Are you tired of constantly fixing things that just end up breaking again?

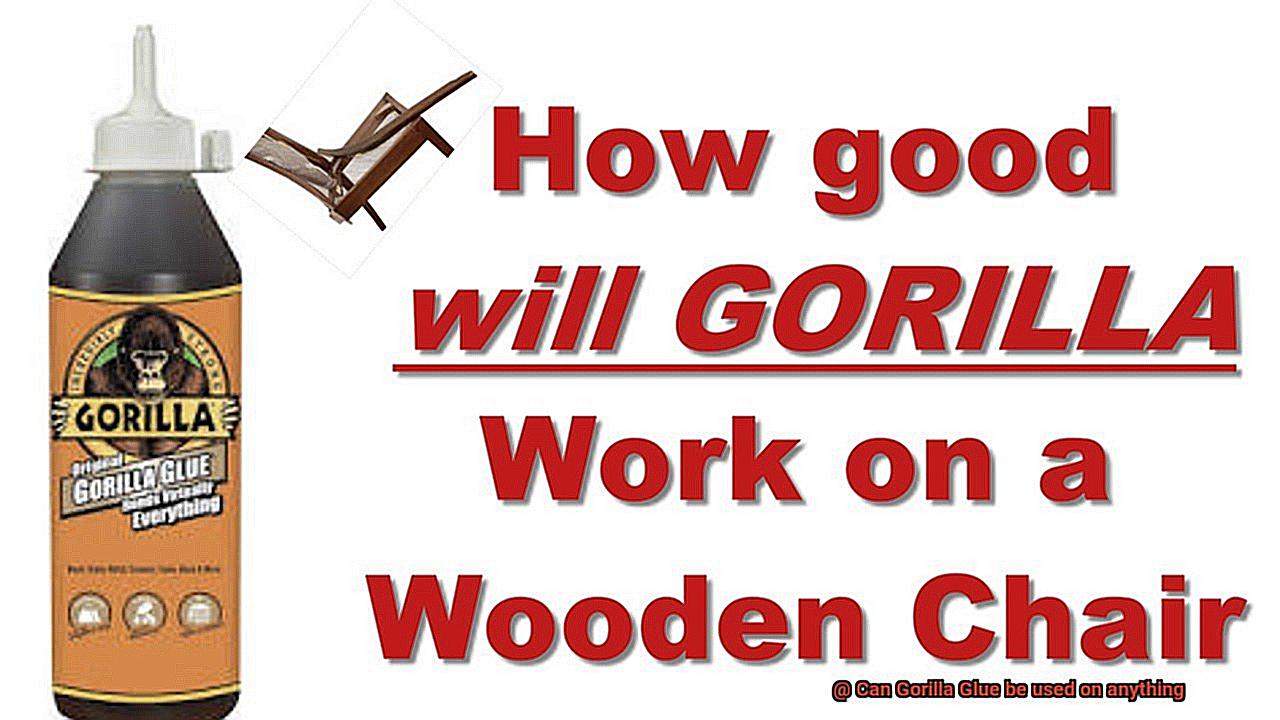

Well, get ready to meet your new best friend: Gorilla Glue. This stuff is like the superhero of adhesives – strong, versatile, and ready to tackle any project you throw its way.

But here’s the burning question: can Gorilla Glue really be used on anything? In this blog post, we’re diving deep into the world of Gorilla Glue to uncover its potential uses and discover why it’s become a must-have for all you DIY enthusiasts out there.

So, put on your safety goggles and join us on this wild adhesive adventure.

What is Gorilla Glue?

Contents

- 1 What is Gorilla Glue?

- 2 What Materials Can Gorilla Glue Bond?

- 3 What Surfaces Should be Avoided when Using Gorilla Glue?

- 4 How to Use Gorilla Glue Properly?

- 5 Does Gorilla Glue Need Moisture to Activate and Cure?

- 6 Is Excess Amount of Gorilla Glue Harmful?

- 7 What are the Advantages of Using Gorilla Glue?

- 8 Is Gorilla Glue Suitable for Outdoor Applications or Areas Exposed to Moisture?

