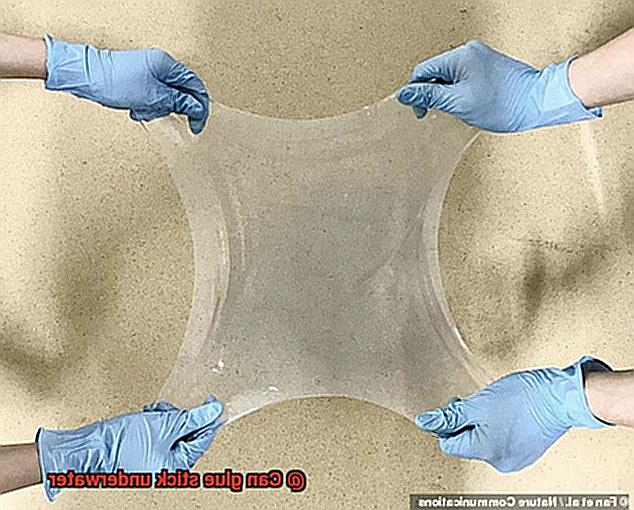

Have you ever found yourself in a situation where you need to fix something underwater? Maybe a leaky pool or a broken aquarium? You might be wondering, can glue stick underwater? Well, wonder no more. This is a question that has puzzled many, but the answer might surprise you.

Glue is designed to bind materials together, but using it underwater can be tricky. Most traditional adhesives tend to lose their sticky properties when submerged in water. And even if they stay sticky, they may not be able to withstand the pressures of water. But fear not. Gluing underwater is possible with the right adhesive and techniques.

In this blog post, we’ll explore the science behind glue and how it works. We’ll also dive into different types of adhesives on the market and which ones we recommend for aquatic use. Plus, we’ll provide some helpful tips on how to use glue effectively underwater.

So, put on your wetsuit and get ready to plunge into the world of gluing underwater.

Types of Glue Suitable for Underwater Bonding

Contents

- 1 Types of Glue Suitable for Underwater Bonding

- 2 Unsuitable Glues for Underwater Bonding

- 3 Advantages and Disadvantages of Using Glue Underwater

- 4 Preparing the Surface for Underwater Bonding

- 5 Applying the Adhesive Properly in Wet Environments

- 6 Curing Process and Factors to Consider When Working with Wet Adhesives

- 7 Tips and Tricks for Achieving Maximum Bond Strength Underwater

- 8 Common Mistakes to Avoid When Using Glue Underwater

- 9 Conclusion

Underwater bonding requires a specific type of glue that can withstand the challenges of being submerged in water. The following are the different types of glue suitable for underwater bonding.

Two-part epoxy

This is a popular adhesive used for underwater repairs on boats, swimming pools, and other water-related structures. Two-part epoxy is made up of two components that are mixed together to create a strong and durable bond. This adhesive is known for its strength and durability, making it ideal for various underwater applications such as repairing leaks in swimming pools or aquariums.

Cyanoacrylate glue

Also known as superglue, this adhesive is perfect for small repairs or bonding tasks in aquatic environments. While cyanoacrylate glue is not specifically designed for use underwater, it can still bond well to certain surfaces when submerged in water. It’s important to choose a product specifically designed for underwater use, as these types of glues are formulated to resist water and maintain their bond.

Silicone adhesive

This type of glue is waterproof and can adhere well to a variety of surfaces, making it a popular choice for underwater repairs on aquariums and other water-related structures. Silicone adhesive is known for its flexibility and waterproof properties, making it an excellent choice for applications that require some degree of movement.

Marine-grade adhesive

Specifically formulated for use in marine environments, including underwater applications, this adhesive can withstand exposure to saltwater and other harsh elements, making it ideal for use on boats or other watercraft. Marine-grade adhesive is perfect for bonding materials in saltwater or freshwater environments and can create a long-lasting bond even under harsh conditions.

PVA glue or hot glue

These types of adhesives are not recommended for use in wet environments as they are not waterproof and will not adhere well when submerged in water. It’s important to choose the right type of adhesive that suits your specific underwater bonding needs.

Epoxy

Epoxy, the adhesive that has become synonymous with strength and durability, has made a name for itself in the world of bonding. But what about using it underwater? Is it really up to the task in extreme conditions?

Epoxy is a two-part adhesive that consists of a resin and a hardener. When combined, they form a bond that can stick to various surfaces, such as ceramics, metals, plastics, and even wood. However, while epoxy is known for its strength, it may not be the best choice for underwater applications.

The main challenge of using epoxy underwater is ensuring that the surfaces to be bonded are clean and dry. Contaminants or moisture can interfere with the bonding process, causing the bond to weaken over time. And let’s face it, keeping things dry when you’re working underwater is no easy feat.

