Linoleum, with its durability, affordability, and wide range of designs, has become a top choice for many homeowners and DIY enthusiasts. But the question remains: is gluing it down necessary?

So, grab a comfy seat, get ready for an adhesive adventure, and let us be your guide.

Types of Linoleum

Contents

- 1 Types of Linoleum

- 2 Advantages of Glue-Down Linoleum

- 3 Disadvantages of Glue-Down Linoleum

- 4 Advantages of Click Linoleum

- 5 Disadvantages of Click Linoleum

- 6 Subfloor Preparation for Installation

- 7 Manufacturer’s Guidelines and Recommendations

- 8 Factors to Consider When Deciding Whether to Glue Down Linoleum

- 9 Conclusion

Linoleum is a versatile flooring option that offers durability, affordability, and eco-friendly properties. With various types of linoleum available, each boasting unique characteristics and installation requirements, it’s essential to understand the options before making a decision. In this comprehensive guide, we will delve into the world of linoleum, exploring five distinct types and their installation specifics.

Sheet Linoleum: The Timeless Classic

Sheet linoleum is the most commonly used type, favored for its seamless and durable surface. Installed by gluing it down to the subfloor using adhesive, sheet linoleum offers stability and longevity even in high-traffic areas. Its wide range of colors, patterns, and designs makes sheet linoleum a versatile choice for any space.

Tile Linoleum: Unleash Your Creativity

For those seeking an adhesive-free option, tile linoleum is the perfect choice. These small individual tiles come with a self-adhesive backing, making installation a breeze. You can arrange them in various patterns or mix them with other flooring materials to create unique designs that reflect your personal style.

Floating Linoleum: Embrace Easy Installation

Click or snap-together linoleum is a floating floor that requires no glue for installation. Interlocking planks or tiles effortlessly click together, creating a stable and durable floor. This type of linoleum is ideal for DIY projects or temporary flooring solutions as it can be easily removed or replaced without damaging the subfloor.

Cushioned Linoleum: Comfort Meets Style

When comfort matters, opt for cushioned linoleum. This type of linoleum features an extra layer of cushioning material, such as foam or cork, providing a soft underfoot experience. It can be either glued down or installed as a floating floor, depending on the product’s recommendations. Cushioned linoleum is particularly suitable for areas where comfort is desired, such as kitchens or playrooms.

Commercial Grade Linoleum: Built to Endure

Designed for high-traffic areas, commercial grade linoleum offers enhanced durability and resistance to wear and tear compared to residential linoleum. It is available in both sheet and tile formats and typically requires professional installation. Commercial grade linoleum is commonly chosen for schools, hospitals, and other commercial settings where longevity is crucial.

Advantages of Glue-Down Linoleum

This type of linoleum offers a multitude of advantages that make it an ideal choice for both residential and commercial spaces.

First and foremost, glue-down linoleum is known for its exceptional durability. When properly installed, the adhesive used to secure the linoleum to the subfloor creates a strong bond that can withstand heavy foot traffic and everyday wear and tear. This makes it perfect for high-traffic areas such as kitchens, hallways, and commercial spaces.

But durability is just the beginning. Glue-down linoleum also offers excellent stability. The secure attachment to the subfloor prevents the linoleum from shifting or buckling over time, ensuring a smooth and even surface. This is particularly important in areas where moisture or temperature fluctuations are common, as glue-down installation helps to prevent the linoleum from expanding or contracting.

Maintenance is a breeze with glue-down linoleum. The adhesive used during installation creates a tight seal that repels dirt, dust, and liquids, making it easier to clean and maintain. Regular sweeping and occasional mopping are usually sufficient to keep glue-down linoleum looking fresh and vibrant.

Noise reduction is another advantage of glue-down linoleum. The adhesive layer acts as an additional sound barrier, absorbing impact noise and minimizing sound transfer between floors. This can be particularly beneficial in multi-story buildings or apartments where noise control is a concern.