- 9 Conclusion

In the realm of adhesives, one name stands out for its exceptional strength and versatility – Gorilla Glue. Since its introduction in 1999 by the Gorilla Glue Company, this polyurethane adhesive has become a trusted choice for DIY enthusiasts and professionals alike. Let’s take a closer look at what makes Gorilla Glue so special and why it should be a staple in your workshop.

A Bonding Powerhouse:

Gorilla Glue is renowned for its ability to bond an extensive range of materials. From wood and metal to stone, ceramic, leather, fabric, and even plastic, this adhesive can tackle virtually any project you throw at it. Say goodbye to the hassle of searching for different adhesives for different materials – Gorilla Glue has got you covered.

Unyielding Strength:

When it comes to strength, Gorilla Glue truly shines. Once it sets, it forms an incredibly strong bond that can withstand heavy loads and harsh conditions. Whether you’re repairing furniture, building shelves, or crafting intricate projects, you can trust Gorilla Glue to provide industrial-strength durability.

Waterproof Wonder:

Unlike many adhesives that lose their effectiveness when exposed to moisture, Gorilla Glue thrives in wet conditions. It is waterproof, making it perfect for repairs or projects in areas prone to water exposure or high humidity. Say goodbye to worrying about your glued items falling apart due to water damage.

Easy Application:

Gorilla Glue comes in a liquid form that requires careful application. Before using it, make sure to dampen the surface as the glue needs moisture to activate and expand properly. Apply a small amount of glue and hold or clamp the surfaces together until it dries completely. Remember: less is more with Gorilla Glue.

Compatibility Considerations:

While Gorilla Glue can work wonders on various materials, it’s important to note its limitations. Avoid using it on polyethylene or polypropylene plastics, as it may not bond effectively. Always read the product instructions and conduct a small test application on a hidden area to ensure compatibility and proper adhesion.

What Materials Can Gorilla Glue Bond?

Prepare to be amazed as we uncover the secrets of this adhesive superhero and reveal the materials it can bond.

Let’s start with the king of craftsmanship, wood. Gorilla Glue is a woodworker’s dream, perfect for projects big and small. From furniture repairs to outdoor applications, this adhesive’s water-resistant properties make it a true champion in the world of woodworking.

But hold on tight, because Gorilla Glue isn’t just for wood. Metal lovers, rejoice. This adhesive can tackle jewelry repairs, tool fixes, and even automotive parts. It’s a force to be reckoned with, no matter the metal.

Stone and ceramic enthusiasts, don’t fret. Gorilla Glue has got your back too. Broken tiles? No problem. Cracked pottery or ceramics? Consider it fixed. With Gorilla Glue, you can unleash your creativity and sculpt beautiful masterpieces.

Now, let’s talk about the tricky subject of glass. Adhering to those smooth, non-porous surfaces can be a challenge, but fear not. With proper preparation and application techniques, Gorilla Glue can create an unbreakable bond on glass.

Foam-tastic. If upholstery projects or crafting applications involving foam are your thing, Gorilla Glue is your new best friend. It securely attaches foam to other surfaces, allowing you to bring your creative visions to life.

But wait, there’s more. Gorilla Glue can also bond plastic, fabric, rubber, leather – you name it. Its versatility knows no bounds.

However, a word of caution: always test Gorilla Glue on a small area before diving headfirst into your project. It’s better to be safe than sorry.

What Surfaces Should be Avoided when Using Gorilla Glue?

When using Gorilla Glue, it’s important to know which surfaces to avoid in order to achieve optimal results and prevent any potential damage. While this versatile adhesive is known for its bonding capabilities, there are certain materials that don’t mesh well with its properties.

First and foremost, porous materials such as wood, fabric, and paper should be approached with caution. While Gorilla Glue can bond these surfaces, its expanding properties can cause the materials to absorb too much glue, resulting in a messy situation. To avoid this, it’s crucial to apply the glue sparingly and follow the instructions carefully.

