Concrete, the unsung hero of the construction world, is renowned for its strength, durability, and versatility. It’s no wonder that when it comes to repairing concrete or creating composite structures, the idea of gluing concrete to concrete has gained popularity. But can you really stick two slabs of concrete together using adhesive?

In this blog post, we dive into the world of concrete adhesives, exploring both the advantages and challenges that arise when attempting to create a bond between two concrete surfaces. We’ll discuss how using adhesives can enhance structural integrity, increase load-bearing capacity, and offer more design flexibility. However, we’ll also shed light on the obstacles you may encounter along the way, such as surface preparation, adhesive selection, and long-term bonding performance.

As we reveal the secrets behind achieving a reliable bond between concrete surfaces, you’ll discover that concrete adhesion is a complex art form. From understanding different types of adhesives to mastering surface preparation techniques, this blog post aims to equip you with the knowledge needed for successful concrete-to-concrete bonding projects.

So join us as we delve deeper into the advantages and challenges of gluing concrete to concrete. Get ready to uncover the intricacies of this fascinating bonding battle that lies at the very foundation of construction and repair projects.

What is Concrete?

Contents

Concrete, a material that has revolutionized the construction industry, forms the backbone of modern architecture. From towering skyscrapers to intricate road networks, concrete structures have shaped the world we live in today.

In this comprehensive exploration of concrete, we will delve into its composition, strengths, weaknesses, and most importantly, its bonding capabilities. Join us as we unravel the wonders of concrete and discover if it can indeed be glued to concrete.

Understanding Concrete:

Concrete is a composite material comprising cement, water, and aggregates such as sand, gravel, or crushed stone. Acting as a binder, cement holds these components together. Through a chemical reaction called hydration, cement and water combine to form crystals that bind the mixture and provide concrete with its remarkable strength.

The Strengths and Weaknesses of Concrete:

Concrete is renowned for its exceptional compressive strength, enabling it to bear substantial loads. However, it falters in terms of tensile strength, struggling to resist stretching or pulling forces effectively. To overcome this limitation, reinforcement materials like steel bars or fibers are introduced to enhance its structural integrity.

Can Concrete be Glued to Concrete?

Indeed. With the right adhesive and proper surface preparation, it is possible to bond concrete to concrete. Epoxy resin stands as the most commonly used adhesive due to its superior bonding properties. Before applying the adhesive, thorough cleaning of the concrete surface is essential to remove any contaminants that might impede bonding. Additionally, roughening the surface with a wire brush or sandpaper promotes better adhesion.

Steps for Successful Concrete Bonding:

- Cleanse the surface: Eliminate dirt, dust, and grease from the concrete.

- Roughen the surface: Employ a wire brush or sandpaper to create a textured surface.

- Select the appropriate adhesive: Epoxy resin is highly recommended for concrete bonding.

- Follow manufacturer’s instructions: Mix the epoxy components according to instructions and apply them to both surfaces.

- Press the surfaces together: Ensure a firm bond by holding the surfaces in place until the adhesive cures.

- Additional reinforcement (if necessary): Consider embedding reinforcing bars or mesh within the adhesive layer for added strength.

Alternative Adhesive Options:

While epoxy resin remains the preferred choice for concrete bonding, other adhesives like polyurethane and acrylic can also provide substantial bonding strength. However, it is crucial to select an adhesive specifically designed for bonding concrete surfaces and adhere to the manufacturer’s instructions for optimal results.

Can Concrete be Glued to Concrete?

Concrete, known for its durability and strength, can indeed be glued to itself using special adhesive products designed specifically for bonding concrete surfaces together. These concrete adhesives, also known as concrete bonding agents, consist of a combination of chemicals like polymers and resins that work in tandem to create a powerful bond capable of withstanding the test of time.

To successfully glue concrete to concrete, proper surface preparation is crucial. Cleaning the surfaces thoroughly to ensure proper adhesion is essential. This involves removing dust, dirt, oil, and loose particles using a wire brush or pressure washer.

Once the surfaces are clean, the adhesive can be applied following the manufacturer’s instructions. It is important to adhere to the recommended curing time for the adhesive, allowing it to fully bond the concrete surfaces together. During this curing period, protecting the bonded area from extreme temperatures and moisture is vital, as these factors can impact the effectiveness of the adhesive.