When it comes to design versatility, glue-down linoleum has you covered. It is available in a wide range of colors, patterns, and styles, allowing homeowners and designers to create unique and personalized spaces. Plus, the precise placement and intricate designs made possible by glue-down installation enable creative freedom in floor layout.

But that’s not all. Glue-down linoleum is also cost-effective. Compared to other flooring options like hardwood or ceramic tiles, glue-down linoleum is generally more affordable. The cost of materials and installation is often lower, and its long-lasting durability means it can withstand years of use without needing to be replaced.

Last but not least, glue-down linoleum is an eco-friendly choice. Made from renewable resources such as linseed oil, wood flour, and cork dust, linoleum is a natural and sustainable flooring material. Moreover, the adhesive used during glue-down installation is typically low VOC (volatile organic compounds) and environmentally friendly, reducing your carbon footprint and promoting a healthier indoor environment.

Disadvantages of Glue-Down Linoleum

Glue-down linoleum flooring may seem like an attractive option for your home or commercial space, but it’s important to consider the potential drawbacks before making a decision. As an expert in the field, I’m here to provide you with a comprehensive overview of the disadvantages of glue-down linoleum.

First and foremost, the installation process can be quite challenging. It requires precise measurements, careful preparation of the subfloor, and the use of adhesive glue. This can be a time-consuming and labor-intensive task, especially for those who are not experienced in flooring installation. From taking accurate measurements to ensuring proper subfloor preparation, the installation of glue-down linoleum demands attention to detail and expertise.

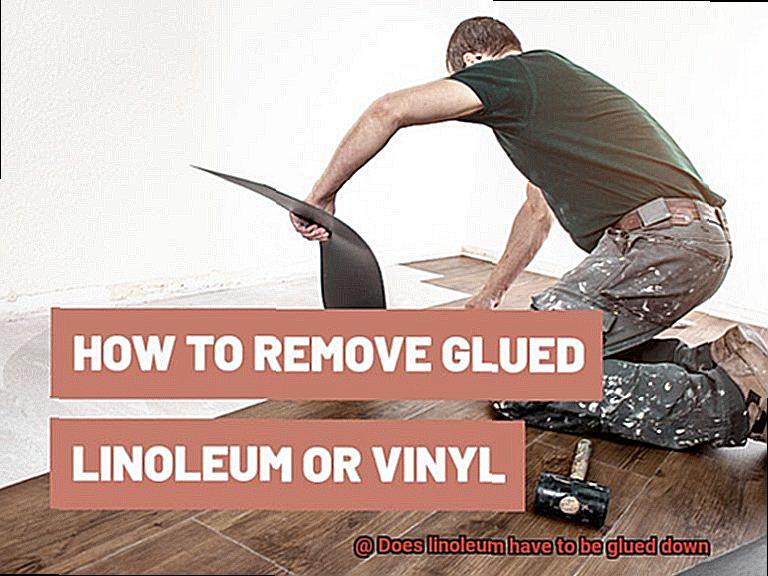

Another major drawback is the difficulty in removing glue-down linoleum. Unlike other types of linoleum flooring that can be easily removed or replaced, glue-down linoleum poses a significant challenge. The adhesive used forms a strong bond with the subfloor, making it difficult to remove without causing damage. This can be a concern if you plan on changing your flooring in the future or if you are renting a property. The permanent nature of glue-down linoleum installation limits your flexibility in design changes.

Additionally, glue-down linoleum is not reusable. Once it is installed and glued down, it cannot be easily salvaged for reuse in another area or property. This lack of reusability can be seen as a disadvantage, especially for those who prioritize sustainability and prefer floorings that can be repurposed. If sustainability is a priority for you, it may be worth exploring other types of linoleum flooring options.

Some adhesives used in glue-down linoleum may contain volatile organic compounds (VOCs) that can release harmful fumes into the air over time. These fumes can negatively impact indoor air quality and potentially cause health issues for individuals who are sensitive to chemicals or have respiratory conditions. It is important to choose low VOC adhesives and ensure proper ventilation during and after installation. Prioritizing the health and well-being of those in your space is crucial when selecting any flooring material.