In addition to cleanliness issues, water pressure can also affect the bond’s strength. The pressure can cause the bond to fail, which is obviously not ideal if you’re trying to repair something underwater.

However, not all hope is lost. Some types of epoxy are designed specifically for use underwater. These special epoxies may contain additives or curing agents that help them bond to wet surfaces and withstand water pressure.

It’s essential to carefully consider your application and choose an adhesive that is designed for the specific conditions and requirements. While epoxy may be a strong adhesive for many applications, using it underwater requires extra caution and attention to detail.

When selecting an adhesive for underwater use, consider the following:

- Research the manufacturer’s recommendations

- Ensure the surfaces are thoroughly cleaned and dry

- Opt for epoxies designed specifically for underwater use

- Check if the product contains any special curing agents or additives

- Consider the water pressure and conditions

Cyanoacrylate (Super Glue)

Before you dive in, let’s explore the limitations of this powerful adhesive.

Cyanoacrylate is known for its strong bonding capabilities, but it requires moisture to cure. This means that the presence of water can interfere with its effectiveness in wet environments. While it may technically bond underwater, it’s not the ideal choice for your aquatic repairs.

However, there are some specialized formulations of cyanoacrylate-based adhesives that are specifically designed for use in wet environments such as aquariums or swimming pools. These adhesives cure quickly and effectively in the presence of water, but they may not be as strong as traditional cyanoacrylate adhesives.

If you must use cyanoacrylate underwater, make sure to dry the surface as much as possible before applying the adhesive. This will help ensure that the glue cures properly and forms a solid bond. But keep in mind that cyanoacrylate can be toxic if ingested or inhaled, so always follow safety precautions and use it in a well-ventilated area. And avoid using it near living organisms in aquatic environments.

Unsuitable Glues for Underwater Bonding

If you’re planning on bonding underwater, it’s essential to choose the right glue for the job. As an expert in this field, I can tell you that not all glues are created equal. Some types of glue are simply unsuitable for underwater bonding due to their chemical composition, inability to set or cure in a wet environment, or lack of strength to withstand water pressure.

Firstly, water-based and solvent-based adhesives may seem like good choices for underwater bonding, but unfortunately, they often break down when exposed to water. This means they won’t be effective in creating a strong bond. Similarly, solvent-based adhesives may also fail to bond properly underwater due to their solvents evaporating too quickly in the presence of water.

Moreover, some glues require a dry environment to cure correctly and won’t set properly in a wet environment. Epoxies are great for bonding surfaces together but need a dry environment to cure properly. Using epoxy underwater will result in it not setting and failing to create a strong bond.

Furthermore, some glues aren’t strong enough to withstand the force and pressure of water. Hot melt glue is an excellent option for bonding surfaces together quickly and easily, but it’s not suitable for use in water as it can easily melt and lose its adhesive properties.

So what should you do if you need to bond something underwater? Opt for stronger options like marine grade epoxy or cyanoacrylate glue specifically designed for underwater use. These glues are specially formulated with unique properties that allow them to bond effectively underwater without breaking down or losing their adhesive properties.

PVA Glue

PVA (polyvinyl acetate) glue is a water-based adhesive that has gained popularity in the arts and crafts world, as well as woodworking and construction. It’s known for its strong bonding properties and its ability to dry clear.

But what about using PVA glue underwater? Unfortunately, it’s not recommended. PVA glue requires air to cure and create a strong bond, so submerging it in water would prevent it from drying properly. This means that any aquatic project you’re working on will have a weak bond that won’t hold up underwater.

Furthermore, PVA glue can dissolve in water, which further weakens its bonding properties. So if you’re planning on using PVA glue for any aquatic projects, you might want to reconsider and look for specialized adhesives designed for underwater use.

For instance, marine epoxy is a two-part adhesive that creates a strong, waterproof bond that can withstand the harsh conditions of saltwater environments. It’s specifically designed for use underwater, making it an excellent choice for aquatic projects.

Hot Glue

Hot glue is a popular adhesive that’s easy to use and versatile, making it perfect for a wide range of craft projects, home repairs, and even some DIY projects. However, when it comes to sticking things underwater, hot glue is like a fish out of water.

The primary reason why hot glue isn’t suitable for underwater projects is due to its chemical composition. Composed of thermoplastic polymers designed to melt and solidify quickly, hot glue can become soft and pliable when exposed to water. This can cause the bond between surfaces to weaken or break.

Furthermore, hot glue’s curing process requires heat to set correctly. When submerged in water, the heat dissipates quickly, making it difficult for the glue to cure properly. This can result in a weak bond or no bond at all.

