Concrete and glass, an unexpected duo in the realm of construction materials, have captivated the imaginations of builders and designers alike. The sheer strength of concrete combined with the elegance of glass seems like a match made in architectural heaven.

But can these two materials truly form an unbreakable bond? In this blog post, we’ll delve into the science behind their compatibility to uncover the truth about their bonding capabilities.

Prepare to be enlightened as we explore the fascinating relationship between concrete and glass. We’ll unveil the factors that ensure a secure and enduring bond, diving into a world where strength meets transparency. Get ready to unravel the secrets behind this captivating connection that brings together raw power and delicate beauty.

Why Does Concrete Not Bond Well to Glass?

Contents

- 1 Why Does Concrete Not Bond Well to Glass?

- 2 Surface Preparation for Bonding Concrete and Glass

- 3 Adhesives for Bonding Concrete and Glass

- 4 Mechanical Fasteners for Bonding Concrete and Glass

- 5 Pros and Cons of Bonding Concrete and Glass with Adhesives vs Mechanical Fasteners

- 6 Alternatives to Bonding Concrete and Glass

- 7 Factors that Affect the Strength of the Bond between Concrete and Glass

- 8 Tips for Ensuring a Strong Bond between Concrete and Glass

- 9 Conclusion

Bonding concrete to glass is a complex task, as these two materials possess distinct physical properties that make achieving a strong and durable bond difficult. In this article, we will delve deeper into the reasons behind this poor bonding and explore potential solutions to overcome these challenges.

Differences in Thermal Expansion:

Concrete and glass have vastly different coefficients of thermal expansion. Concrete expands and contracts very little when exposed to temperature changes, while glass undergoes significant expansion and contraction. This discrepancy in thermal behavior creates stress at the interface of the materials, leading to cracks and delamination over time.

Surface Properties:

Another factor that hinders the bond between concrete and glass is their divergent surface properties. Concrete has a rough and porous surface, whereas glass boasts a smooth and non-porous surface. The roughness of the concrete makes it difficult for adhesives or mortar to penetrate its pores effectively, thereby weakening the bond. Furthermore, the non-porous nature of glass inhibits adhesives from adhering effectively.

Chemical Composition:

Concrete primarily consists of calcium silicate hydrates (C-S-H), while glass is predominantly composed of silicon dioxide (SiO2). The chemical incompatibility between these two materials further impedes their ability to bond well together.

Overcoming the Challenges:

To address these bonding challenges, various techniques and products have been developed:

- Adhesion Promoters: Primers or adhesion promoters specifically designed for bonding concrete to glass help improve the adhesion between these two materials. These products enhance the compatibility between the surfaces, creating a stronger bond.

- Specialized Adhesives and Mortars: Certain adhesives and mortars are formulated to accommodate differential thermal expansion between concrete and glass. They provide improved adhesion by compensating for the stress caused by temperature variations.

- Mechanical Fasteners: In some cases, mechanical fasteners such as screws, bolts, or anchors can be used to augment the bond between concrete and glass. This method provides a more reliable and stronger connection, particularly in applications where a seamless bond is not a concern.

Surface Preparation for Bonding Concrete and Glass

Surface preparation is a critical step when it comes to bonding concrete and glass. To achieve a strong and durable bond, it is essential to properly clean and prepare the surfaces before applying any adhesive or glue. There are several key factors to consider in surface preparation for bonding concrete and glass:

- Cleanliness: Both the concrete and glass surfaces must be free from dust, dirt, grease, or other contaminants that could interfere with the bonding process. Thoroughly clean the surfaces using a suitable cleaner or solvent to ensure optimal adhesion.

- Roughening: In addition to cleaning, it may be necessary to roughen the surfaces to enhance adhesion. This can be done through techniques such as sanding or grinding. Creating a rough texture on the surfaces provides more surface area for the adhesive or glue to grip onto, resulting in a stronger bond.

- Primers: Primers are specially formulated to improve adhesion between different materials. There are primers available specifically designed for bonding concrete and glass. Applying a primer before applying the adhesive can significantly enhance bond strength.

- Dryness: Moisture is the enemy of adhesion, so it is crucial to ensure that both the concrete and glass surfaces are completely dry before bonding. Allow sufficient time for the surfaces to air dry after cleaning before applying any adhesive or glue.

- Repairing: It is important to inspect the surfaces for any loose or damaged parts. Remove any loose concrete or repair cracks in the glass before bonding. Ensuring that the surfaces are in good condition maximizes bonding effectiveness.

