Finding the perfect adhesive for your DIY projects can be as challenging as untangling a mess of rubber bands. And when it comes to bonding rubber, the struggle is real. Rubber, with its versatility and prevalence in everyday items, poses a unique challenge for those seeking a reliable adhesive solution. Enter Gorilla Wood Glue.

Known for its heavy-duty strength and unwavering reputation, Gorilla Wood Glue has become a go-to choice for both DIY enthusiasts and seasoned professionals. But here’s the million-dollar question: can this mighty adhesive conquer the slippery slopes of rubber? Will it create an unbreakable bond with this flexible material? In this blog post, we’ll dive headfirst into the world of Gorilla Wood Glue and rubber, exploring its triumphs, limitations, and real-life applications that put its compatibility to the test. So buckle up and get ready to stick around as we uncover whether Gorilla Wood Glue is truly a match made in adhesive heaven for rubber materials.

Factors affecting the effectiveness of Gorilla Wood Glue on rubber surfaces

Contents

- 1 Factors affecting the effectiveness of Gorilla Wood Glue on rubber surfaces

- 2 Preparing the rubber surface for better adhesion with Gorilla Wood Glue

- 3 Testing the bond strength between Gorilla Wood Glue and rubber surfaces

- 4 Applications where Gorilla Wood Glue may work reasonably well on rubber surfaces

- 5 Limitations and considerations when using Gorilla Wood Glue on rubber surfaces

- 6 Alternatives to consider for bonding rubber surfaces effectively

- 7 Tips and best practices for using Gorilla Wood Glue on rubber surfaces

- 8 Real-life examples and experiences from users who have tried using Gorilla Wood Glue on rubber

- 9 Conclusion

Gorilla Wood Glue is renowned for its strong bonding capabilities, but when it comes to rubber surfaces, several factors can influence its effectiveness. In this blog post, we will explore the key factors that impact how well Gorilla Wood Glue works on rubber surfaces.

By understanding these factors, you can make informed decisions for your bonding projects and achieve optimal results.

Type of Rubber:

Rubber comes in different forms, each with unique properties. Natural rubber, synthetic rubber, and silicone rubber all have varying levels of elasticity and surface energy. Natural rubber, for example, has high elasticity, making it more challenging for adhesives to bond effectively.

It is crucial to identify the type of rubber you are working with to determine if Gorilla Wood Glue is suitable.

Surface Preparation:

To achieve a strong bond between Gorilla Wood Glue and rubber surfaces, proper surface preparation is vital. Ensure that the rubber surface is thoroughly cleaned and free from contaminants like dust, oil, or grease. These substances can hinder the adhesive’s ability to form a robust bond. Additionally, roughening the surface with sandpaper or a wire brush can enhance the grip of the glue on the rubber.

Temperature and Humidity:

Environmental conditions during the bonding process play a significant role in Gorilla Wood Glue’s effectiveness on rubber surfaces. Extreme temperatures and high humidity levels can impact curing time and overall bond strength. It is essential to follow the manufacturer’s guidelines regarding temperature and humidity ranges for optimal bonding results.

Application Technique:

The way you apply Gorilla Wood Glue onto rubber surfaces greatly affects its effectiveness. Ensure an even layer of glue with full coverage, avoiding excessive pooling or gaps. Applying too much glue can lead to longer curing times and weaker bonds, while applying too little may result in inadequate adhesion. A consistent and controlled application technique is key to a successful bond.

Curing Time:

Rubber surfaces typically require longer curing times compared to other materials. It is crucial not to rush the bonding process by subjecting the glued surfaces to stress or load before the glue has fully cured. Following the recommended curing time for Gorilla Wood Glue on rubber surfaces allows sufficient time for the adhesive to set and form a strong bond.