Next on the “avoid” list are surfaces that are sensitive to moisture. Cardboard, foam, and certain plastics fall into this category. Gorilla Glue contains moisture that can cause these materials to warp or become damaged. So if you want to keep your craft projects from turning into a soggy mess, it’s best to steer clear of using Gorilla Glue on these surfaces.

Smooth and non-porous surfaces like glass, metal, and plastic also present challenges for Gorilla Glue. These surfaces don’t provide enough surface area for the glue to adhere properly, resulting in a weak bond that won’t hold up. So if you’re working on glass or metal projects, it’s advisable to use alternative adhesives specifically designed for these surfaces.

Additionally, extreme temperatures should be avoided when using Gorilla Glue. Surfaces exposed to high heat like ovens, stovetops, or hot pipes can cause the glue to break down or lose its effectiveness. This compromises the bond and may lead to a less-than-stellar result.

In addition to considering specific surfaces, it’s important to take into account the overall conditions in which Gorilla Glue is being used. Factors such as humidity, temperature, and proper surface preparation all play a role in the success of bonding with this adhesive.

To ensure the compatibility of Gorilla Glue with a particular surface, it’s recommended to test it on a small and inconspicuous area before applying it to the desired surface. This allows for evaluation of the bond’s effectiveness without risking any damage or discoloration.

If there is any uncertainty about whether Gorilla Glue is suitable for a specific surface, it is always best to consult the manufacturer’s instructions or seek professional advice.

How to Use Gorilla Glue Properly?

This extraordinary adhesive is renowned for its unrivaled strength and versatility. But before we dive in, let’s learn the ins and outs of using Gorilla Glue properly. Prepare to become a glue hero.

Prepare the Surfaces:

To ensure a successful bond, cleanliness is crucial. Thoroughly clean and dry the surfaces you plan to bond. Use a mild detergent or rubbing alcohol to remove any dirt, grease, or contaminants. Remember, we need those surfaces sparkling clean.

Less is More:

Gorilla Glue is a superhero that doesn’t require hefty amounts. Apply a small amount of glue to one of the surfaces you want to bond. Don’t fret. The glue expands as it cures, so a thin layer will do wonders.

Hold It Tight:

Now comes the moment of truth. Press the two surfaces firmly together. Utilize clamps or heavy objects to maintain pressure while the glue works its magic. Our goal is an unbreakable and secure bond, after all.

Activate and Cure:

Activate Gorilla Glue’s powers by introducing moisture. Lightly mist the glued area with water before clamping it together. This moisture helps the glue expand and creates an incredibly strong bond that can withstand anything.

Watch Out for the Foam.

Be mindful of Gorilla Glue’s foam-like expansion during the curing process. Leave a small gap between the surfaces to allow for this expansion. We don’t want any sticky surprises ruining our project.

Patience is Key:

Allow at least 24 hours for the glue to dry and cure. During this time, avoid putting any stress on the bond. Remember, good things come to those who wait.

Does Gorilla Glue Need Moisture to Activate and Cure?

In the world of adhesive superheroes, one brand stands tall above the rest – Gorilla Glue. Loved by DIYers, craft enthusiasts, and professionals alike, this adhesive is renowned for its exceptional strength and versatility. But does Gorilla Glue need moisture to activate and cure? Let’s dive into the science behind this superhero adhesive and uncover the truth.

The Science Behind Gorilla Glue:

Gorilla Glue is a polyurethane-based adhesive that works its magic through a chemical reaction to create an unyielding bond. Unlike some other glues, moisture is not a prerequisite for activating this powerful adhesive’s superpowers. In fact, excessive moisture can even hinder its bonding process.

The Role of Moisture:

When Gorilla Glue comes into contact with moisture, it expands, creating a foam-like substance. This expansion allows the glue to effectively penetrate porous surfaces, resulting in a formidable bond. However, too much moisture can cause excessive foaming, which weakens the adhesive’s effectiveness.

Humidity Matters:

While Gorilla Glue doesn’t require moisture to activate and cure, it does rely on some level of humidity in the air to facilitate the curing process. In extremely dry conditions, the glue may take longer to cure and achieve its full strength. However, fear not. Normal indoor conditions typically provide sufficient humidity for optimal curing.