Adhesives for Bonding Concrete and Glass

Adhesives play a crucial role in bonding concrete and glass together, creating a secure connection that can withstand various stresses and environmental conditions. When it comes to selecting the perfect adhesive for this purpose, there are several options to consider.

First up is epoxy adhesive, known for its exceptional strength and ability to bond various materials, including concrete and glass. Comprised of resin and hardener components that are mixed before application, epoxy forms a strong chemical bond with both surfaces. This adhesive is ideal for projects requiring a reliable and durable connection between concrete and glass.

Polyurethane adhesives are another popular choice, offering excellent bonding properties and resistance to water, heat, and chemicals. Their flexibility allows them to absorb vibrations and movements without compromising the bond. This makes polyurethane adhesives suitable for both indoor and outdoor applications, ensuring long-lasting connections.

For a watertight seal between concrete and glass, silicone sealants are the go-to option. These sealants possess exceptional adhesive properties and can withstand extreme temperatures and weather conditions. Silicone sealants are perfect for outdoor applications where the bond may be exposed to harsh environments.

Lastly, hybrid adhesives combine the best properties of different adhesive technologies to provide improved bond strength, flexibility, and durability. These adhesives offer the best of both worlds, making them an excellent choice when optimal performance is required.

When selecting an adhesive for bonding concrete and glass, it is essential to consider factors such as the application, environmental conditions, and required bond strength. Following the manufacturer’s instructions regarding surface preparation, application techniques, and curing time is crucial for a successful bond.

Mechanical Fasteners for Bonding Concrete and Glass

In the world of construction and design, concrete and glass often unite to create stunning structures. However, achieving a strong and durable bond between these materials requires the use of mechanical fasteners. This article explores the best options available for bonding concrete and glass, providing detailed insights into their features and applications.

Anchor Bolts:

For attaching glass panels to concrete surfaces, anchor bolts are the go-to choice. These steel fasteners excel in strength and corrosion resistance, providing secure attachment points when embedded into the concrete. With their exceptional load-bearing capacity, anchor bolts are a popular favorite in construction projects involving glass.

Glass Clamps:

Specifically designed for securing glass panels to concrete surfaces, glass clamps offer a straightforward solution. These clamps consist of metal brackets, often made of stainless steel or aluminum for their lightweight nature and corrosion resistance. By using screws or bolts, these clamps attach to the concrete, while their clamp mechanism securely holds the glass panel in place.

Brackets:

When attaching glass panels to concrete walls or structures, brackets provide stability and security. These versatile fasteners also offer flexibility in terms of design and aesthetic requirements. For added strength and stability, brackets can be combined with adhesive bonding, ensuring a reliable bond between concrete and glass.

Expansion Bolts:

When seeking a secure attachment between concrete and glass, expansion bolts should be considered. These unique bolts expand when tightened, creating a tight fit between the materials. They are particularly useful when dealing with heavy loads or extreme conditions that require an unyielding bond.

Installation Tips:

To ensure a successful bond between concrete and glass using mechanical fasteners, proper installation techniques and adherence to manufacturer guidelines are crucial. It is essential to select the appropriate type and size of fasteners for the specific application, taking into account factors such as load capacity, weather resistance, and aesthetic requirements.

Pros and Cons of Bonding Concrete and Glass with Adhesives vs Mechanical Fasteners

Concrete and glass may seem like an odd combination, but their fusion can create breathtaking structures. When it comes to bonding these materials, you have two options: adhesives or mechanical fasteners. In this article, we’ll explore the pros and cons of each method to help you make an informed decision.

Adhesives – A Seamless Solution:

Adhesives offer a seamless bond between concrete and glass, resulting in a visually appealing finish with no visible joints or gaps. They evenly distribute stress across the bond line, reducing the risk of localized stress concentrations that can occur with mechanical fasteners. Adhesives can also bond irregular or non-uniform surfaces, making them suitable for challenging applications. Additionally, they provide excellent resistance to moisture, chemicals, and temperature variations, creating a watertight seal and maintaining their strength even under extreme conditions.

Drawbacks of Adhesives:

While modern adhesives have improved bond strength, there is still a possibility of bond degradation over time due to environmental factors and aging. Adhesive bonding requires surface preparation, mixing or application, and curing time. Deviations from recommended procedures can compromise the integrity of the bond.

Mechanical Fasteners – Quick and Reliable:

Mechanical fasteners like screws or bolts can be quickly installed without the need for surface preparation or curing time. They offer greater adjustability and reusability compared to adhesives, allowing for easy modifications without damaging the materials being bonded.

