Introduction:

Contents

- 1 The Materials Used in Doc Marten Soles

- 2 How the Soles Are Attached to the Upper Part of the Shoe

- 3 The Benefits of Goodyear Welt Construction

- 4 Potential Issues with Glue Deterioration

- 5 How to Tell If Your Doc Martens Need Repairing

- 6 Professional Repair Services for Doc Marten Shoes

- 7 Alternatives to Glue and Stitching for Attaching Soles

- 8 DIY Options for Resoling Your Own Shoes

- 9 Conclusion

Hey there, shoe enthusiasts. Let’s talk about a brand that knows how to rock the footwear game: Doc Marten.

These bad boys have been stomping their way into our hearts for decades, with their unbeatable combo of style, comfort, and durability. But have you ever wondered how these iconic shoes are put together?

Specifically, are Doc Marten soles glued on or do they use some mystical sorcery to keep them attached? Well, my friend, you’ve come to the right place.

In this blog post, we’re diving deep into the construction process and revealing the truth behind those soles. We’ll also explore why their chosen method of attachment makes these shoes perfect for both casual hangouts and professional settings.

So, buckle up, because we’re about to uncover the secrets behind Doc Marten’s exceptional craftsmanship.

Let’s get started.

The Materials Used in Doc Marten Soles

When it comes to iconic footwear, nothing can beat the timeless charm of Doc Martens. Renowned for their rugged durability and distinctive style, these boots have become a wardrobe staple for countless individuals.

One of the key elements that contribute to their unparalleled longevity is the meticulous selection of materials used in their construction, particularly in their soles. In this article, we will delve into the fascinating world of Doc Marten soles and explore the diverse materials that make them the epitome of durability and comfort.

The Power of PVC:

At the heart of every Doc Marten sole lies a formidable material known as PVC (Polyvinyl chloride). This synthetic plastic polymer possesses an unwavering reputation for its exceptional toughness, flexibility, and resistance to abrasion.

Employed across various industries, PVC’s remarkable durability equips Doc Marten soles to withstand even the harshest conditions and endure heavy use, making them the perfect companion for outdoor adventures.

The Comfort of Rubber:

In addition to PVC, certain models of Doc Martens incorporate the natural marvel of rubber into their soles. Rubber, with its inherent flexibility and shock absorption properties, elevates the comfort levels to unprecedented heights.

By integrating rubber into their soles, Doc Martens ensure a cushioned embrace that allows you to stride confidently throughout the day without an ounce of discomfort.

A Perfect Balance:

The harmonious marriage of PVC and rubber in Doc Marten soles strikes an exquisite balance between unwavering durability and unmatched comfort. While PVC provides the backbone of strength and resilience against any onslaught, the addition of rubber infuses each step with a cloud-like cushioning and flexibility.

This meticulously crafted combination guarantees that your boots can conquer the most treacherous terrains while pampering your feet with unparalleled comfort.

Resistance to the Elements:

A distinctive feature of Doc Marten soles lies in their impervious resistance to oil, fat, acid, petrol, and alkali. This impenetrable shield renders them ideal for industries such as food service, where exposure to such substances is a constant reality. Not only do these remarkable soles protect your feet from potential hazards, but they also retain their pristine quality and performance over time.

Proper Care for Longevity:

To ensure the longevity of your cherished Doc Marten soles, proper care becomes an essential ritual. Regular cleansing with gentle soap and water liberates them from the clutches of dirt and debris that may accumulate on their surface.

Additionally, applying a protective polish or conditioner specifically formulated for PVC or rubber tenderly nurtures their appearance and extends their lifespan, ensuring that they will faithfully accompany you on countless adventures to come.

How the Soles Are Attached to the Upper Part of the Shoe

Shoe construction is a fascinating world, and understanding how the soles are attached to the upper part is a crucial aspect of it. Doc Marten shoes, known for their durability and reliability, employ various techniques and materials to ensure a strong and secure bond between the sole and the upper.