In terms of design options, glue-down linoleum is limited compared to other types of linoleum flooring. It typically comes in large sheets or rolls, which restricts customization and variety in patterns. This may be a disadvantage for those who seek more flexibility in their flooring choices. If you are looking for a flooring option that offers a wide range of design possibilities, you may want to consider alternatives to glue-down linoleum.

Advantages of Click Linoleum

This innovative flooring option offers a range of advantages over traditional glued-down linoleum. As an expert on this topic, let me guide you through the numerous benefits of click linoleum. From easy installation to eco-friendly materials, this flooring solution has it all.

Easy Installation:

Say goodbye to messy glue and long drying times. Click linoleum features a convenient click-lock system that allows for a hassle-free installation process. Simply snap the planks or tiles together, creating a seamless and secure floor. With clear instructions provided by the manufacturer, even DIY enthusiasts can achieve professional-looking results.

DIY Friendly:

Are you a fan of taking on home improvement projects yourself? Click linoleum is perfect for you. Its user-friendly click-lock system requires no specialized tools or professional assistance. Whether you’re a seasoned DIYer or a novice, installing click linoleum is a breeze.

Versatility:

When it comes to design options, click linoleum leaves no stone unturned. With a wide range of colors, patterns, and designs available, you can find the perfect style to match your aesthetic preferences and home decor. From classic wood and stone designs to bold and modern patterns, click linoleum offers versatility for every room in your house.

Durability:

Click linoleum is known for its durability and long-lasting performance. Made from natural materials such as linseed oil, wood flour, and cork dust, it is inherently resistant to scratches, stains, and wear. Additionally, click linoleum is often coated with protective layers that enhance its durability and make it more resistant to moisture and fading.

Easy Maintenance:

Nobody wants to spend hours cleaning their floors. With click linoleum, maintenance is a breeze. Its smooth and non-porous surface is resistant to dirt, dust, and stains. Regular sweeping or vacuuming, along with occasional mopping using a mild cleaning solution, is usually sufficient to keep click linoleum looking clean and fresh.

Eco-Friendly:

If you’re conscious of the environment, click linoleum is the flooring choice for you. Made from natural and renewable materials, such as linseed oil and cork dust, it is biodegradable and sustainable. Unlike some other flooring materials that release harmful chemicals into the air, click linoleum has low levels of volatile organic compounds (VOCs), making it a healthier choice for indoor air quality.

Disadvantages of Click Linoleum

Click linoleum may seem like a convenient option for your flooring needs, but it’s important to be aware of its disadvantages. As an expert in the field, I can provide you with all the necessary information to make an informed decision.

One of the main drawbacks of click linoleum is its limited durability compared to glue-down linoleum. Over time, the click mechanism can weaken, causing the flooring to become loose or even dislodged. This not only creates an uneven surface but also poses potential tripping hazards. Imagine walking across your floor and suddenly stumbling over a loose piece of linoleum. It’s not only inconvenient but also dangerous.

Furthermore, click linoleum is generally thinner than glue-down linoleum, making it more susceptible to wear and tear. Heavy furniture or appliances may leave unsightly indentations on the surface, and the flooring may show signs of scratching or fading more quickly. You don’t want to invest in a flooring option that will easily show signs of damage, do you?

Another disadvantage to consider is that click linoleum is not suitable for areas with high moisture levels. While linoleum is generally water-resistant, the click joints can be a weak point where moisture can seep through. This can lead to warping or even mold growth if not properly addressed. Imagine the hassle of dealing with mold growth under your flooring due to moisture seeping through the click joints.

Unlike glue-down linoleum, click linoleum cannot be easily repaired if damaged. If a section of the flooring becomes worn or damaged, it may need to be completely replaced rather than simply patched up. This can be costly and time-consuming, especially if you have a large area of click linoleum installed.

