Do you love getting your hands dirty with creative projects? Whether it’s painting, papercraft, or DIY home decor, we all want our finished products to endure the test of time. That’s where sealers come in handy. But have you ever wondered if glue can be used as a sealer?

It might sound like an odd question, but it’s one that many people ask. In this blog post, we’ll explore the world of glues and sealers to help you understand whether using glue as a sealer is a good idea or not.

We’ll dive into the different types of glue and their unique properties. From PVA glue to epoxy and superglue, we’ll cover them all. We’ll also explain the different types of sealers and how they work.

But what about using glue as a sealer? We’ll discuss the pros and cons of this approach and provide some practical tips for anyone who wants to try it out.

Whether you’re an experienced DIY-er or just starting on your creative journey, this blog post is for you. So grab your favorite glue gun and let’s get started on exploring the fascinating world of glues and sealers.

What Types of Glue Can be Used as a Sealer?

Contents

- 1 What Types of Glue Can be Used as a Sealer?

- 2 What Surfaces Can Glue be Used to Seal?

- 3 Advantages of Using Glue as a Sealer

- 4 Disadvantages of Using Glue as a Sealer

- 5 Different Types of Glues for Sealing Purposes

- 6 How to Choose the Right Type of Glue for Sealing

- 7 Tips and Tricks for Applying Glue as a Sealer

- 8 Common Mistakes When Using Glue as a Sealer

- 9 Conclusion

When it comes to sealing surfaces, glue can be a versatile and effective option. However, not all types of glue are created equal, and choosing the wrong type of glue can lead to ineffective seals or even damage to the surface.

Here are five types of glue that can be used as sealers, along with their strengths and weaknesses.

PVA Glue

Polyvinyl acetate (PVA) glue is a popular choice for sealing porous materials like paper, cardboard, and wood. PVA glue can be mixed with water to create a sealant that dries clear and non-toxic. It’s also known for its strong adhesive properties, making it ideal for sealing porous surfaces. However, PVA glue may not be suitable for non-porous surfaces like metal or plastic.

Epoxy Resin

Epoxy resin is a two-part adhesive that creates a strong and durable seal that is resistant to water, heat, and chemicals. This makes it a popular choice for sealing surfaces like countertops or floors. However, epoxy resin can be difficult to work with and requires proper ventilation due to its strong fumes.

Polyurethane Glue

Polyurethane glue is known for its strong bonding properties and water resistance. It’s an ideal choice for sealing wood surfaces like furniture or floors, as well as other materials such as metal or plastic. However, like epoxy resin, polyurethane glue can be difficult to work with and requires proper ventilation.

Silicone Sealant

Silicone sealant is a specialized type of adhesive that is formulated specifically for sealing purposes. It’s ideal for use on non-porous surfaces like glass or metal and can withstand exposure to water and extreme temperatures. However, silicone sealant may not be suitable for porous surfaces like wood or cardboard.

Acrylic Sealant

Acrylic sealant is another specialized type of adhesive that is formulated for sealing purposes. It’s ideal for sealing joints or gaps in construction materials like wood or metal. Acrylic sealant dries clear and can withstand exposure to water and mildew. However, it may not be suitable for surfaces that will be exposed to extreme temperatures or chemicals.

In conclusion, choosing the right type of glue for sealing depends on the specific surface being sealed and the conditions it will be exposed to. PVA glue, epoxy resin, polyurethane glue, silicone sealant, and acrylic sealant are all suitable options for sealing surfaces, but it’s important to choose the right one for the job.

What Surfaces Can Glue be Used to Seal?

As an expert on this topic, I can tell you that there are several types of glue available that can be used to seal different surfaces.

Porous surfaces such as paper, cardboard, and wood require PVA glue, also known as white glue or school glue. This glue dries clear and is easy to use, making it a popular choice for crafting and DIY projects. It’s perfect for creating a smooth and seamless finish on your porous surfaces.

For non-porous surfaces like metal, glass, and plastic, epoxy glue is your go-to option. It forms a strong bond that is resistant to water and chemicals, making it ideal for sealing surfaces that will face harsh conditions. Whether you’re repairing a broken glass or sealing a metal surface from rust, epoxy glue will get the job done.

Cyanoacrylate glue, commonly known as superglue, is another option for sealing certain surfaces. This type of glue dries quickly and forms a strong bond, making it useful for sealing small cracks and gaps in materials like ceramics and porcelain.

When using glue to seal surfaces, it’s important to choose the right type of glue based on the material you are working with. Using the wrong type of glue can result in a weak bond or even damage to the surface. Additionally, following the manufacturer’s instructions is key to ensuring a successful seal. This may include applying multiple coats or allowing the glue to dry completely before using the sealed surface.

Advantages of Using Glue as a Sealer

Look no further than your trusty bottle of glue. As an expert on the advantages of using glue as a sealer, let me tell you, this versatile adhesive can work wonders on almost any surface.