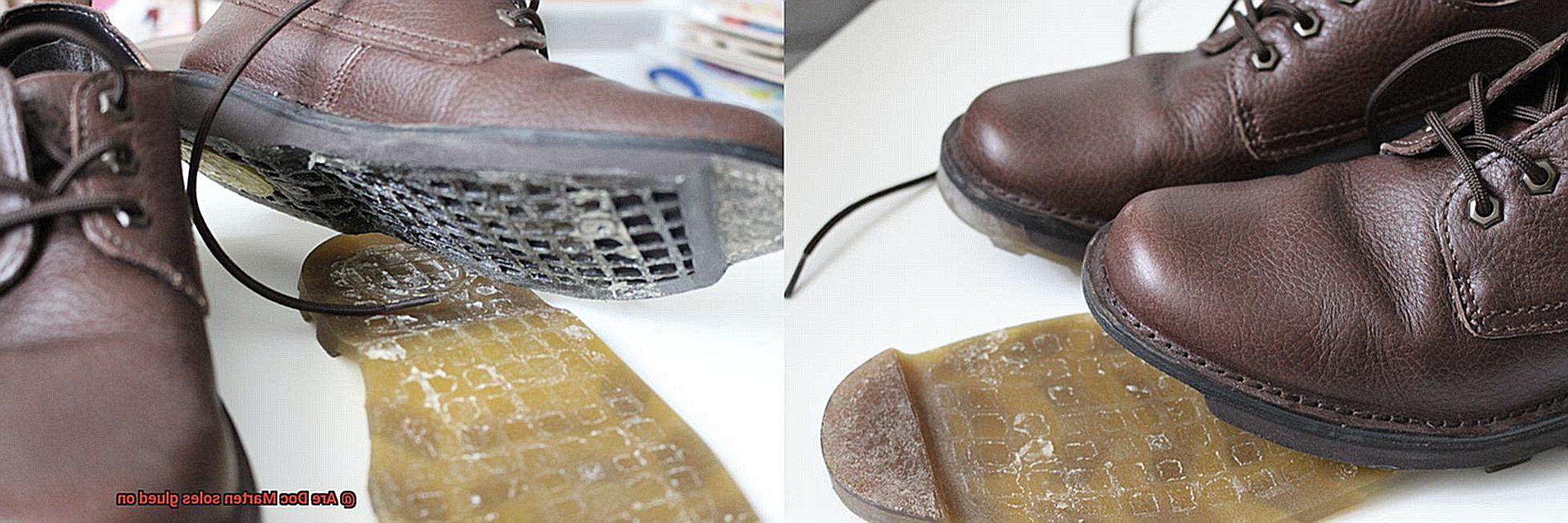

One of the primary methods used in attaching the soles to the upper part of Doc Marten shoes is called Goodyear welting. This technique involves stitching the upper part of the shoe to a strip of leather known as the welt. But stitching alone isn’t enough; glue also plays a vital role. The outsole, typically made from rubber or PVC, is glued to the welt using a powerful adhesive.

So why do we need both stitching and glue? It’s all about strength and durability. While gluing provides initial adhesion, it’s the stitching that truly holds everything together. The combination of stitching and glue creates a robust connection between the welt, upper, and insole, ensuring that your shoes can withstand all kinds of wear and tear.

But wait, there’s more. Some Doc Marten shoes also incorporate another method of sole attachment called direct injection molding. This process involves injecting molten material directly into a mold that encompasses both the upper and sole components. Once cooled and hardened, this material forms a super-strong bond, securing the sole to the upper part of the shoe.

To achieve this attachment, skilled craftsmen play a crucial role. They carefully stitch the welt to both the upper and insole using specialized sewing machines, ensuring precision and quality. This meticulousness guarantees that each shoe is built to last.

The Benefits of Goodyear Welt Construction

When it comes to investing in a pair of shoes, durability and longevity are key factors to consider. One method that has stood the test of time is Goodyear welt construction. This traditional technique involves stitching the upper, insole, and outsole together, creating a bond that is as strong as the glue that holds friendships together. In this article, we will explore the numerous benefits of Goodyear welt construction and why it should be your go-to choice when it comes to footwear.

Easy Resoling:

The standout advantage of Goodyear welt construction is its ability to be easily resoled. When the sole wears out, it can be removed and replaced without causing any damage to the rest of the shoe. This means that your favorite pair can last for many years, making it a worthwhile investment.

Excellent Water Resistance:

Wet feet can dampen even the sunniest of days. With Goodyear welted shoes, you won’t have to worry about soggy socks anymore. The tight seal created by the stitching provides excellent water resistance, keeping your feet dry and comfortable even in wet or rainy conditions.

Superior Support and Stability:

Goodyear welt construction not only ensures durability but also provides exceptional support and stability. The stitching reinforces the structure of the shoe, preventing it from collapsing or losing its shape over time. This makes them an ideal choice for those who spend long hours on their feet or need extra support for their arches.

Flexibility for Comfort:

Comfort is paramount when it comes to choosing footwear. Goodyear welt construction allows for more flexibility in the sole, thanks to the stitching. This enables the sole to move with your foot as you walk, providing a more comfortable and natural feel.

Prolonged Lifespan:

The flexibility offered by Goodyear welt construction not only enhances comfort but also prolongs the life of the shoe. It reduces stress on the sole, preventing cracking or splitting, and ensuring that your shoes remain in top condition for longer.