Cons of Mechanical Fasteners:

Mechanical fasteners create visible joints or gaps between concrete and glass, which may not appeal to those seeking a seamless finish. They can also create localized stress concentrations at the points where they are installed.

Alternatives to Bonding Concrete and Glass

Bonding concrete and glass poses a challenge due to the stark differences in their properties. Concrete, solid and porous, meets delicate and non-porous glass. Achieving a strong, enduring bond requires meticulous consideration and the use of appropriate adhesive systems. In this article, we will delve into alternative methods to bond concrete and glass, with a focus on glue as a viable solution.

Mechanical Fastening:

Using screws, bolts, or brackets to secure glass onto the concrete surface allows for easy removal and replacement if necessary. However, this method may lack the seamless bond achieved through adhesive bonding.

Silicone Sealants:

Specifically formulated for bonding glass and concrete, silicone sealants guarantee excellent adhesion to both materials. They accommodate differential movement between surfaces while offering flexibility, weather resistance, and durability. Silicone sealants have become a popular choice in applications requiring concrete-glass bonding.

Epoxy Adhesives:

Renowned for their superior adhesive properties, epoxy adhesives are widely utilized for bonding concrete and glass. They create robust bonds with high strength, chemical resistance, and durability. Transparent formulations further enhance the aesthetic appeal of the bond.