In addition, click linoleum may have limitations in terms of design options. Glue-down linoleum often comes in a wider range of patterns and colors, allowing for greater customization. However, click linoleum may have a more limited selection, making it harder to find a specific style that matches your aesthetic preferences. You don’t want to compromise on the design of your flooring, do you?

Lastly, the installation process of click linoleum can be more challenging compared to glue-down linoleum. The click-and-lock mechanism requires precise alignment and proper technique to ensure a secure fit. This may require professional installation or additional time and effort for DIY enthusiasts. If you’re not skilled in installing flooring, you may end up with a subpar result.

Subfloor Preparation for Installation

Proper subfloor preparation is essential for a successful and long-lasting installation of linoleum flooring. Taking the time to prepare the subfloor ensures that it is level, clean, and free from moisture or debris that could affect the adhesive bond and overall quality of the installation.

The subfloor preparation process begins with inspecting the existing subfloor for any damage or irregularities. Cracks, holes, and uneven areas should be repaired before proceeding with the installation. This can be done by filling cracks or holes with a suitable patching compound and leveling out any uneven areas with a self-leveling compound. By doing so, you create a smooth surface for the linoleum flooring to be installed on.

Next, it is important to thoroughly clean the subfloor to remove any dust, dirt, grease, or other contaminants. Vacuuming or sweeping the subfloor will help remove loose particles. For stubborn stains or residues, use a mild detergent solution and a scrub brush. It is crucial to allow the subfloor to dry completely before moving on to the next steps.

Moisture is another factor that needs to be addressed during subfloor preparation. Excessive moisture can cause damage to both the linoleum flooring and the subfloor itself. Moisture testing using a moisture meter should be conducted to determine if there are any moisture issues. If high moisture levels are detected, appropriate measures should be taken to address them before proceeding with the installation. This may involve using a moisture barrier or installing a vapor retarder.

Once the subfloor has been inspected, repaired, cleaned, and moisture issues have been addressed, it’s time to prime the subfloor. Priming helps improve the adhesive bond between the subfloor and the linoleum flooring. Choose a suitable primer based on the type of subfloor material and follow the manufacturer’s recommendations. Apply the primer evenly using a roller or brush and allow it to dry according to the manufacturer’s instructions.

Now, let’s talk about glue. While some linoleum flooring products may not require gluing down if installed over a suitable underlayment, it’s important to check the manufacturer’s instructions and recommendations. Underlayments provide additional cushioning, sound insulation, and moisture resistance. They also help create a smooth and level surface for the linoleum flooring. However, not all linoleum flooring products are suitable for installation without adhesive.

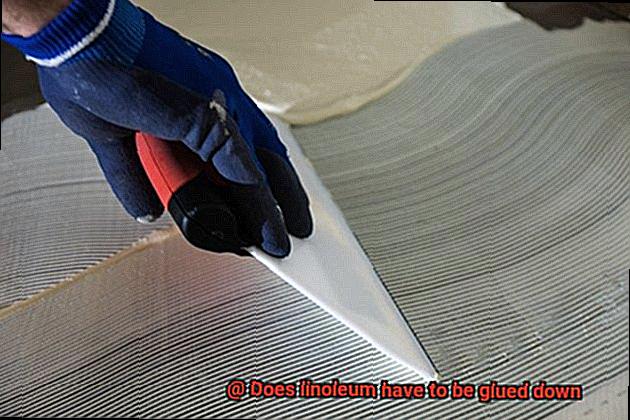

If glue is required for your linoleum flooring installation, follow these steps:

- Choose a high-quality adhesive recommended by the manufacturer.

- Apply the adhesive according to the manufacturer’s instructions, using a trowel or roller.

- Spread the adhesive evenly, covering the entire subfloor surface.

- Allow the adhesive to set for the recommended amount of time before installing the linoleum flooring.

Manufacturer’s Guidelines and Recommendations

When it comes to installing linoleum flooring, following the manufacturer’s guidelines and recommendations is paramount. These guidelines provide valuable insights into the proper installation methods and materials to ensure a long-lasting and high-performing linoleum floor.