One of the most significant advantages of using glue as a sealer is its incredible versatility. No matter what material you’re working with – wood, metal, plastic, or paper – there’s a type of glue out there that can get the job done. Moreover, many types of glue are waterproof, making them perfect for use in damp or humid environments.

But it’s not just about versatility. Glue also creates a robust bond between surfaces that can stand up against heavy use and wear. This is especially important when sealing items like cutting boards or furniture that are subjected to frequent use and abuse. Plus, glue is easy to apply and dries quickly, so you can get your sealing done in no time.

Another advantage of using glue as a sealer is the convenience it offers. Many types of glue come in convenient spray bottles or aerosol cans, making them easy to apply evenly across large surfaces. Additionally, using glue as a sealer can be a cost-effective solution compared to purchasing specialized sealers or coatings for specific materials.

Disadvantages of Using Glue as a Sealer

While it may seem like a quick and easy solution, there are several disadvantages to this method that should be considered. As an expert on this topic, I’m here to give you the lowdown on the potential drawbacks of using glue as a sealer.

Firstly, let’s discuss durability. Glue is not designed to withstand exposure to the elements and can break down over time. This means that any item sealed with glue may not remain waterproof or airtight for long periods of time, defeating the purpose of sealing them in the first place. Furthermore, certain types of glue may become brittle over time, causing the seal to crack and allowing air or moisture to enter.

In addition, using glue as a sealer may not adhere well to certain materials. For example, if you’re trying to seal wood or plastic, you may find that the glue doesn’t bond properly and the seal is not effective. Moreover, some types of glue can damage or discolor certain materials, which could be disastrous if you’re trying to preserve the appearance of your item.

Lastly, applying glue as a sealer can be messy and difficult to do evenly. Depending on the type of glue you’re using, it may require multiple coats or a specific application method in order to create a strong and effective seal. This can be time-consuming and frustrating, especially if you’re working with a large or intricate surface area.

To summarize, while using glue as a sealer may seem like an easy solution, it is not always the most effective or reliable option. Here’s a list of potential disadvantages to keep in mind:

- Glue may not withstand exposure to the elements

- Certain types of glue may become brittle over time

- Glue may not adhere well to certain materials

- Some types of glue can damage or discolor certain materials

- Applying glue as a sealer can be messy and difficult to do evenly

Different Types of Glues for Sealing Purposes

When it comes to sealing surfaces, not all glues are created equal. It is important to understand the different types of glues available and their specific purposes. Here are five types of glues that can be used for sealing purposes:

PVA Glue

Polyvinyl acetate (PVA) glue is a popular choice for woodwork and arts and crafts projects. This white glue dries clear, making it perfect for sealing porous surfaces like paper and wood. It is water-based and non-toxic, making it safe for children’s projects.

Epoxy Glue

Epoxy glue is a strong adhesive that can be used to seal a variety of surfaces. It is ideal for metal, glass, and plastic surfaces that are exposed to water or heat. However, it requires mixing two separate components together before use, making it a bit tricky to work with.

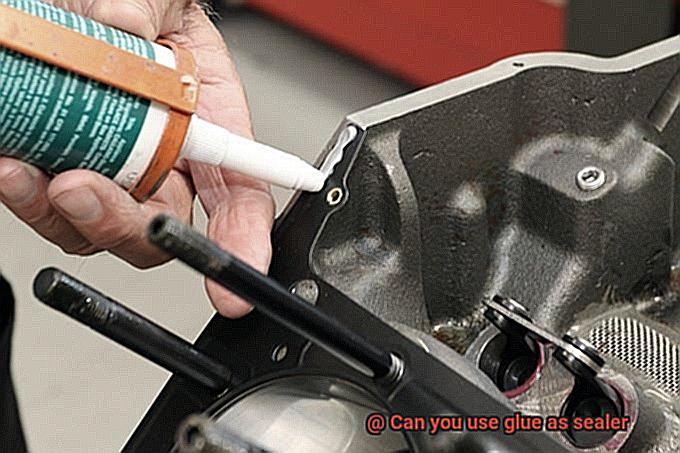

Silicone Adhesive

This versatile adhesive can be used for both sealing and bonding purposes. It is perfect for sealing gaps and cracks in windows, doors, and other surfaces. Silicone adhesive is flexible and resistant to water and heat, making it an ideal choice for areas with moisture or high temperatures.

Super Glue

Super glue is a fast-drying adhesive that can bond almost any surface. It is perfect for sealing small cracks and gaps in metal, plastic, and other materials. However, it should not be used on surfaces that will be exposed to water or heat.

Contact Cement

This type of adhesive creates a strong bond that is resistant to water and heat. It is commonly used for sealing leather, rubber, and other flexible materials. Contact cement works by bonding two surfaces together when they come into contact with each other.

When selecting a glue for sealing purposes, consider the material you’re working with, the level of moisture exposure the surface will face, and any temperature or environmental factors that may affect the bond. In addition to these types of glues, there are also specialized sealants designed for specific materials or applications.