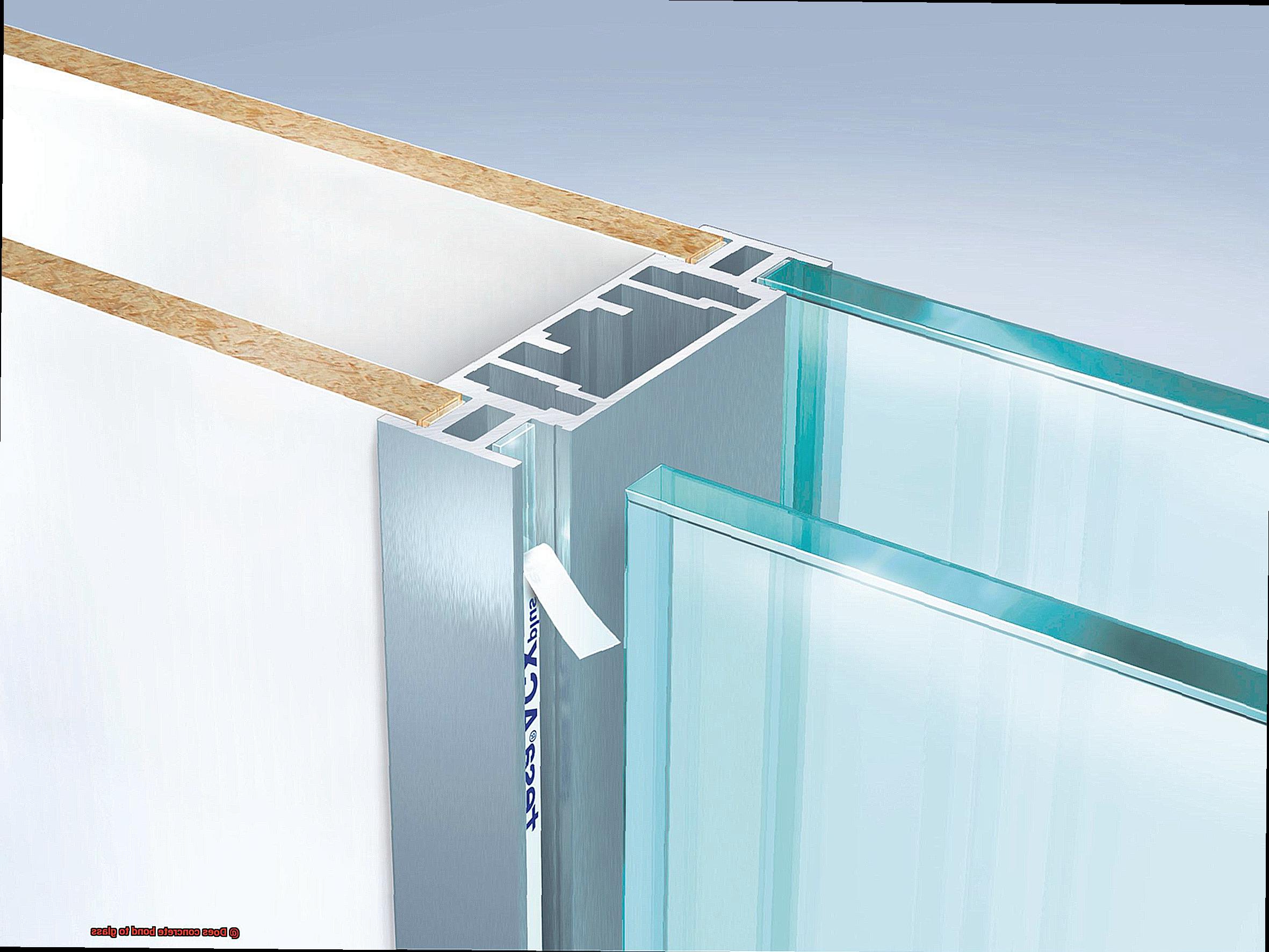

Structural Glazing Systems:

Structural glazing systems employ specialized structural silicone sealants that combine adhesive strength with structural support. These systems establish a continuous bond between glass panels and concrete surfaces, making them ideal for architectural applications like curtain walls or glass facades.

Mechanical Interlock:

In certain cases, enhancing the bond between concrete and glass can be achieved by creating a mechanical interlock. Roughening the concrete surface or using mechanical anchors embedded in the concrete provides additional grip. Caution should be exercised when roughening the glass surface to safeguard its structural integrity.

Factors that Affect the Strength of the Bond between Concrete and Glass

The strength of the bond between concrete and glass is influenced by several factors that must be carefully considered during the bonding process. Proper surface preparation is essential to ensure a clean and adhesive-friendly surface. Techniques such as sandblasting or acid etching can create a rough texture on the concrete surface, enhancing the bond strength with glass.

Choosing the right adhesive is crucial. Epoxy adhesives are commonly used due to their high strength and excellent adhesion properties. Curing time is also important, as the adhesive needs sufficient time to reach its full strength. Following the manufacturer’s instructions regarding curing time is crucial to avoid a weak bond.

Environmental conditions, such as temperature and humidity, play a significant role in bond strength. Higher temperatures can accelerate curing but may also cause faster evaporation of solvents in the adhesive. Low temperatures can slow down curing and reduce bond strength. Excessive moisture can interfere with adhesive performance.

The design of the joint between concrete and glass affects bond strength. Factors like joint width, depth, and shape distribute stress evenly across the bonded surfaces. A wider joint allows for better adhesive penetration, while a deeper joint provides more surface area for bonding. Chamfering or providing a beveled edge to the joint minimizes stress concentration and enhances bond strength.

Material compatibility is crucial for a strong bond. The coefficient of thermal expansion (CTE) of both materials should be considered to ensure they can withstand temperature changes without causing stress or delamination. Incompatible CTEs can compromise the bond.

Load distribution on the bonded interface also affects bond strength. Proper design and execution are necessary to evenly distribute loads across the bonded area. Uneven or excessive loads can cause stress concentrations and lead to bond failure over time.

Tips for Ensuring a Strong Bond between Concrete and Glass

Achieving a strong bond between concrete and glass can be challenging due to the differences in their physical properties. Concrete is porous, while glass is non-porous and smooth, making it difficult for the two materials to adhere effectively. In this article, we will discuss some tips and techniques that can help ensure a durable bond between concrete and glass.

Thoroughly Clean Both Surfaces:

Before attempting to bond concrete and glass, it is crucial to clean both surfaces thoroughly. Any dirt, dust, or contaminants on the surfaces can hinder the bonding process. Use a mild detergent or degreaser to clean the surfaces, followed by rinsing with water. This will create a clean surface that allows for maximum adhesion.

Roughen the Glass Surface:

To enhance adhesion, lightly sand the glass surface with fine-grit sandpaper or use a glass etching solution. This creates a slightly rough texture that allows the adhesive to penetrate and bond effectively with the glass. The roughened surface provides more surface area for the adhesive to grip onto, ensuring a stronger bond.

Choose the Right Adhesive:

Select an adhesive specifically designed for bonding concrete and glass. Epoxy, polyurethane, or silicone-based adhesives are commonly used for this purpose. These adhesives have enhanced bonding properties that can withstand the stresses associated with concrete and glass. Be sure to choose an adhesive that is compatible with both materials and provides good adhesion strength.

Use a Primer:

Applying a primer to both surfaces before applying the adhesive can promote better adhesion between concrete and glass. The primer creates a chemical bond between the surfaces, improving the overall bond strength. Follow the manufacturer’s instructions for proper primer application and drying time to ensure optimal results.