If you’re looking for better options for underwater projects, epoxy and silicone adhesives are specifically designed to bond with surfaces in wet environments. They provide a secure and long-lasting hold that won’t break down or become pliable when exposed to water.

Advantages and Disadvantages of Using Glue Underwater

You’ve probably faced the challenge of finding the right adhesive to use underwater. While hot glue may be versatile, it struggles to bond underwater due to its thermoplastic composition and curing process. But don’t worry, there are other options available, such as epoxy and silicone adhesives. However, before jumping into using glue underwater, it’s crucial to understand the advantages and disadvantages that come with it.

Let’s start with the advantages. For one, underwater glues are incredibly versatile. They can be used on a range of materials, including metal, plastic, and glass, making them an excellent choice for various applications. Moreover, gluing underwater can save time by eliminating the need to drain water from an area before making repairs or attaching objects. And lastly, some underwater adhesives are formulated to create a strong bond even in wet conditions.

Despite its benefits, using glue underwater also has its drawbacks. One major disadvantage is that not all underwater glues can be used on all types of materials. This can limit your options when choosing an adhesive for your project. Another disadvantage is that some underwater adhesives may not work as well in colder water temperatures. Lastly, if not used responsibly, underwater glue can harm marine life and damage the environment.

It is essential to note that using glue underwater should be done cautiously and according to the product’s instructions. Furthermore, it’s crucial to choose a product that is safe for both the surrounding environment and marine life. When working on an aquatic project, consider the following points:

Advantages:

- Versatile adhesive

- Time-saving

- Strong bond

Disadvantages:

- Limited material range

- Temperature sensitivity

- Potential harm to marine life

Preparing the Surface for Underwater Bonding

I’m here to guide you through the essential steps of preparing the surface for underwater bonding.

Surface preparation is key to ensuring that glue will stick underwater. Contaminants such as oil, grease, or dirt can prevent the adhesive from adhering properly. Therefore, thorough surface cleaning is imperative to create an optimal environment for adhesive bonding.

But cleaning alone is not enough. The surface must also be roughened or etched to provide a better bond for the adhesive. One common technique for this is abrasive blasting. This process involves shooting abrasive particles at the surface, removing any contaminants and creating a texture that allows the adhesive to adhere effectively.

Chemical etching is another method used to prepare surfaces for underwater bonding. However, this technique should only be performed by trained professionals since it involves using an acid or other chemicals that can be dangerous if not handled correctly. It dissolves a thin layer of the surface, creating a roughened texture that improves adhesive bonding.

Once the surface has been prepared, it’s crucial to ensure that it’s completely dry before applying any adhesive. Any moisture on the surface can prevent the glue from bonding correctly. Therefore, it’s essential to use a drying agent or wait for the surface to dry naturally before proceeding.

In conclusion, preparing the surface for underwater bonding is a crucial step in ensuring success. To summarize:

- Thoroughly clean the surface to remove any contaminants.

- Roughen or etch the surface to create an optimal environment for adhesive bonding.

- Ensure that the surface is completely dry before applying any adhesive.

Applying the Adhesive Properly in Wet Environments

Choosing the right type of adhesive and properly preparing the surfaces are vital for ensuring the success of your project.

When it comes to wet environments, not all adhesives are created equal. Epoxy, a two-part adhesive consisting of a resin and a hardener, is a popular option for underwater applications due to its ability to create a strong, waterproof bond.

It’s perfect for repairing boats or watercraft and adhering tiles in areas frequently exposed to water. On the other hand, cyanoacrylate, also known as super glue, can be an alternative option for wet conditions. However, it may not work as well on certain materials such as rubber or silicone. So, before making a selection, ensure you do your research.

Now that you have chosen your adhesive, it’s time to prepare the surfaces correctly. This step is often overlooked but is essential. You need to remove any dirt or debris and ensure the surfaces are completely dry before applying the adhesive. In some cases, roughing up the surface with sandpaper or a wire brush can improve the bond.

Lastly, it is important to consider temperature and humidity when applying adhesive in wet environments. Some adhesives may not set properly if it’s too cold or if there is too much moisture in the air. Therefore, you should check the manufacturer’s instructions for optimal temperature and humidity levels.

Curing Process and Factors to Consider When Working with Wet Adhesives

Working with wet adhesives can be a challenging task, particularly when it comes to achieving a robust bond in an underwater application. The curing process is a critical step in creating a reliable bond, and there are several factors to consider when working with wet adhesives.