Proper Application Techniques:

To ensure the best results when using Gorilla Glue, it is recommended to lightly dampen one of the surfaces being bonded. This activates the curing process and enhances the bond’s strength. However, be cautious not to oversaturate the surface with water, as this can compromise the glue’s ability to bond effectively.

Follow the Manufacturer’s Guidance:

To truly harness the extraordinary powers of Gorilla Glue, it is vital to follow the manufacturer’s instructions meticulously. This includes applying the glue sparingly and ensuring proper ventilation during the curing process. Ignoring these guidelines may result in weaker bonds or other issues.

Is Excess Amount of Gorilla Glue Harmful?

Today, we’re going to uncover the truth about using an excess amount of this adhesive. Get ready for a sticky adventure filled with expansion, cleanup challenges, and unsightly residue.

Let’s start with expansion. When Gorilla Glue meets moisture or water, it undergoes a magical chemical reaction that causes it to expand and foam up. It’s like watching glue come alive. But be careful, my friends. Too much glue can create a messy situation and potentially damage the surfaces you’re trying to bond. We don’t want your masterpiece turning into a sticky disaster.

Speaking of disasters, let’s talk cleanup. Once Gorilla Glue dries and hardens, it becomes as stubborn as your least favorite ex. Trust me, you do not want to tangle with a glue mess that refuses to budge. It’s like wrestling an alligator. And if that’s not enough, it can leave behind a visible residue that will haunt your project forever. Nobody wants their masterpiece ruined by lingering glue ghosts.

Now, let’s not forget the golden rule: always follow the manufacturer’s instructions. They know their stuff. Applying too much Gorilla Glue goes against their recommendations and can lead to unwanted consequences. Don’t be a rebel when it comes to adhesive application. Stick (pun intended) to the guidelines for a successful project.

To sum it all up, excess Gorilla Glue (or any adhesive, really) can cause expansion problems, cleanup nightmares, and unsightly residue. It’s like entering the jungle without a map – you’re bound to get lost. So remember my fellow glue enthusiasts, less is more when it comes to adhesive application. Keep it moderate and follow the rules for a happy gluing experience.

What are the Advantages of Using Gorilla Glue?

Today, we’ll explore the numerous advantages of using Gorilla Glue – a true game-changer for all your projects. So, grab your safety goggles and let’s dive into the wonders of this remarkable adhesive.

Versatility:

Gorilla Glue is an all-rounder adhesive that can bond a vast array of materials. From wood and metal to stone, ceramics, foam, and glass, it’s a one-stop solution. Say goodbye to cluttered toolboxes filled with multiple adhesives.

Unyielding Bond:

Need a bond that can stand up to heavy loads and extreme weather conditions? Look no further. Gorilla Glue forms an incredibly strong and durable bond that can tackle even the toughest tasks. It’s perfect for outdoor repairs or securing loose tiles with confidence.

Waterproof Wonder:

Don’t let water sabotage your projects. Once cured, Gorilla Glue becomes resistant to water, making it ideal for repairs in wet environments or fixing leaking pipes. No more soggy surprises.

Bonding Different Materials:

Gorilla Glue breaks barriers by effortlessly bonding dissimilar materials. Whether it’s wood to metal or ceramic to plastic, this adhesive is a true matchmaker for all your project needs.

Expanding Magic:

Frustrated by uneven or irregular surfaces? Fear not. Gorilla Glue expands as it cures, filling in gaps and creating a secure bond. It’s like magic that ensures your project stays intact, no matter the surface challenges.

Safety First:

Once fully cured, Gorilla Glue is non-toxic, making it safe to use on items that come into contact with food or are handled by children or pets. Just remember to keep it away from your eyes and skin during application.

Temperature Resistant:

No matter the temperature fluctuations, Gorilla Glue can handle it all. Whether your project is exposed to scorching heat or freezing cold, this adhesive won’t let you down. It’s a glue you can rely on, in any climate.