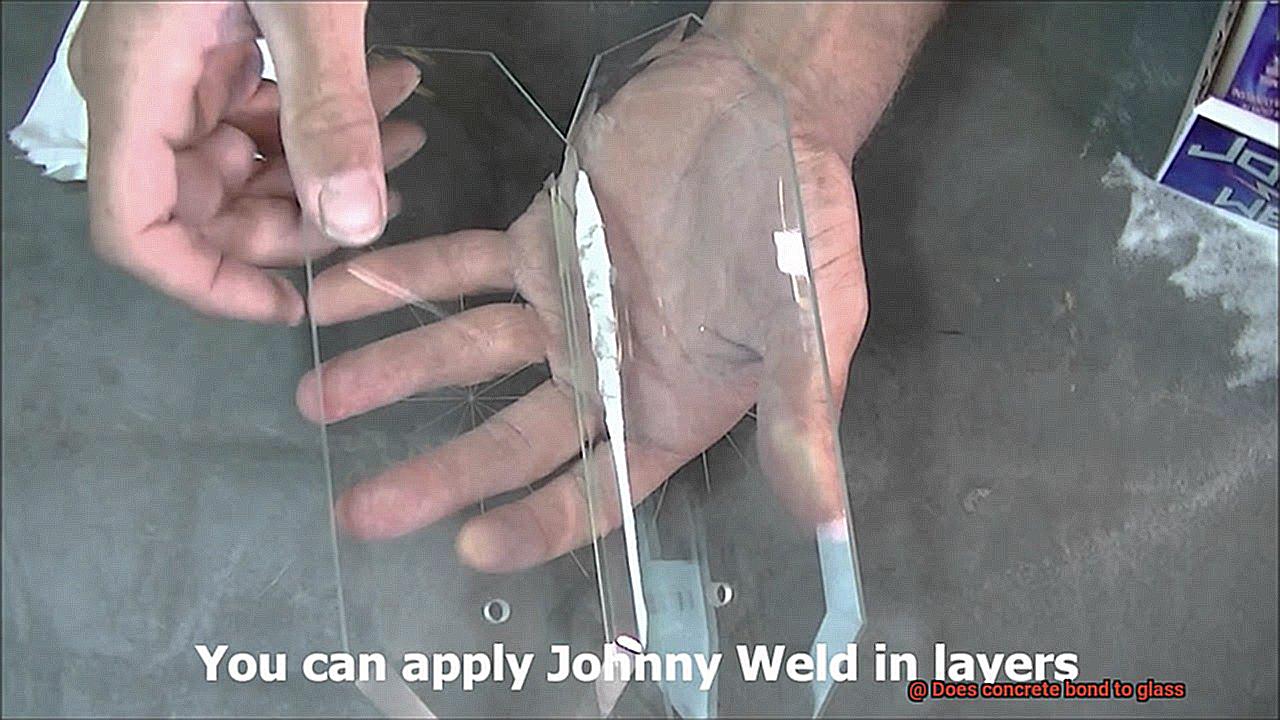

Apply the Adhesive Properly:

Follow the manufacturer’s instructions carefully when applying the adhesive. Apply it evenly on both surfaces, ensuring complete coverage. Consider the working time of the adhesive to allow for proper placement and adjustment of the glass onto the concrete surface. Use a notched trowel or a suitable applicator to ensure an even and consistent application.

ewRIJ_Km1Nk” >

Conclusion

In conclusion, the union of concrete and glass may seem unlikely, but it is not an insurmountable challenge. The contrasting characteristics of these materials – thermal expansion, surface properties, and chemical composition – pose difficulties in establishing a robust and enduring bond.

Fortunately, innovative techniques and products have been developed to overcome these challenges. Adhesion promoters, specialized adhesives and mortars, and mechanical fasteners all contribute to enhancing the connection between concrete and glass. However, the key lies in meticulous surface preparation. Thorough cleansing, roughening of surfaces, and the application of primers are vital steps before any adhesive or glue can be applied.

When selecting an adhesive for bonding concrete and glass together, several options exist depending on project requirements. Epoxy adhesives, polyurethane adhesives, silicone sealants, and hybrid adhesives all offer viable solutions.

To achieve a secure connection between concrete and glass, mechanical fasteners such as anchor bolts, glass clamps, brackets, and expansion bolts can also be utilized.

Ultimately, both adhesives and mechanical fasteners present advantages and disadvantages. Adhesives provide a seamless finish without visible joints or gaps but necessitate meticulous surface preparation. On the other hand, mechanical fasteners offer quick installation but create visible joints between materials.