Firstly, it’s important to recognize that wet adhesives can be adversely affected by water or high moisture levels. As a result, it’s crucial to follow the manufacturer’s instructions carefully and apply the adhesive in a dry environment. This will guarantee that the adhesive cures correctly and creates a durable bond.

Surface preparation is another vital factor to consider. It may be necessary to use a primer or surface preparation product to ensure that the adhesive bonds correctly to the substrate. This will eliminate any contaminants or debris that could interfere with the bonding process.

Temperature and humidity also play a role in the curing process of wet adhesives. Some adhesives require specific environmental conditions such as elevated temperatures or low humidity to cure correctly. Therefore, it’s essential to consider the application requirements and substrate materials when selecting an adhesive for underwater applications.

When selecting an adhesive for underwater applications, it’s vital to choose one that is specifically designed for submerged environments. Some adhesives may not be suitable for underwater applications and could fail to create a strong bond.

To sum up, achieving a robust bond with wet adhesives requires careful consideration of several factors. Proper surface preparation, environmental conditions, and adhesive selection are all critical elements that can influence the curing process and lead to a successful bond.

By taking these factors into account, you can ensure that your underwater applications are reliable and long-lasting.

Tips and Tricks for Achieving Maximum Bond Strength Underwater

If you’re planning on bonding materials underwater, you need to ensure that the bond strength is maximized. From selecting the right adhesive to applying it correctly, there are several tips and tricks to follow to achieve a strong and durable bond underwater.

Choose the Right Adhesive

Not all adhesives are suitable for underwater applications. To ensure maximum bond strength, choose an adhesive that is specifically designed for wet environments. Marine epoxy and cyanoacrylate glue are two popular options that work well underwater.

Prepare the Surface

For an adhesive to form a strong bond underwater, the surfaces being bonded must be clean and dry. This can be challenging due to the presence of debris and algae. Use a wire brush or sandpaper to roughen up the surface and improve adhesion.

Apply Correctly

To achieve maximum bond strength, follow the manufacturer’s instructions carefully when applying the adhesive. Some adhesives may require mixing before application, while others can be applied directly from the tube. Applying pressure to the bond with clamps or weights, or by pressing the surfaces together firmly with your hands can also help.

Allow for Sufficient Curing Time

Underwater conditions can slow down the curing process of adhesives. It is important to allow sufficient time for them to fully cure before subjecting them to any stress or pressure. This can help ensure maximum bond strength.

Reinforce if Needed

Sometimes, additional techniques or materials may be necessary to reinforce the bond strength underwater. Consider using mechanical fasteners or other types of reinforcement materials in addition to the adhesive.

Common Mistakes to Avoid When Using Glue Underwater

It’s essential to understand the common mistakes people make when working with adhesives in submerged environments. Avoiding these mistakes will not only save you time and money but also prevent possible environmental damage. Keep reading to learn about the most common mistakes to avoid when using glue underwater.

Not Using the Right Type of Glue

The first and most crucial mistake people make is using the wrong type of glue. Not all adhesives are created equal, and not all of them are meant to be used underwater. Using an unsuitable adhesive can result in a weak bond or no bond at all, compromising your project’s success.

It is essential to use a glue specifically designed for underwater use. Look for adhesives labeled “water-resistant” or “submersible” to ensure a strong bond.

Failing to Prepare the Surface

Another common mistake is failing to prepare the surface adequately before applying the adhesive. As with any other adhesive, the surface that you’re attaching something to needs to be clean and dry for the glue to work properly.

Underwater surfaces can be particularly challenging to prepare because they may have algae or other debris that needs to be removed before application. Take the time to clean and dry the surface thoroughly before applying any adhesive.

Applying Too Much Glue

Applying too much glue is another common mistake that can weaken the bond rather than strengthen it. Contrary to popular belief, more adhesive doesn’t always mean a stronger bond; it can even create a mess that’s challenging to clean up afterward. Therefore, it’s crucial to apply just enough adhesive to create a secure bond without overdoing it.

Rushing the Drying Process

Lastly, rushing the drying process can lead to a weak bond or no bond at all. Glues need time to dry and cure correctly, even underwater. Rushing this process can prevent the adhesive from bonding correctly and compromise its strength. Therefore, it’s essential to allow enough time for the glue to dry and cure entirely before testing its strength.

SM6CaWA9Snw” >

Also Read: Is Super Glue Waterproof? – Glue Things

Conclusion

When it comes to the question of whether glue can stick underwater, the answer is not a simple yes or no.

While some types of glue may be able to adhere in wet environments, others simply cannot withstand the moisture. It’s important to consider the specific type of glue and its intended use before attempting to use it underwater.

So, if you’re planning on using glue in an aquatic setting, make sure to do your research and choose a product that is specifically designed for underwater use.