In some cases, additional reinforcement may be necessary to provide extra strength and stability to the bonded concrete surfaces. This reinforcement can include using steel reinforcement bars or mesh.

When attempting to glue concrete to concrete, it is advisable to consult with a professional or manufacturer for specific product recommendations and guidance. Different adhesives may have various requirements and limitations, making it crucial to select the right product for the intended application.

What Type of Adhesive Should I Use for Gluing Concrete?

Concrete, known for its strength and durability, can be bonded together using the right adhesive. But with a multitude of options available, it can be challenging to determine which adhesive is best for gluing concrete to concrete. Don’t fret. We have delved into the world of adhesives to provide expert advice on this crucial matter.

The Power Players: Epoxy, Polyurethane, and Construction Adhesive

When it comes to bonding concrete surfaces, three adhesives reign supreme: epoxy, polyurethane, and construction adhesive. Let’s explore their unique properties and strengths.

Epoxy Adhesive:

Epoxy adhesives are renowned for their exceptional bonding properties and high strength. Comprised of a resin and a hardener that require mixing before application, epoxy adhesives create robust and lasting bonds that can withstand heavy loads and harsh environmental conditions.

Polyurethane Adhesive:

Flexibility and versatility are the hallmarks of polyurethane adhesives when it comes to bonding different materials, including concrete. They offer excellent resistance to moisture, chemicals, and temperature variations, making them suitable for indoor and outdoor applications alike.

Construction Adhesive:

Specifically designed for bonding various construction materials, including concrete, construction adhesives provide a strong bond between surfaces. Whether you prefer solvent-based or water-based formulas, these adhesives offer flexibility to suit different application requirements.

Preparation is Key: Surface Preparation Tips

To achieve an impeccable bond when gluing concrete to concrete, proper surface preparation is essential. Thoroughly clean the surfaces, ensuring they are dry and free from dust or debris. Enhance the adhesive’s grip by roughening the surfaces with sandpaper or a wire brush.

The Sacred Application Ritual

Now that the stage is set, it’s time for the adhesive to work its magic. Follow the manufacturer’s instructions diligently, applying the adhesive with precision and care. Allow ample time for the adhesive to cure and solidify its grip on your concrete creation.

Protecting Your Bonded Creation

To ensure the longevity of your adhesive alliance, shield it from extreme temperatures and moisture. Consider reinforcing the bond with steel bars or mesh for added stability and resilience.

Seeking Expert Guidance

When embarking on this concrete bonding adventure, it’s wise to consult professionals or manufacturers for specific product recommendations and guidance. Each adhesive may have unique requirements and limitations, making expert advice invaluable for achieving success.

Preparing the Surface for Gluing Concrete

Before we dive into the exciting world of gluing concrete, it’s crucial to lay a solid foundation for success by properly preparing the surface. In this comprehensive guide, we will explore the essential steps required to achieve a strong and unbreakable bond between concrete surfaces. So, grab your tools and let’s get started on our journey to mastering the art of gluing concrete.