Compatibility Testing:

Before embarking on a full-scale bonding project, conducting compatibility testing is highly recommended. Apply Gorilla Wood Glue on a small test piece of rubber and allow it to cure according to the manufacturer’s instructions. You can then assess the bond strength and durability to determine if Gorilla Wood Glue is suitable for your specific rubber surface.

Preparing the rubber surface for better adhesion with Gorilla Wood Glue

Today, we embark on a journey to discover the secrets of preparing rubber surfaces for an unbreakable bond with Gorilla Wood Glue. Whether you’re mending rubber-soled shoes or unleashing your creativity with a DIY rubber project, we’ve got you covered.

So, let’s dive in.

Before we begin, it’s crucial to understand that Gorilla Wood Glue is primarily formulated for wood surfaces. However, with proper preparation, it can perform its magic on rubber as well.

Cleanliness is Key:

Let’s start by banishing any dust, dirt, or grease that might undermine our bonding efforts. Grab a mild detergent or rubbing alcohol and give the rubber surface a thorough cleaning. Remember to let it dry completely before moving forward.

Rough it Up:

To create an optimal surface for the glue to grip onto, gently rough up the rubber surface using sandpaper or a rough cloth. Be mindful not to damage the rubber; we’re aiming for a subtly textured finish.

Primer Power:

To maximize the bond strength between the rubber and Gorilla Wood Glue, apply a specialized rubber primer or adhesive promoter. Follow the manufacturer’s instructions diligently and allow it to dry thoroughly before proceeding.

Get Sticky:

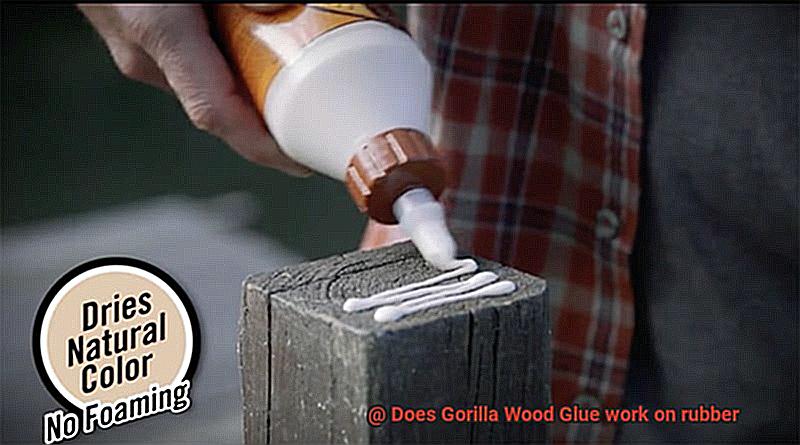

Now, it’s time for the main event – applying Gorilla Wood Glue. Use a brush or spatula to spread a thin, even layer of glue onto the prepared rubber surface. Exercise caution to avoid excessive buildup that could compromise the quality of our bond.

Press and Hold:

Once glued up, press the rubber surfaces firmly together and maintain the pressure for several minutes. This allows the glue to work its magic and form an unyielding bond. For added assurance, employ clamps or weights to keep everything in place.

Patience is a Virtue:

Exercise patience as we grant the glue ample time to cure. Consult the Gorilla Wood Glue bottle for recommended drying times. During this period, refrain from disturbing or stressing the bond – our patience will be rewarded with a robust adhesion.

Inspect and Reinforce:

After the glue has fully cured, carefully inspect the bond for any weak areas that may benefit from additional reinforcement. If necessary, apply another thin layer of Gorilla Wood Glue and repeat the bonding process.

Testing the bond strength between Gorilla Wood Glue and rubber surfaces

Here, we’ll take you on a step-by-step journey to test the strength of this adhesive on rubber – from preparing the surfaces to conducting the bond strength test. So, let’s dive in and discover the secrets behind this unbreakable union.

Before embarking on our adhesive adventure, let’s understand the basics. Gorilla Wood Glue is renowned for its wood bonding capabilities, but can it conquer rubber too? That’s what we’re here to find out.

