. Extremely cold temperatures can slow down or prevent proper curing altogether. Check the product packaging for recommended working temperature ranges and play it cool.

Allow Sufficient Curing Time:

While some types of Gorilla Glue offer fast curing times, it’s important to allow enough time for the adhesive to fully cure and achieve maximum strength. Rushing the process can compromise the bond’s integrity and durability, especially in high temperature environments. Patience is a virtue.

Test in a Controlled Environment:

Before fully relying on Gorilla Glue in high temperature applications, it’s wise to conduct a test in a controlled environment. Apply a small amount of glue on a sample surface and subject it to the desired temperature conditions. This will help ensure that the adhesive is suitable for your specific high temperature requirements. Testing, testing, 1-2-3.

Alternatives to Consider for High Temperature Applications

When it comes to high temperature applications, Gorilla Glue may not always be the best choice. While it is a versatile and strong adhesive, it may fail under extreme heat conditions. However, fear not. There are several alternatives available that can withstand high temperatures and provide reliable bonding. In this blog post, we will explore some of these alternatives and their applications.

Epoxy Resin:

Epoxy resin, the superhero of adhesives, is a two-part adhesive known for its ability to withstand heat, chemicals, and moisture with ease.

With a temperature resistance of up to 300°F or higher, it’s the go-to option for automotive repairs, industrial machinery, and electronic components. Whether you’re fixing a car engine or repairing a circuit board, epoxy resin has got your back when the heat is on.

Silicone Adhesive:

If you need an adhesive that can handle extreme temperatures without breaking a sweat, look no further than silicone adhesive. With thermal stability ranging from -85°F to 500°F or more, it’s like having a firefighter on standby for your bonding needs. Used in aerospace, automotive, and electrical industries for sealing and bonding applications, silicone adhesive is the ultimate heat-resistant solution.

Ceramic Adhesives:

When high temperatures are the name of the game, ceramic adhesives take the gold medal. These specialized adhesives can endure temperatures up to a scorching 2000°F or more.

From furnace repairs to kiln linings to metal casting, ceramic adhesives have got the heat resistance needed to keep things together even in the hottest of situations.

Specialized High-Temperature Adhesives:

For applications that demand next-level heat resistance, specialized high-temperature adhesives are here to save the day. Designed specifically for extreme heat conditions, these adhesives can handle temperatures ranging from 500°F to over 2000°F. From aerospace to automotive to electronics, these adhesives are the superheroes of high-temperature bonding.

Manufacturer’s Instructions and Guidelines for Using Gorilla Glue

When it comes to tackling high-temperature projects, Gorilla Glue is a game-changer. This powerhouse adhesive is renowned for its unbeatable strength and versatility. However, to make the most of its heat resistance capabilities, it’s vital to follow the manufacturer’s instructions and guidelines.

Here, we’ll dive into the specifics of using Gorilla Glue in high heat environments, so buckle up and let’s get started.

Temperature Limits and Precautions:

Gorilla Glue can handle a lot, but even it has its limits when it comes to heat resistance. The manufacturer advises against continuous exposure to temperatures exceeding 200°F (93°C). Beyond this threshold, the glue may soften, weaken, or lose its adhesive properties. Remember, different formulations of Gorilla Glue may have varying heat resistance capabilities. So always refer to the specific product instructions for precise temperature limits.

Testing and Preparation:

Before diving headfirst into your high-heat project, it’s wise to conduct a trial run or test a small inconspicuous area. This will confirm whether Gorilla Glue can withstand the desired temperature without compromising its adhesive strength.

Additionally, proper surface preparation is vital for a successful bond. Ensure that surfaces are clean, dry, and free from any contaminants that could hinder adhesion.

Curing Time and Application Techniques:

Patience is key when using Gorilla Glue in high-temperature environments. Allow a 24-hour curing period for maximum bond strength. Rushing this process may result in weaker bonds that are more susceptible to damage under high heat.

Pay close attention to application techniques as well, following the manufacturer’s instructions. Proper application ensures optimal bonding performance and increases the chances of withstanding extreme temperatures.

Safety First:

While Gorilla Glue is a robust adhesive, exercise caution. Avoid direct contact between the glue and open flames or hot surfaces, as extreme heat sources can cause the glue to melt or catch fire. These safety precautions ensure your well-being and prevent potential hazards.

Exploring Alternatives:

If you’re dealing with temperatures beyond Gorilla Glue’s capabilities, fear not. Specialized adhesives designed for high-temperature applications, such as epoxy resin, silicone adhesive, and ceramic adhesives, are worth exploring. Consult the manufacturer or seek professional advice to identify suitable alternatives for your specific needs.

Conclusion:

01XSsJ3ki3M” >

Also Read: How Much Weight Can Hot Glue Hold?

Conclusion

In conclusion, Gorilla Glue has proven to be a reliable adhesive that can withstand high temperatures.

Its exceptional heat resistance makes it suitable for various applications where other glues may fail. Whether you’re working on a DIY project or repairing an item exposed to extreme heat, Gorilla Glue will hold strong.

So, if you’re looking for a glue that can handle the heat, Gorilla Glue is your go-to choice.