Step 1: Removing Loose or Crumbling Concrete

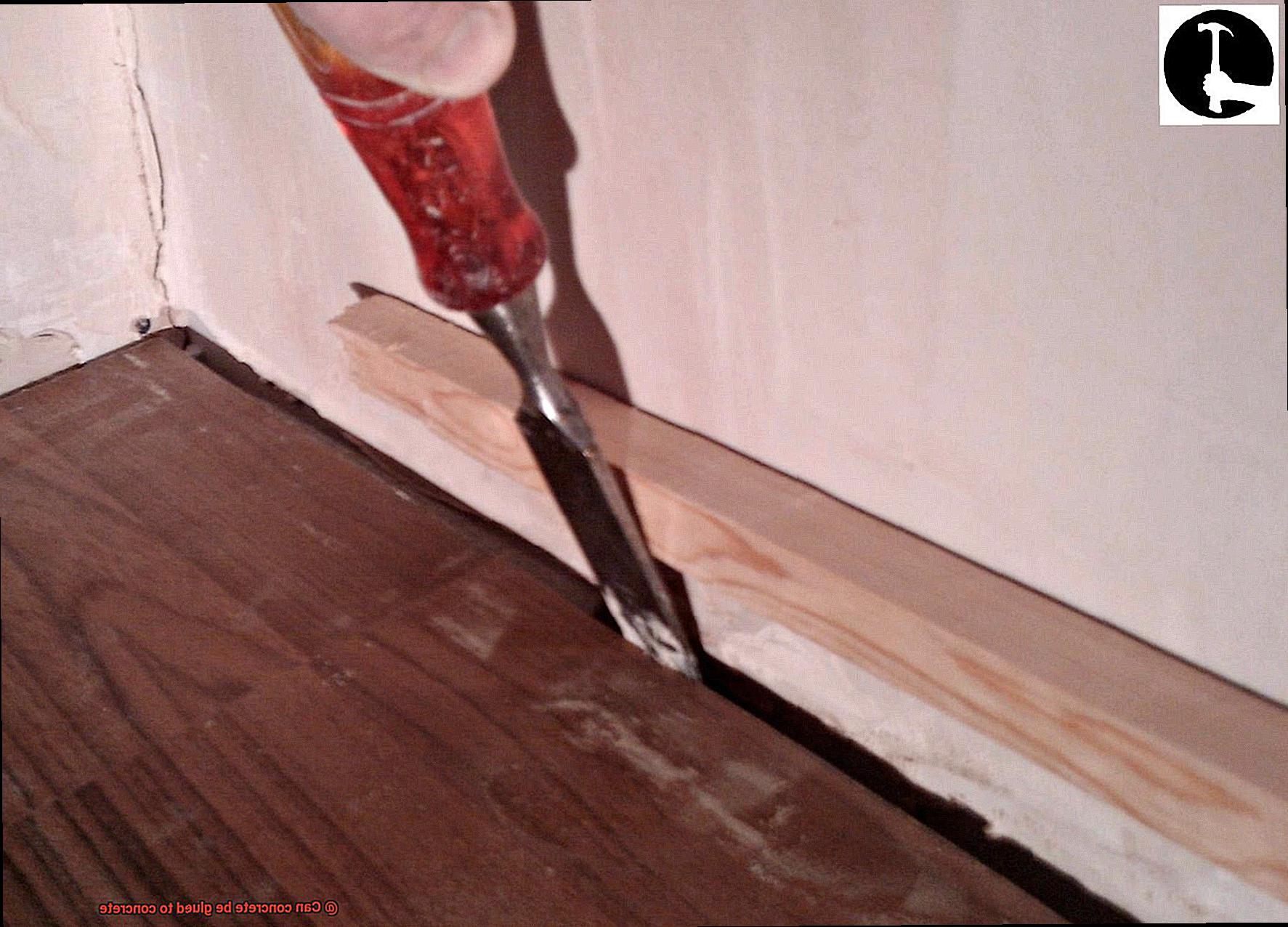

The first step in preparing the surface for gluing is to eliminate any loose or crumbling concrete. Use a trusty chisel or hammer and chisel to carefully remove all unstable material. This step creates a smooth and even surface, allowing the adhesive to grip securely.

Step 2: Thoroughly Cleaning the Surface

A clean surface is a prerequisite for a successful bond. Start by sweeping away any dirt or dust that may hinder adhesion. Then, use a pressure washer or hose to wash away any remaining debris. It is vital to allow the surface ample time to dry completely before moving forward.

Step 3: Banishing Contaminants

Contaminants such as oil or grease can sabotage your bonding efforts. To ensure optimal adhesion, use a degreaser or concrete cleaner to remove these substances from the surface. By banishing contaminants, you pave the way for a strong and enduring bond.

Step 4: Roughening the Surface (If Necessary)

If your concrete surface is too smooth, it may hinder the adhesive’s ability to grip effectively. To overcome this challenge, gently roughen the surface using a wire brush or grinder. This process enhances adhesion by creating microscopic ridges and strengthens the bond.

Step 5: Leveling Uneven Areas

Smooth out any uneven areas on the surface by filling them with an appropriate patching compound or mortar. This step guarantees a level playing field for gluing and eliminates any gaps that could compromise the bond’s strength. Take your time to ensure a smooth and even surface.

Step 6: Choosing the Right Glue

Not all glues are created equal when it comes to bonding concrete surfaces. When selecting an adhesive, opt for one specifically designed for concrete-to-concrete bonding, such as epoxy-based or polyurethane-based adhesives. Carefully follow the manufacturer’s instructions and apply the adhesive evenly to both surfaces.

Applying the Adhesive

Let’s delve into the step-by-step process to ensure your project holds together flawlessly.