Potential Issues with Glue Deterioration

In the world of footwear, glue deterioration is a potential problem that can impact the lifespan and performance of your beloved shoes. Whether you’re wearing Doc Martens or any other type of footwear, understanding the potential issues associated with glue degradation is essential. In this article, we will delve into the potential problems that arise from glue deterioration and provide practical maintenance tips to help you protect your shoes.

Understanding Glue Deterioration:

Glue deterioration occurs when the adhesive used to bond different parts of a shoe starts to break down and lose its effectiveness over time. This process can present several challenges for shoe wearers. One significant problem is that it can cause soles to become loose or even detach from the shoe entirely. Walking in ill-fitting shoes not only leads to discomfort but also poses potential safety hazards.

Additionally, glue deterioration can result in gaps or spaces between the sole and the shoe. These gaps become gateways for water and debris, causing discomfort, damage, and a shorter lifespan for both the sole and the shoe itself. Moreover, weakened adhesive compromises the overall durability of the shoe, making it more susceptible to wear and tear.

Maintenance Tips for Prolonging Lifespan:

Preserving the longevity of glued-on soles requires regular maintenance. Here are some essential tips:

- Proper Cleaning and Drying: Keep your shoes clean by regularly wiping them with a damp cloth or brushing away dirt and grime. Avoid submerging them in water or using harsh chemicals that could damage the adhesive. After cleaning, allow them to air dry naturally at room temperature to prevent accelerated glue degradation.

- Avoid Moisture and Extreme Temperatures: Excessive exposure to moisture or extreme temperatures can expedite glue deterioration. Protect your shoes by keeping them away from direct sunlight, radiators, or heaters. If your shoes get wet, stuff them with newspaper or use a shoe tree to maintain their shape while facilitating proper drying.

- Use Appropriate Products: When it comes to maintaining adhesive bonds, use products specifically designed for this purpose. Look for shoe adhesives or glue that is compatible with the materials used in your shoes, such as Doc Marten soles. Follow the manufacturer’s instructions carefully when applying glue to reattach loose soles.

- Seek Professional Repair Services: If glue deterioration becomes severe and self-repair attempts are unsuccessful, it may be time to seek professional repair services or contact the manufacturer for guidance. Professionals can offer expert advice on addressing glue deterioration issues and ensure a longer lifespan for your shoes.

How to Tell If Your Doc Martens Need Repairing

Doc Martens are renowned for their durability and timeless style. However, even the toughest boots may require repair work over time. In this guide, we will explore how to tell if your Doc Martens need repairing, with a specific focus on the important role of glue in keeping the soles securely attached.

Visible Damage to the Soles:

The first thing to look for is visible damage to the sole of your Doc Martens. Are there cracks, holes, or separation between the sole and the upper part of the shoe? These signs indicate that your shoes need repairing. Weakened or deteriorated glue may be responsible, necessitating prompt attention to prevent further damage.

Check the Tread Pattern:

Another way to determine if your Doc Martens need repairing is by examining the tread pattern on the sole. Over time, tread can wear down, affecting traction and stability. If you notice significantly worn or uneven tread, it’s a sign that your shoes need attention. While not directly related to glue, this indicates that your boots may benefit from a professional inspection and potential repairs.

Comfort and Support:

Pay attention to how your shoes feel when you walk in them. Do you experience discomfort or pain in your feet or ankles? This could signify inadequate support or cushioning from the soles. Wear and tear or glue problems may be responsible. Address these issues promptly to ensure optimal comfort and prevent potential injuries.

Water Leakage:

If you experience water leakage when walking on wet surfaces, there are gaps or openings in the sole that need repair. Weakened glue or sole damage could be responsible. Water can damage your boots and lead to discomfort and foot-related problems. Prompt fixing is essential to maintain the integrity and functionality of your Doc Martens.

Unusual Noises:

Listen for any unusual noises when you walk in your shoes. Squeaking or creaking sounds may indicate a loose or detached sole. The glue holding the sole in place may have weakened or failed, requiring professional repair to ensure a secure attachment.

Seek Professional Inspection:

Finally, if you’ve had your Doc Martens for a long time without inspection or repair, take them to a professional cobbler for a thorough check-up. They have the expertise to identify hidden issues and provide necessary repairs to ensure your shoes last for years to come.

Professional Repair Services for Doc Marten Shoes

When it comes to durability, Doc Marten shoes are in a league of their own. But even the toughest boots can experience wear and tear over time. That’s where professional repair services come in. Not only do they restore your footwear to its original condition, but they also contribute to sustainability by reducing waste.