For example, there are sealants designed for use on concrete or masonry surfaces, as well as those designed for use in automotive applications. These specialized sealants may provide a stronger or more durable bond for specific materials.

How to Choose the Right Type of Glue for Sealing

Choosing the right type of glue for sealing is essential to achieving a strong and long-lasting seal. With so many different types of glue available, it can be overwhelming to know where to begin. Here are five sub-sections to guide you through the process:

Consider the Material

The first step in choosing the right type of glue for sealing is to consider the material you will be working with. Different materials require different types of adhesive. For example, if you are sealing wood, a waterproof wood glue such as Titebond III would be a good choice. However, if you’re sealing metal, a two-part epoxy or cyanoacrylate (super glue) would work better.

Think About the Conditions

It’s important to consider the conditions that your sealant will be exposed to. If it will be exposed to moisture or water, use a waterproof glue or sealant. This will help prevent water damage and ensure a long-lasting seal. If your sealant will be exposed to extreme temperatures, use a high-temperature adhesive to ensure that it won’t break down under heat stress.

Consider the Strength

Another important factor to consider is the strength required for your sealant. If your sealant needs to withstand heavy loads or stress, use a strong adhesive such as construction adhesive or epoxy. These types of adhesives are designed to provide maximum holding power and are ideal for heavy-duty applications. However, for lighter applications, a general-purpose adhesive such as white glue or school glue may suffice.

Check for Special Requirements

If you’re sealing something that will come into contact with food, make sure to use a food-safe glue that won’t contaminate your food. Similarly, if you’re working in an area with limited ventilation, choose a low-odor or non-toxic glue to avoid any harmful fumes.

Do Your Research

If you’re unsure about which type of glue to use, do some research online or consult with an expert in the field. There are many resources available that can help you choose the right type of adhesive for your specific needs. Using the wrong type of adhesive can damage your project and result in a weak seal, so it’s important to take the time to choose the right one.

Tips and Tricks for Applying Glue as a Sealer

When it comes to sealing your project, glue can be a versatile and effective option. However, to achieve professional-looking results, there are some tips and tricks you should keep in mind.

Choose the right type of glue

Different types of glue are better suited for different materials. For example, if you’re sealing paper or cardboard, a white school glue or clear-drying PVA glue may work well. On the other hand, if you’re sealing wood or metal, an epoxy or polyurethane glue may be more appropriate. Make sure to choose a glue that is compatible with your project’s material.

Apply glue in thin, even layers

To avoid lumps and bumps, it’s important to apply glue in thin, even layers using a brush or sponge. Don’t rush the process; let each layer dry completely before applying the next one. This will help ensure that the glue dries evenly and creates a smooth surface.

Sand between layers

After each layer has dried, use fine-grit sandpaper to lightly sand the surface. This will help create an even surface and help the layers adhere better to each other. Be gentle and don’t sand too hard, as you don’t want to remove any of the layers of glue.

Protect the surface with varnish or polyurethane

If your project will be frequently used or handled, it’s important to protect the surface with a coat of varnish or polyurethane after the glue has dried completely. This will help protect the surface from scratches and wear-and-tear. Choose a varnish or polyurethane that is compatible with your glue and material.

Clean up excess glue before it dries

Excess glue can ruin your project’s finish, so it’s important to clean it up before it dries. Use a damp cloth or sponge to wipe away any drips or smudges as soon as you notice them. If the glue has already dried, use a small razor blade or sandpaper to carefully remove any excess.

Common Mistakes When Using Glue as a Sealer

Before you dive in, let’s discuss the common mistakes people make when using glue as a sealer.

First and foremost, choosing the right type of glue is crucial. Not all glues are created equal, and using the wrong one can compromise the integrity of the seal. For instance, water-based glue may break down when exposed to moisture, rendering your sealant ineffective. So, it’s essential to do your research and choose a glue that’s appropriate for your project.

Another mistake to avoid is not applying enough glue. You want to create a strong seal, but you don’t want to make a mess or apply too little glue that won’t hold up over time. Therefore, strike a balance and apply enough glue to create a durable seal.

One of the most significant mistakes people make when using glue as a sealer is not letting it dry properly. It’s tempting to rush this process, but doing so can cause the seal to break down over time. So, be patient and allow enough time for the glue to dry before proceeding with additional layers or moving on to the next step.

Lastly, using glue as a sealer without proper ventilation can be hazardous. Some glues emit harmful fumes when they dry, which can pose health risks if inhaled in large quantities. Therefore, always work in a well-ventilated area and follow safety guidelines when working with glue as a sealer.

3HU_LhbX7-U” >

Also Read: Can you use Elmer’s glue as a sealant?

Conclusion

In conclusion, while glue may provide a temporary seal for certain materials, it is not a reliable or long-lasting solution for sealing.

Using a proper sealer designed specifically for the material you are working with will ensure a more durable and effective seal. Don’t risk compromising the quality of your project by substituting glue for a proper sealer.

Remember, shortcuts may save time in the short term but can lead to costly mistakes in the long run.