One common dilemma faced by installers is whether to glue down the linoleum or opt for a floating installation. In this comprehensive guide, we will explore the manufacturer’s guidelines and recommendations regarding glue usage, empowering you to make an informed decision that aligns with your project’s specific needs.

Gluing Down Linoleum Flooring:

- High-Traffic Areas and Moisture-Prone Spaces: Manufacturers strongly advise gluing down linoleum in high-traffic areas like hallways and kitchens, as well as moisture-prone spaces like bathrooms. The adhesive creates a stable and secure installation capable of withstanding heavy foot traffic and potential exposure to water.

- Subfloor Condition and Stability: If your subfloor is not perfectly level or there are concerns about potential movement or shifting, manufacturers may recommend gluing down the linoleum. This minimizes any movement that could lead to premature wear or damage, ensuring a durable and long-lasting floor.

Floating Linoleum Flooring:

- Floating Options: Some manufacturers offer floating linoleum flooring options that do not require adhesive for installation. These innovative alternatives utilize interlocking systems or adhesive strips on the edges of the linoleum tiles or planks to hold them securely in place.

- Easier and Quicker Installation: Floating linoleum can be a dream come true for DIY enthusiasts, as it offers easier and quicker installation compared to glued-down linoleum. The interlocking system or adhesive strips simplify the process, making it an attractive option for those seeking convenience without compromising on quality.

Considerations and Final Thoughts:

Before making a decision, it is crucial to consult the manufacturer’s guidelines specific to your linoleum product. Factors such as subfloor condition, moisture levels, and anticipated foot traffic should also be taken into account. By following the manufacturer’s instructions and seeking professional guidance when needed, you can ensure that your linoleum flooring is installed correctly and performs as expected.

Factors to Consider When Deciding Whether to Glue Down Linoleum

Choosing between gluing down linoleum or opting for a floating installation is a crucial decision when it comes to flooring. To ensure a successful and long-lasting installation, it’s essential to consider several factors that influence this choice. In this article, we will explore the key factors to consider when deciding whether to glue down linoleum, empowering you to make an informed decision that aligns with your project’s specific requirements.

Type of Linoleum:

- Sheet linoleum offers a seamless and secure installation, making it ideal for gluing down.

- Linoleum tiles provide more flexibility and ease of replacement, allowing for both gluing down and floating installations.

Subfloor Condition:

- Uneven or damaged subfloors benefit from gluing down linoleum for enhanced stability.

- Gluing down also helps prevent future issues like shifting or creaking caused by subfloor moisture problems.

Foot Traffic:

- High-traffic areas such as entryways or commercial spaces require gluing down linoleum for better durability and prevention of loosening over time.

- Low-traffic areas like bedrooms or closets may suffice with floating installations.

Moisture Levels:

- Gluing down linoleum is recommended for moisture-prone areas such as bathrooms or basements due to its superior moisture resistance.

- Adequate adhesive application creates a barrier against water seepage, protecting the subfloor.

Long-Term Plans:

- If you anticipate changing the flooring in the future or if you’re renting the property, gluing down linoleum may not be the best option.

- Glued-down linoleum can be challenging to remove and may cause subfloor damage or require additional effort during replacement.

Installation Skill Level:

- Gluing down linoleum requires specific techniques and tools.

- If you lack confidence in your DIY skills, it is advisable to hire a professional for the installation to ensure proper adhesion and minimize issues like bubbling or premature wear and tear.

pkOMxSPcTtE” >

Conclusion

The answer to the question “Does linoleum have to be glued down?” is a resounding yes. Linoleum flooring requires adhesive to ensure a secure and long-lasting installation.

This adhesive acts as a bond between the linoleum and the subfloor, preventing any movement or shifting of the flooring material. Without proper glue application, linoleum can become loose, causing potential tripping hazards and compromising the overall integrity of the floor.

Don’t skimp on this crucial step; invest in a high-quality adhesive that is specifically designed for linoleum installation.