- Prepare the surface: The foundation of any successful bonding endeavor lies in meticulous surface preparation. Begin by meticulously cleaning the concrete surfaces, banishing any loose particles, dirt, or debris. A pristine canvas guarantees superior adhesion and an unyielding bond.

- Choose the perfect adhesive: Not all adhesives are created equal, especially when it comes to uniting concrete. Consider variables like application requirements, curing time, and strength properties. Epoxy, polyurethane, and construction-grade adhesive are popular contenders. Seek guidance from seasoned professionals to determine the ideal adhesive for your unique project.

- Apply the adhesive: Armed with the ideal adhesive, it’s time to coat both surfaces evenly with a thin layer of glue. Employ a trusty trowel or a versatile putty knife for seamless application onto the concrete surfaces. Adhere strictly to the manufacturer’s guidelines regarding application techniques and coverage rates.

- Allow for ample curing time: Patience is not just a virtue; it’s the secret ingredient for achieving an unwavering bond. Grant the adhesive sufficient time to dry or cure according to the manufacturer’s instructions. The duration may differ depending on the type of adhesive employed.

- Exert pressure: To ensure a steadfast union between the concrete surfaces, apply pressure. Secure clamps or judiciously position weights atop the glued area. This pressure eliminates pesky air gaps and elevates adhesion to unparalleled heights.

- Prioritize safety: Your well-being should always reign supreme when working with adhesives. Adhere diligently to safety precautions stipulated by the manufacturer, such as donning protective gloves and operating in a well-ventilated environment.

Reinforcing the Bond

When it comes to bonding concrete surfaces, the strength of the bond is crucial for the durability and longevity of any project. In this article, we will explore the methods and techniques used to reinforce the bond between two concrete surfaces, ensuring a steadfast union that withstands the test of time.

Adhesive Bonding Agents:

Adhesive bonding agents are the superheroes of concrete bonding. They penetrate the porous concrete, creating a chemical bond that enhances strength and durability. Imagine epoxy resins, polyurethane adhesives, and acrylic bonding agents working their magic to unite concrete surfaces.

Surface Preparation:

Proper surface preparation is like laying the foundation for a strong bond. Clean both concrete surfaces thoroughly, removing dirt, dust, and oils using suitable detergents or degreasers. Then, roughen the surfaces slightly with a wire brush or sandpaper to increase the surface area for better adhesion. It’s all about creating the perfect canvas for a lasting connection.

Mechanical Methods:

Reinforcing the bond with metal might sound like a superhero team-up, and it kind of is. Enter rebar and steel mesh reinforcements. These mighty warriors are embedded within the concrete, preventing any cracking or separation between bonded surfaces. They provide additional strength and stability to ensure a rock-solid structure.

Dowels and Anchors:

Dowels and anchors are like loyal sidekicks that secure the bond between concrete surfaces. Dowels are inserted into pre-drilled holes in both surfaces, aligning and securing them together while providing extra strength. Anchors take it up a notch by creating both mechanical and chemical bonds. They are inserted into pre-drilled holes along with adhesive, ensuring an unbreakable alliance.

Environmental Considerations:

Just like any relationship, environmental conditions can impact bond strength. Temperature, humidity, and moisture content all play a part. To keep the bond strong, follow manufacturer instructions regarding application and curing times. It’s all about understanding and working with the elements to achieve optimal results.

Alternatives to Epoxy Resin

When it comes to gluing concrete to concrete, epoxy resin is often the go-to choice for its strong adhesive properties and durability. However, there are alternatives to epoxy resin that can be just as effective in bonding concrete surfaces together. Let’s explore some of these alternatives and their advantages and disadvantages.

One alternative to epoxy resin is polyurethane adhesive. This flexible adhesive is capable of bonding different materials together, including concrete. Its strong bond can withstand heavy loads and is resistant to moisture and chemicals. Despite its effectiveness, polyurethane adhesives can be more expensive than epoxy resin and may require longer curing times.

Another option is acrylic adhesive, a water-based adhesive that provides a strong bond between concrete surfaces. Acrylic adhesive is easy to apply, dries quickly, and has good resistance to weathering and aging. Compared to epoxy resin, acrylic adhesives are more affordable. However, they may not be as durable in extreme temperature conditions.