Start by cleaning both the rubber and wood surfaces using a mild detergent and water solution. This ensures a pristine foundation for our testing. Now that our surfaces are squeaky clean, it’s time to apply the Gorilla Wood Glue.

Grab your trusty brush or applicator and spread a thin, even layer onto the rubber surface. Remember, even distribution is key to achieving a solid bond.

Press the wood surface firmly onto the glued rubber surface, aligning them accurately. Apply sufficient pressure for a few minutes to allow the adhesive to work its magic. This step is crucial for creating a strong initial bond.

As much as we’d love to see instant results, patience is essential in this process. Allow the adhesive to cure undisturbed for at least 24 hours before subjecting it to any stress or load. This wait ensures maximum bond strength.

The moment of truth has arrived. Gradually apply force to separate the bonded surfaces. You can use a mechanical force tester or simply rely on your own brute strength. Observe and record the force required to break the bond between Gorilla Wood Glue and rubber surfaces. This measurement will determine the bond strength of the adhesive.

Keep in mind that external factors like temperature, humidity, and rubber type can influence the bond strength. Be mindful of these variables during testing and note any variations in results. This will help you understand the glue’s effectiveness in different conditions.

While Gorilla Wood Glue may work wonders on some rubber surfaces, it’s important to remember that not all rubbers are created equal. Certain types may require specialized adhesives designed specifically for that material. So, always check compatibility before committing to any adhesive for your rubber projects.

Applications where Gorilla Wood Glue may work reasonably well on rubber surfaces

Prepare to be amazed by the hidden potential of Gorilla Wood Glue. While renowned for its exceptional bond on wood surfaces, this mighty adhesive can also work wonders on certain rubber surfaces. In this comprehensive guide, we will delve into the diverse applications where Gorilla Wood Glue can effectively bond rubber, showcasing its versatility and strength.

Repairing Rubber-Soled Shoes:

Picture this: you have a beloved pair of shoes with a detached or loose rubber sole. Fear not, for Gorilla Wood Glue is here to save the day. With just a touch of this adhesive, you can confidently reattach the sole to the shoe upper, creating a bond that withstands the trials of daily wear and tear. No more worries about losing your footing or sacrificing style.

Fixing Rubber Gaskets or Seals:

Leaky rubber gaskets or seals in mechanical or plumbing systems can be a real headache. But worry not, as Gorilla Wood Glue comes to the rescue once again. Consider it your temporary fixer-upper for small cracks or tears in rubber gaskets. By applying this adhesive, you can prevent further damage and buy yourself valuable time until a permanent solution is within reach.

Craft Projects with Rubber Materials:

Embrace your creative spirit and let Gorilla Wood Glue unveil a world of possibilities with rubber materials. Whether you’re crafting exquisite rubber jewelry or fashioning unique accessories, this adhesive guarantees a strong and durable bond that ensures your creations stand the test of time. Remember to consider the specific type of rubber and the purpose of your masterpiece before diving into your craft project.

Attaching Rubber Grips or Handles:

Slipping grips or handles on tools, sports equipment, or bicycle handlebars can be a frustrating experience. Fear not, for Gorilla Wood Glue is here to provide a secure solution. By applying this adhesive, you can ensure that rubber components stay firmly in place, even during the most intense use. Say goodbye to wobbly handles and hello to unwavering confidence.

Limitations and considerations when using Gorilla Wood Glue on rubber surfaces

Today, we embark on a journey into the realm of adhesive magic, delving into the complexities and considerations when using Gorilla Wood Glue on rubber surfaces. So, grab your goggles and let’s dive in.

Limitations Abound:

Imposing Non-Porous Barrier:

Gorilla Wood Glue, a master of bonding wood, faces a formidable foe in rubber. The non-porous nature of rubber presents a challenge for the glue to penetrate and create a robust bond. The battle against the barrier begins.