Here, we’ll dive into the world of professional repair services for Doc Martens, exploring the crucial role of glue and other techniques in extending the lifespan of your beloved boots.

Addressing Sole-Related Issues:

- Sole separation: Picture this – your soles become detached from the upper part of the shoe. It’s a common problem, but fear not. Skilled professionals are equipped with high-quality adhesive and specialized techniques to reattach them securely.

- Sole damage: Whether it’s from rigorous use or unforgiving conditions, sole damage is an unfortunate reality. But don’t despair – professional repair services have the expertise to repair or replace damaged soles, ensuring your boots retain their original functionality and appearance.

The Glue that Holds It All Together:

- High-quality adhesive: When it comes to reattaching soles or repairing other components, skilled professionals rely on top-notch adhesives specifically designed for shoe repair. These adhesives create a strong bond that withstands regular wear and tear.

- Specialized techniques: Professional repair services have mastered various techniques that guarantee effective bonding between the sole and the upper part of the shoe. By employing these methods, they maximize the longevity of your Doc Martens.

Choosing the Right Repair Service:

- Knowledge and experience: Seek out professional repair services that specialize in working with Doc Martens. Their in-depth knowledge of the brand’s construction and materials ensures tailored solutions for any sole-related issues.

- Customer reviews and testimonials: Let the experiences of others guide you. Read reviews and testimonials to gauge the quality of a repair service’s workmanship.

- Direct communication: Don’t hesitate to reach out to the repair service directly. Inquire about their process, turnaround time, and pricing – clear communication is key.

Alternatives to Glue and Stitching for Attaching Soles

We’ve all experienced the frustration of a loose sole or a shoe falling apart. While glue and stitching are the standard methods for attaching soles to shoes, there are exciting alternative techniques available. In this blog post, we will delve into unique ways to attach soles that go beyond tradition, offering both durability and style. Let’s explore these innovative solutions.

Mechanical Fasteners:

For those seeking an edgy, industrial vibe, mechanical fasteners like screws or rivets are an excellent choice. These fasteners provide a secure attachment and allow for easy replacement or repair of the sole if needed.

Heat Bonding:

Heat bonding involves using heat to melt the sole material and fuse it with the shoe upper. This creates an incredibly strong bond that is resistant to peeling or separation. Widely used in athletic shoes, heat bonding ensures longevity and stability.

Adhesive Tapes:

Believe it or not, adhesive tapes can also be used to attach soles. Double-sided tapes or adhesive films with powerful backing offer a secure bond between the sole and the shoe upper. This method provides convenience and easy application.

Combination Techniques:

Some shoe manufacturers employ a combination of techniques to maximize durability and longevity. They may use both glue and stitching alongside mechanical fasteners for added strength and stability.

DIY Options for Resoling Your Own Shoes

One popular DIY method for resoling Doc Martens is using a product called Shoe Goo. This powerful adhesive is like a superhero for your soles, creating a new layer of protection and extending the life of your shoes. Just imagine, you’ll be saving money and the environment by giving your trusty Docs a second chance at life.

To start, give your soles a good clean to ensure that the Shoe Goo bonds well with the surface. Get rid of any dirt or loose rubber bits. Once they’re squeaky clean, it’s time to apply the adhesive. Use a spatula or an old credit card to spread the Shoe Goo evenly over the worn-out areas. Cover all the cracks and holes, adding more layers if needed.

Now comes the hard part – waiting for the Shoe Goo to dry completely. Patience is key here, my friends. Let those Docs rest until the adhesive has fully cured.

If you’re looking for a more heavy-duty resoling option, consider using rubber soling sheets or strips. These can be purchased online or at shoe repair suppliers and come in various thicknesses and sizes. Trace the outline of your existing sole onto the rubber sheet, cut it out, and clean the sole of your shoes.

Next, roughen up the surface with sandpaper to ensure better adhesion. Apply a strong adhesive like Barge Cement to both the rubber sole and the shoe sole. Press them firmly together, making sure all edges are well-bonded. Use clamps or heavy objects to apply pressure and let the adhesive set properly.

Keep in mind that these DIY methods may not be as durable or long-lasting as professional resoling, but they’re a cost-effective option for extending the life of your beloved Docs. So go ahead and give it a try, but remember to assess your own skills and comfort level before diving into this DIY adventure.

BO6z55bFMU0″ >

Conclusion

The conclusion to the question “Are Doc Marten soles glued on” is clear – yes, they are.

This adhesive method ensures a secure bond between the sole and the rest of the shoe, guaranteeing that your Docs will withstand even the toughest conditions.