For those seeking maximum strength and durability, structural adhesive is specifically designed for bonding concrete and other construction materials together. It provides high strength and excellent resistance to impact, temperature changes, and moisture. Structural adhesives, however, can be more expensive than other alternatives and may require special handling precautions.

If you’re looking for a more budget-friendly option, cementitious adhesive is worth considering. Made from cement and other additives, cementitious adhesive offers good adhesion strength and resistance to moisture and chemicals. It is commonly used for bonding tiles and stones but can also be used for bonding concrete surfaces together. The only downside is that cementitious adhesives may require longer curing times compared to epoxy resin.

It’s important to note that the choice of adhesive will depend on factors such as the specific application, desired bond strength, environmental conditions, and the type of concrete being bonded. Consulting with a professional or adhesive manufacturer is recommended to determine the most suitable alternative to epoxy resin for your specific project.

Applications of Gluing Concrete to Concrete

Gluing concrete to concrete is not just a construction technique; it’s a game-changer. With its ability to increase structural integrity, enhance aesthetics, and improve durability, this adhesive solution is the superhero you need for your construction and repair projects.

One of the primary applications of gluing concrete to concrete lies in its ability to repair damaged structures. When cracks or chips mar the surface of concrete, adhesive can work its magic by bonding the broken pieces back together. This not only restores the structural integrity of the concrete but also prevents further damage. From sidewalks to driveways, gluing is a reliable solution for areas with heavy foot traffic.

But that’s not all – gluing concrete to concrete is also commonly used in installing decorative elements. Whether it’s adding tiles or pavers to a concrete surface, adhesive ensures that these elements remain securely attached. Even in outdoor spaces like patios or pool decks, where harsh weather conditions can wreak havoc, gluing provides steadfast support.

Moreover, gluing concrete to concrete finds its place in the construction of precast elements. Precast concrete walls, beams, and columns are manufactured off-site and then transported for installation. The secret ingredient? Gluing. By connecting these precast elements seamlessly with adhesive, a robust and sturdy structure emerges.

To achieve such remarkable results, specialized adhesive products are available for gluing concrete to concrete. These products boast high bonding strength, excellent resistance to moisture, and the ability to withstand extreme temperature variations. They are specifically formulated to provide durable bonds between concrete surfaces.

Gluing concrete to concrete isn’t just about practicality; it can also be a tool for artistic expression and design. For instance, in the realm of concrete countertops, adhesive can be used to attach decorative elements like glass chips or metal accents onto the surface. The possibilities for customization and design are endless.

It’s important to note that successful bonding when gluing concrete to concrete hinges on proper surface preparation. The surfaces must be clean, dry, and free from contaminants or loose particles. Additionally, roughening the surface with a mechanical tool or acid etching can enhance the adhesion of the glue.

Also Read: Does Liquid Nails Work on Concrete? – Glue Things

Conclusion

Concrete can indeed be glued to concrete, and it opens up a world of possibilities for construction projects. The key lies in using the right adhesive, one that is specifically designed for bonding concrete surfaces together. With the right adhesive, you can create strong and durable connections between concrete elements, whether it’s for repairing cracks or joining new additions to existing structures.

One popular type of adhesive for bonding concrete is epoxy. Epoxy adhesives are known for their exceptional strength and ability to bond different materials together. When used on concrete surfaces, epoxy forms a powerful chemical bond that can withstand heavy loads and extreme weather conditions.

To ensure a successful bond between two concrete surfaces, proper surface preparation is crucial. Both surfaces should be clean, free from dust, dirt, and any loose particles. It’s also important to roughen the surface slightly to provide more grip for the adhesive.

Applying the adhesive requires precision and care. The adhesive should be spread evenly on both surfaces using a trowel or a brush. Then, the two surfaces should be pressed firmly together and held in place until the adhesive sets. Depending on the specific product used, this may take anywhere from a few minutes to several hours.

Once the adhesive has cured fully, you can trust that your concrete-to-concrete bond is strong and reliable. Whether you’re working on a small DIY project or a large-scale construction endeavor, knowing that concrete can be glued to concrete gives you endless possibilities for creating sturdy and long-lasting structures.

In conclusion, yes, concrete can be effectively glued to concrete with the right adhesive and proper surface preparation. This opens up numerous opportunities in construction projects where joining or repairing concrete elements is required.

By choosing an appropriate adhesive like epoxy and following correct application techniques, you can create bonds that are not only strong but also withstand the test of time.