Durability at Stake:

Rubber surfaces endure countless trials – flexing, stretching, and exposure to harsh environmental elements. Unfortunately, this may weaken or fracture the bond forged by Gorilla Wood Glue over time. The quest for long-lasting durability is not without obstacles.

Flexibility: A Crucial Factor:

Rubber possesses an innate elasticity, allowing it to stretch and move. Alas, a glue lacking sufficient flexibility may falter under the pressure of these movements. The need for adaptability becomes paramount to maintain a steadfast bond amidst stress and motion.

Considerations to Ponder:

Water Woes:

Gorilla Wood Glue’s water-based composition renders it unsuitable for situations where bonded rubber surfaces will encounter moisture or water. Like a fragile flower wilting under raindrops, the bond weakens and deteriorates over time.

Surface Preparation as the Key:

To unlock optimal adhesion, meticulous surface preparation is essential. Cleanliness reigns supreme – ensure the rubber surface is devoid of oily or greasy residues, dry as a desert breeze. Gently sanding or roughening the surface may be necessary to bolster the strength of the bond.

Specialized Alternatives Beckon:

In certain cases, the battlefield calls for reinforcements. Specialized adhesives crafted explicitly for bonding rubber may prove superior to Gorilla Wood Glue. These formidable allies offer unparalleled adhesion and flexibility on rubber surfaces. Seek guidance from the manufacturer’s instructions or consult with the experts for a triumphant outcome.

Stress Test: Trials Before Triumph:

Before embarking on ambitious conquests, it is wise to conduct a stress test in a small, inconspicuous area. This valiant endeavor will unveil the compatibility and strength of the bond, ensuring Gorilla Wood Glue is indeed suited for your rubber material and application.

Alternatives to consider for bonding rubber surfaces effectively

When it comes to bonding rubber surfaces effectively, traditional adhesives like Gorilla Wood Glue may not always be the best choice. Luckily, there are specialized adhesives available that offer superior performance and adhesion strength. In this blog post, we will delve into several alternatives to consider for achieving optimal bonding of rubber surfaces.

Rubber Adhesives:

For a reliable and strong bond on rubber surfaces, specifically formulated rubber adhesives are the way to go. These liquid adhesives can be easily applied using a brush or nozzle. With their quick drying time and flexibility once cured, they are ideal for bonding rubber materials effectively.

Cyanoacrylate Adhesives (Super Glue):

When looking for a fast and secure bond on various materials, including rubber, cyanoacrylate adhesives, commonly known as super glue, are a great option. Available in different viscosities, you can select the one that suits your project best. However, it’s important to verify compatibility with rubber by checking the product label or consulting the manufacturer.

Epoxy Adhesives:

For larger or more complex bonding projects involving rubber, epoxy adhesives offer exceptional strength and durability. These two-component adhesives consist of resin and hardener that must be mixed before application. Once cured, epoxy adhesives provide a robust bond capable of withstanding harsh conditions.

Mechanical Fasteners:

If you’re seeking a reliable and secure bond, mechanical fasteners such as screws, bolts, or other fasteners can effectively bond rubber surfaces. This method is particularly suitable for applications requiring high strength. It’s crucial to ensure that the chosen fasteners are appropriate for use with rubber without causing any damage or puncturing the material.

Heat-Activated Adhesives:

Heat-activated adhesives are an excellent choice for achieving a strong and durable bond on rubber surfaces. These adhesives require the application of heat to activate the bonding process. However, it’s important to carefully follow the manufacturer’s instructions to ensure proper bonding without causing any harm to the rubber surface.

Tips and best practices for using Gorilla Wood Glue on rubber surfaces

When it comes to bonding rubber surfaces, Gorilla Wood Glue may not be the first adhesive that comes to mind. However, with some caution and proper technique, Gorilla Wood Glue can be a viable option for certain applications. In this article, we will provide tips and best practices to help you achieve a strong and durable bond between rubber surfaces using Gorilla Wood Glue. Let’s dive in.