Ease of Use:

No need to stress over complicated application techniques. Gorilla Glue comes in various formats and can be applied using a brush or spreader. Excess glue can be easily wiped away with a damp cloth, saving you from sticky situations.

Long Shelf Life:

Say goodbye to wasted glue. Gorilla Glue has a long shelf life when stored properly. You can keep it for future projects without worrying about it drying out or losing its effectiveness. It’s an adhesive that stands the test of time.

Is Gorilla Glue Suitable for Outdoor Applications or Areas Exposed to Moisture?

When it comes to outdoor projects or areas exposed to moisture, finding the right adhesive can be a challenge. But fear not, avid DIYers and craft enthusiasts. We’re here to shed light on whether Gorilla Glue is suitable for such applications. So grab your tool belt and let’s dive into the world of Gorilla Glue.

Factor 1: Water Resistance:

Gorilla Glue is like a superhero when it comes to water resistance. It can tolerate some exposure to moisture, making it perfect for outdoor applications. However, keep in mind that it isn’t completely waterproof. If your project is frequently drenched or submerged, you might want to consider specialized waterproof adhesives instead.

Factor 2: Surface Preparation:

Before unleashing the power of Gorilla Glue outdoors, make sure the surface is as clean and dry as a desert breeze. Moisture or dirt can interfere with the bonding process and compromise its strength. So, give that surface a good scrub-down before applying Gorilla Glue for optimal results.

Factor 3: Specialized Waterproof Adhesives:

For areas with constant exposure to water or high moisture levels – think bathrooms or kitchens – it’s wise to opt for specialized waterproof adhesives. These adhesives are like armor against moisture, specifically formulated to withstand the harshest conditions and provide a bond that won’t let you down.

Factor 4: Seal It Up:

If you do decide to use Gorilla Glue for outdoor applications, consider adding an extra layer of protection. Apply a waterproof sealant or protective coating over the glued area. This superhero duo will enhance durability and shield against moisture intrusion, ensuring your project withstands the test of time.

Factor 5: Extreme Temperatures:

Gorilla Glue is strong, but extreme temperatures can be its kryptonite. It performs best within certain temperature ranges. So, before embarking on your outdoor adventure, check the manufacturer’s instructions for temperature requirements to ensure optimal performance. Don’t let the elements get the upper hand.

Also Read: Gorilla Glue – Glue Things

Conclusion

Gorilla Glue, renowned for its strength and versatility, has become a go-to adhesive for many DIY enthusiasts. Its exceptional bonding power makes it suitable for a wide range of materials, from wood and metal to plastic and fabric. Whether you’re fixing broken furniture or creating intricate crafts, Gorilla Glue can be your reliable companion.

But let’s not get carried away. While Gorilla Glue is indeed a formidable adhesive, it does have its limitations. Despite its impressive capabilities, it may not be suitable for every surface or material out there. It’s essential to consider factors such as porosity, flexibility, and compatibility before deciding to use Gorilla Glue.

For instance, when it comes to porous surfaces like foam or certain fabrics, Gorilla Glue may not provide the best results. Its strong adhesive properties can cause excessive expansion and damage delicate materials. In these cases, opting for a more specialized adhesive designed specifically for porous surfaces would be a wise choice.

Furthermore, Gorilla Glue may not be the ideal option for flexible materials that require some degree of movement or bending. Its rigid nature can hinder the flexibility of certain items like rubber or elastic bands. In such instances, seeking an adhesive that offers both strength and flexibility would be more appropriate.

It’s also crucial to note that while Gorilla Glue excels in bonding various materials together securely, it may struggle with certain types of plastics due to their low surface energy. Some plastics contain additives like silicone or polypropylene that can make adhesion challenging even for mighty Gorilla Glue.

So yes, while Gorilla Glue is undoubtedly a remarkable adhesive with countless applications, it’s important to remember that it might not work on everything. Understanding its strengths and limitations will help you make informed decisions when choosing the right adhesive for your specific project.

In conclusion, Gorilla Glue is an exceptional adhesive that can tackle many tasks with ease. However, it’s crucial to assess the surface, material, and intended use before reaching for this mighty adhesive.