Clean the Surface:

Before applying Gorilla Wood Glue on a rubber surface, it is crucial to ensure that the surface is clean and free from any dirt, dust, or grease. A dirty surface can hinder the adhesive’s ability to bond effectively. To clean the surface, simply wipe it with a clean cloth or use a mild detergent and water solution. This step will create an optimal bonding environment.

Apply a Thin Layer:

To achieve a strong bond, it is recommended to apply a thin layer of Gorilla Wood Glue evenly on both surfaces that need to be bonded. Remember, less is more when it comes to applying glue. Using too much can result in excess adhesive oozing out and creating a messy appearance. Applying a thin layer will ensure proper adhesion without any unsightly residue.

Use Pressure:

Gorilla Wood Glue requires pressure to activate its bonding properties fully. To ensure a tight bond between the rubber and the other material, use clamps or other means of applying pressure to hold them together until the glue dries completely. This will allow the glue to penetrate the rubber surface and create a strong bond. The pressure applied should be enough to keep the surfaces in contact but not too excessive as it may cause deformation.

Allow Drying Time:

The drying time of Gorilla Wood Glue may vary based on factors such as temperature and humidity. It is essential to follow the manufacturer’s instructions regarding the drying time for the specific product you are using. Patience is key here. Allow the glue to dry completely before testing the bond strength or subjecting the bonded surfaces to any stress or load. Rushing this step can compromise the bond’s integrity.

Test the Bond Strength:

Once the glue has dried, it is crucial to test the bond strength before assuming it is secure enough for your intended application. Gently pull or apply pressure on the bonded area to check if it holds firmly. If there are any signs of weakness, additional adhesive might be necessary. Testing the bond strength will ensure that your rubber surfaces are securely bonded and ready for use.

Real-life examples and experiences from users who have tried using Gorilla Wood Glue on rubber

Today, we will delve into real-life examples and experiences from users who have dared to explore this unconventional combination. From salvaging sneakers to fixing household appliances, prepare to be captivated by the remarkable possibilities of Gorilla Wood Glue on rubber.

Sneaker Savior

Picture your beloved sneakers with a torn rubber sole. Enter John, a brave experimenter who found himself in this exact predicament. Determined to find a solution, he decided to give Gorilla Wood Glue a shot.

With precision, he applied a thin layer of the glue onto the damaged area and firmly pressed the sole against the shoe. Weeks turned into months, yet the bond remained resolute, enduring the trials of everyday wear and tear. Thanks to Gorilla Wood Glue, John’s sneakers were resurrected, allowing him to stride confidently once more.

Dishwasher Delight

In another tale of triumph, Sarah discovered the magic of Gorilla Wood Glue when her dishwasher suffered from a torn rubber gasket causing incessant leaks. Seeking solace in her toolbox, she reached for Gorilla Wood Glue.

Carefully tracing along the tear and patiently holding the gasket in position until it dried completely, Sarah anxiously awaited the outcome. To her delight, not a single drop escaped during subsequent dishwashing cycles. The power of Gorilla Wood Glue had spared her from plumbing headaches and restored harmony in her kitchen.

Gardening Tool Troubles

However, not all journeys bear fruit. Mike’s quest to mend a rubber handle on his trusty gardening tools using Gorilla Wood Glue proved to be a challenge. Despite meticulously following instructions to the letter, he discovered that the bond created was ill-equipped to endure the relentless strain of gripping and wielding the tools.

In the face of adversity, Mike had to pivot and seek an adhesive specifically formulated for rubber bonding, ultimately finding success in his pursuit.

Conclusion

Yes, Gorilla Wood Glue is indeed effective for bonding rubber materials.

Its strong adhesive properties make it a reliable choice for various applications involving rubber. Whether you’re repairing a rubber sole on your favorite shoes or fixing a rubber gasket in your car, Gorilla Wood Glue has got you covered.